Hydrogen-oxygen composite reactor

A reactor, hydrogen-oxygen technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as uneven temperature field distribution, and achieve uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

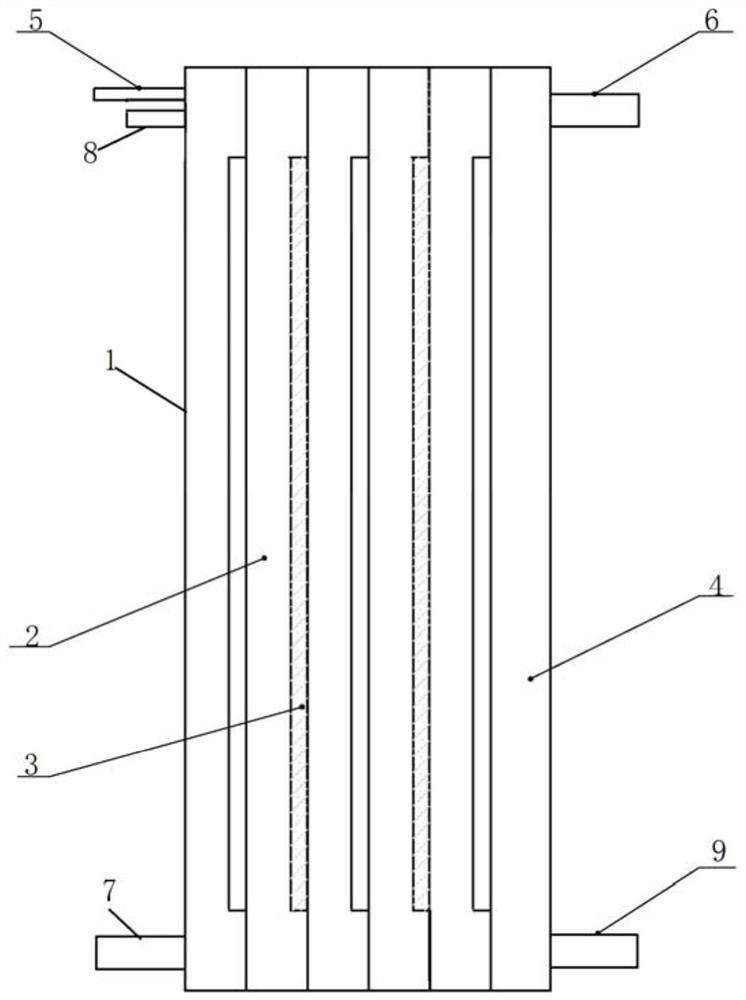

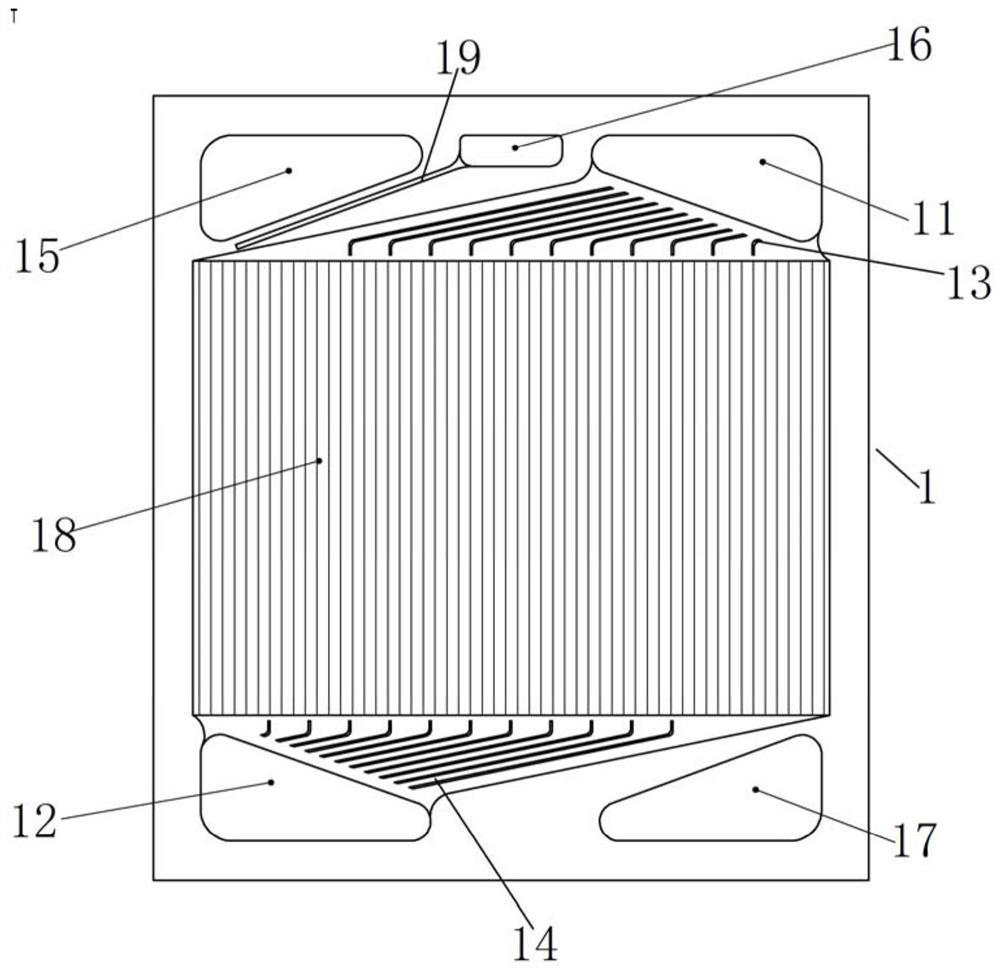

[0029] combine Figure 1-3 , this embodiment proposes a hydrogen-oxygen recombination reactor, which is provided with a plurality of alternately arranged heat exchange plates 1 and reaction plates 2 from left to right, and the contact surfaces of heat exchange plates 1 and reaction plates 2 are close to each other;

[0030] Both ends of the heat exchange plate 1 are provided with a plurality of first through holes, and both ends of the reaction plate 2 are provided with a plurality of second through holes, and a plurality of the first through holes overlap with a plurality of the second through holes to form a A plurality of channels, the plurality of channels including cooling water channels, air channels, hydrogen channels and flue gas channels;

[0031] The middle part of the heat exchange plate 1 is provided with a water flow channel 18, and the water flow channel 18 communicates with the cooling water channel, and the middle part of the reaction plate 2 is provided with a...

Embodiment 2

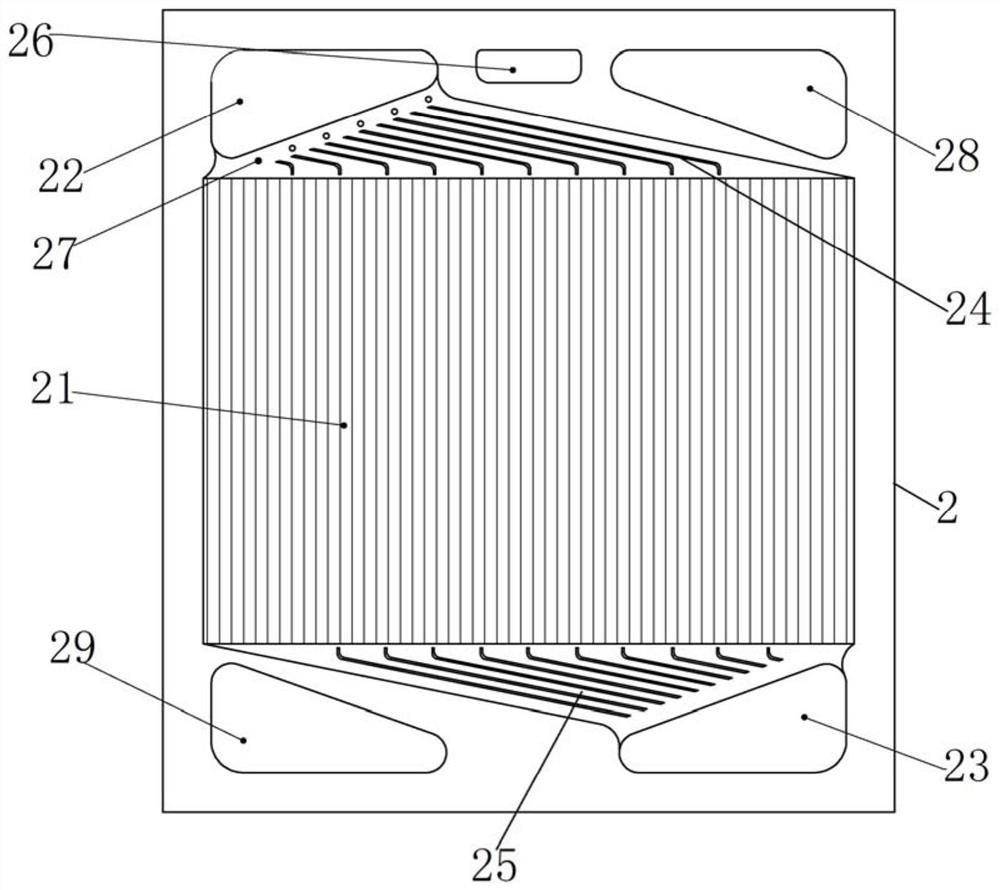

[0054] The difference between this embodiment and embodiment 1 is that the thickness of the FeCrAlNb alloy plate is 1.0 mm, the water flow channel 18 on the heat exchange plate 1, the first drainage channel 13 and the second drainage channel 14 are semicircular, with a diameter of 0.6 mm; The third drainage channel 24, the fourth drainage channel 25 and the airflow channel 21 on the reaction plate 2 are semicircular with a diameter of 0.5 mm.

[0055] The catalyst thin film structure 3 in this embodiment is in the form of a graphene thin film supported noble metal monolithic thin film structure. The graphene film is composed of graphene sheets and aluminum oxide powder with a particle size of 0.05 mm, the thickness is 0.05 mm, and the mass percentage is: graphene sheets account for 90%, aluminum oxide powder accounts for 10%; the active particles of noble metals are Pd particles , the particle size range is 3nm, and the noble metal loading is 0.5wt%.

[0056] The catalyst thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com