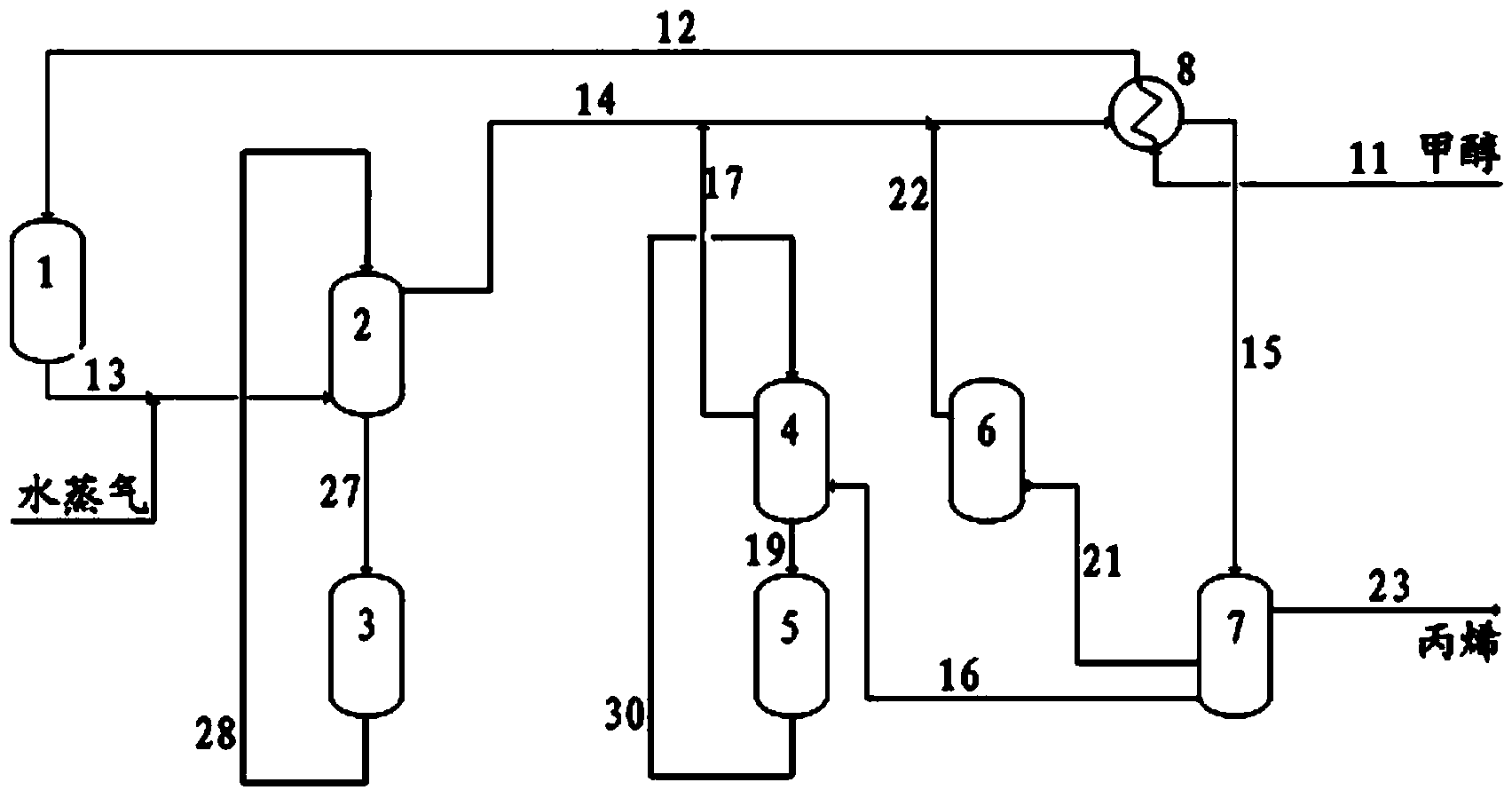

Method and system for preparing propylene by using methanol

A technology for propylene and methanol, which is applied in chemical instruments and methods, ethylene production, hydrocarbon cracking and hydrocarbon production, etc. It can solve the problems of easy coking and deactivation of the catalyst, high energy consumption of the device, and low propylene yield, so as to reduce the cost of the catalyst, The effect of reducing complexity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

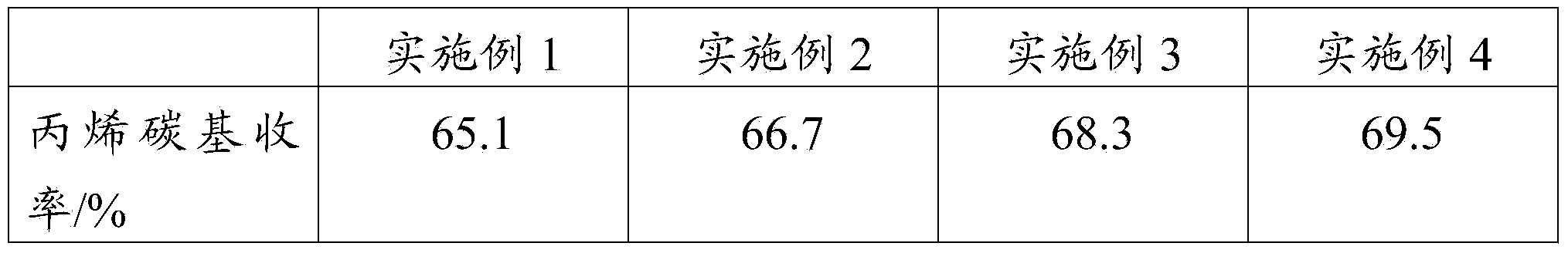

Embodiment 1

[0066] The first fixed bed reactor: the feed space velocity of raw material methanol is 1h -1 , the reaction bed temperature is 365~380℃, the reaction pressure is 1.1~1.2MPa, and the catalyst is γ-Al 2 o 3 (Südchem Catalyst Works, DME-1 type catalyst) to obtain a first product stream.

[0067] The first moving bed reactor: the feed is a mixture of the first product stream and water vapor as a reactant diluent, and the feed space velocity of the first product stream is 1h -1 , and its mass ratio to water vapor is 1:1. The reaction temperature is 520-530° C., the reaction pressure is 0.2-0.25 MPa, and the catalyst is ZSM-5 molecular sieve catalyst (MTPROP-1 catalyst from the Southern Chemical Catalyst Factory in Germany) to obtain the second product stream.

[0068] Second moving bed reactor: Feed is propylene-free C from the separation unit 2 ~C 4 hydrocarbon mixture. The reaction temperature is 120-130° C., the reaction pressure is 0.6-0.7 MPa, and the catalyst is ZSM-5 ...

Embodiment 2

[0072] The first fixed bed reactor: the feed space velocity of raw material methanol is 1h -1 , the reaction temperature is 365-380°C, the reaction pressure is 1.1-1.2MPa, and the catalyst is γ-Al 2 o 3 (Südchem Catalyst Works, DME-1 type catalyst) to obtain a first product stream.

[0073] The first moving bed reactor: the feed is a mixture of the first product stream and water vapor as a reactant diluent, and the feed space velocity of the first product stream is 1h -1 , and its mass ratio to water vapor is 1:1. The reaction temperature is 520-530° C., the reaction pressure is 0.2-0.25 MPa, and the catalyst is ZSM-5 molecular sieve catalyst (MTPROP-1 catalyst from the Southern Chemical Catalyst Factory in Germany) to obtain the second product stream.

[0074] Second moving bed reactor: Feed is propylene-free C from the separation unit 2 ~C 4 hydrocarbon mixture. The reaction temperature is 120-130°C, the reaction pressure is 0.6-0.7MPa, and the catalyst is Mo / Al from F...

Embodiment 3

[0078] The first fixed bed reactor: the feed space velocity of raw material methanol is 1h -1 , the reaction temperature is 290-300°C, the reaction pressure is 1.5-1.6MPa, and the catalyst is γ-Al 2 o 3 (Südchem Catalyst Works, DME-1 type catalyst) to obtain a first product stream.

[0079] The first moving bed reactor: the feed is a mixture of the first product stream and water vapor as a reactant diluent, and the feed space velocity of the first product stream is 1h -1 , and its mass ratio to water vapor is 1:1. The reaction temperature is 460-470°C, the reaction pressure is 0.06-0.07MPa, and the catalyst is ZSM-5 molecular sieve catalyst (MTPROP-1 catalyst, Südchem Catalyst Factory, Germany) to obtain the second product stream.

[0080] Second moving bed reactor: Feed is propylene-free C from the separation unit 2 ~C 4 hydrocarbon mixture. The reaction temperature is 80-90°C, the reaction pressure is 1.2-1.3MPa, and the catalyst is Mo / Al from Fushun Kerui Catalyst Co....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com