A microwave heating device

A microwave heating device, microwave transmitter technology, applied in lighting and heating equipment, heating to dry solid materials, furnaces, etc., can solve the problem of lack of engineering application and economical technology and technology, low production capacity, loss of coal volatiles, etc. problems, to achieve the effect of reducing moisture content and transportation costs, uniform residence time distribution, and eliminating mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

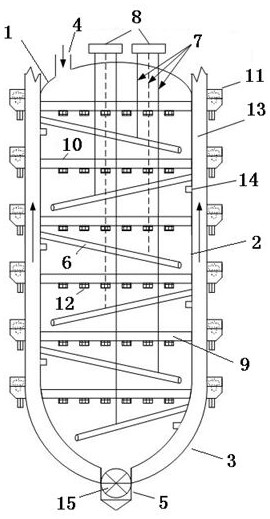

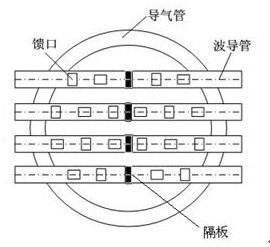

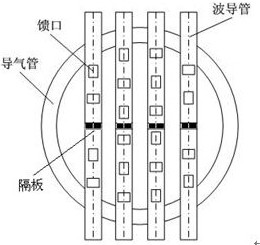

[0036] The microwave heating device provided by the present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereby.

[0037] The present invention provides a microwave heating device. The microwave heating device includes an upper head 1, a shell 2 and a lower head 3. The upper head 1 is provided with a feed port 4, and the lower head 3 is provided with a discharge port 5. The shell 2 is provided with 4-10 layers of vibrating beds, preferably 5-8 layers, and most preferably 6 layers of vibrating beds. The distance between two adjacent vibrating beds can be adjusted according to actual needs. The angles between the vibrating beds of each layer and the horizontal cross section of the microwave heating device are 0° to 45°, preferably, the angles between the vibrating beds of each layer and the horizontal cross section of the microwave heating device are 0° to 30°, more preferably Preferably, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com