Processing method of spherical material quasicrystal lattice distribution in base material

A technology of matrix material and processing method, which is applied in the processing field of spherical material quasi-lattice distribution in the matrix material, can solve the problems of inconsistent physical and chemical properties, inability to obtain, and difficulty in achieving uniform mixing results, etc., to avoid local performance instability , Increase unit fuel consumption and avoid local hot spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the drawings:

[0020] The present invention includes the following steps:

[0021] (1) Design the distribution pattern of the reinforcing phase material balls in the matrix material;

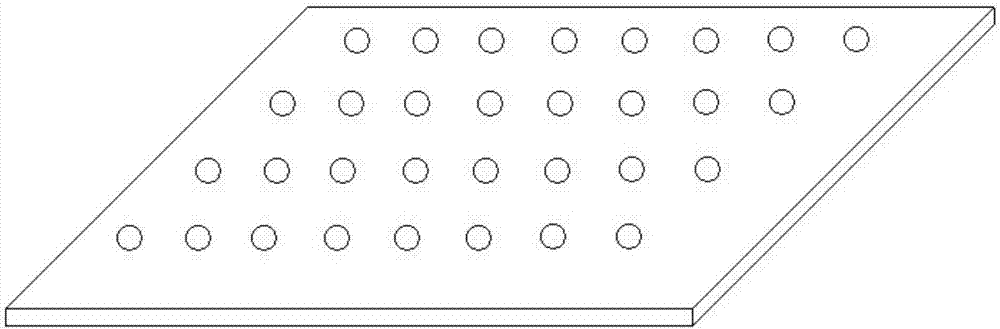

[0022] (2) such as figure 1 As shown, the base material is used to make a strip, and the strip is punched and punched according to the designed reinforcing phase material ball distribution pattern. The inner diameter of the hole is the same as the diameter of the reinforcing phase material ball. In the embodiment of the present invention , The strip is designed as a rectangular plate structure, according to needs, it can also be made into other shapes, such as a circular plate structure;

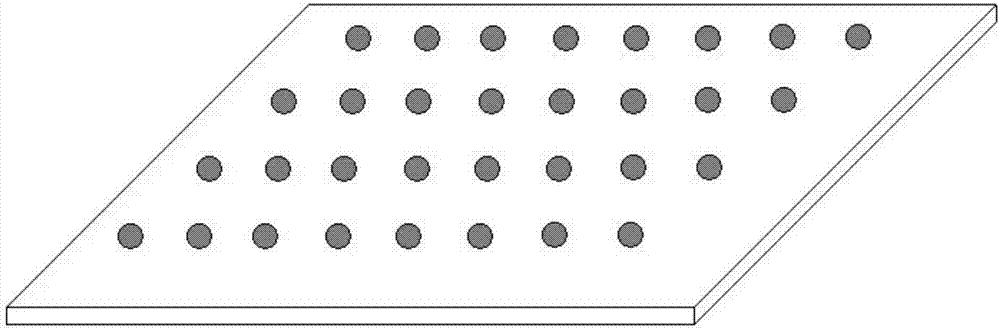

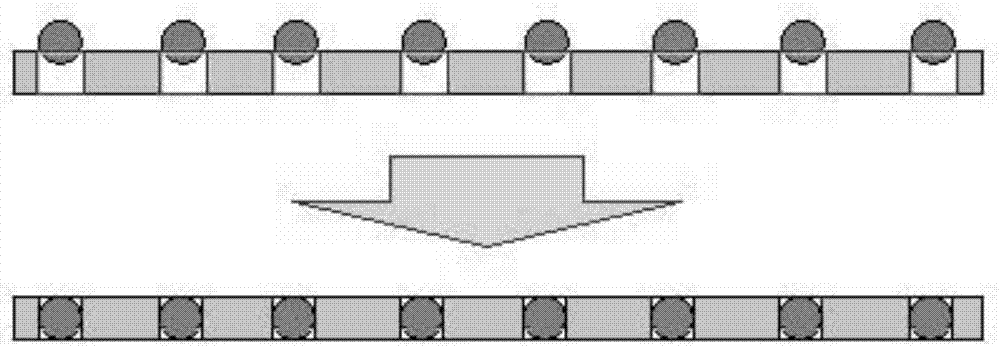

[0023] (3) such as figure 2 As shown, a vacuum ball head is used to grab the reinforced phase material ball and put it into the hole on the strip. Each hole corresponds to a reinforced phase material ball. There are multiple vacuum ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com