Patents

Literature

48results about How to "Avoid local hotspots" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-supporting nickel phosphide catalyst and preparation method and application thereof

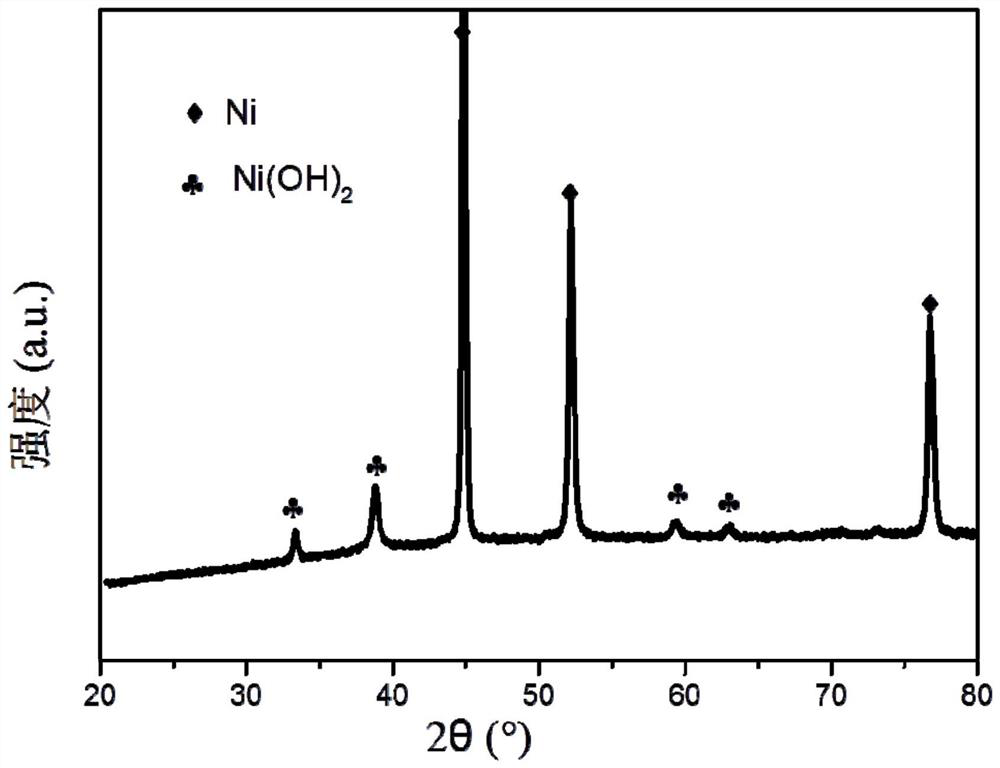

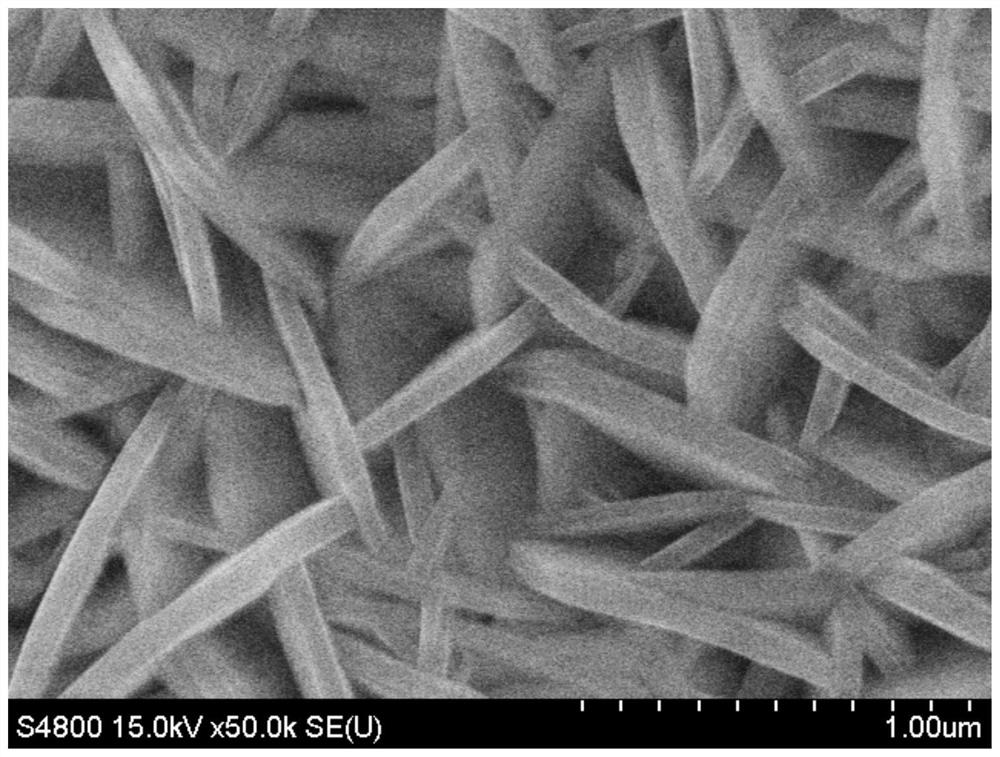

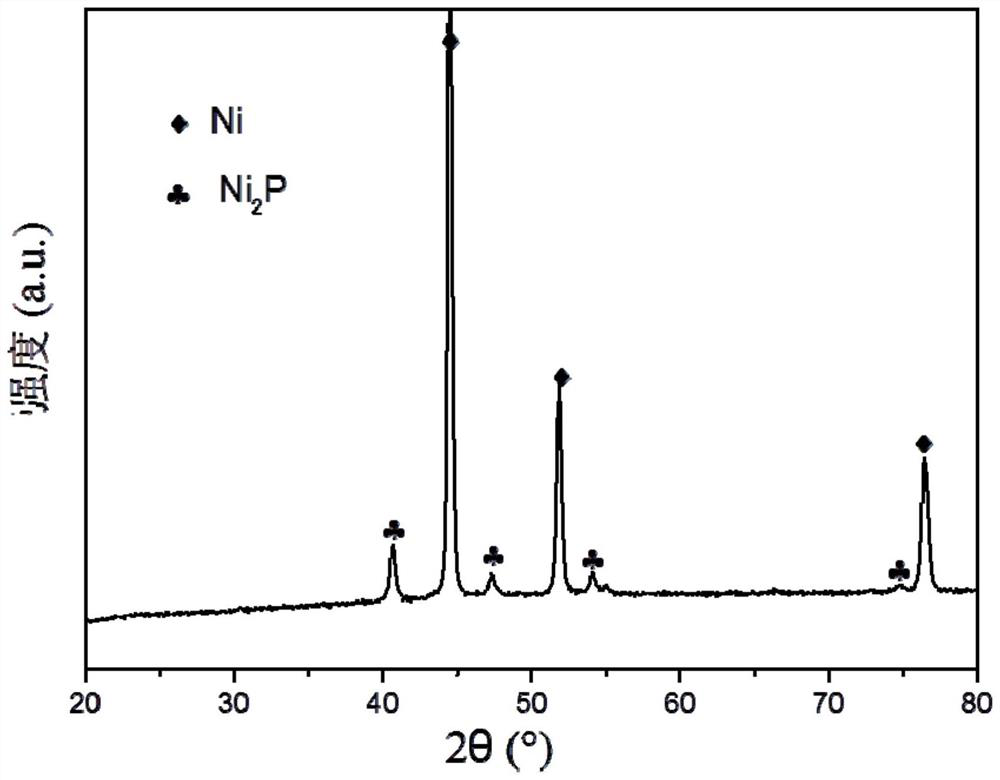

ActiveCN107694584AGood thermal conductivityHigh selectivityOrganic compound preparationCarboxylic acid esters preparationThermal conductivityNickel oxide hydroxide

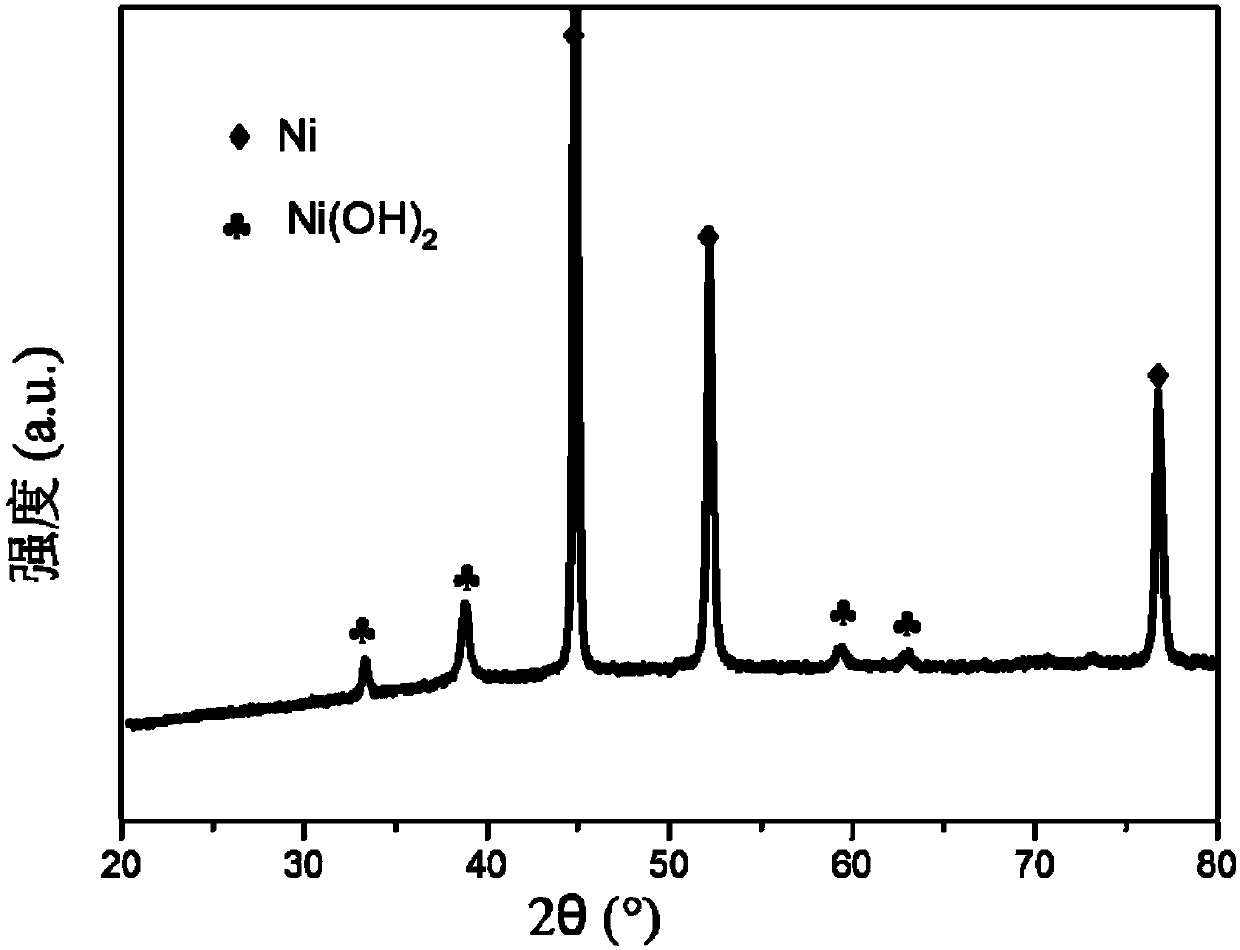

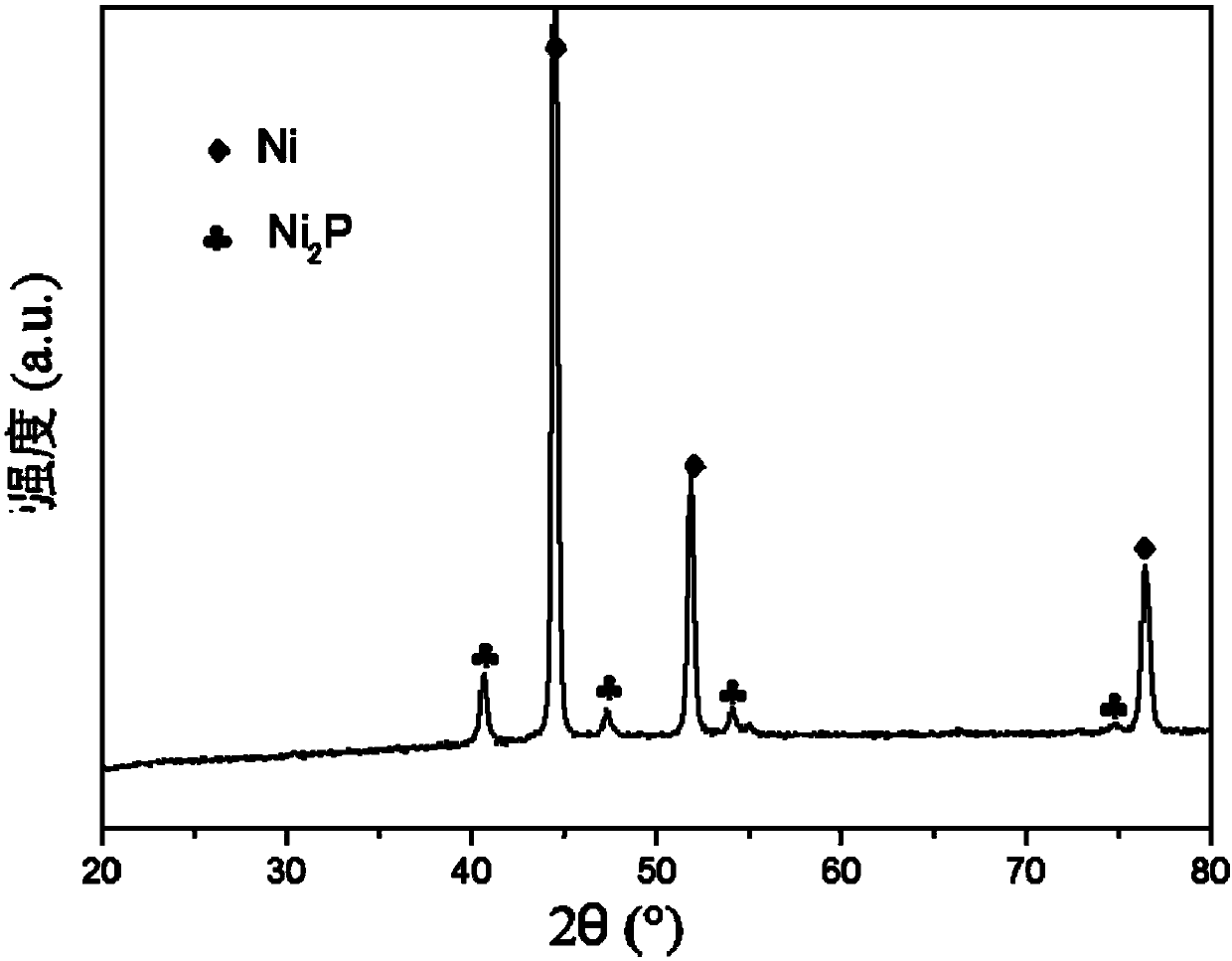

The invention discloses a self-supporting nickel phosphide catalyst and a preparation method and application thereof. The self-supporting nickel phosphide catalyst is a nickel phosphide catalyst obtained by in-situ growing of a nickel oxalate or nickel hydroxide crystal layer on a framework matrix through a hydrothermal method and performing phosphating while secondary forming is not needed, and the nickel phosphide catalyst is composed of the framework matrix and a nickel-phosphorus compound, wherein the nickel-phosphorus compound is at least one of Ni3P, Ni12P5, Ni2P and Ni5P4, total mass ratio of the nickel-phosphorus compound is 0.1-50%, and the balance is the framework matrix. Experiments show that the self-supporting nickel phosphide catalyst is high in stability and thermal conductivity, easy to form and fill, high in flux and low in pressure drop, especially has the advantages of high low-temperature activity, high dimethyl oxalate conversion rate and high methyl glycolate selectivity and can be used as a reaction catalyst for hydrogenating dimethyl oxalate to prepare methyl glycolate.

Owner:EAST CHINA NORMAL UNIVERSITY

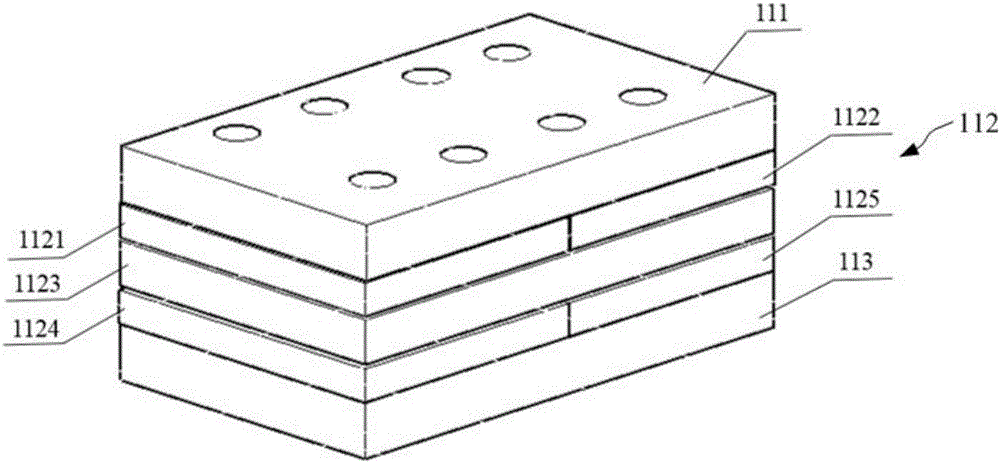

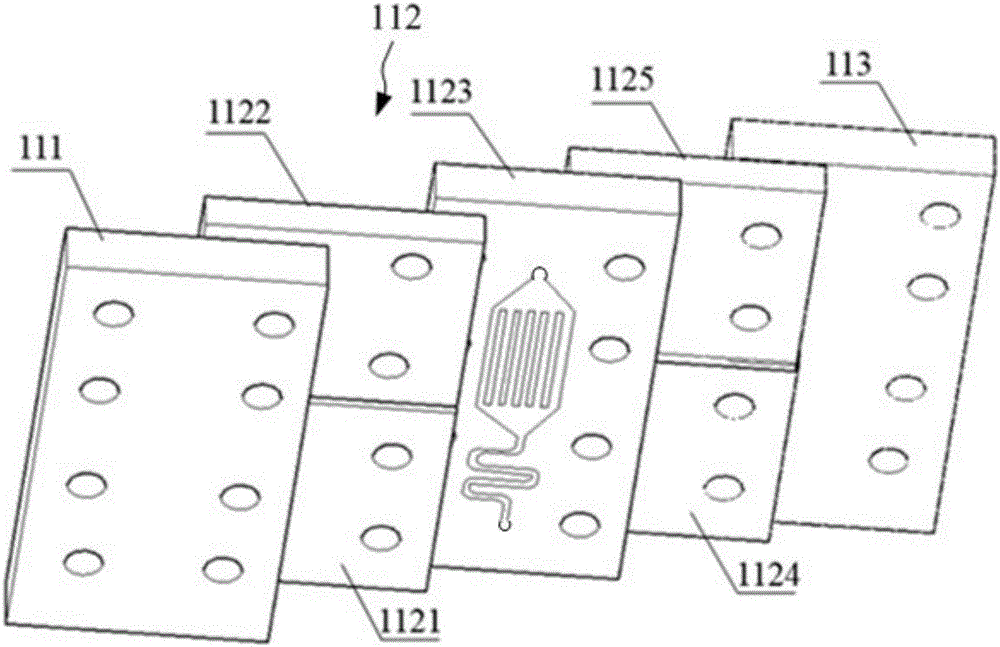

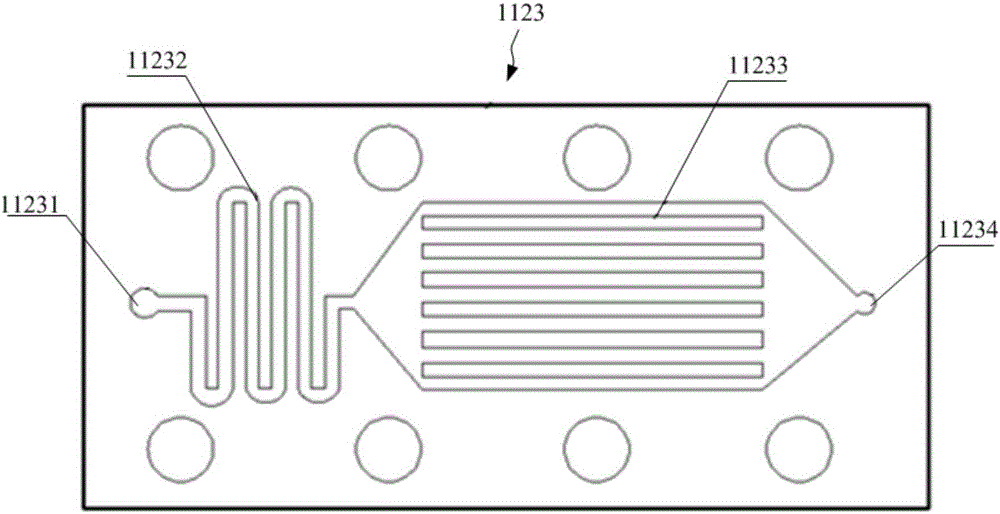

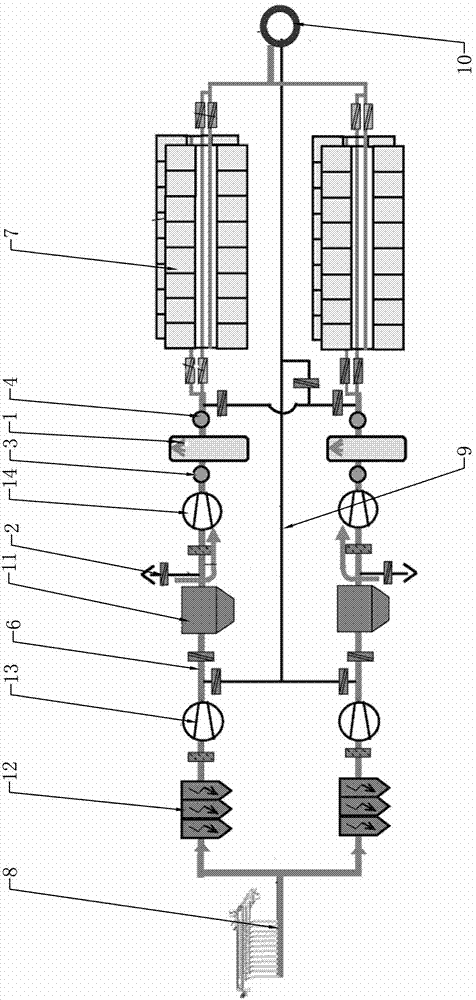

Microchannel reaction device, microchannel reaction system and method for preparing olefin

InactiveCN106215828ALarge specific surface areaImprove heat transfer efficiencyProductsHydrocarbon from carbon oxidesEngineeringReaction system

The invention provides a microchannel reaction device which comprises an upper sealing plate, a lower sealing plate and at least one microchannel reactor located between the upper sealing plate and the lower sealing plate. The microchannel reactor comprises a microchannel reaction plate, a first heat exchange channel plate, a second heat exchange channel plate, a third heat exchange channel plate and a fourth heat exchange channel plate, the first heat exchange channel plate and the second heat exchange channel plate are located on the upper surface of microchannel reaction plate, and the third heat exchange channel plate and the fourth heat exchange channel plate are located on the lower surface of the microchannel reaction plate. The microchannel reaction plate comprises an inlet, a preheating channel connected with the inlet, a reaction microchannel and an outlet connected with the reaction microchannel, the preheating channel is located between the first heat exchange channel and the third heat exchange channel, the reaction microchannel is connected with the preheating channel and located between the second heat exchange channel plate and the fourth heat exchange channel plate, and an olefin catalyst is arranged in the reaction microchannel. According to the microchannel reaction device, a microchannel reaction system and a method for preparing olefin, the problems that when olefin is prepared in the prior art, the selectivity of olefin is reduced due to a local hot spot, and the catalyst fails are solved.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

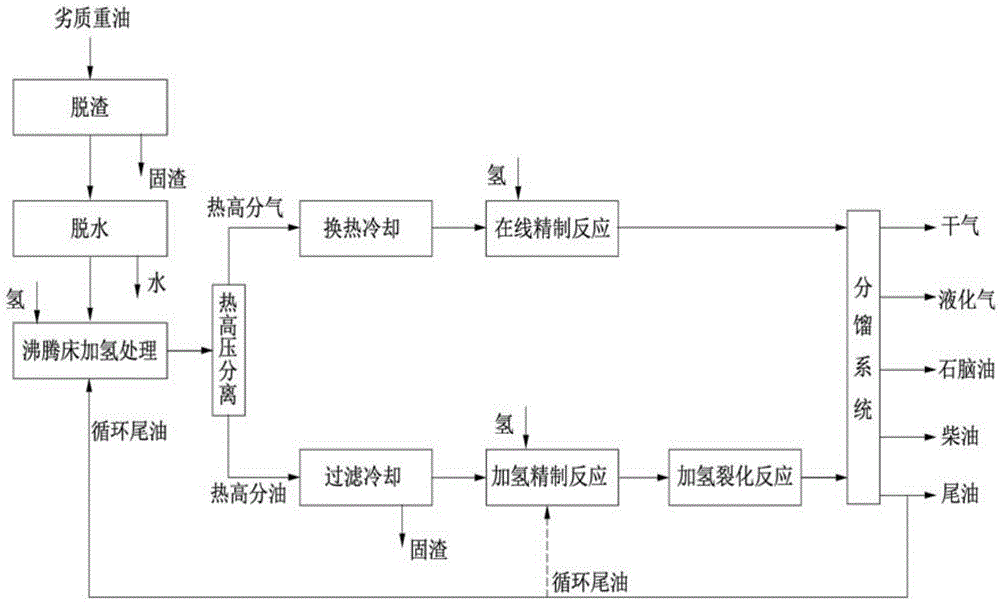

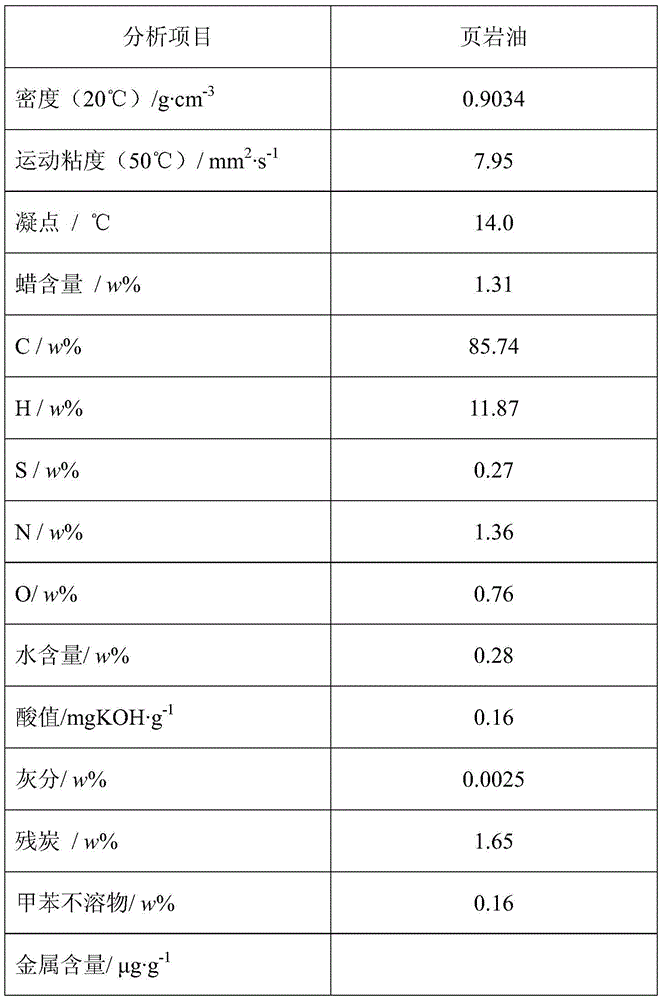

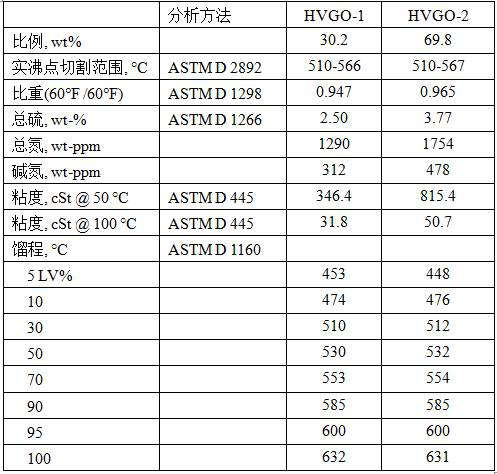

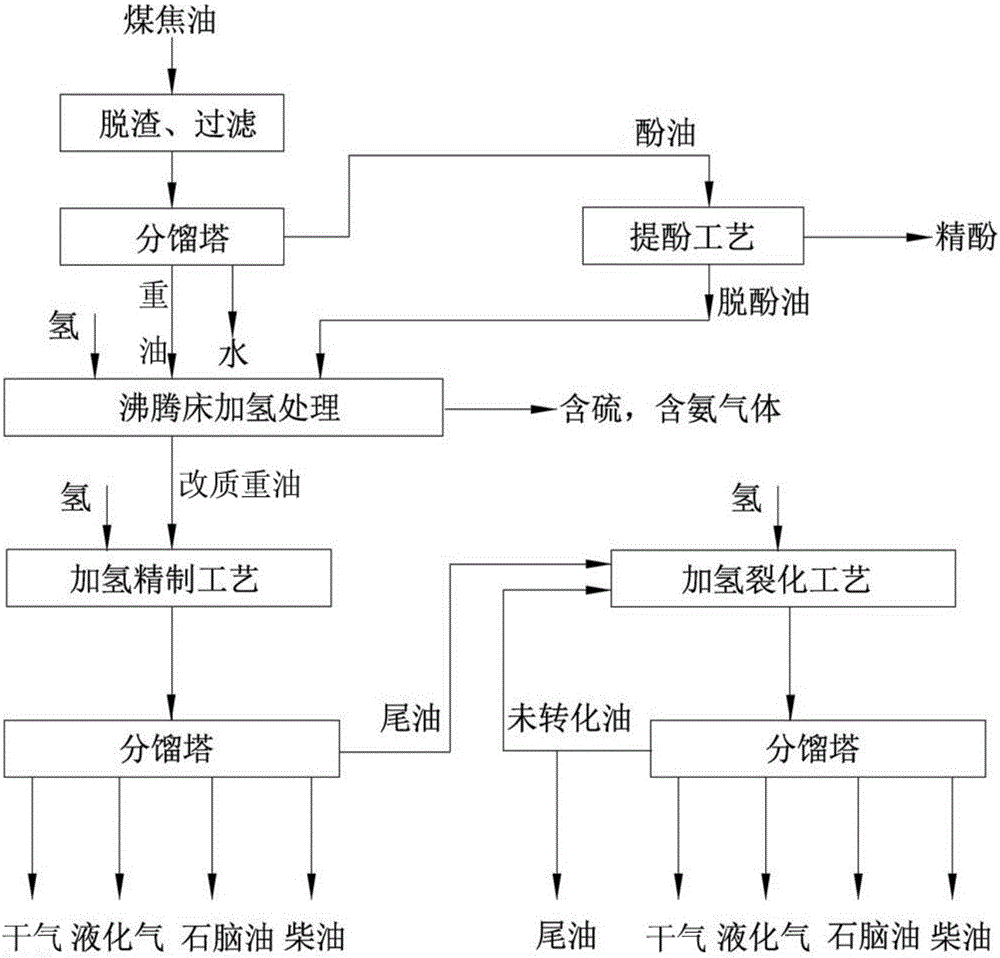

Tinpot heavy oil processing and treating method

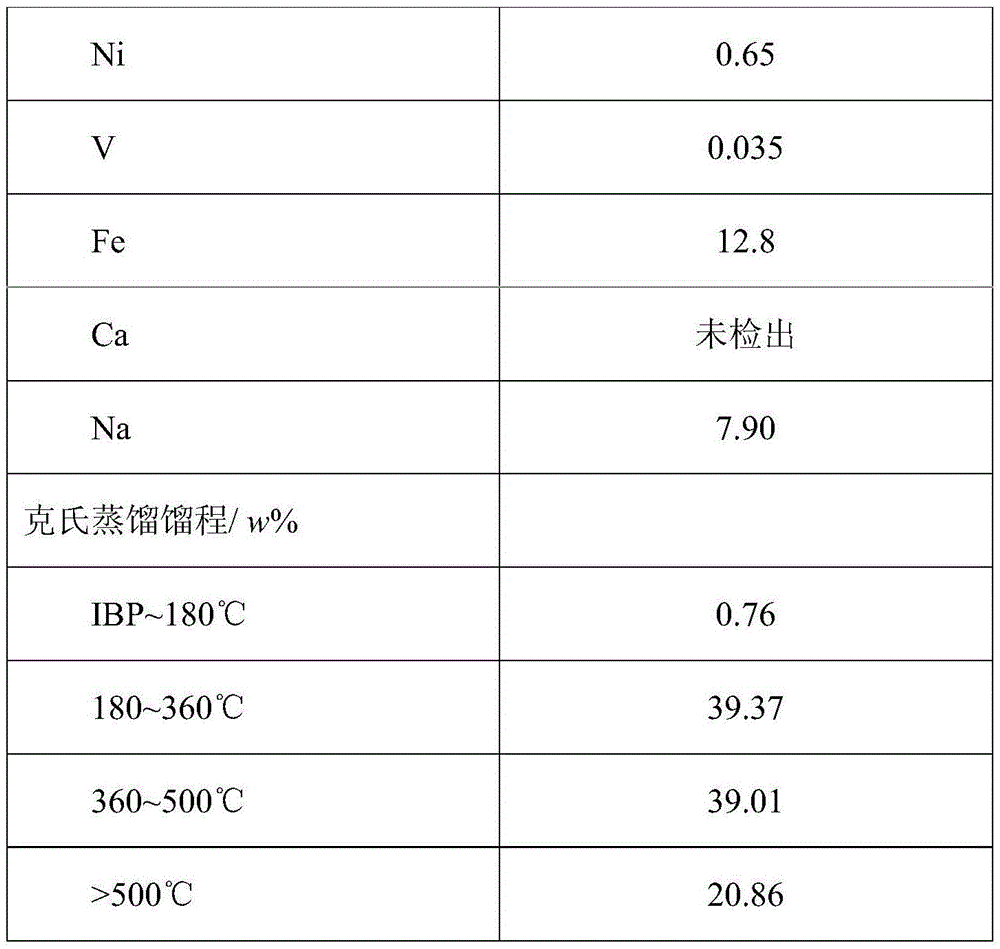

ActiveCN105567316AStable and uniform activityStable and uniform inactivation rateTreatment with hydrotreatment processesOil processingPetrochemical

The invention belongs to the field of petrochemical industry and coal chemical industry processes, and particularly relates to a tinpot heavy oil processing and treating method. The method includes: removing solid residue and water in tinpot heavy oil; mixing the tinpot heavy oil with hydrogen, and feeding a mixture into a fluidized bed hydrogenation reactor for hydrogenation; directly flashing a reaction product to obtain hot high-component gas and hot high-component oil; after heat exchange cooling of obtained hot high-component gas, hydrorefining the hot high-component gas to obtain refined hot high-component gas; after depressurizing of obtained hot high-component oil, filtering, pressurizing the hot high-component oil, and mixing with hydrogen for hydrorefining and hydrocracking to obtain cracked hot high-component oil; fractionally distilling the refined hot high-component gas and the cracked hot high-component oil to obtain dry gas, liquefied gas, naphtha, diesel and tail oil products. By using the method, high-quality light oil products can be produced by adopting tinpot heavy oil, the tinpot heavy oil is utilized to greatest extent, product liquid yield is increased, and the processing problem of heavy components in the tinpot heavy oil is solved.

Owner:上海竣铭化工工程设计有限公司

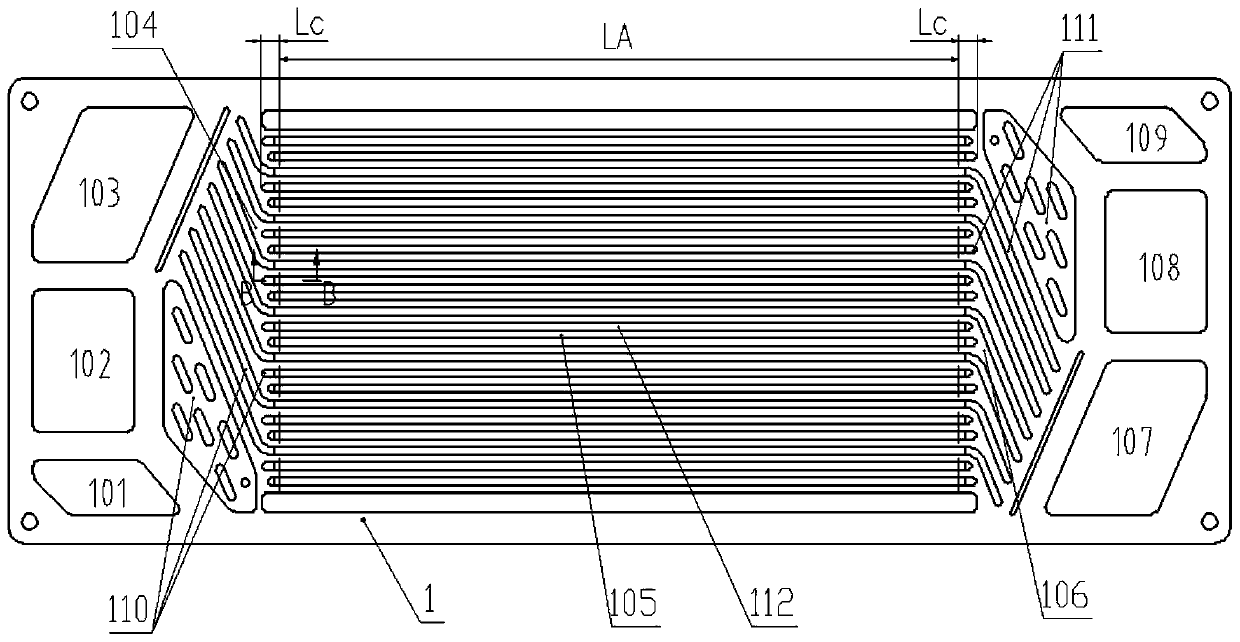

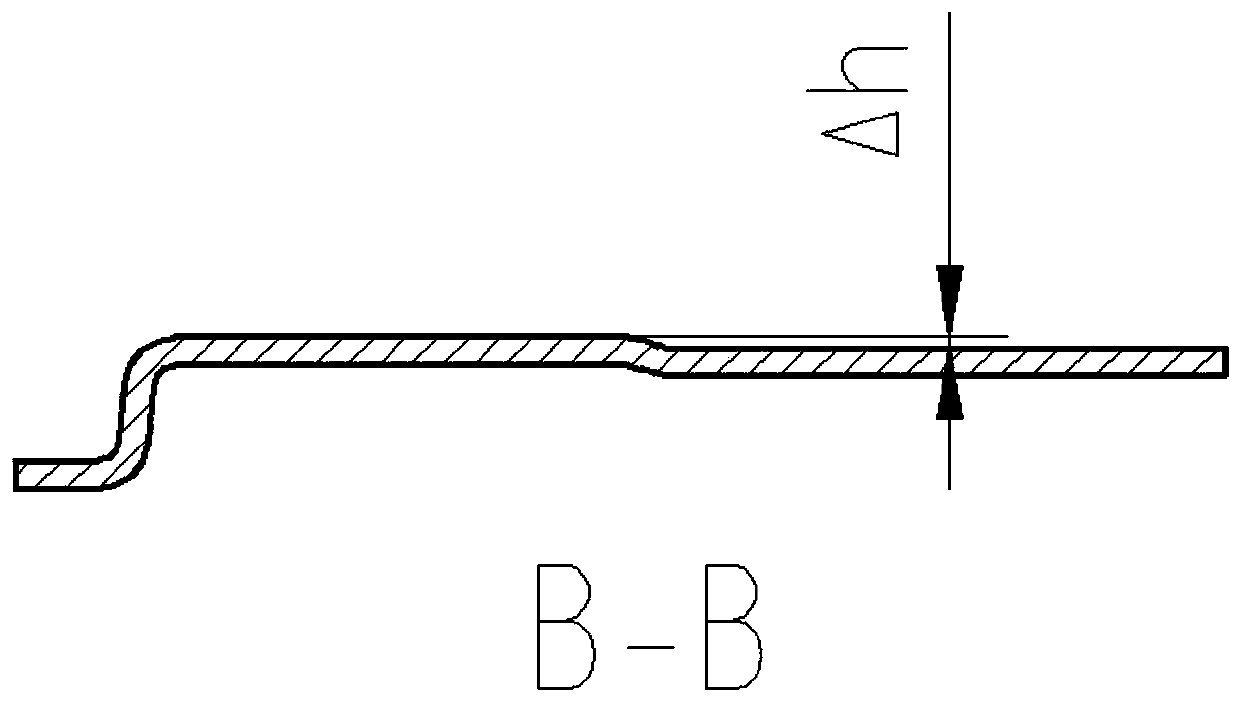

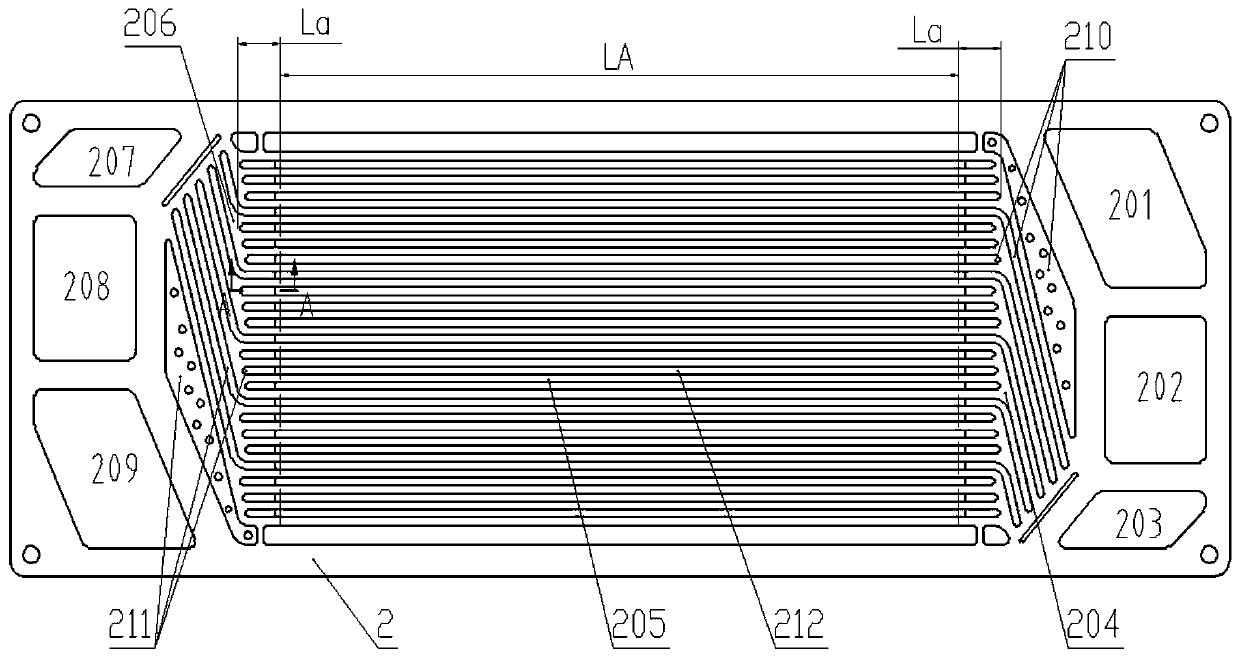

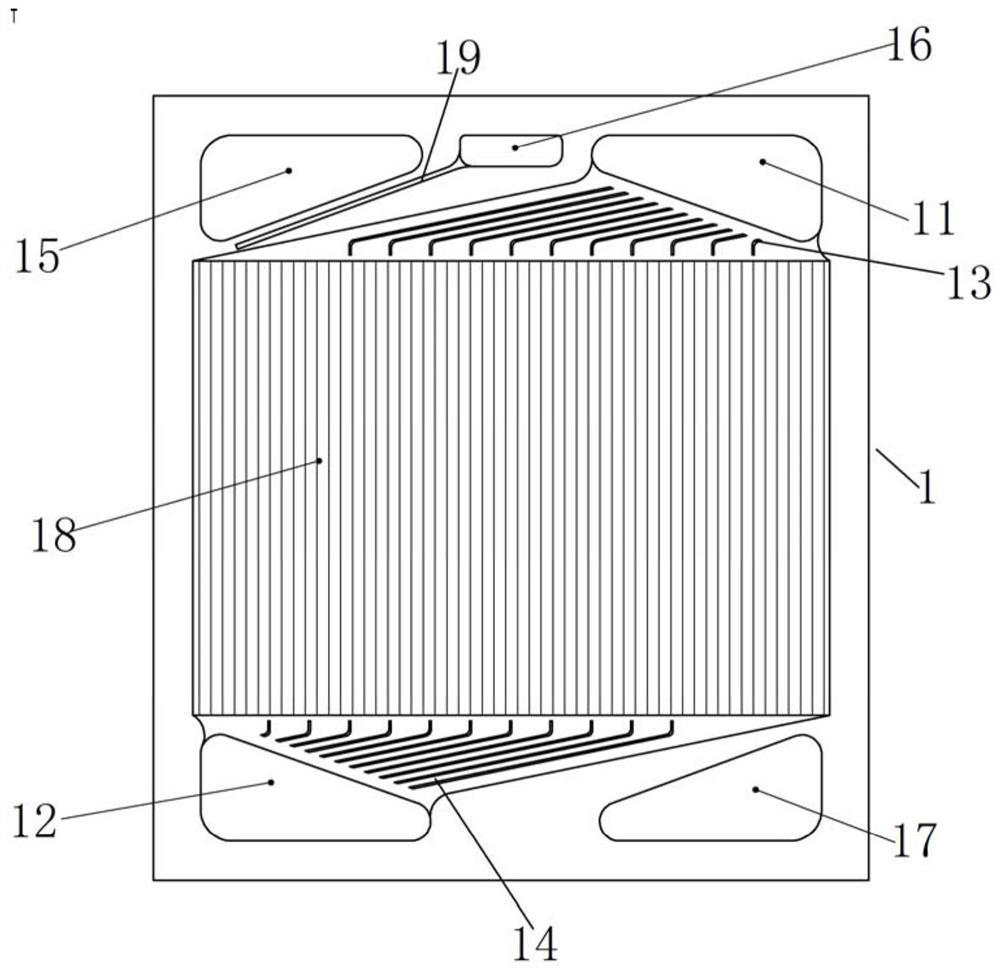

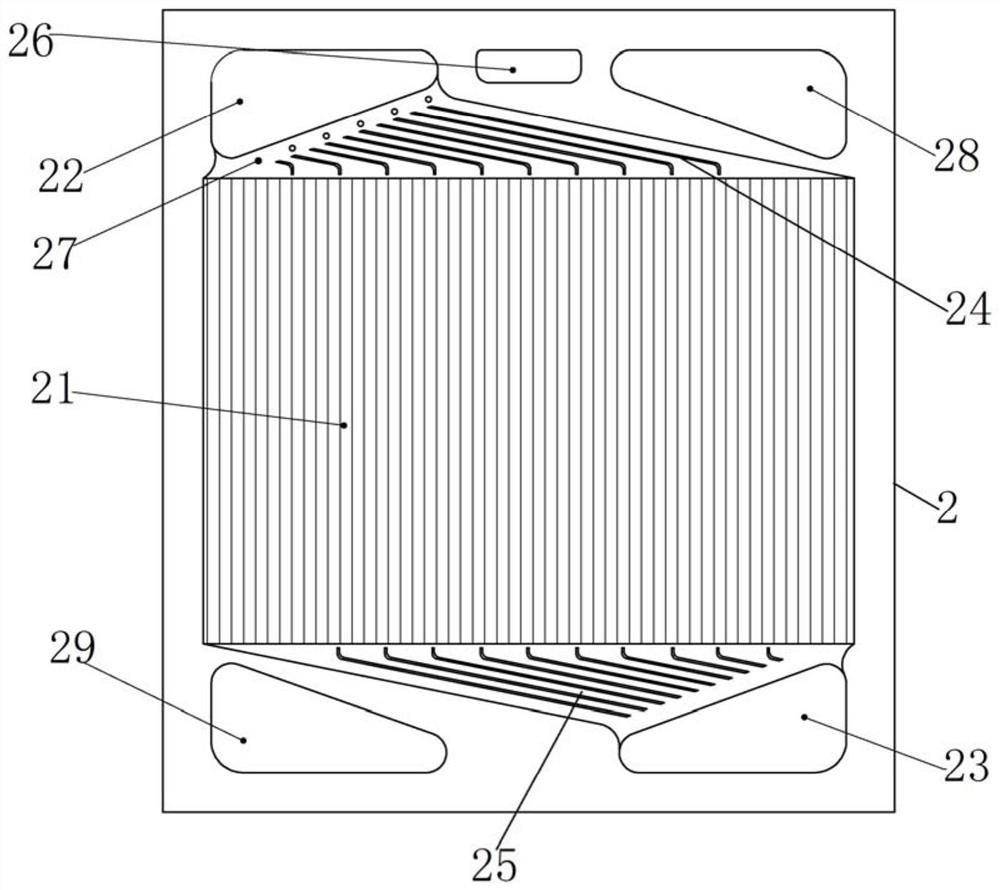

Fuel cell bipolar plate

The invention provides a fuel cell bipolar plate, comprising a cathode plate and an anode plate. The backs of the two plates are opposite to each other to form a bipolar plate, and a bipolar plate cooling water flow channel is formed between the two plates. The flow channel in the flow field of the cooling water active zone corresponding to one plate extends to the coverage of the flow field of the cooling water distribution zone corresponding to the other plate, in order to circulate the cooling water; or the flow channel in the flow field of the cooling water active zone corresponding to thecathode plate extends to the coverage of the flow field of the cooling water distribution zone corresponding to the anode plate, and the flow channel in the flow field of the cooling water active zone corresponding to the anode plate extends to the coverage of the flow field of the cooling water distribution zone corresponding to the cathode plate. The technical scheme of the invention solves theproblem that overall connection of cooling water cannot be realized in the existing bipolar plate with discontinuous water flow channels.

Owner:SUNRISE POWER CO LTD

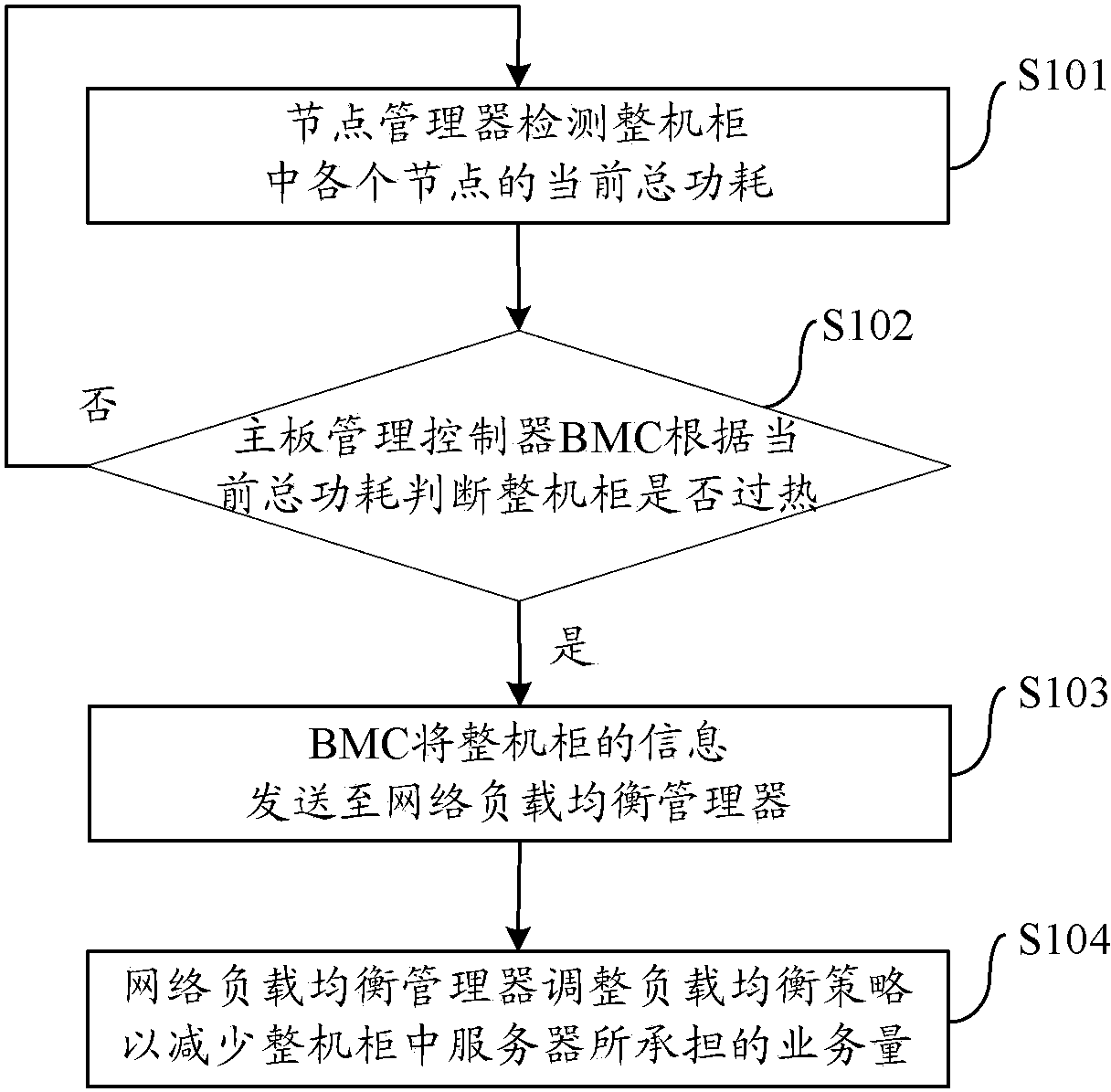

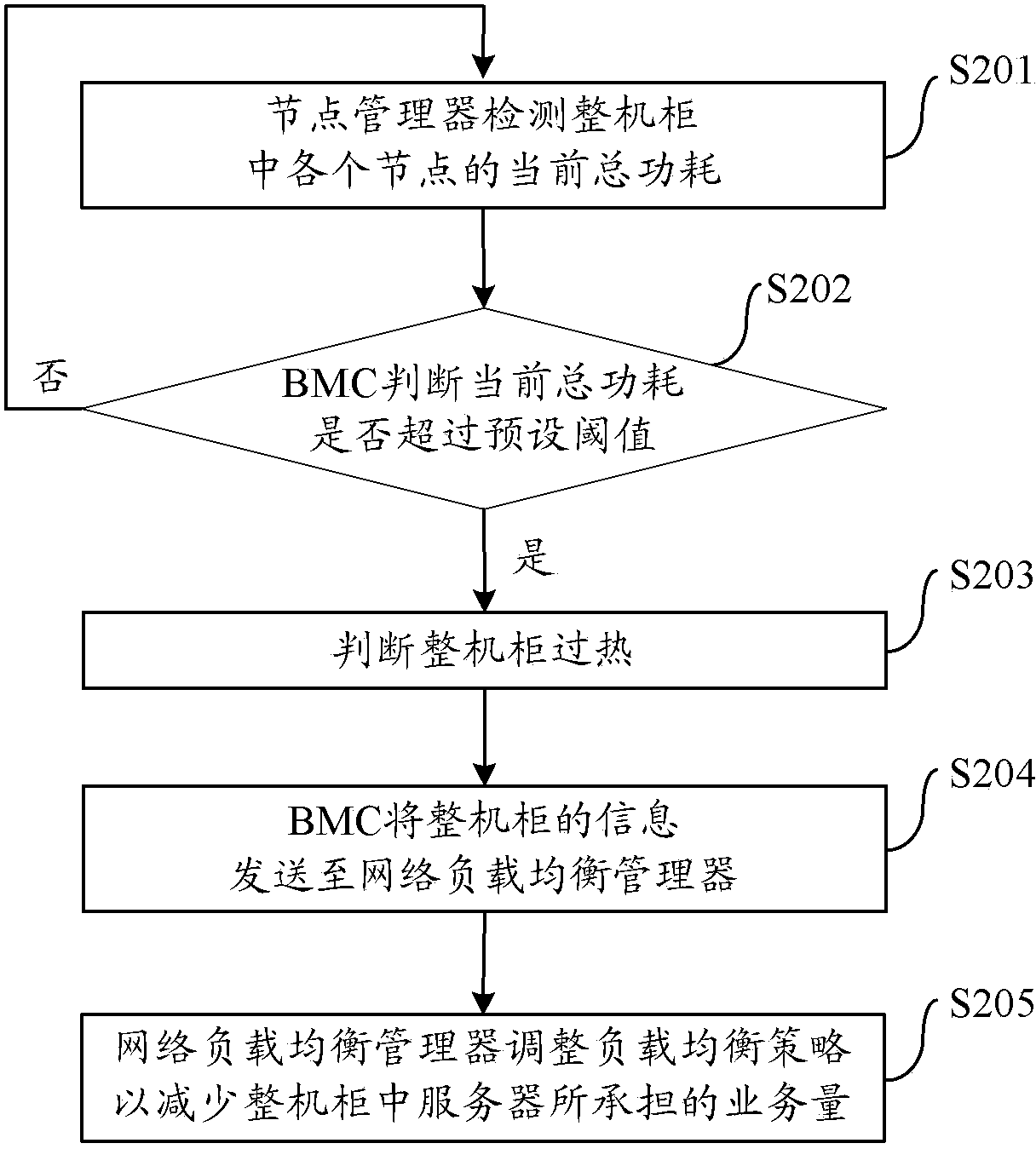

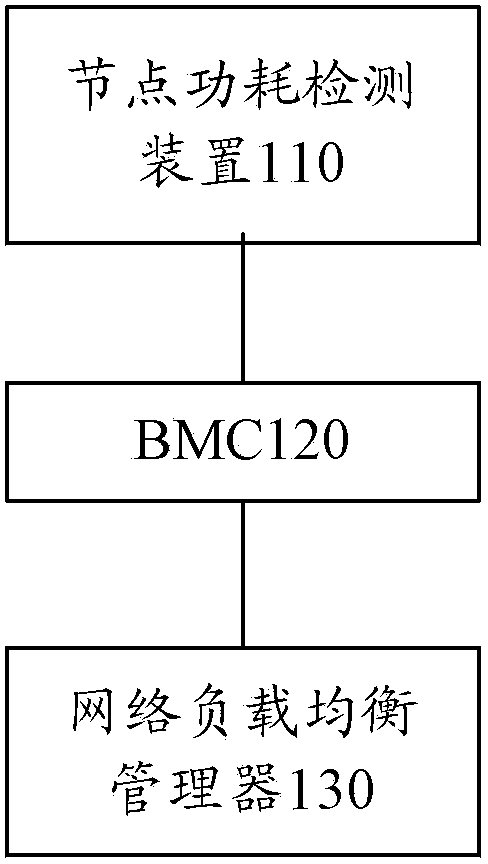

Power consumption management method of whole cabinet and system thereof, and the whole cabinet

InactiveCN103516537APower Management ImplementationPower management automationData switching networksElectricityEngineering

The invention provides a power consumption management method of a whole cabinet and a system thereof, and the whole cabinet. The method comprises the following steps that a node manager detects current total power consumption of each node in the whole cabinet; a mainboard management controller BMC determines whether the whole cabinet is overheating according to the current total power consumption; if the whole cabinet is determined to be overheating, the BMC sends information of the whole cabinet to a network load balancing manager; the network load balancing manager adjusts a load balancing strategy so as to reduce a service volume undertaken by a server in the whole cabinet. According to the method in an embodiment of the invention, power consumption management of the automatic whole cabinet can be realized; a local hot spot generated by non-uniform electricity utilization caused by imbalance of the service volume of the whole cabinet is effectively prevented; service equilibrium between the servers of the whole cabinet in a whole network is realized so that concentrated heat dissipation is used maximumly; invalid power consumption is reduced and cost is further reduced too.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

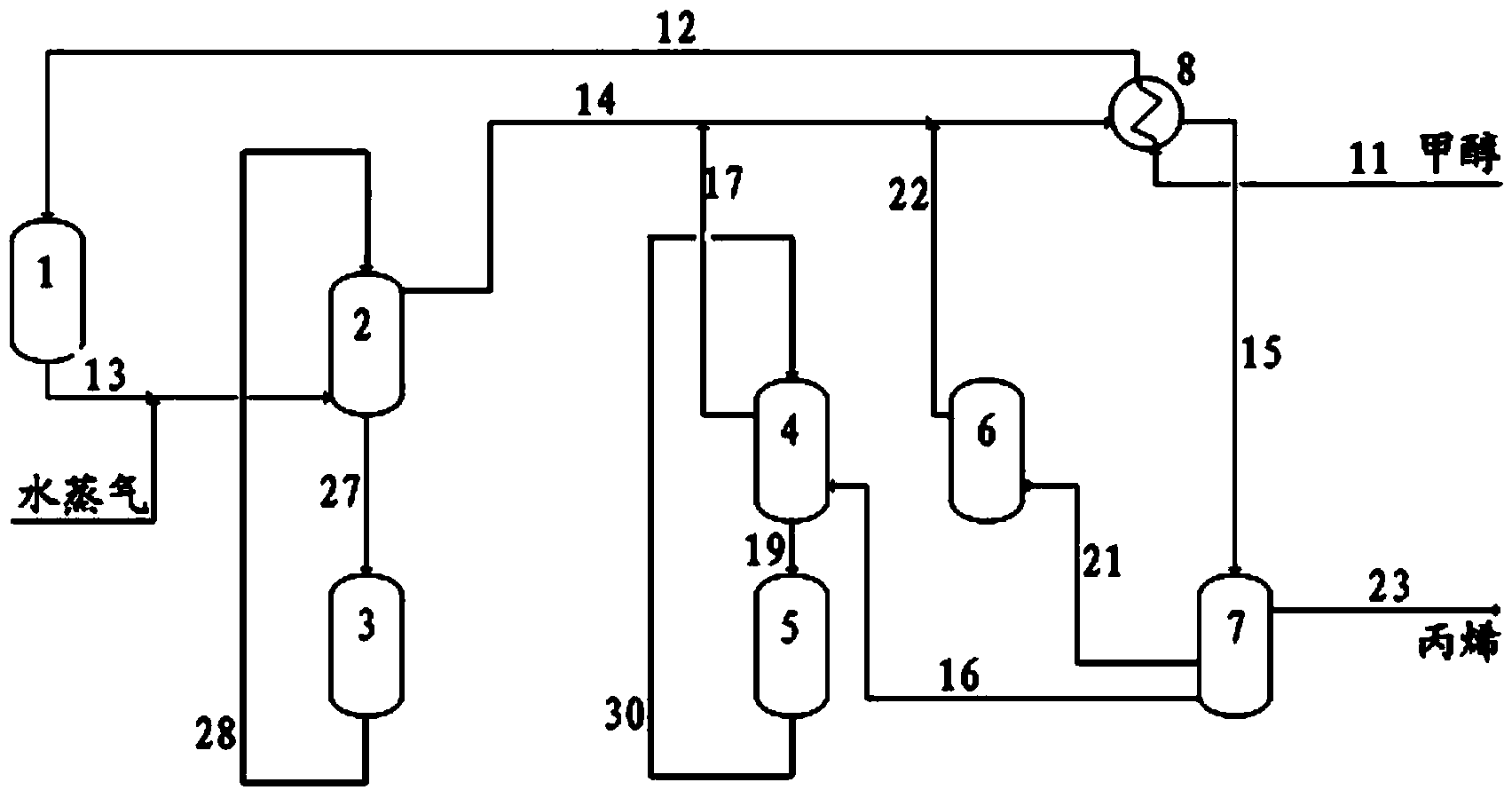

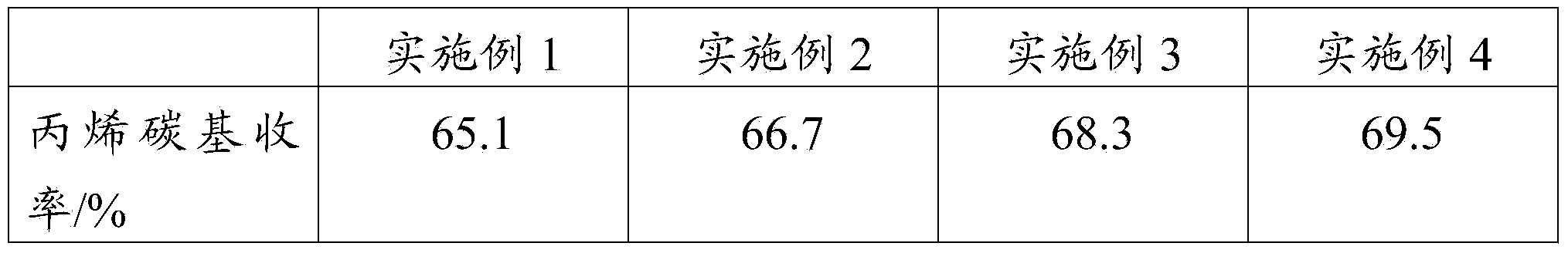

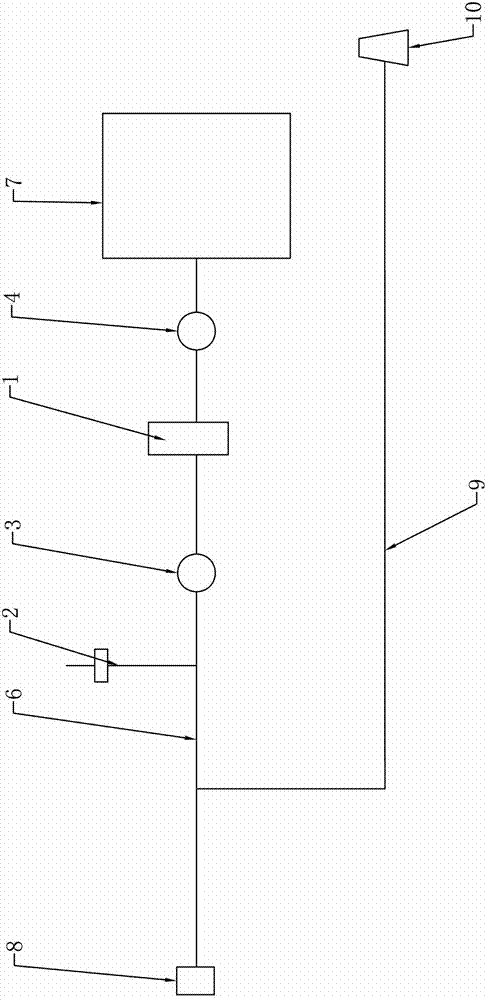

Method and system for preparing propylene by using methanol

ActiveCN103553863AHigh yieldIncrease profitHydrocarbon from oxygen organic compoundsEthylene productionHydrocarbon mixturesFixed bed

The invention discloses a method for preparing propylene by using methanol. The method comprises the steps of: feeding methanol into a first fixed bed reactor to obtain a first product flow; mixing the first product flow with a reactant diluting agent and feeding the mixture in a first moving bed reactor to obtain a second product flow; feeding a C2-C4 hydrocarbon mixture without propylene, which is from a separating device, into a second moving bed reactor to obtain a third product flow; feeding a C5+ hydrocarbon mixture, which is from the separating device, into a second fixed bed reactor to obtain a fourth product flow, wherein the separating device is used for separating the second, third and fourth product flows so as to separate out products: propylene, the C2-C4 hydrocarbon mixture without propylene, and the C5+ hydrocarbon mixture. The invention further discloses a system for preparing propylene by utilizing the method, and the problems in the existing technology for preparing propylene by using methanol that propylene yield is low, a catalyst is likely to coke and deactivate and is complicated to regenerate, and the energy consumption of devices is high can be solved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

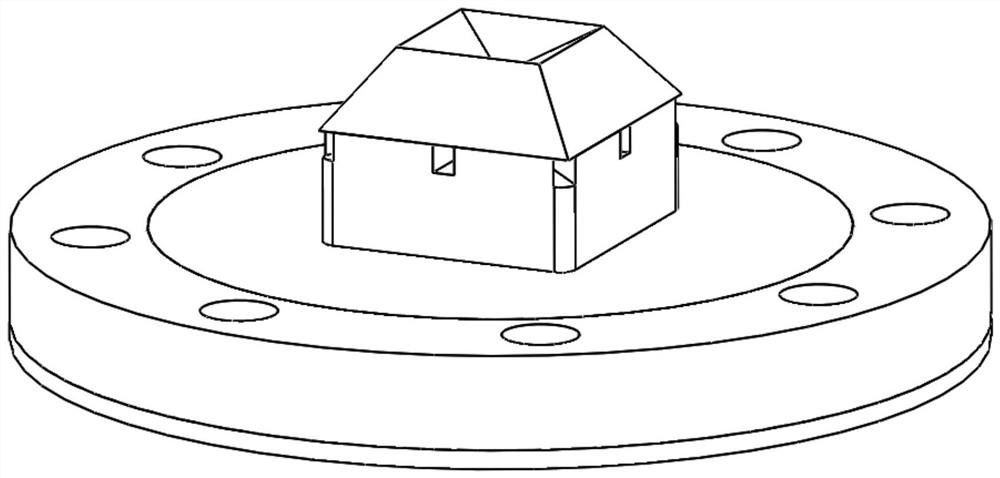

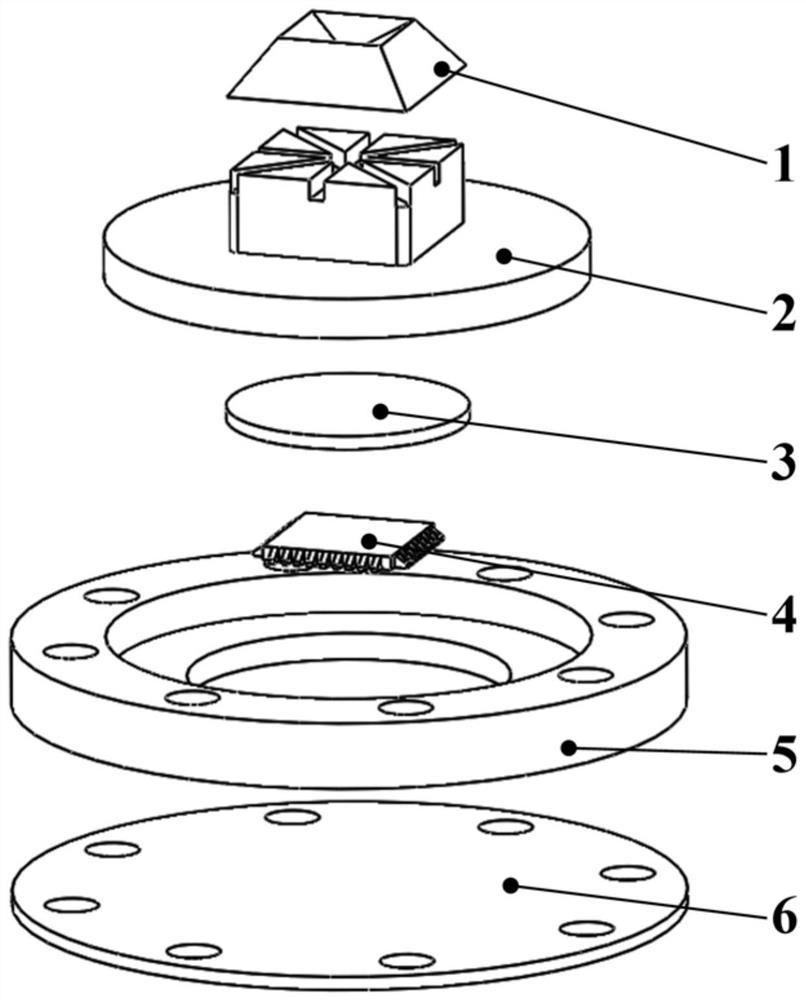

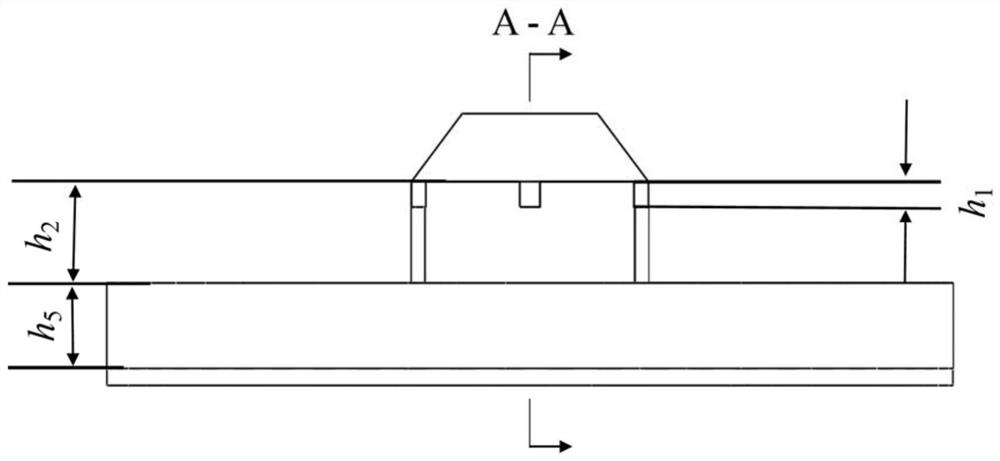

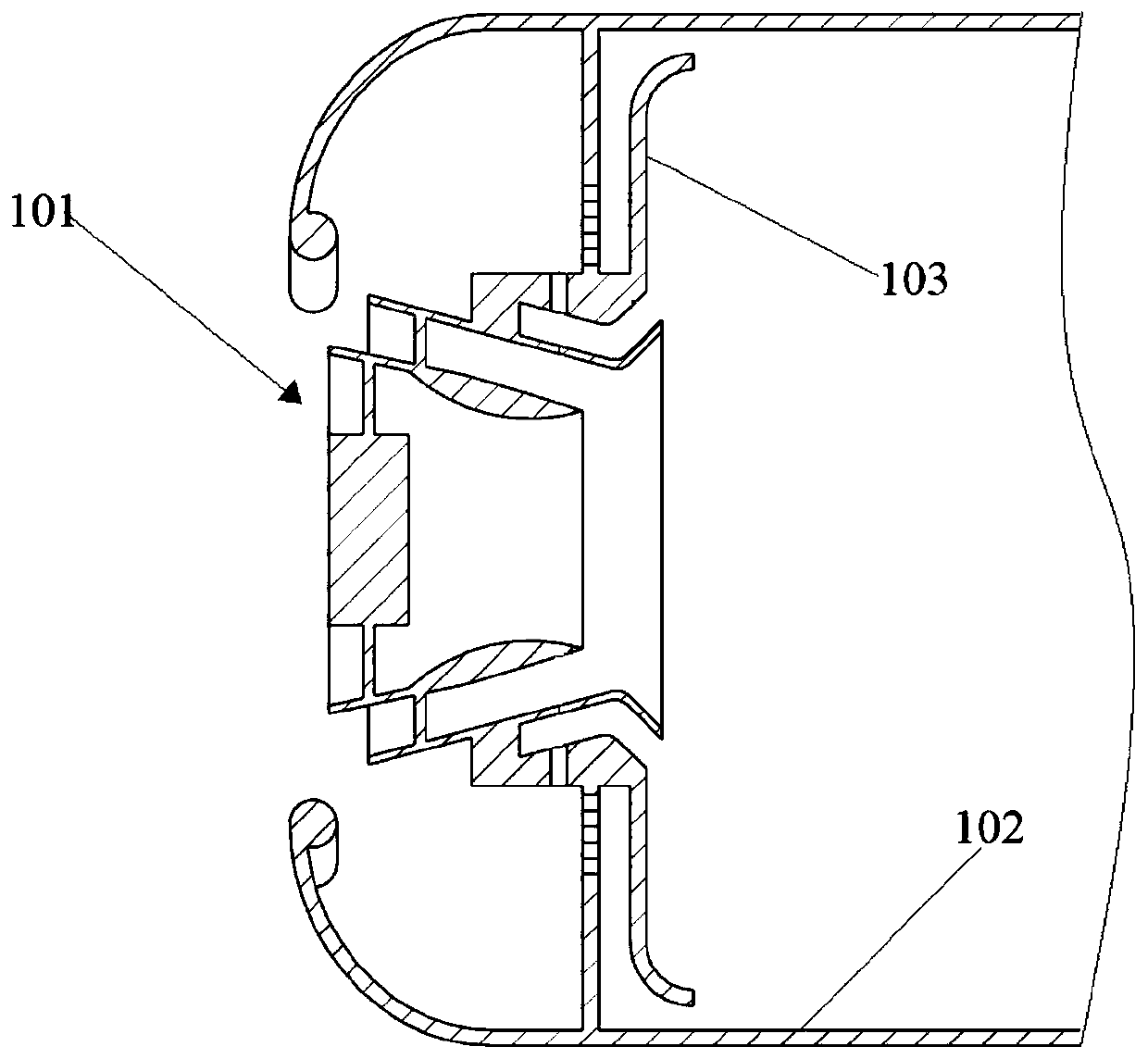

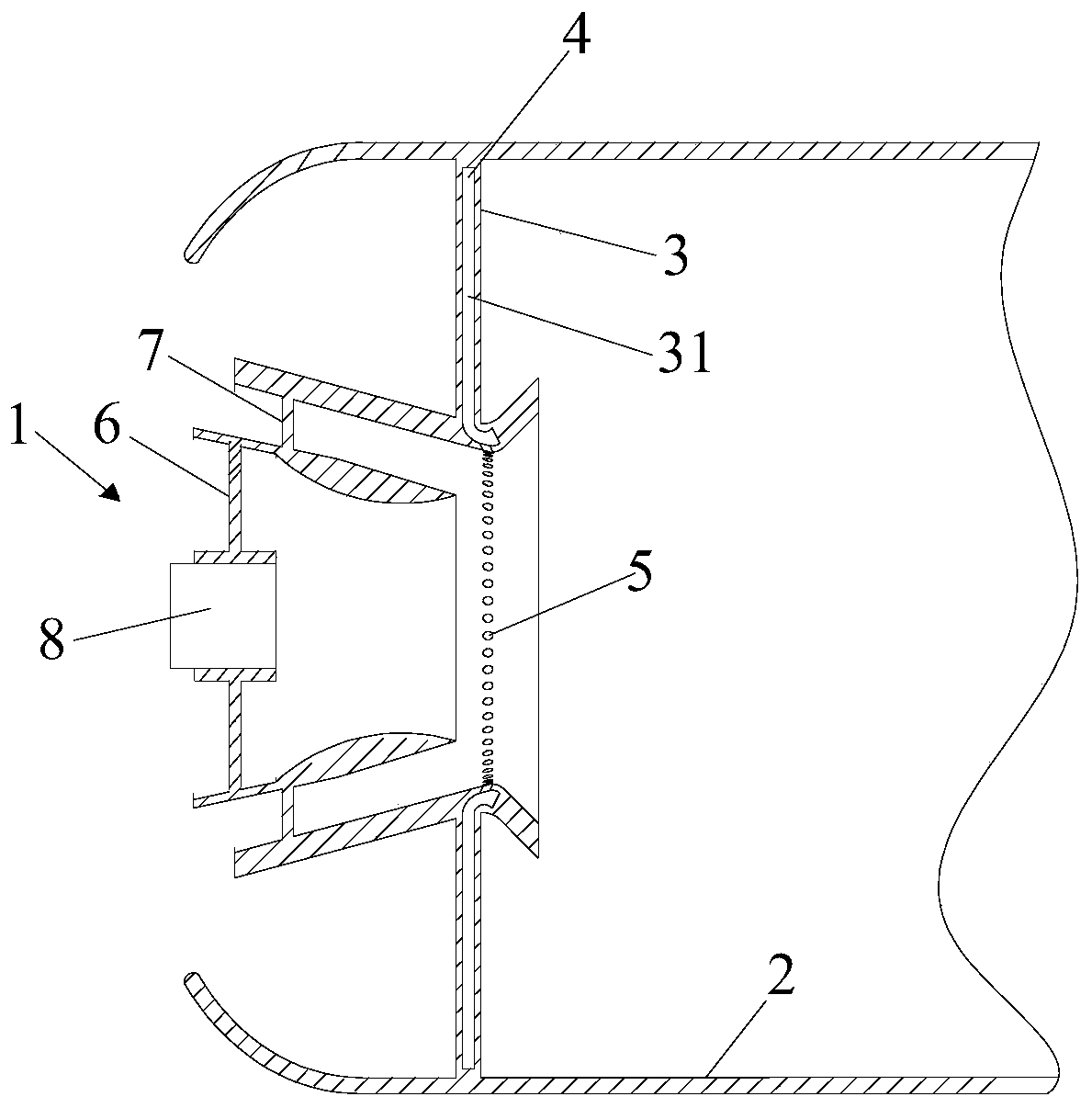

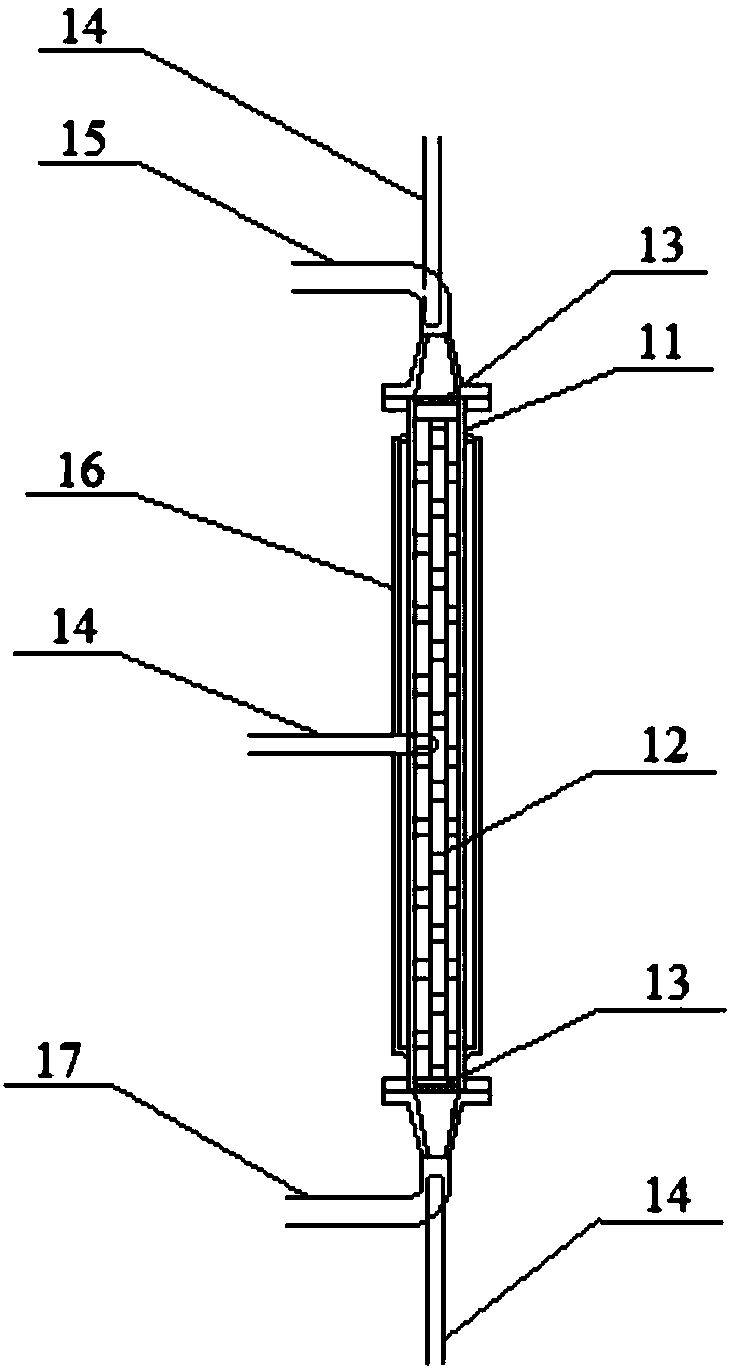

Immersed liquid cooling sintering porous capillary core coupling micro-channel heat dissipation device

ActiveCN113357953AAvoid local hotspotsImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesSilica gelCopper substrate

The invention discloses an immersed liquid cooling sintering porous capillary core coupling micro-channel heat dissipation device. An exhaust micro-channel copper substrate comprises a square boss and a circular soaking table, the boss is located at the center position of the upper side of the soaking table, a *-shaped exhaust micro-channel is formed in the boss through linear cutting, and a boiling-evaporation sintering porous capillary core is in the shape of a prismatic table. The top of the boiling-evaporation sintering porous capillary core is provided with a porous capillary core conical groove, the bottom of the boiling-evaporation sintering porous capillary core and the top face of the polished exhaust micro-channel copper substrate are in contact with each other and are sintered into a whole, a heat conduction piece adheres to the bottom of the soaking table, and a chip heat source adheres to the bottom of the heat conduction piece. The chip heat source is embedded on a packaging substrate, and a heat insulation silica gel pad capable of nesting the heat conduction piece and the chip heat source between the soaking table and the packaging substrate is tightly attached to the packaging substrate. According to the immersed liquid cooling sintering porous capillary core coupling micro-channel heat dissipation device, the phase-change heat transfer capacity and the working stability of the device under medium-high heat flow can be remarkably improved.

Owner:XI AN JIAOTONG UNIV

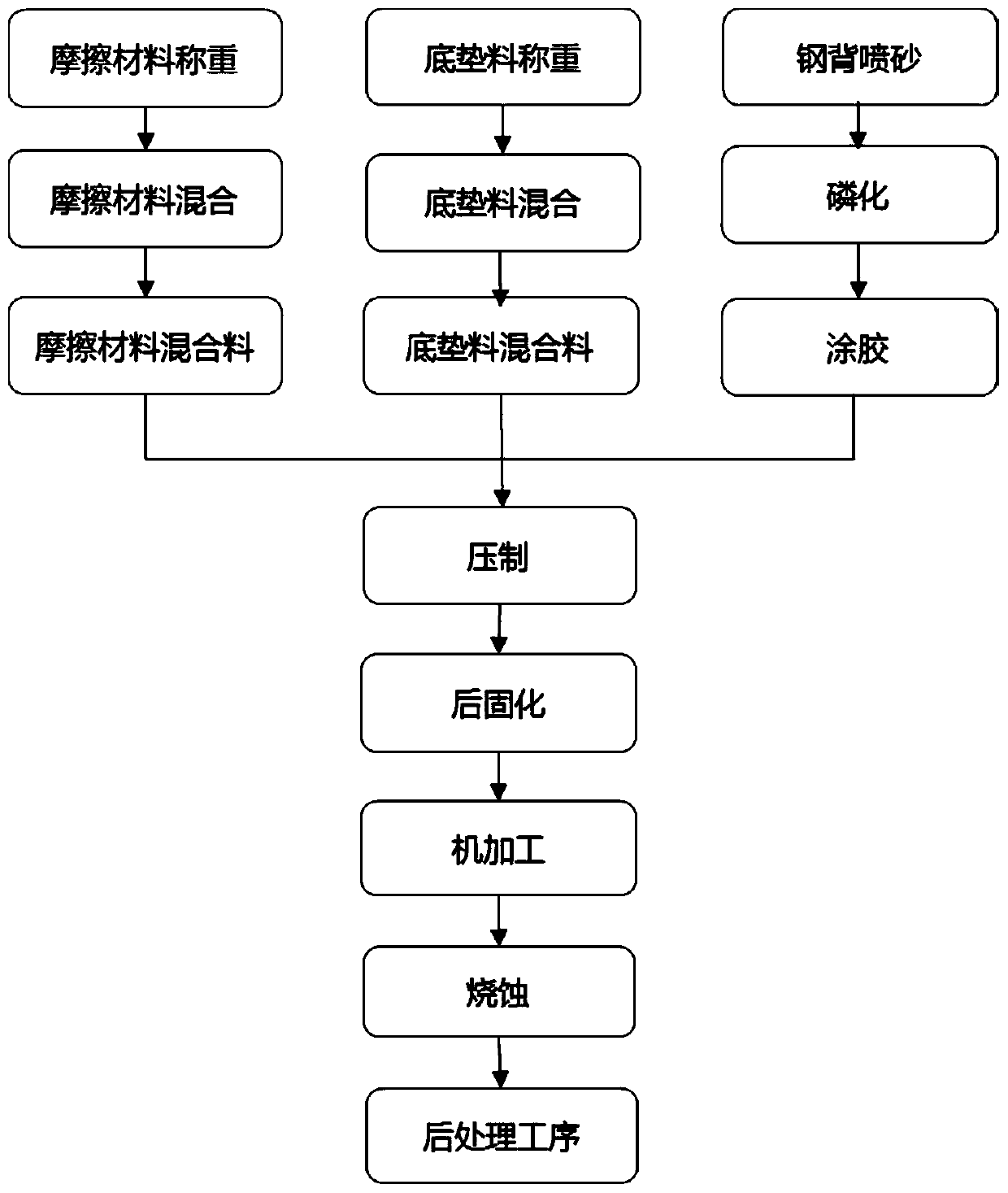

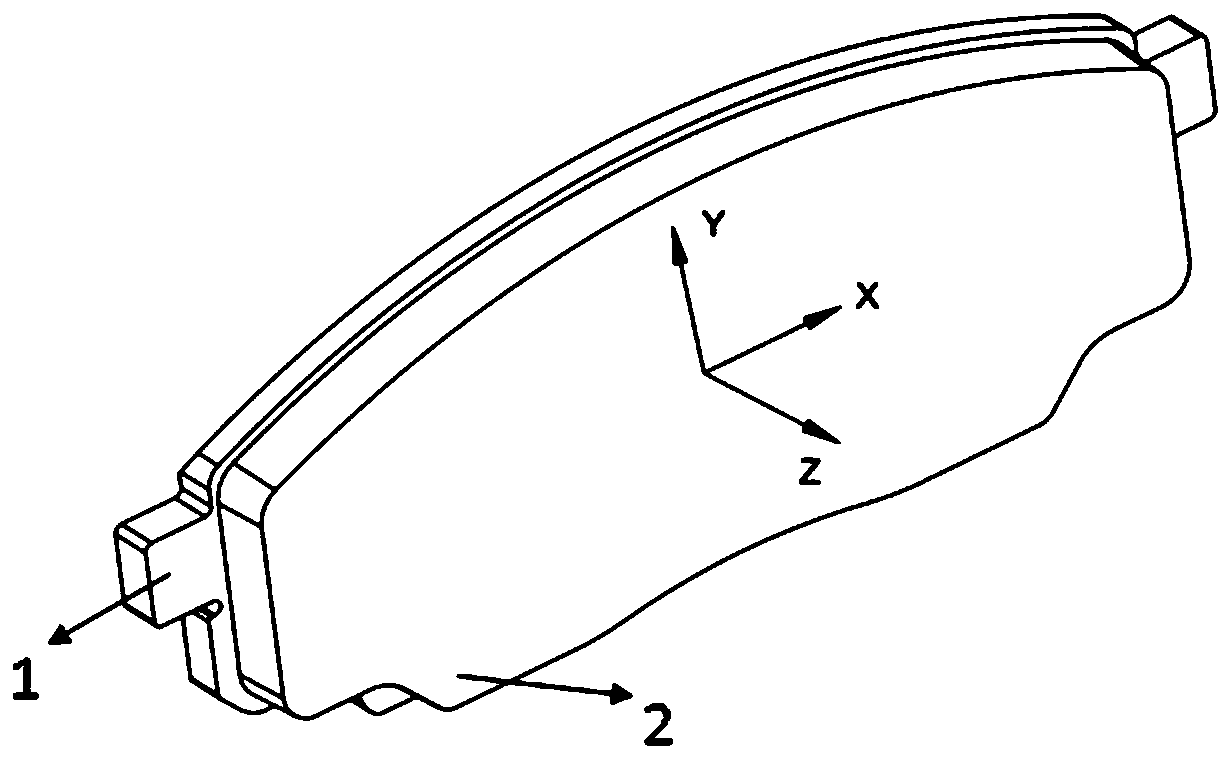

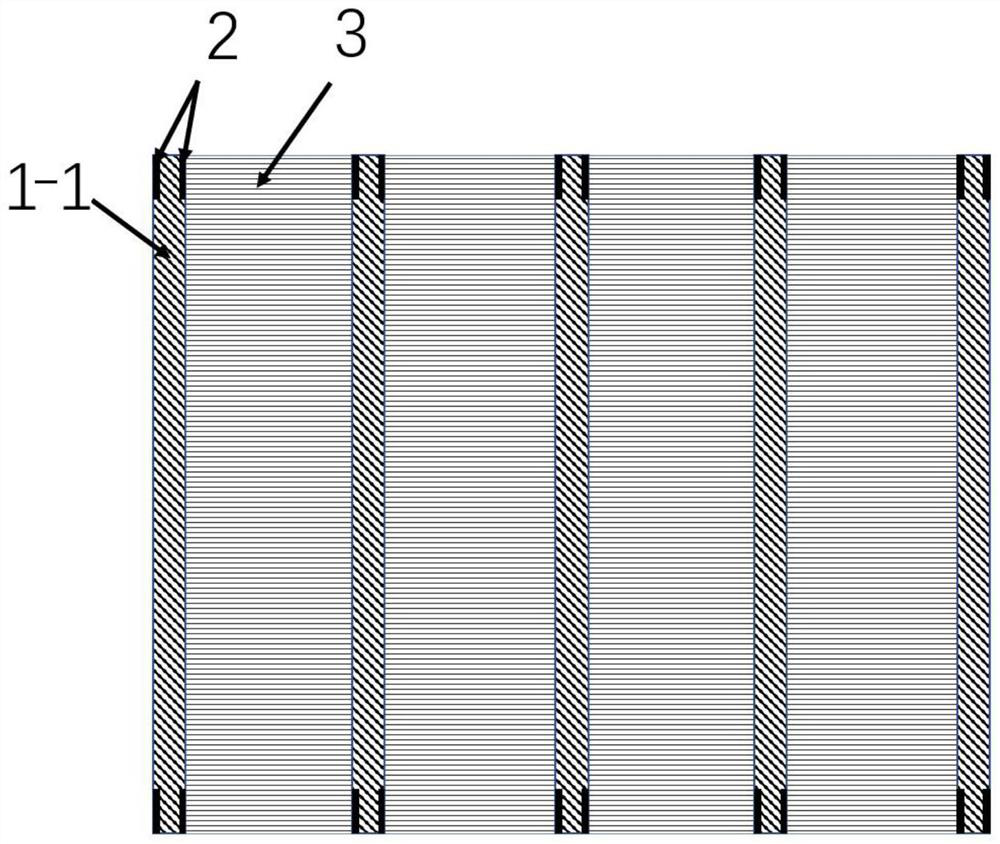

Copper-free friction material and brake pad

PendingCN111396482ASpecial thermal conductivityImprove thermal conductivityFriction liningActuatorsCopperWear resistance

The invention discloses a copper-free friction material and a brake pad prepared based on the copper-free friction material. The copper-free friction material is characterized in that anisotropic heatconduction materials and isotropic heat conduction materials are adopted and combined to form a heat conduction system, the isotropic heat conduction materials are evenly and randomly distributed andfill among anisotropic heat conduction material particles, the anisotropic heat conduction materials are connected, and the effect of replacing metal copper is achieved; and the scheme of the copper-free friction material is an environment-friendly friction material. According to the copper-free friction material and the brake pad, the brake pad prepared based on the friction material has the special heat conduction characteristics that the heat conductivity in the direction of the friction surface is very good, the heat conductivity in the thickness direction of the brake pad is relatively low, in the braking process, the brake pad can release heat generated by braking in time, local hot spots are prevented from being formed on the brake pad or a brake disc, and therefore, the copper-free friction material has very good characteristics of recession resistance, wear resistance, shaking resistance and the like.

Owner:泰明顿摩擦材料技术(上海)有限公司

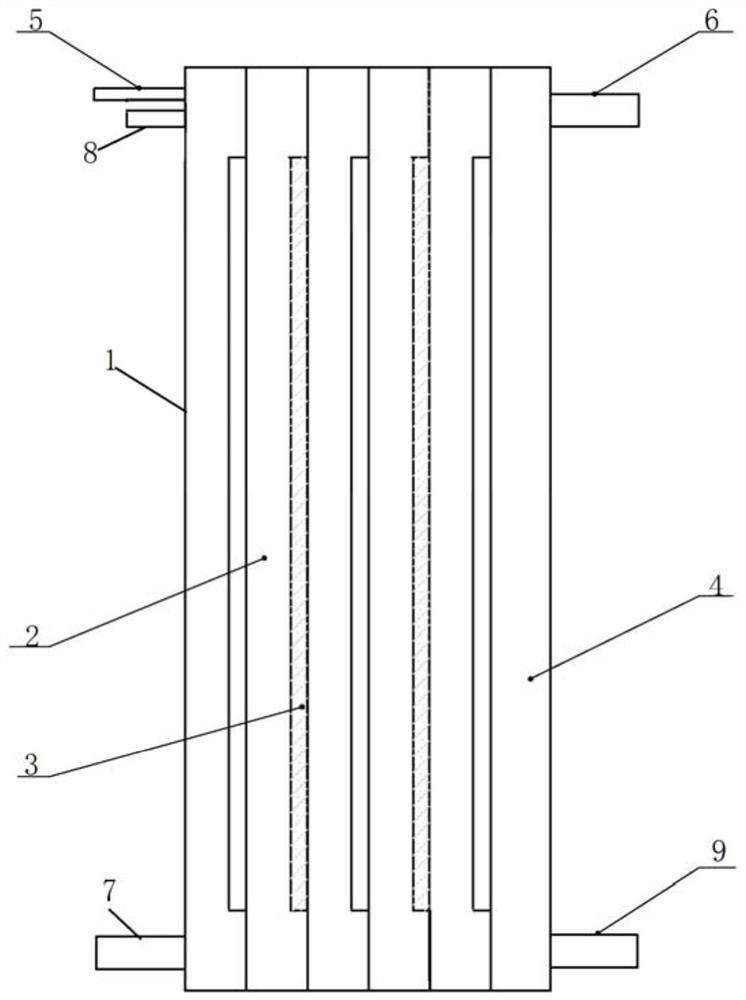

Hydrogen-oxygen composite reactor

ActiveCN113546582AComprehensive and uniform coolingEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsThermodynamicsPtru catalyst

The invention discloses a hydrogen-oxygen composite reactor, and belongs to the field of hydrogen energy application. The hydrogen-oxygen composite reactor is provided with a plurality of heat exchange plates and reaction plates which are alternately arranged from left to right, and the contact surfaces of the heat exchange plates and the reaction plates are tightly attached; a plurality of first through holes are formed in the two ends of the heat exchange plates, a plurality of second through holes are formed in the two ends of the reaction plates, the first through holes and the second through holes are overlapped to form a plurality of channels, and the channels comprise a cooling water channel, an air channel, a hydrogen channel and a flue gas channel; a water flowing channel is arranged in the middle of each heat exchange plate and is communicated with the corresponding cooling water channel, and an airflow channel is arranged in the middle of each reaction plate and is communicated with the corresponding air channel, the corresponding hydrogen channel and the corresponding flue gas channel; and the reactor further comprises a catalyst film structure, and the catalyst film structure is arranged on the middle part of the reaction plate and is used for catalyzing the introduced air to react with hydrogen. The temperature distribution of the temperature field in the hydrogen-oxygen composite reactor is uniform, and local hot spots are avoided.

Owner:武汉氢能与燃料电池产业技术研究院有限公司 +1

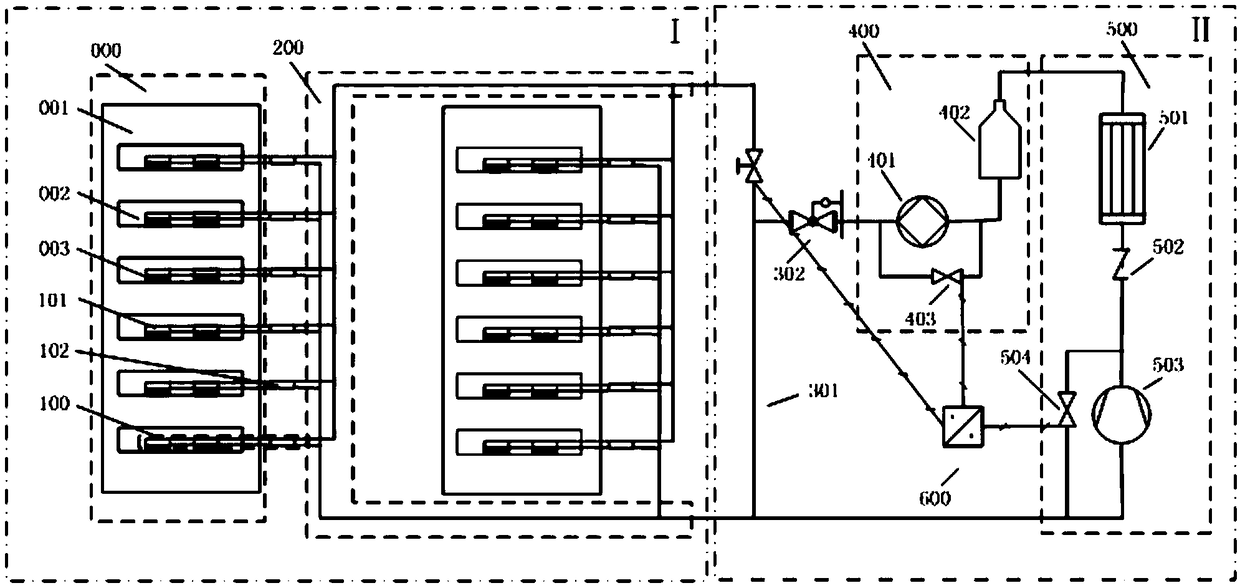

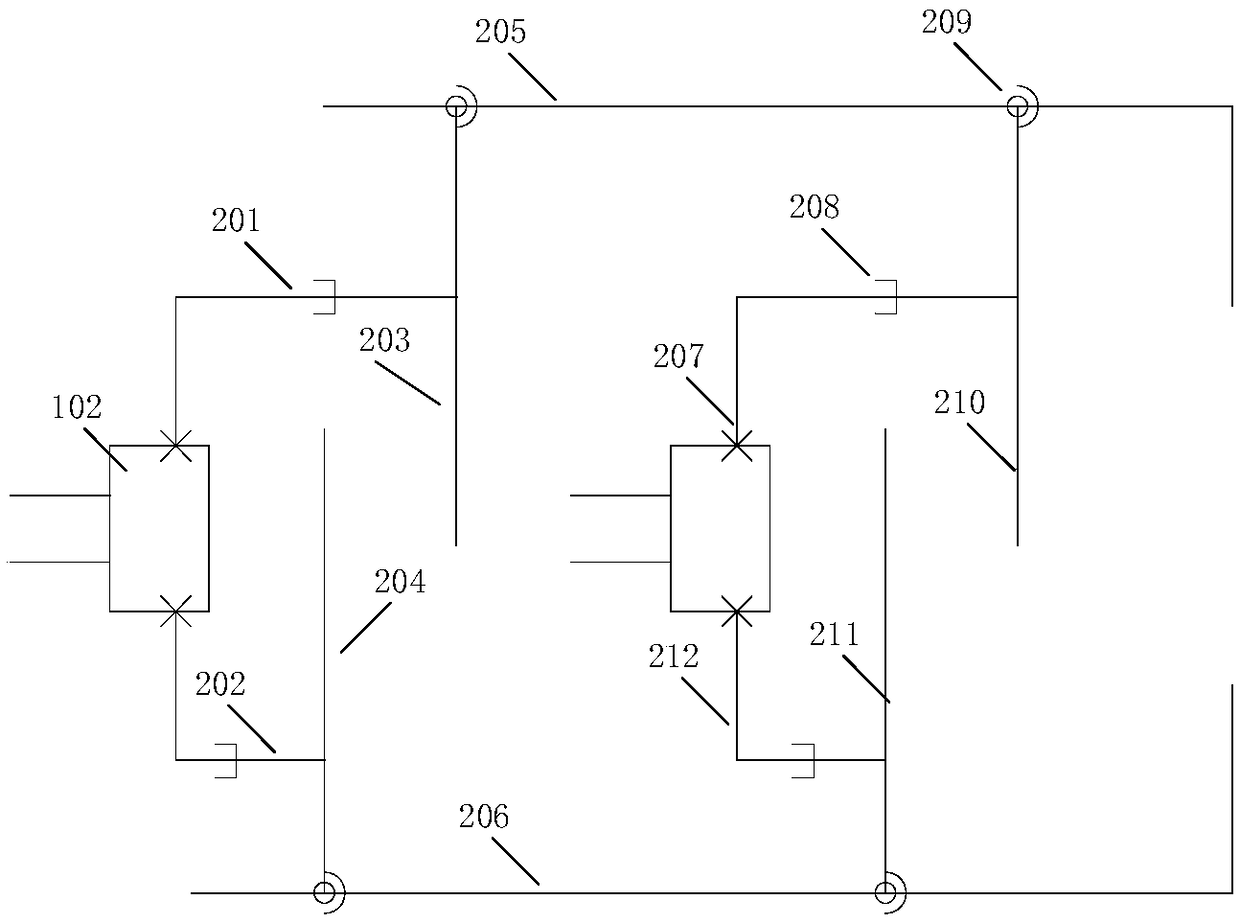

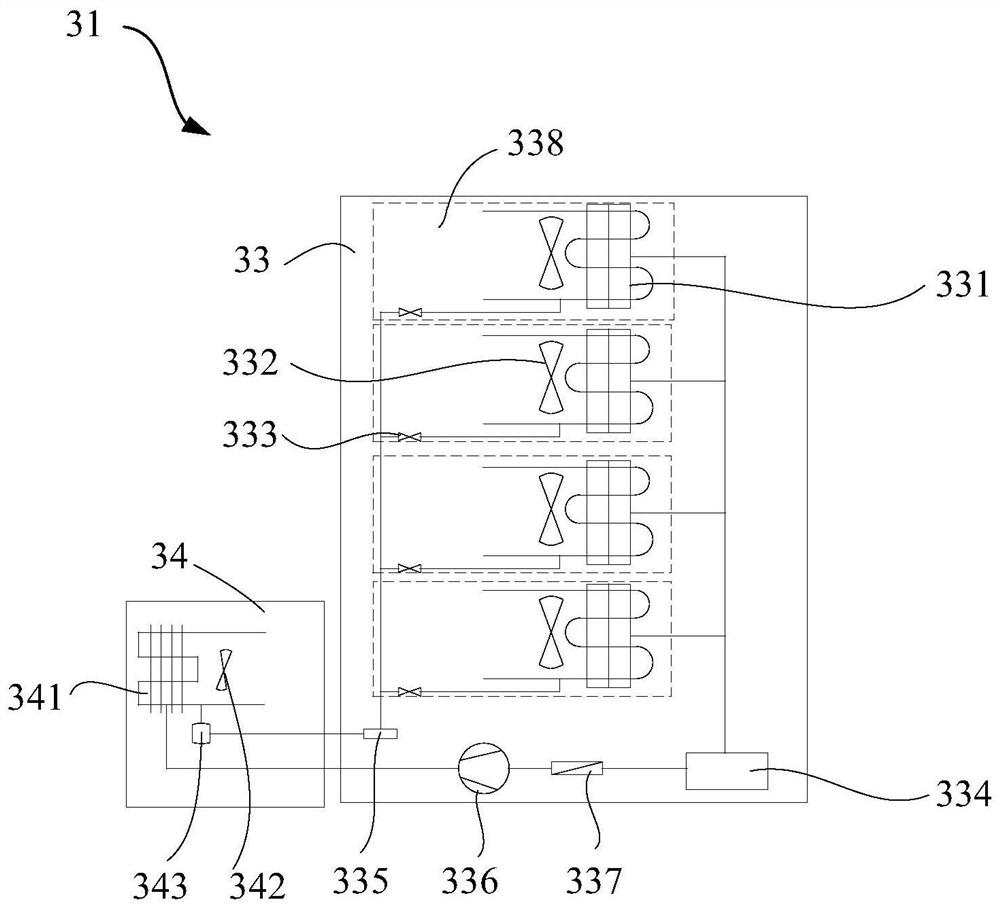

Data center heat dissipation system with direct connection between loop heat pipe and refrigeration cycle pipe

ActiveCN109496110AReduce energy consumptionReduce noiseCooling/ventilation/heating modificationsMicro-loop heat pipeData center

The invention relates to a data center heat dissipation system with direct connection between a loop heat pipe and a refrigeration cycle pipe. The system comprises a loop heat pipe unit, a circulatingworking-medium fast joint unit, and a refrigerant circulation unit. The loop heat pipe unit includes a gas pipe, a liquid pipe, an evaporation end and a condensation end; liquid generated by condensation in the condensation end flows through the liquid pipe to the evaporation end; the evaporation end is adhered to a chip in a server; and heat generated by the chip in the server heats the liquid to generate gas by evaporation and the gas returns to the condensation end along the gas pipe. The condensation end is connected to a refrigeration cycle pipe of the refrigerant circulation unit through the circulating working-medium fast joint unit; the circulating working medium transmits the heat generated by the condensation end of the loop heat pipe unit to a condenser of the refrigerant circulation unit; and the heat is exchanged to the outdoor space by the condenser. Because of direct connection between the heat pipe and the refrigeration cycle pipe, the heat exchange link and the temperature difference loss from the chip to the refrigeration circulation are reduced; and the energy consumption and noises caused by the traditional machine room heat dissipation technology are reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

A method for hydrogenation of benzene to prepare cyclohexane in a magnetically stabilized bed

ActiveCN103232315AExtended service lifeReduce churnHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneHydrogen

The present invention discloses a method for hydrogenation of benzene to prepare cyclohexane in a magnetically stabilized bed. The method comprises steps of: first loading sodium borohydride reduced Ni2 + and metal cation additive on a magnetic catalyst, and then loading the magnetic catalyst into the reaction unit of the magnetically stabilized bed, and controlling reaction conditions of a ratio of hydrogen to benzene, a space velocity, and a magnetic field strength to enable a bed layer to form a magnetically stabilized state for hydrogenation of benzene to prepare cyclohexane. By using the magnetically stabilized bed to control the bed layer fluidization state for hydrogenation of benzene to prepare cyclohexane, the method of the present invention prevents local hot spots from emerging in the bed layer, reduces catalyst deactivation, maintains a relatively high benzene conversion rate and cyclohexane selectivity, and substantially increases the service life of the catalyst; and the magnetic field can be used to separate and recover the catalyst, thus reduce production costs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

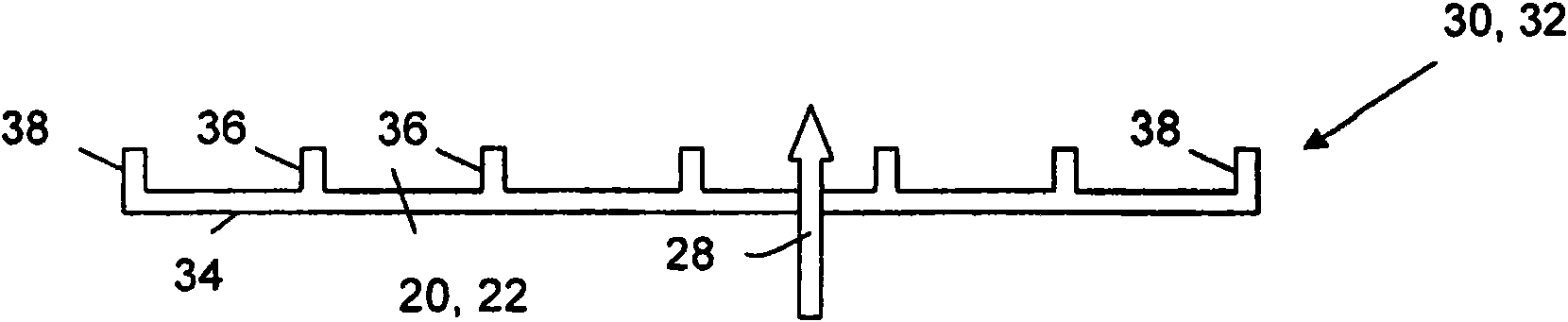

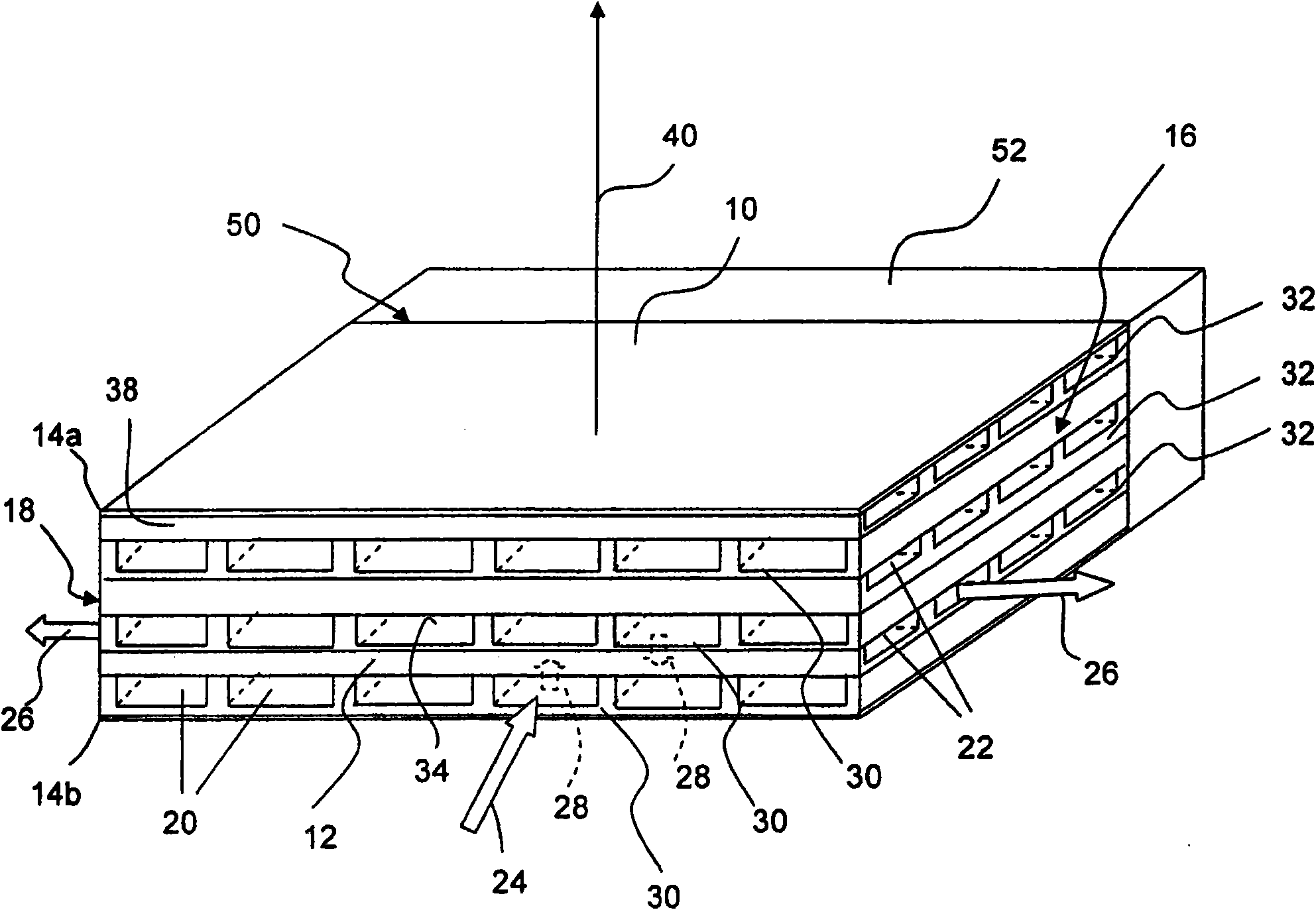

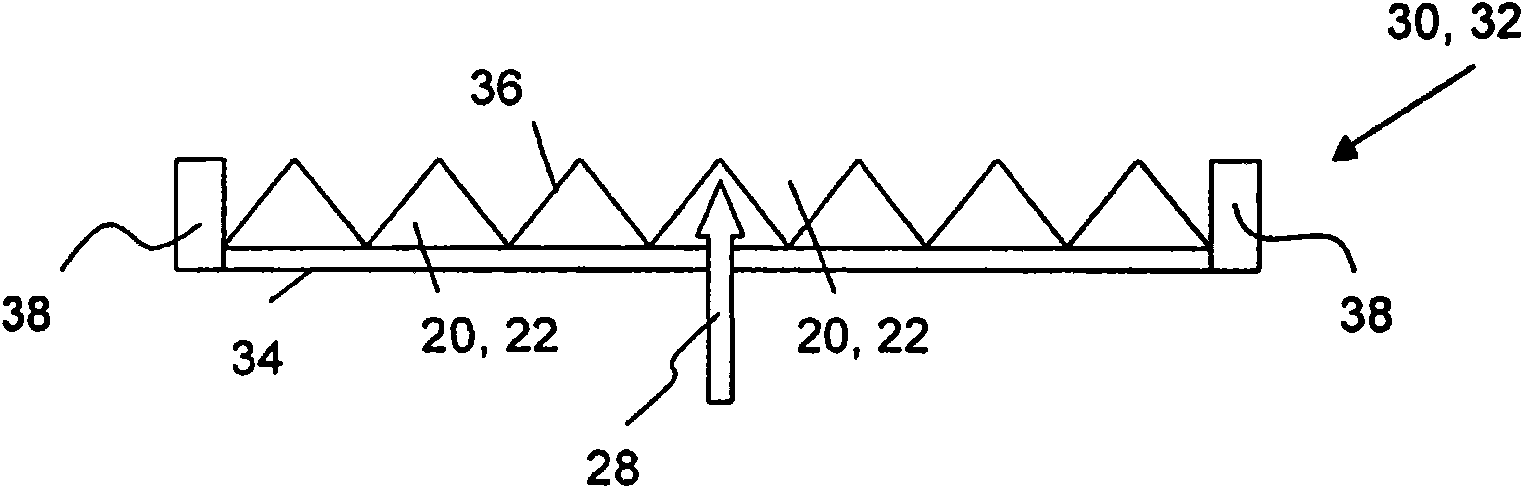

Particulate filtration device

InactiveCN101903080AFast heat conductionAvoid local hotspotsGas treatmentDispersed particle filtrationParticulatesFiltration

The invention relates to a particulate filtration device (100) comprising a filter (10) with a feed inlet side (12) for a feed gas and an filtrate outlet (16, 18) for a filtrate, further comprising feed gas channels (20) and filtrate channels (22) and one or more diaphragms (34) between the feed inlet side (12) and the filtrate outlet (16, 18). Opposite to the feed inlet side (12) a particulate outlet (50) is arranged with a collector compartment (52) attached to the particulate outlet (50) for collecting particulates retained in the feed gas channels (20).

Owner:VOLVO TECH +1

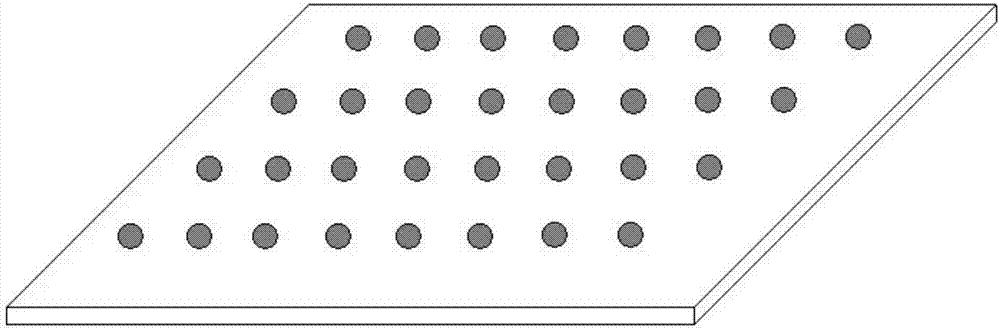

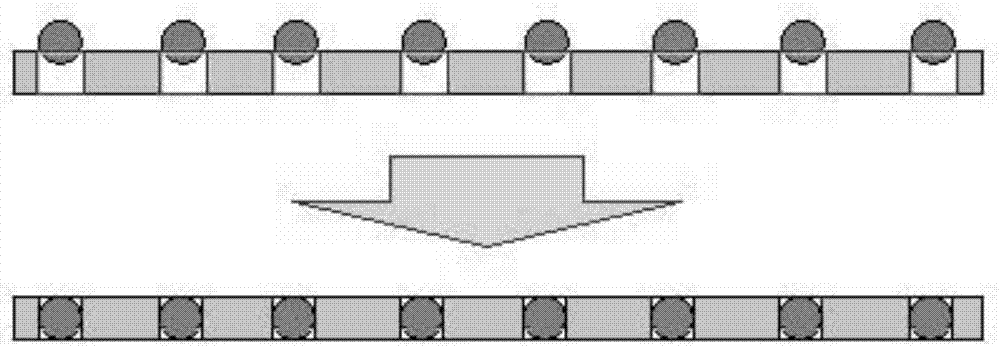

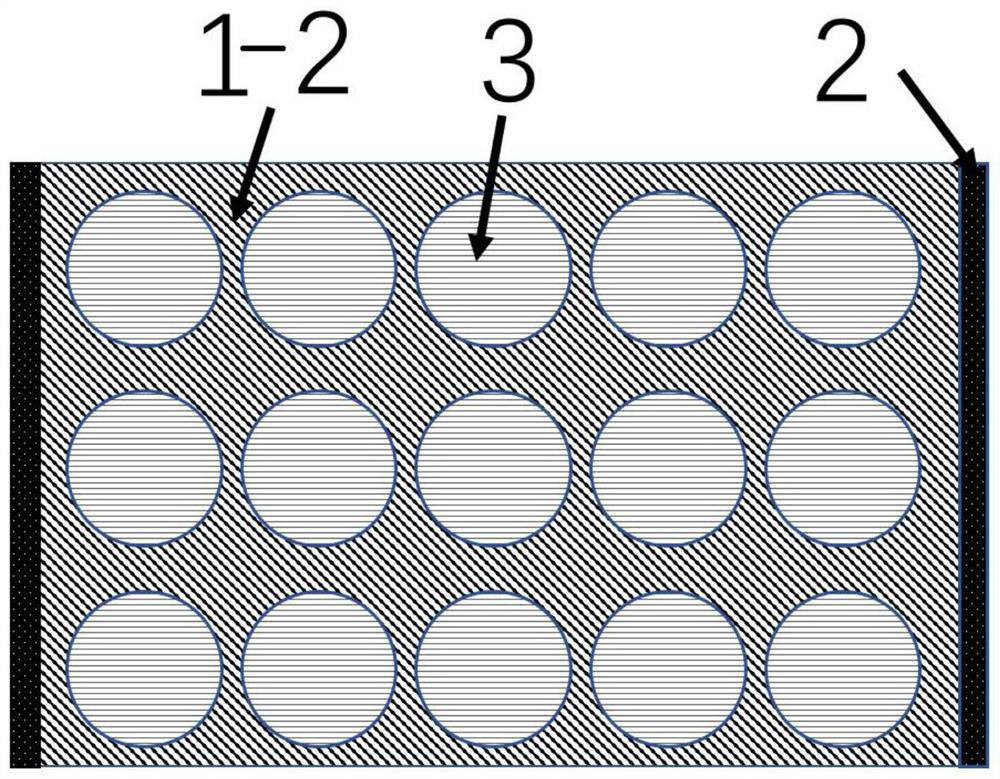

Processing method of spherical material quasicrystal lattice distribution in base material

The invention discloses a processing method of spherical material quasicrystal lattice distribution in a base material. The processing method comprises two parts of a pre-forming base plate sphere placement technology and sphere including base plate laser cladding. Compared with a traditional powder metallurgy mechanical mixing manner, according to the technology of the method, the uniformity degree of a composite material doped phase is greatly increased and is close to an ideal lattice degree, the physical performance and the chemical performance of a composite material are greatly improved, and unstable partial performance of the material is avoided; and if the method is used in nuclear fuel element manufacturing, by means of the adoption of the technology, the technology plays an important role in reactor core power expansion, unit burnup increase and partial hot spot avoiding.

Owner:成都青石激光科技有限公司

Combustion chamber

ActiveCN109899831AAvoid damageReduce the temperatureContinuous combustion chamberAutomotive engineeringFuel oil

The invention provides a combustion chamber, and relates to the field of aero-engines. The combustion chamber comprises a combustion chamber head and a flame tube. In addition, the combustion chambercomprises a splash plate and a first-stage oil supply system, wherein the splash plate is arranged between the combustion chamber head and the flame tube, and connected to the periphery of the combustion chamber head; a cavity is formed in the splash plate, and an oil outlet hole communicating with the cavity and the combustion chamber head is formed in the side wall of the combustion chamber head; and the first-stage oil supply system is arranged at the end, away from the combustion chamber head, of the splash plate, communicates with the cavity , and is used for injecting fuel oil into the cavity. According to the combustion chamber, the wall face cooling effect can be enhanced, and the production cost can be reduced.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

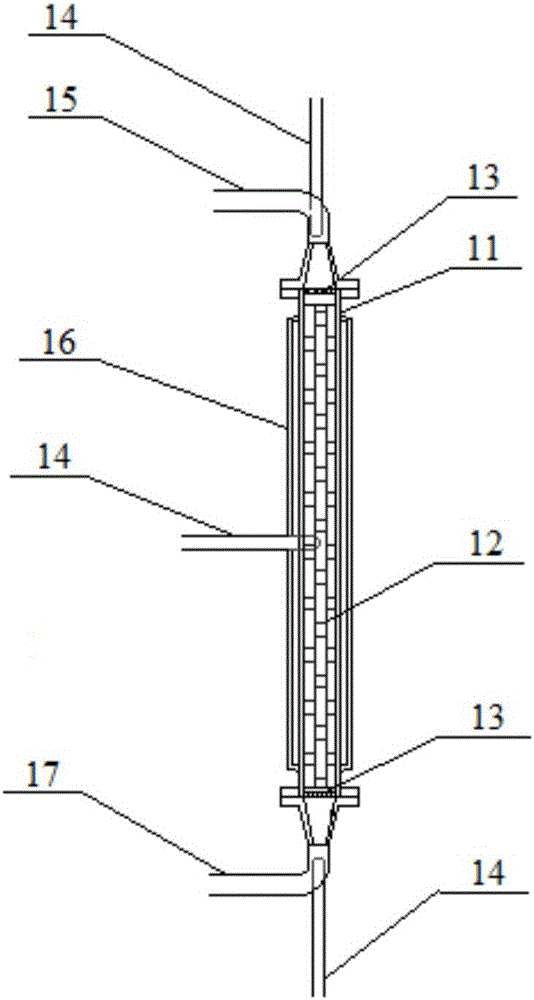

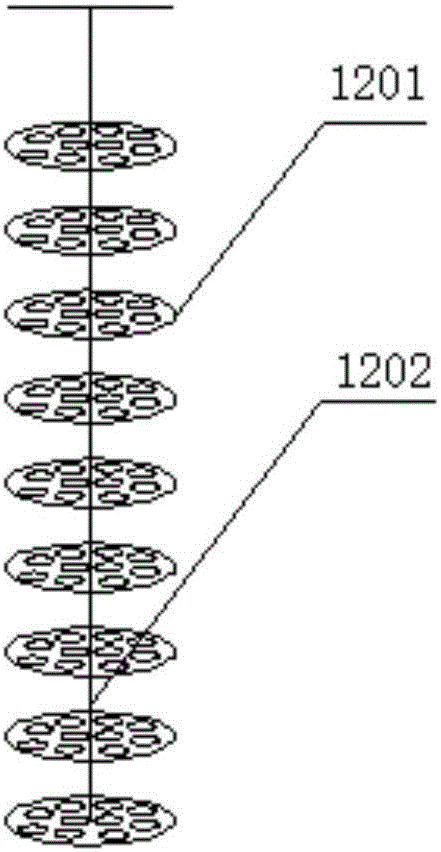

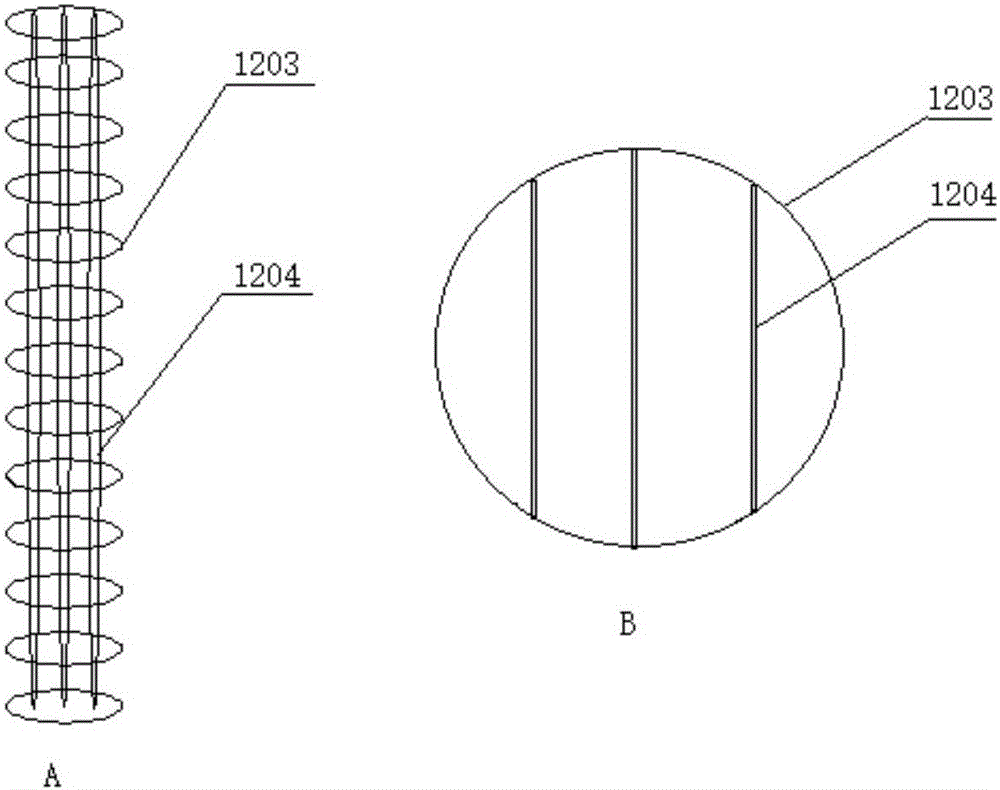

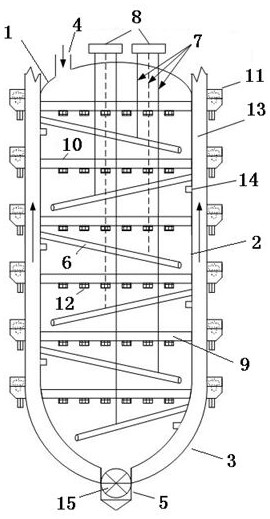

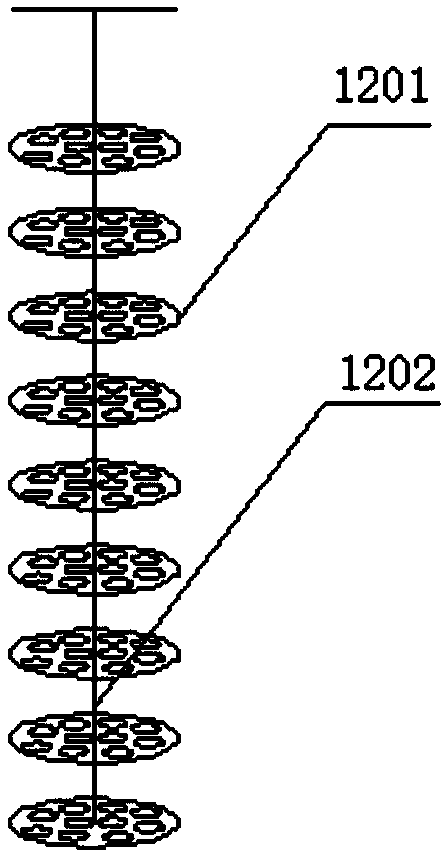

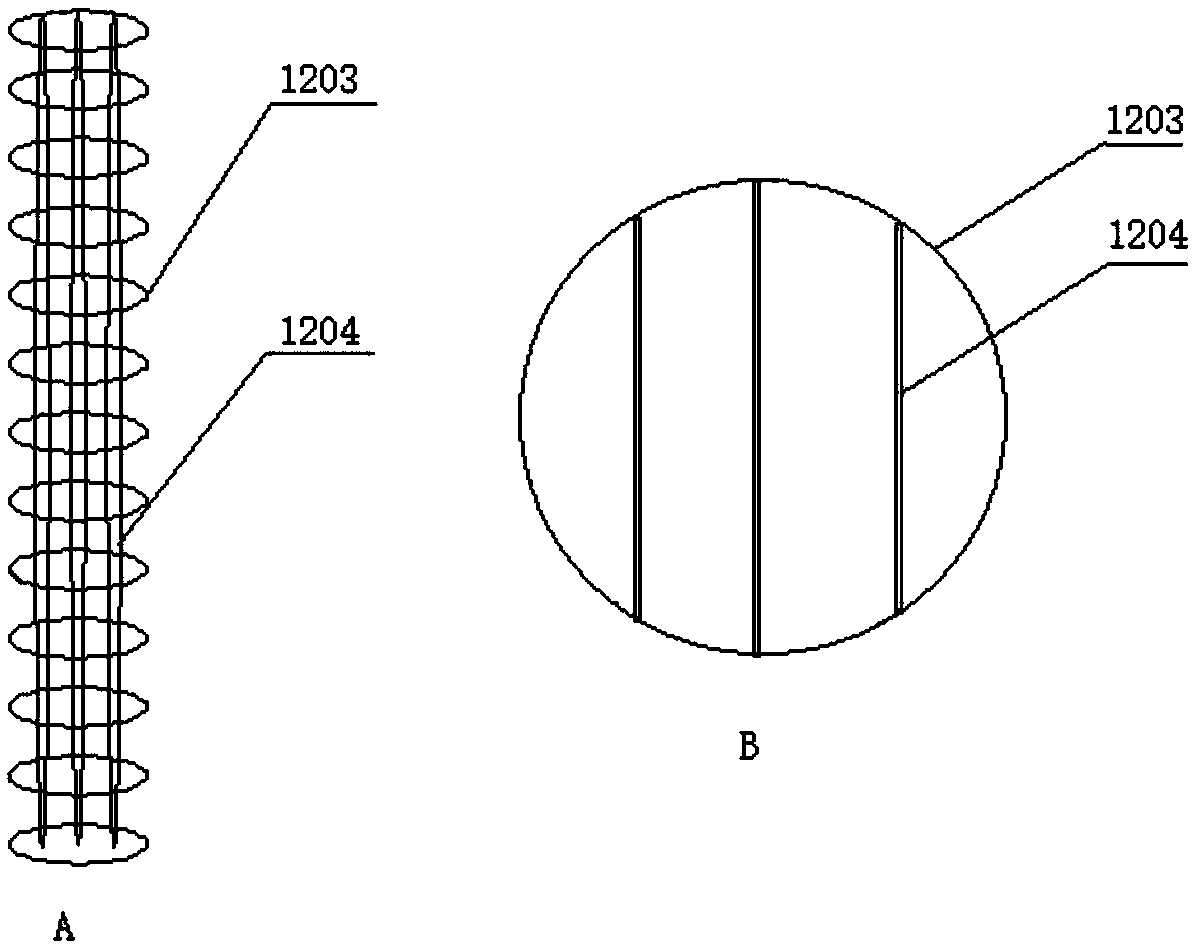

Multiflux load catalytic continuous reaction device

ActiveCN106076208AEvenly distributedReduce dosageChemical/physical processesSmall footprintDistributor

The invention discloses a load continuous catalytic column. The load continuous catalytic column comprises a column body, a gas-liquid separator and a load catalyst distributor. According to the specific reaction, catalyst can be replaced, and the filling quantity of the catalysts can be controlled, so that convenience and flexibility in use can be realized. Materials and load catalysts are uniformly distributed, so that local hot spots can be effectively prevented, and the mass transfer efficiency is high. The invention also discloses a multiflux load catalytic continuous reaction device. The multiflux load catalytic continuous reaction device comprises load continuous catalytic columns and an automatic feeding system, wherein the load continuous catalytic columns are connected with the automatic feeding system. The multiflux load catalytic continuous reaction device is less in liquid holding amount, small in floor occupation area, high in safety and simple to operate; and the quantity and connection way of the load continuous catalytic columns can be adjusted according to the real situation, so that convenience and flexibility can be realized. The multiflux load catalytic continuous reaction device can be used for efficiently screening various load catalysts, optimizing a continuous reaction condition and amplifying a continuous process.

Owner:ASYMCHEM LAB TIANJIN +4

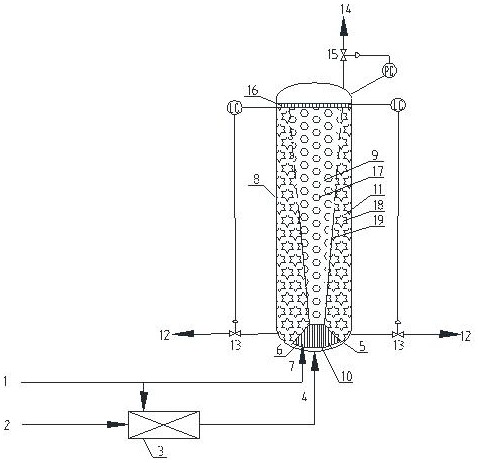

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

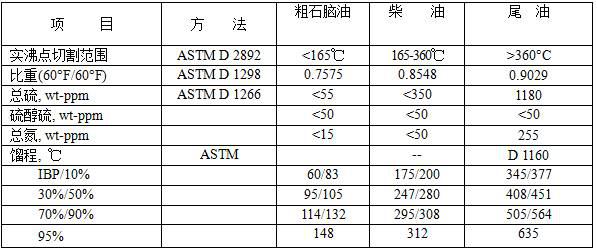

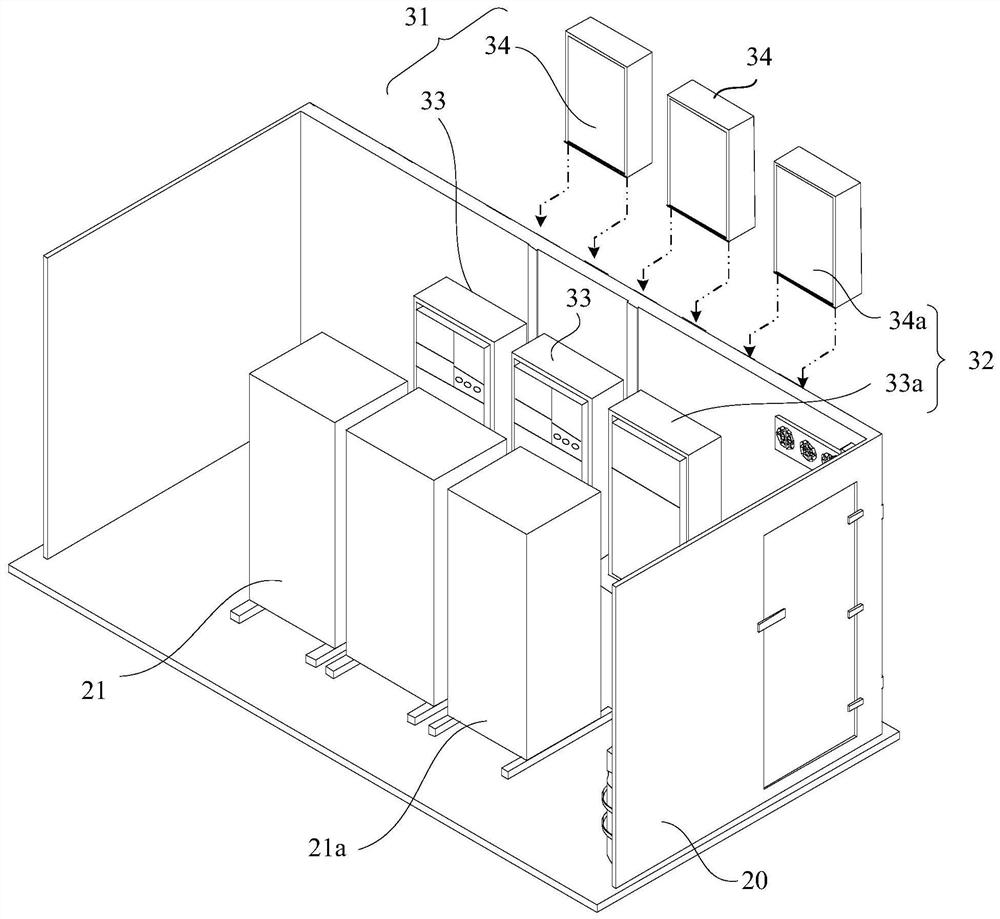

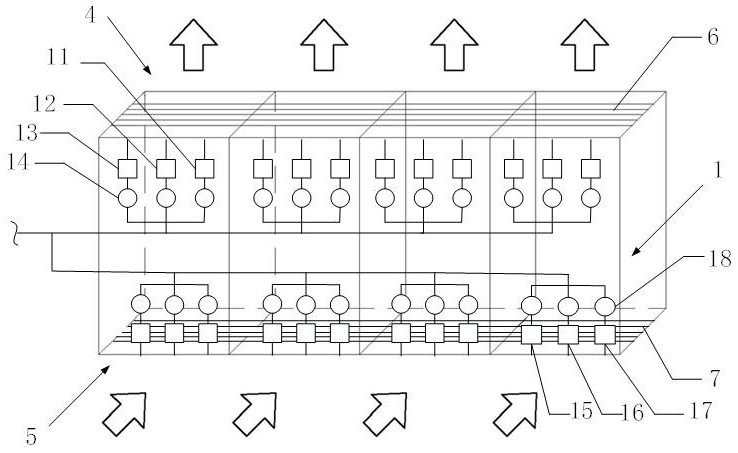

Data center device

InactiveCN112616291AAvoid failureAvoid local hotspotsCooling/ventilation/heating modificationsCold airData center

The embodiment of the invention provides a data center device which comprises a machine room and a refrigerating system, wherein at least one cabinet is arranged in the machine room, multiple layers of loads are arranged in the cabinet, and the refrigerating system comprises at least one row-level multi-connected air conditioner. Each row-level multi-connected air conditioner comprises an indoor unit and an outdoor unit which are connected, the indoor unit is located in the machine room, and the outdoor unit is located outside the machine room; the indoor unit comprises a plurality of sub indoor units which are connected in parallel; the indoor unit and the cabinet are arranged in parallel, and the multiple sub indoor units are opposite to multiple layers of loads in the cabinet so that cold air blown out of the multiple sub indoor units can be blown to all the layers of loads. Therefore, the problems that an existing data center device is poor in refrigeration effect and wastes energy are solved.

Owner:HUAWEI DIGITAL POWER TECH CO LTD

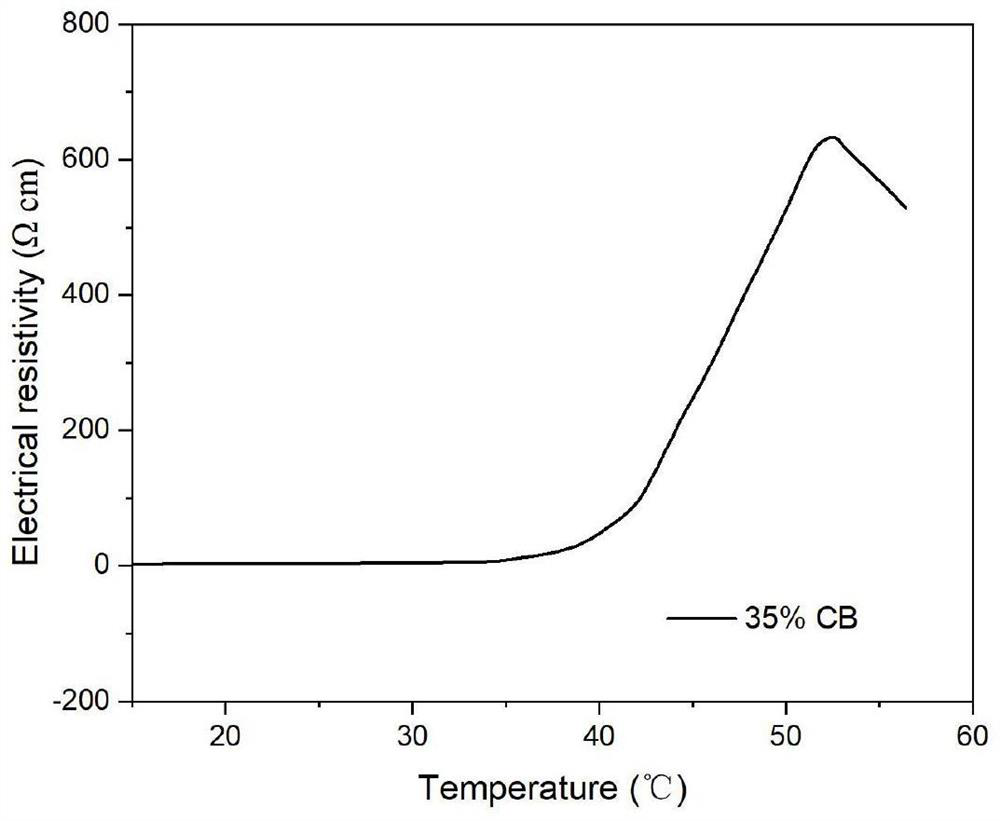

Flexible composite phase change material, preparation method and application thereof, battery heating element and ion battery pack with low-temperature thermal management system

PendingCN114867135AImprove flexibilityMeet the needs of thermal managementSecondary cellsHeating element materialsHeat managementThermal management system

The invention belongs to the technical field of ion batteries, and particularly relates to a flexible composite phase change material, a preparation method and application thereof, a battery heating piece and an ion battery pack with a low-temperature heat management system. The invention provides a flexible composite phase change material. The flexible composite phase change material comprises the following components in parts by mass: 20-35 parts of spherical conductive filler, 1-5 parts of multi-dimensional conductive filler, 20-30 parts of polymer matrix and 40-50 parts of organic phase change material. The flexible composite phase change material provided by the invention has the characteristic of flexibility, and can be well attached to the surface of a battery, so that the heat transfer resistance is reduced, and local hot spots are avoided; meanwhile, good conductivity is achieved, rapid heating can be achieved by applying small voltage, and therefore the battery can be rapidly and efficiently preheated; and constant-temperature heating can be achieved, and higher safety is achieved.

Owner:SOUTH CHINA UNIV OF TECH +1

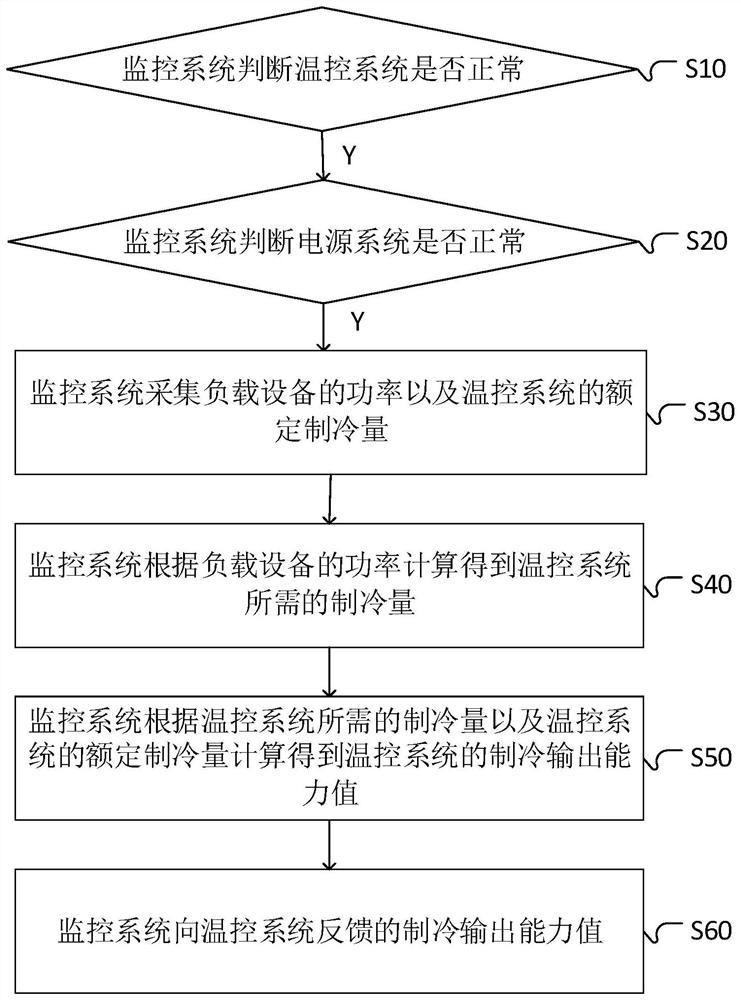

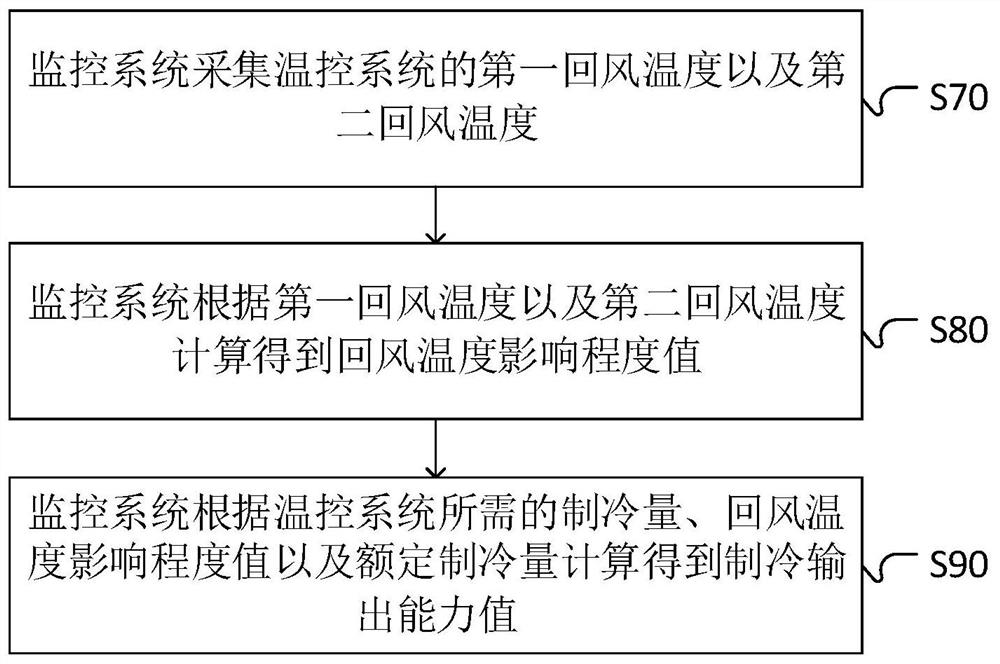

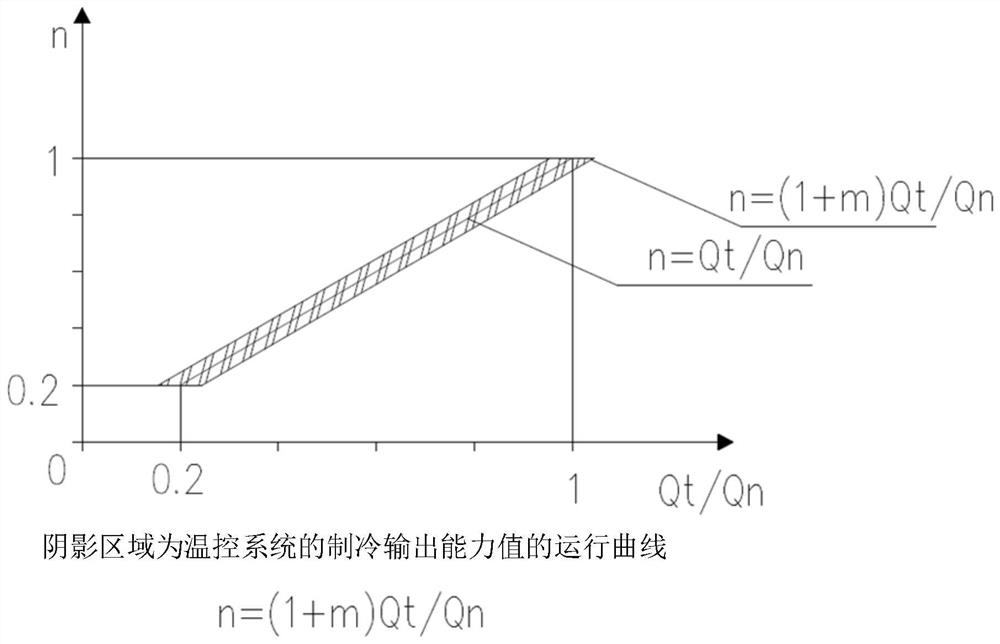

Cabinet temperature control method and control system

PendingCN111988961AAvoid local hotspotsCooling/ventilation/heating modificationsTemperature controlControl system

The invention discloses a cabinet temperature control method and system. The method comprises: a monitoring system judging whether a temperature control system is normal or not; if the temperature control system is normal, the monitoring system judging whether the power supply system is normal or not; if the power supply system is normal, the monitoring system collecting the power of load equipment and the rated refrigerating capacity of a temperature control system; the monitoring system calculating the refrigerating capacity required by the temperature control system according to the power of the load equipment; the monitoring system calculating the refrigeration output capacity value of the temperature control system according to the refrigerating capacity required by the temperature control system and the rated refrigerating capacity of the temperature control system; and the monitoring system feeding back the refrigeration output capacity value to the temperature control system, so that the temperature control system controls refrigeration output of the refrigeration equipment according to the refrigeration output capacity value. The cabinet temperature control system can track the real-time change of the power of the load equipment and timely adjust the temperature control refrigeration capability to avoid local hot spots.

Owner:SHENZHEN KEXIN COMM TECH

A kind of self-supporting nickel phosphide catalyst and its preparation method and application

ActiveCN107694584BImprove thermal conductivityGood choiceOrganic compound preparationCarboxylic acid esters preparationOxalateNickel catalyst

The invention discloses a self-supporting nickel phosphide catalyst as well as its preparation method and application. The self-supporting nickel phosphide catalyst is a nickel oxalate or nickel hydroxide crystal layer grown in situ on the skeleton substrate by hydrothermal method, and then phosphating treatment without secondary molding nickel phosphide catalyst. Skeleton matrix and nickel phosphorus compound, the nickel phosphorus compound is Ni 3 P, Ni 12 P 5 、Ni 2 P, Ni 5 P 4 At least one of them, and the total mass proportion of the nickel-phosphorus compound is 0.1-50%, and the rest is the skeleton matrix. Experiments show that: the self-supporting nickel phosphide catalyst provided by the invention has good stability, good thermal conductivity, easy molding, easy loading and high throughput and low pressure drop, especially has high low-temperature activity, high conversion rate of dimethyl oxalate, glycolic acid It has many advantages such as high methyl ester selectivity, and can be used as a catalyst for the hydrogenation of dimethyl oxalate to methyl glycolate.

Owner:EAST CHINA NORMAL UNIV

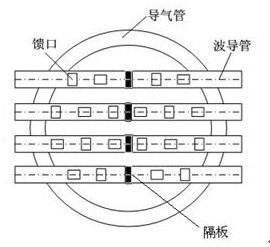

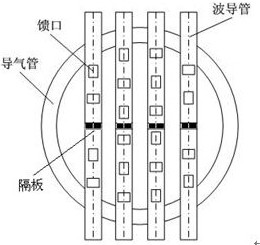

A microwave heating device

ActiveCN107796177BIncrease the electromagnetic field densityImprove utilization efficiencyDrying solid materials with heatHearth type furnacesThermodynamicsEngineering

The invention discloses a microwave heating device which comprises an upper sealing head, a shell and a lower sealing head. The upper sealing head is provided with a feed inlet, the lower sealing headis provided with a discharge outlet, a plurality of vibration beds are arranged in the shell and arrayed in a multi-layer staggered mode in a Z shape from top to bottom, the vibration beds are connected with vibrators through linkage rods, microwave emitters are arranged above the vibration beds separately, each microwave emitter comprises one or more waveguide pipes, the waveguide pipes penetrate through the shell horizontally from one end of the shell to the other end, the two ends of the portions, outside the shell, of the waveguide pipes are connected with magnetrons, and the portions, inside the shell, of the waveguide pipes are provided with feed troughs. According to the microwave heating device, the microwave incoherent power synthesis technology is adopted, rapid heating and rapid drying are achieved, and the efficiency of converting microwave energy into heat energy is improved. The microwave heating device has the advantages of being thorough in drying, clean, environmentally friendly and easy to scale up, saving energy, reducing consumption and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

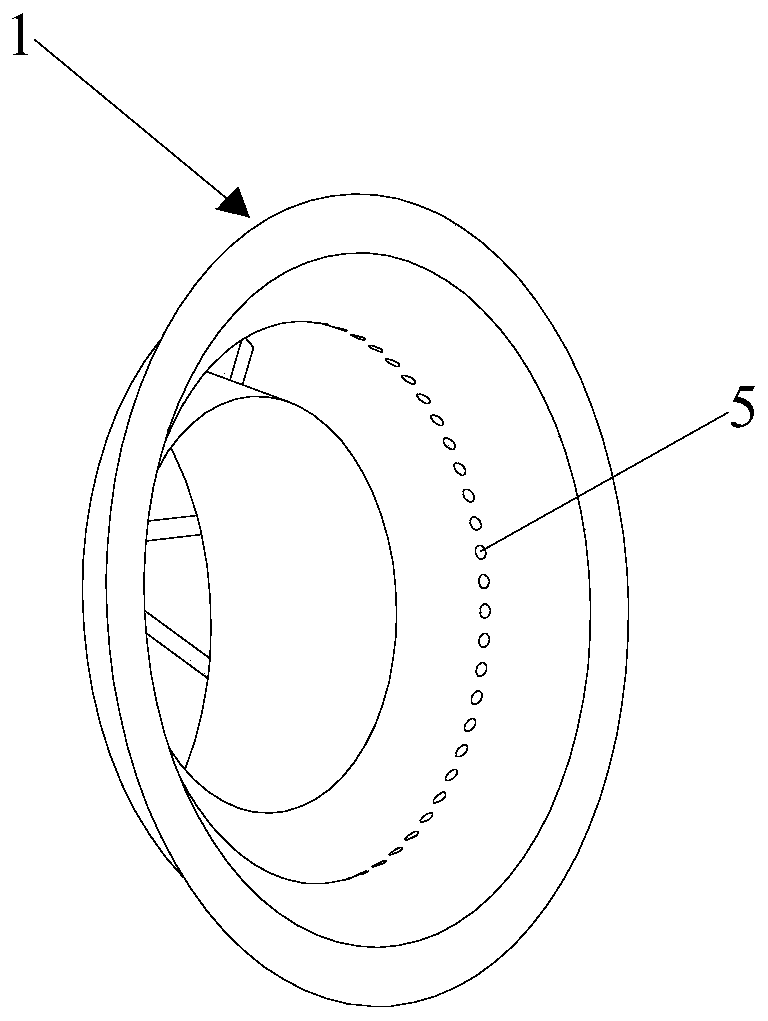

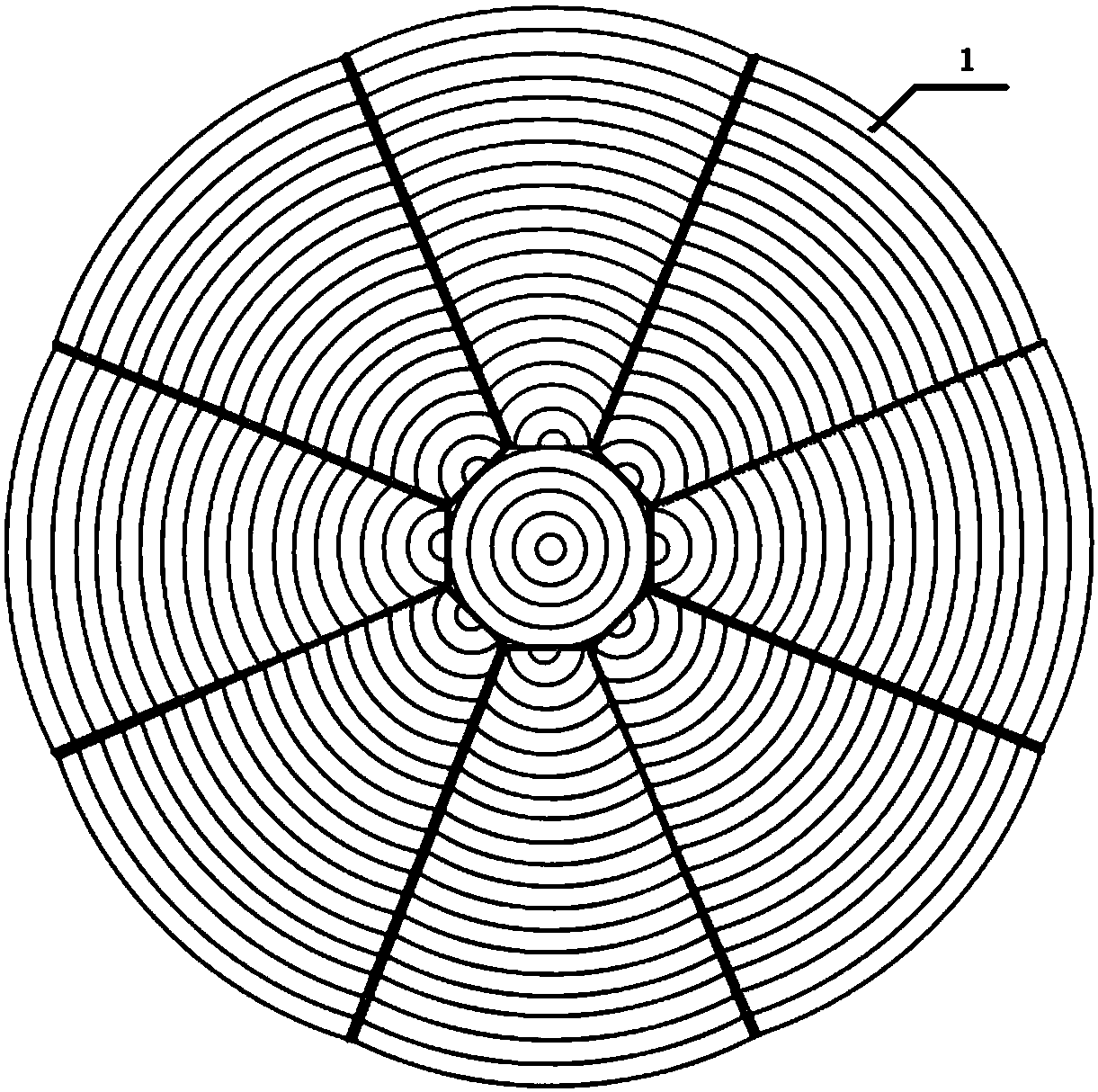

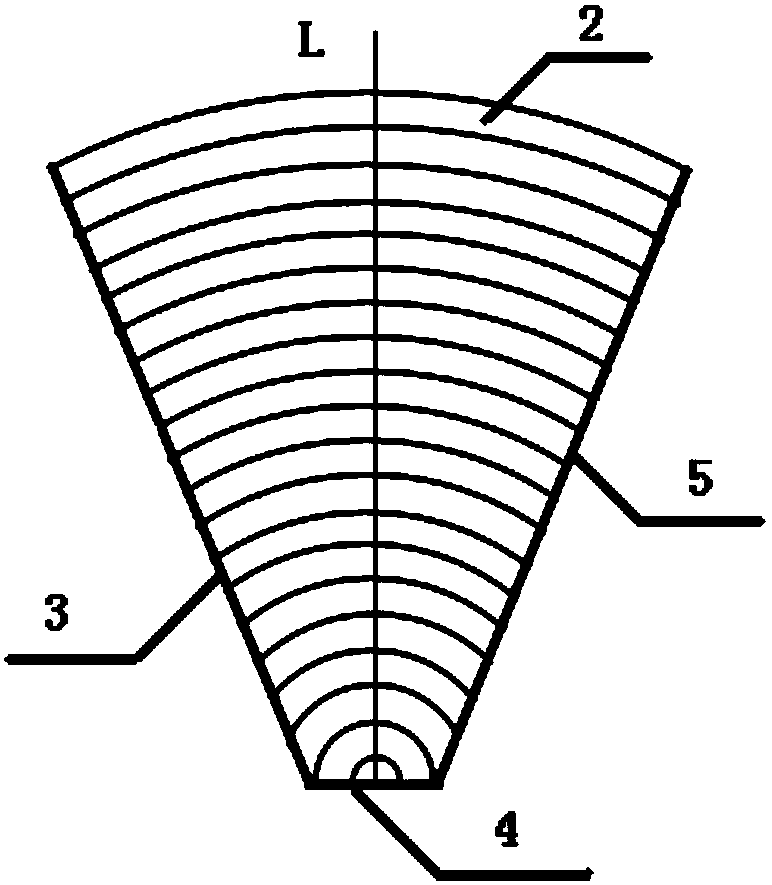

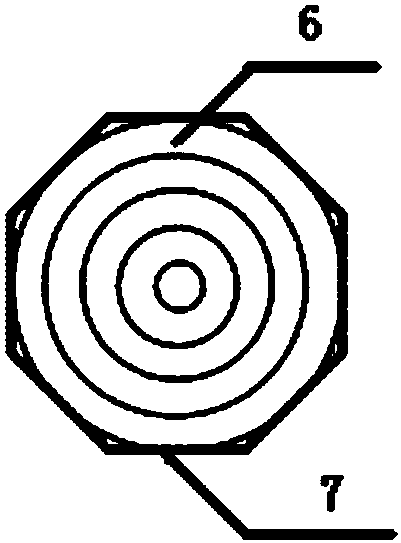

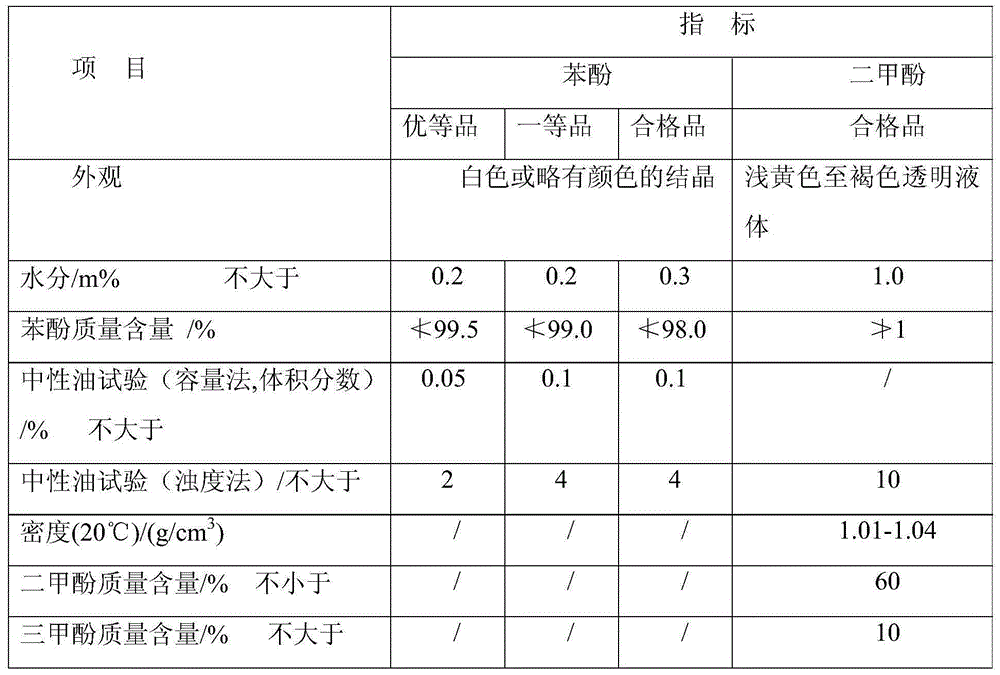

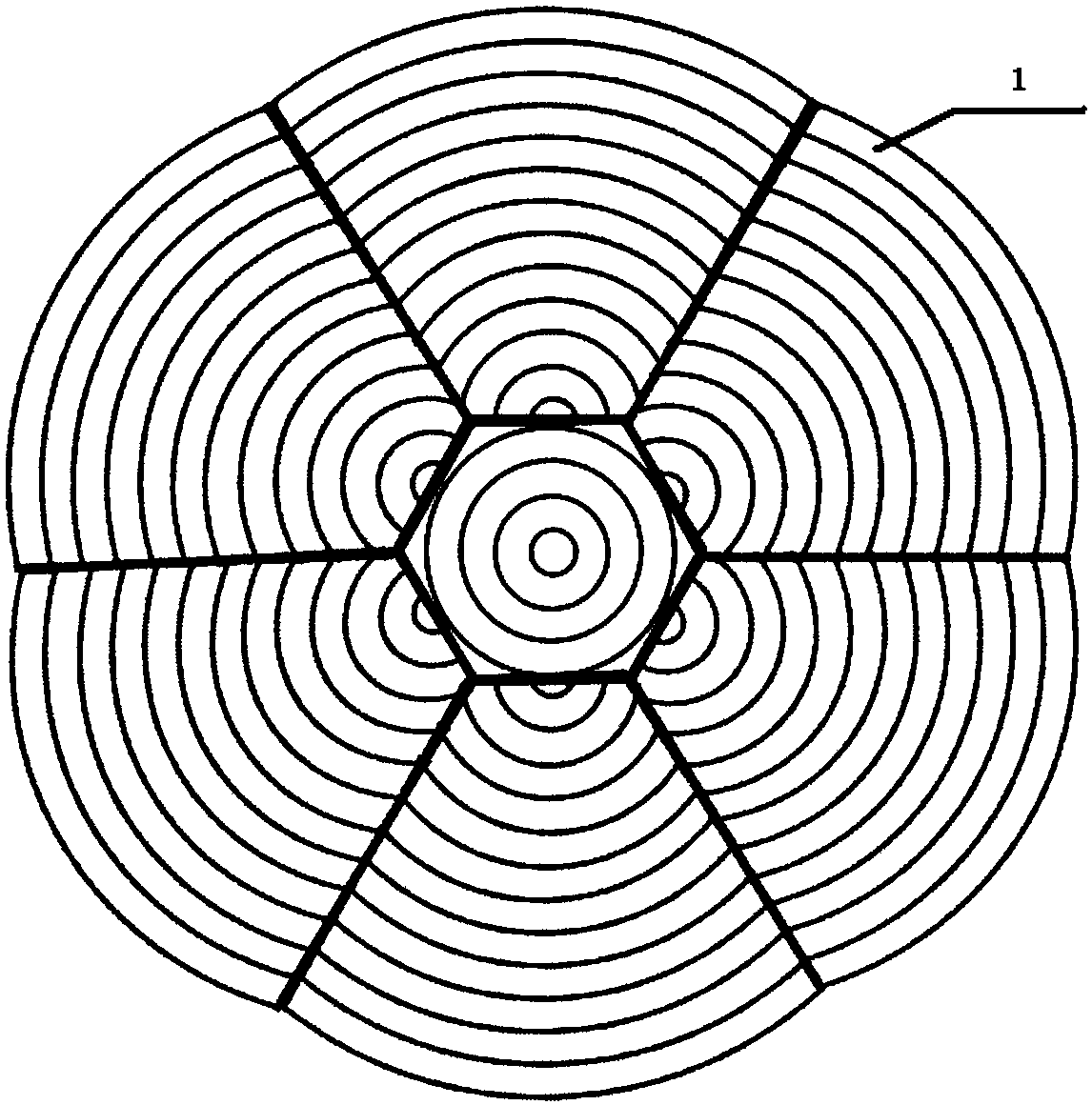

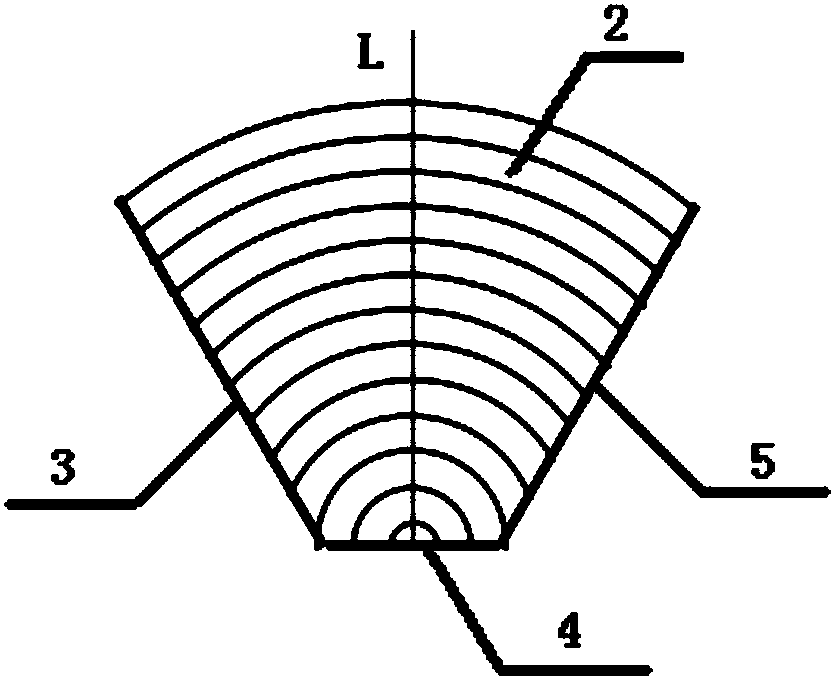

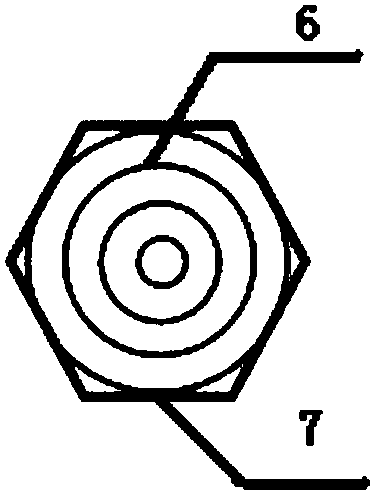

Nine-focal superposition uniform concentrating Fresnel lens applied to concentrated photovoltaic power generation

ActiveCN105607238BImprove uniformityImprove conversion efficiencyCondensersLensFresnel lensSolar energy conversion efficiency

The invention provides a nine-focus superposition uniform concentration Fresnel lenses for concentration photovoltaic power generation. The lenses comprise eight same concentric polygon sector unit Fresnel lenses and one regular octagon unit Fresnel lens, wherein second edges of the eight same concentric polygon sector unit Fresnel lenses are sequentially connected in a head to tail mode, the second edges of the eight same concentric polygon sector unit Fresnel lenses are then sequentially and tightly connected with a fourth edge of the regular octagon unit Fresnel lens, and length of the second edges is identical to length of the fourth edge; concentration light spot energy uniformity is improved through light wave superposition by the nine Fresnel lenses, a problem of hot local spots formed by non-uniform concentration existing in traditional point concentration Fresnel lenses can be avoided, and thereby the solar conversion efficiency and service life of cells are improved. The nine-focus superposition uniform concentration Fresnel lenses has advantages of simple structure, easy realization and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

Flue gas cooling system and method

Owner:HONGKONG NOROTAEIL ENVIROMENTAL PROTECTION TECH CO +1

Loaded continuous catalytic column, multi-flux loaded catalytic continuous reaction equipment and its application

ActiveCN106076208BEvenly distributedReduce dosageChemical/physical processesSmall footprintDistributor

The invention discloses a load continuous catalytic column. The load continuous catalytic column comprises a column body, a gas-liquid separator and a load catalyst distributor. According to the specific reaction, catalyst can be replaced, and the filling quantity of the catalysts can be controlled, so that convenience and flexibility in use can be realized. Materials and load catalysts are uniformly distributed, so that local hot spots can be effectively prevented, and the mass transfer efficiency is high. The invention also discloses a multiflux load catalytic continuous reaction device. The multiflux load catalytic continuous reaction device comprises load continuous catalytic columns and an automatic feeding system, wherein the load continuous catalytic columns are connected with the automatic feeding system. The multiflux load catalytic continuous reaction device is less in liquid holding amount, small in floor occupation area, high in safety and simple to operate; and the quantity and connection way of the load continuous catalytic columns can be adjusted according to the real situation, so that convenience and flexibility can be realized. The multiflux load catalytic continuous reaction device can be used for efficiently screening various load catalysts, optimizing a continuous reaction condition and amplifying a continuous process.

Owner:ASYMCHEM LAB TIANJIN +4

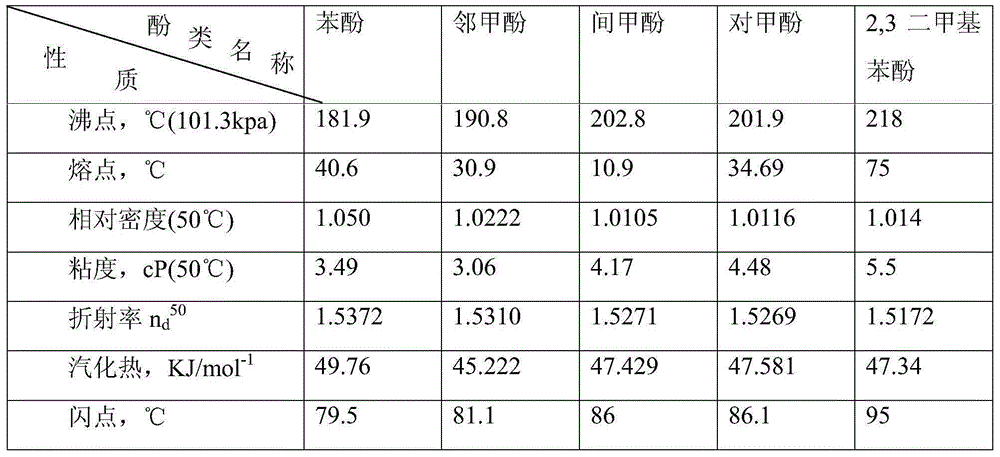

Medium and low temperature coal tar processing method

ActiveCN103695036BHigh yieldSolve problems such as short operation cycleTreatment with hydrotreatment processesWorking-up tarFixed bedFuel oil

The invention belongs to the field of the coal chemical industry, and in particular relates to a medium and low temperature coal tar processing method. The method comprises the following steps: removing solid residues from the medium and low temperature coal tar, preprocessing the coal tar to obtain carbolic oil, water and heavy oil; performing phenol extraction on the obtained carbolic oil to obtain a pure phenol product and dephenolized oil; mixing the obtained heavy oil and the obtained dephenolized oil and introducing the mixture in a fluidized bed reactor to perform a hydrogenation reaction, and obtaining modified heavy oil, sulfur-containing and ammonia-containing gas side products; performing hydrorefining and hydrocracking reactions on the modified heavy oil to obtain dry gas, liquefied gas, naphtha, a diesel oil product and a tail oil product. The naphtha and the diesel oil are clean and stable in performance. In addition, a plurality of high value added products are obtained. After hydrotreatment of the fluidized bed, the catalyst service life of the fixed bed reactor is prolonged; furthermore, the heavy component processing problem in the coal tar can be solved. The modified heavy oil after hydrotreatment of the fluidized bed can be subjected to hydrorefining and hydrocracking to improve the oil property.

Owner:上海竣铭化工工程设计有限公司

Seven-focal superposition uniform concentrating Fresnel lens applied to concentrated photovoltaic power generation

ActiveCN105607237BImprove uniformityImprove conversion efficiencyCondensersLensFresnel lensSolar energy conversion efficiency

The invention provides a seven-focus superposition uniform concentration Fresnel lenses for concentration photovoltaic power generation. The lenses comprise six same concentric polygon sector unit Fresnel lenses and one regular hexagon unit Fresnel lens, wherein second edges of the six same concentric polygon sector unit Fresnel lenses are sequentially connected in a head to tail mode, the second edges of the six same concentric polygon sector unit Fresnel lenses are then sequentially and tightly connected with a fourth edge of the regular hexagon unit Fresnel lens, and length of the second edges is identical to length of the fourth edge; concentration light spot energy uniformity is improved through light wave superposition by the seven Fresnel lenses, a problem of hot local spots formed by non-uniform concentration existing in traditional point concentration Fresnel lenses can be avoided, and thereby solar conversion efficiency and service life of cells are improved. The seven-focus superposition uniform concentration Fresnel lenses has advantages of simple structure, easy realization and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

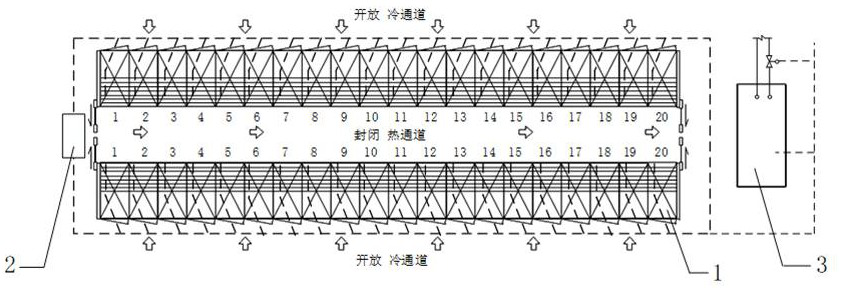

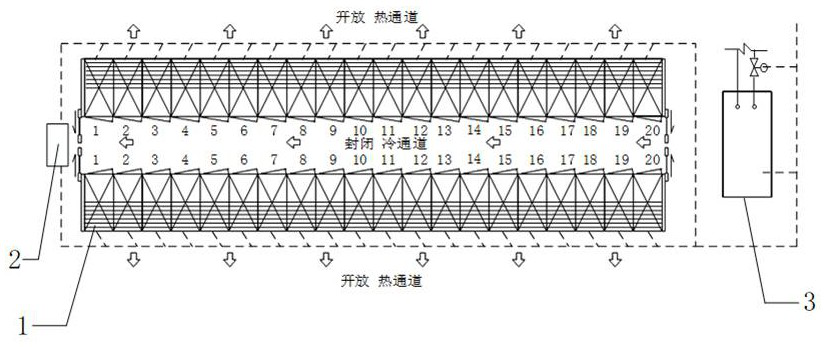

Airflow organization adjusting system and method for eliminating local hot spots of modular machine room

PendingCN114710934AReduce resistanceAvoid local hotspotsModifications using gaseous coolantsMoisture sensorMechanical engineering

The invention discloses an airflow organization adjusting system and adjusting method for eliminating local hot spots of a modular machine room, the airflow organization adjusting system comprises a plurality of cabinets and a control terminal, the plurality of cabinets are respectively connected with the control terminal, the top of each cabinet is provided with an airflow adjusting device, and the bottom of each cabinet is provided with an inlet shutter. The airflow adjusting device and the inlet shutter are connected with the control terminal, a first temperature sensor, a first humidity sensor, a first speed sensor and a first alarm are arranged on the airflow inlet, and a second temperature sensor, a second humidity sensor, a second speed sensor and a second alarm are arranged on the airflow outlet. The uniform and adjustable air flow adjusting device is arranged at the top of the cabinet, the inlet shutter capable of being independently adjusted is arranged at the bottom of the cabinet, hot plume in the cabinet is used for adjusting air flow distribution in the cabinet, and balance is achieved, local hot spots are avoided and air flow distribution is promoted to be balanced by changing resistance of the cabinet.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

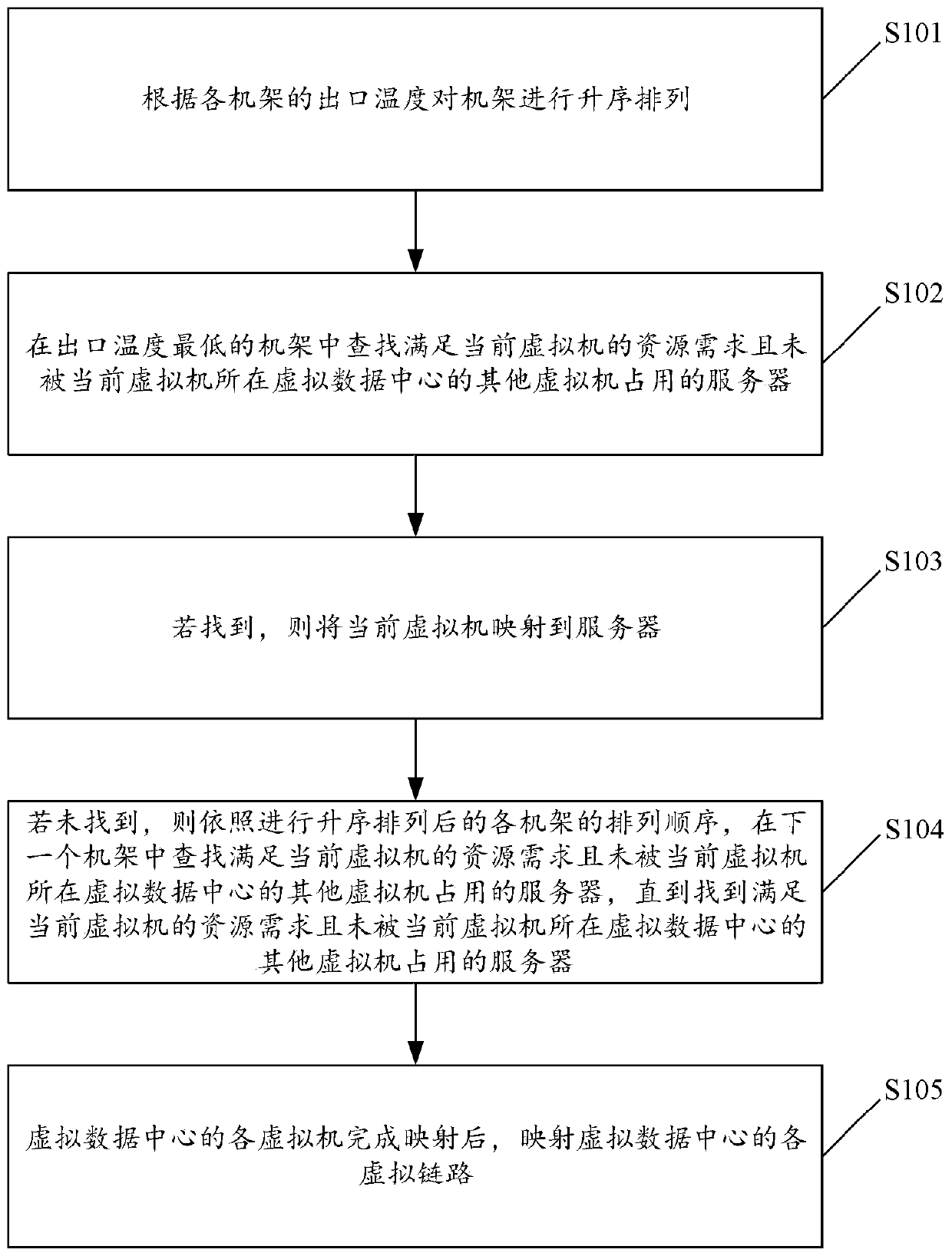

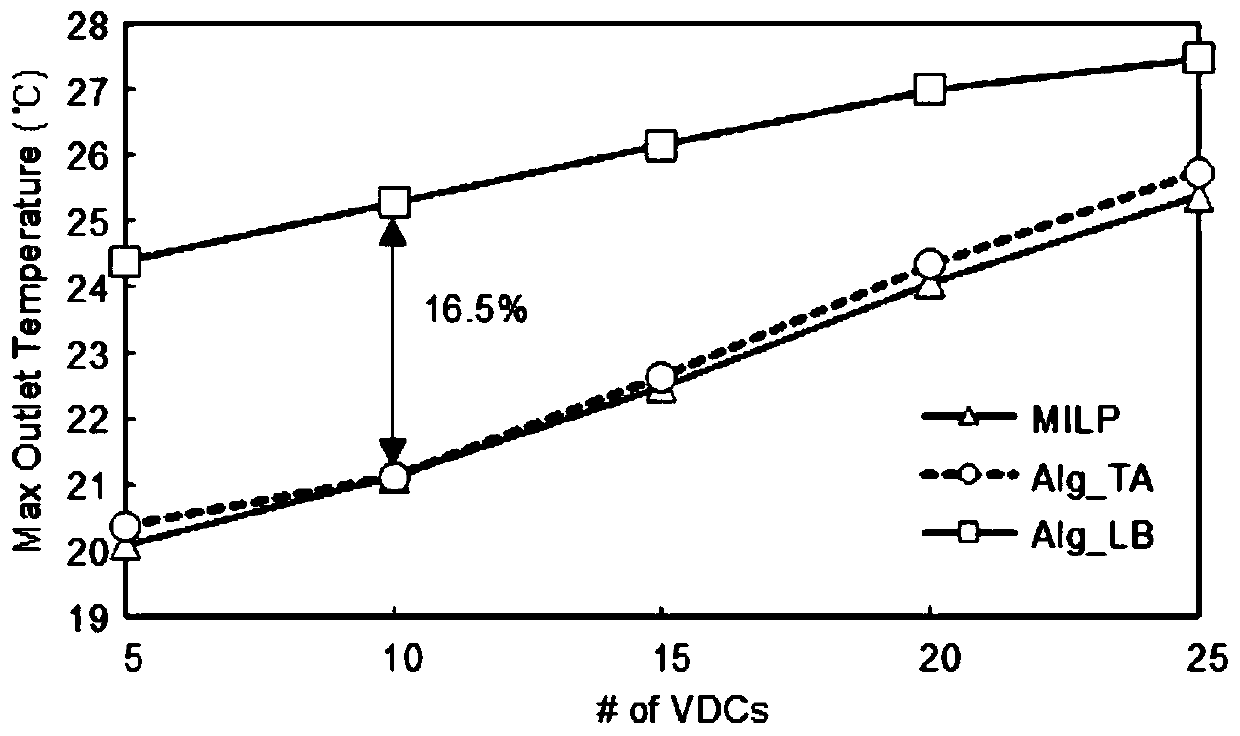

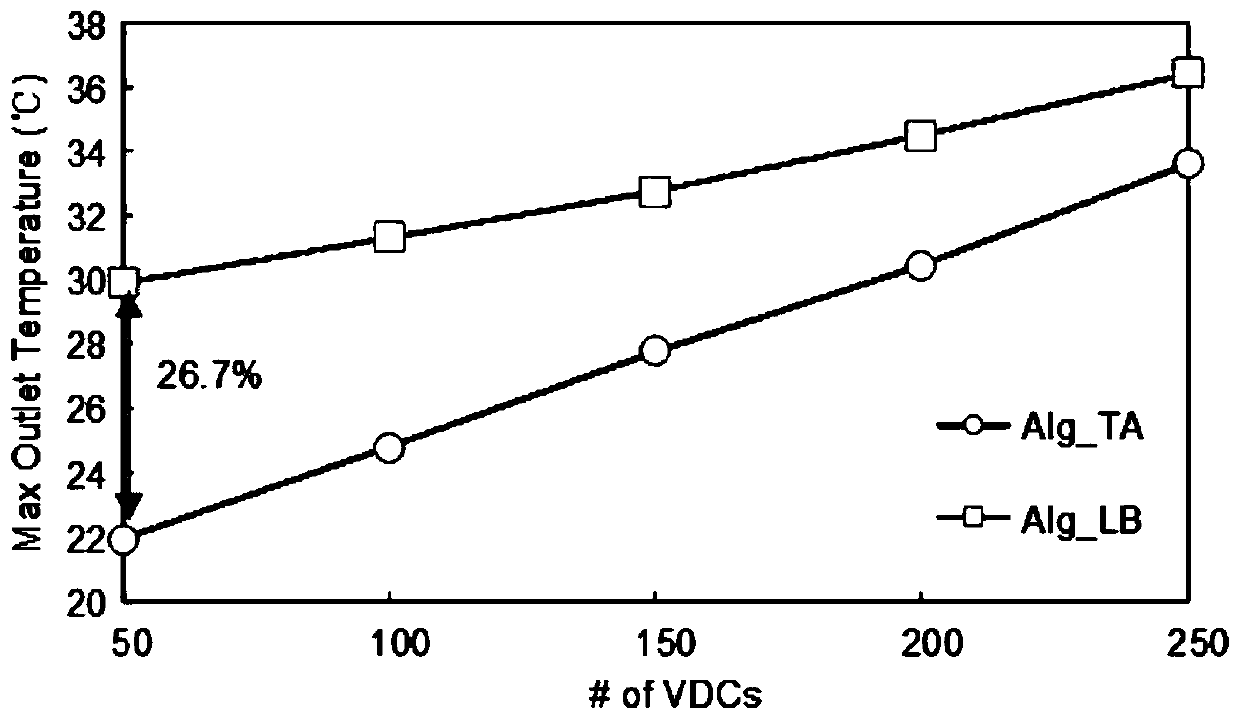

Mapping method of virtual data center and related device

PendingCN111078365AAvoid local hotspotsOutlet temperature balanceEnergy efficient computingSoftware simulation/interpretation/emulationServerComputer engineering

The invention discloses a mapping method of a virtual data center. The mapping method comprises the steps of ranking racks in an ascending order according to the outlet temperature of each rack; searching a server which meets the resource requirement of the current virtual machine and is not occupied by other virtual machines of the virtual data center where the current virtual machine is locatedin the rack with the lowest outlet temperature; if the server is found, mapping the current virtual machine to the server; if not found, based on the arrangement sequence of the racks after ascendingarrangement, searching a server which meets the resource requirement of the current virtual machine and is not occupied by other virtual machines in the virtual data center where the current virtual machine is located in the next rack until the server which meets the resource requirement of the current virtual machine and is not occupied by other virtual machines in the virtual data center where the current virtual machine is located is found; and mapping each virtual link of the virtual data center after each virtual machine of the virtual data center finishes mapping. According to the method, energy consumption and cost can be reduced while local hotspots of the data center are avoided.

Owner:ZHONGTIAN BROADBAND TECH +2

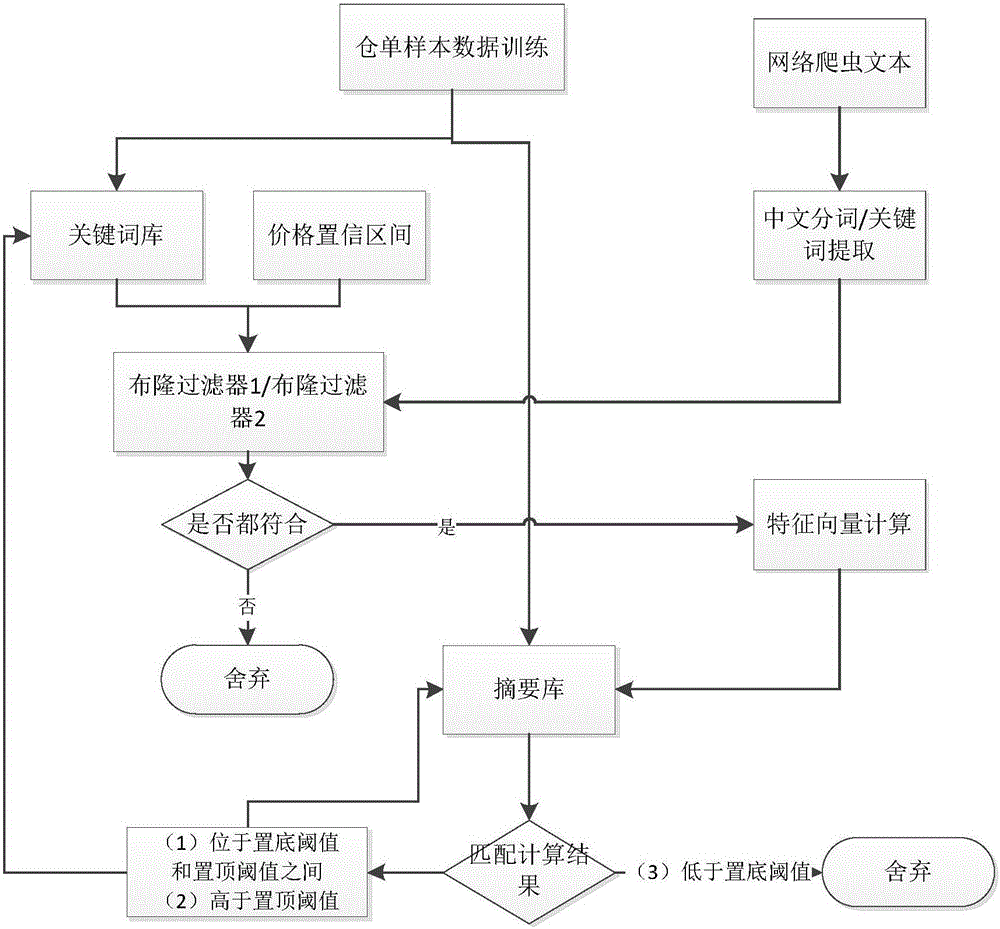

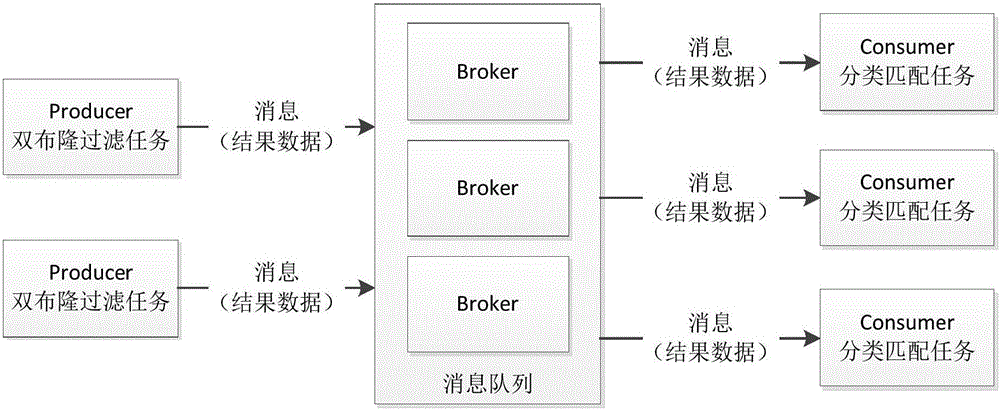

Web crawler method for financial warehouse warrant risk control

ActiveCN106096008AImplement automatic additionQuick filterFinanceSpecial data processing applicationsRisk ControlBloom filter

The invention provides a web crawler method for financial warehouse warrant risk control. Double bloom filter keyword matching is adopted, and the web crawler information comprising the cargo information result is screened rapidly; different classes of cargo are sorted accurately on the basis of a classification matching manner, the regulation is compared by the combination of the threshold value, and new cargo classes are added automatically; on the basis of an information mechanism, load balancing of front and rear end tasks of the whole processing process is realized, the controllability and the efficiency of the processing process are ensured to be maximum, and local hot spots are prevented. With the adoption of the technical scheme, efficient crawling and accurate screening of financial warehouse warrant mortgage cargo information can be realized.

Owner:BEIJING UNIV OF TECH

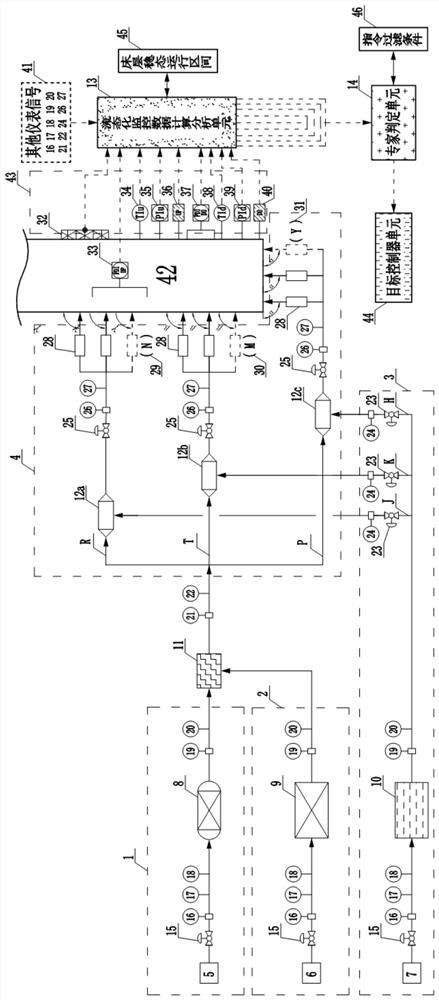

Dense-phase fluidization reaction control device and method

ActiveCN112546971AControl reactivityEffective Fluidization MonitoringTotal factory controlChemical/physical processesReaction control systemInert gas

The invention discloses a dense-phase fluidization reaction control device and method; the dense-phase fluidization reaction control device comprises a dense-phase fluidization reaction gas supply system and a dense-phase fluidization reaction control system; the dense-phase fluidization reaction gas supply system comprises a feed gas I unit, a feed gas II unit, an inert gas unit and a dense-phasefluidization reaction gas distribution unit; the dense-phase fluidization reaction control system comprises a dense-phase bed fluidization monitoring unit, a fluidization monitoring data calculationand analysis unit, an expert judgment unit, a target controller unit and other instrument signal units. The invention further provides the dense-phase fluidization reaction control method based on computer autonomous learning; the flow and the reaction activity of the feed gas entering the dense-phase zone of the reactor are controlled by analyzing the flow characteristics of a reaction bed layer,and then the dense-phase fluidization reaction process is controlled. The device and method are high in automation degree and efficient and convenient in data analysis, have the characteristic of machine learning, and have a wide application prospect in the field of dense-phase fluidization reaction control.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com