Data center heat dissipation system with direct connection between loop heat pipe and refrigeration cycle pipe

A refrigeration cycle, loop heat pipe technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve problems such as loud noise, corroded components, liquid leakage circuits, etc., to reduce energy consumption and temperature difference loss, reduce start-up time and power, reduce energy consumption and noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

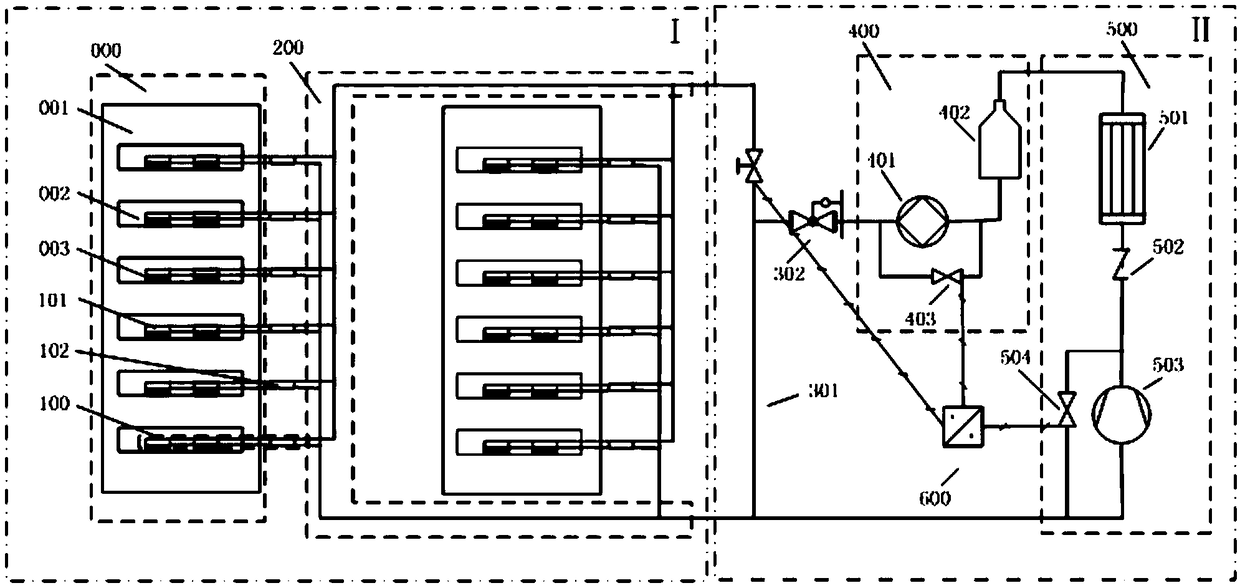

[0037] The invention provides a data center heat dissipation system in which a loop heat pipe and a refrigeration cycle pipe are directly connected. , the heat pipe has the advantages of high heat conduction efficiency and does not consume additional energy to provide the working medium circulation power; the cabinet to the outdoor is realized by the refrigerant circulation unit.

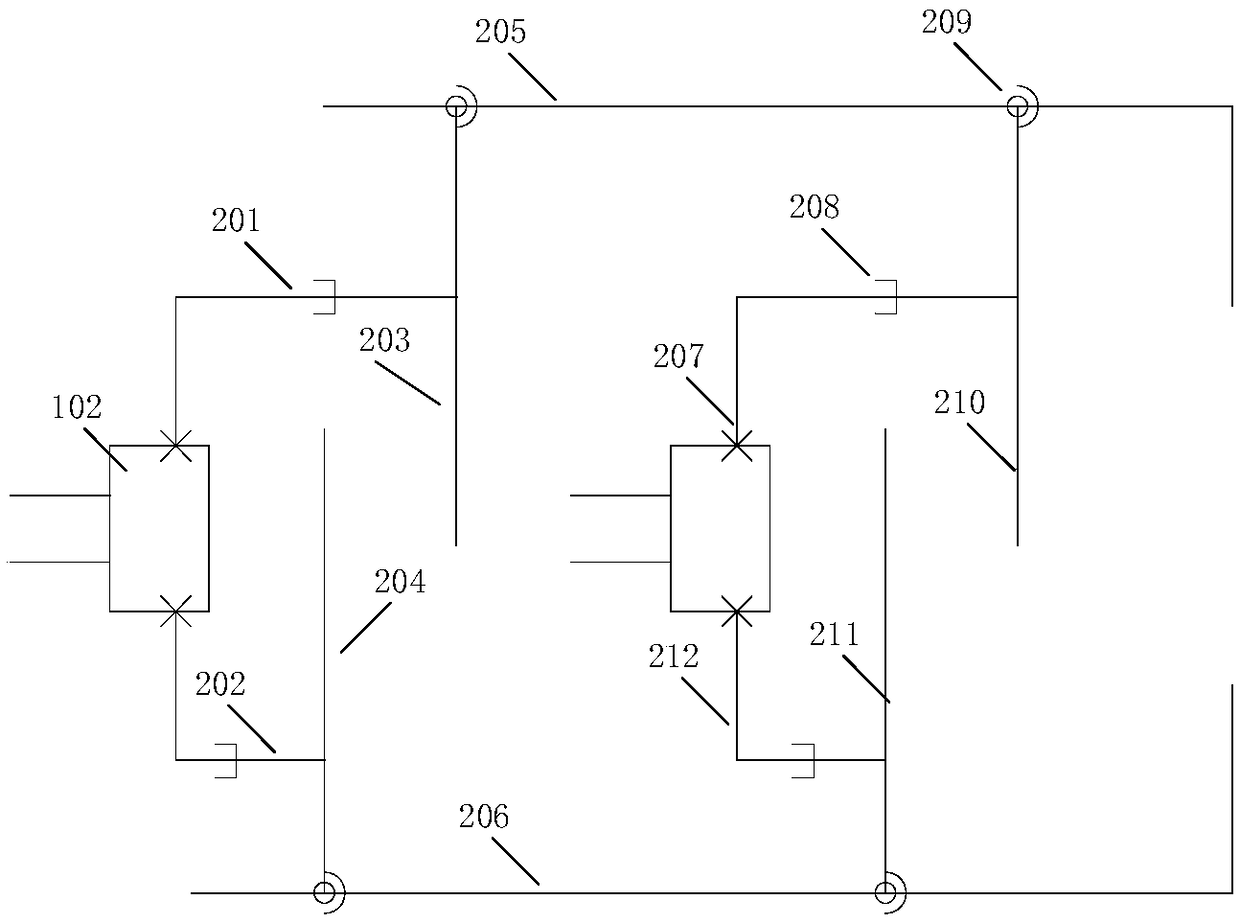

[0038] figure 1 A schematic diagram of the device structure principle according to an embodiment of the present invention is given. like figure 1 As shown, in this embodiment, the computer room unit includes two sets of server units, wherein one set of server units includes a rack 001 and one or more servers 002 installed on the rack, and the server 002 may include one or more chips 003. The present invention will be described below by taking the set of servers as an exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com