Microchannel reaction device, microchannel reaction system and method for preparing olefin

A technology of microchannel reaction and microchannel reactor, applied in the direction of hydrocarbon production from carbon oxides, chemical instruments and methods, chemical/physical/physicochemical reactors, etc., can solve problems such as reducing olefin selectivity and catalyst deactivation , to achieve the effect of increasing the reaction rate, increasing the specific surface area, and good economic feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

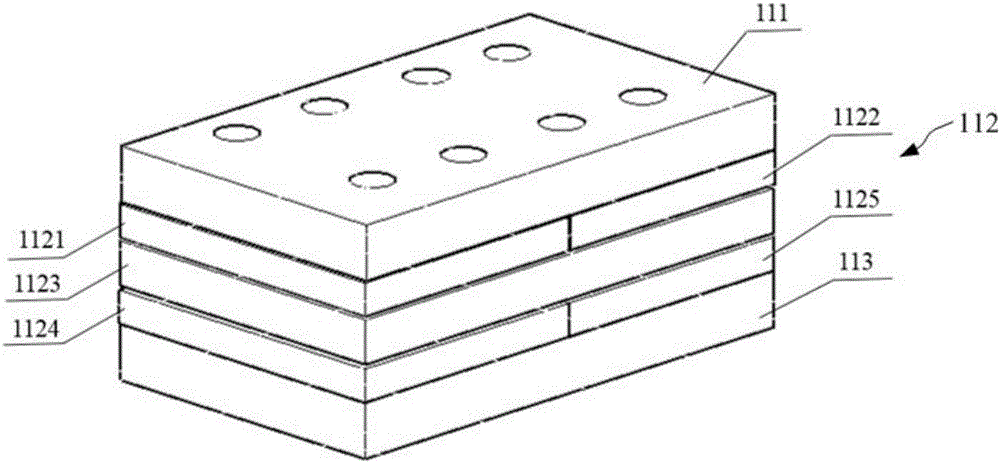

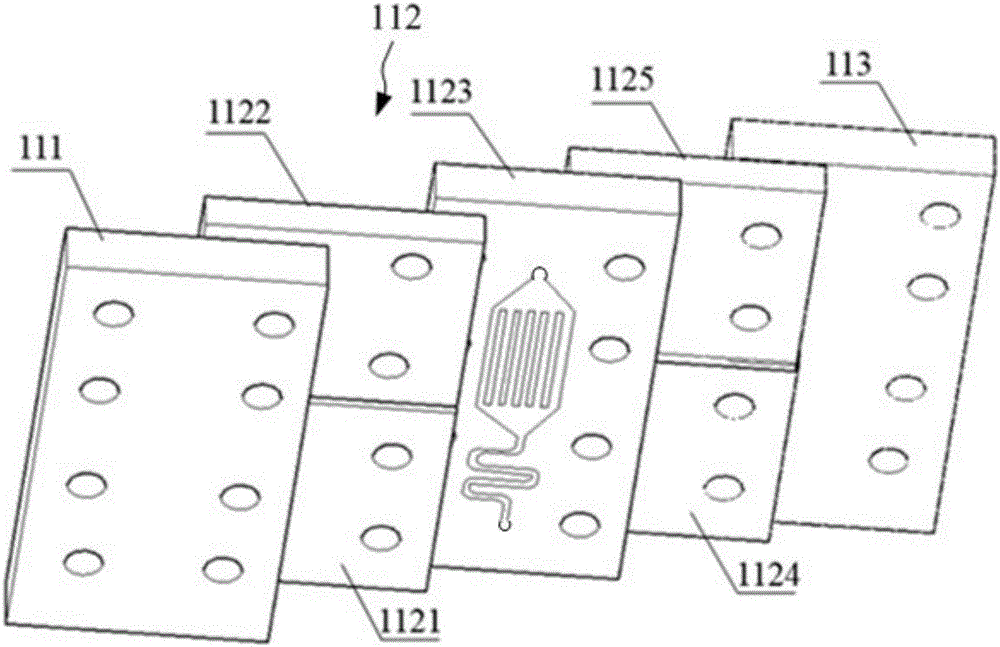

[0081] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a microchannel reaction device 11, and the microchannel reaction device 11 includes: an upper sealing plate 111, a lower sealing plate 113, and an upper sealing plate 111 and a lower sealing plate 113 Between at least one microchannel reactor 112; Described microchannel reactor 112 comprises:

[0082] Microchannel reaction plate 1123;

[0083] The first heat exchange channel plate 1121 and the second heat exchange channel plate 1122 located on the upper surface of the microchannel reaction plate 1123;

[0084] And the third heat exchange channel plate 1124 and the fourth heat exchange channel plate 1125 located on the lower surface of the microchannel reaction plate 1123;

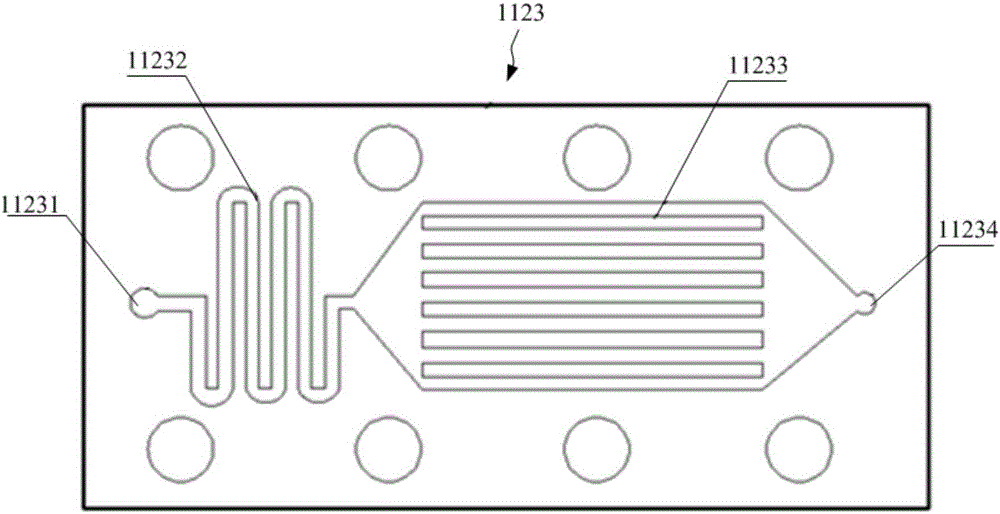

[0085] Wherein, the microchannel reaction plate 1123 comprises:

[0086] import 11231;

[0087] A preheating channel 11232 connected to the inlet 11231, the preheating channel 11232 is located between the first heat exchange ...

Embodiment 2

[0102] Such as Figure 4 As shown, the present embodiment provides a kind of microchannel reaction system 1, and described microchannel reaction system 1 comprises:

[0103] Microchannel reaction device 11 as described in embodiment one;

[0104] A gas-liquid separation device 12 connected to the microchannel reaction device 11;

[0105] A rectification unit 13 connected with the gas-liquid separation unit 12;

[0106] And a circulation device 14 connected between the gas-liquid separation device 12 and the microchannel reaction device 11.

[0107] Specifically, the product in the microchannel reaction device 11 is subjected to gas-liquid separation through the gas-liquid separation device 12, and the gas phase product, the oil phase product and water are separated. Wherein, the gas-liquid separation device 12 is any existing device capable of realizing the gas-liquid separation function.

[0108] Preferably, in this embodiment, as Figure 5 As shown, the gas-liquid separ...

Embodiment 3

[0124] Such as Figure 6 As shown, this embodiment provides a method for preparing olefins using the microchannel reaction system described in Embodiment 2, the preparation method comprising:

[0125] S1: Mix hydrogen and carbon monoxide in a certain proportion and enter the preheating channel through the inlet, and preheat the gas in the preheating channel through the first and third heat exchange channel plates to make it reach the required temperature for the reaction. Then the gas in the preheating channel enters the reaction microchannel and reacts under the action of the olefin catalyst;

[0126]S2: The reacted product enters the gas-liquid separation device through the outlet, and is separated by the gas-liquid separation device to separate the gas phase product, oil phase product and water;

[0127] S3: the oil phase product is rectified by a rectification device to obtain olefin products;

[0128] S4: The gaseous phase product passes through the circulation device, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com