Flexible composite phase change material, preparation method and application thereof, battery heating element and ion battery pack with low-temperature thermal management system

A composite phase-change material and ion battery technology, which is applied in the field of ion batteries, can solve the problems of not being able to meet the thermal management requirements of drone power battery packs, not being able to use thermal management methods, and not being able to fit the batteries tightly, so as to achieve light weight, Small size, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides the preparation method of the flexible composite phase change material described in the above technical solution, comprising the following steps:

[0040] Mixing the polymer matrix, the organic phase change material, the spherical conductive filler and the multi-dimensional conductive filler to obtain a mixture;

[0041] The mixture is milled to obtain the flexible composite phase change material.

[0042] In the present invention, a polymer matrix, an organic phase change material, a spherical conductive filler and a multi-dimensional conductive filler are mixed to obtain a mixed material.

[0043] In the present invention, the mixing preferably comprises the following steps:

[0044] The polymer matrix and the organic phase change material are heated and then mixed for a first time to obtain a first mixed material;

[0045] The first mixture, the spherical conductive filler and the multi-dimensional conductive filler are mixed for a se...

Embodiment 1

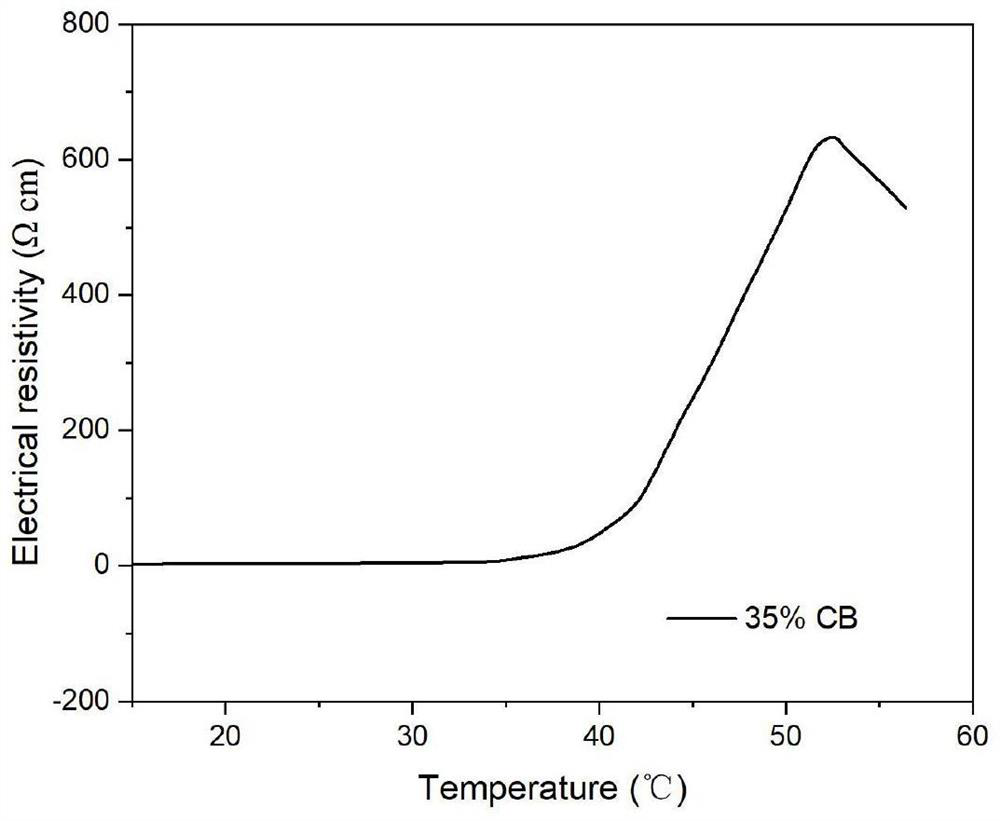

[0079] 21 parts of SEBS and 49 parts of paraffin wax (melting temperature of 44°C) were heated and mixed evenly, and the ratio of the two was 3:7, as the matrix of the phase change material; then two conductive fillers, carbon black and expanded graphite, were added and mixed evenly. The mass fraction of black is 35 parts, and the mass fraction of expanded graphite is 1 part, and the mixture is uniformly mixed to obtain a mixture; and then the mixture is put into an open mill for 30min opening, and the opening temperature is 135 ℃ to obtain a flexible composite phase change material;

[0080] The flexible composite phase change material was vulcanized at 135°C to obtain a heating pad with a thickness of 3 mm.

[0081] The heating pad prepared in this example has good flexibility and can be bent arbitrarily. Through the temperature-resistance experiment, the heating pad is placed in a high and low temperature box, and the temperature rise and fall test is performed, and the res...

Embodiment 2

[0083] 24 parts of SEBS and 48 parts of paraffin wax (melting temperature of 44°C) are heated and mixed evenly, the ratio of the two is 4:6, as the matrix of the phase change material; then carbon black and expanded graphite conductive filler are added and mixed evenly, among which the mass of carbon black is The parts are 20 parts, and the mass parts of expanded graphite are 5 parts, and the mixture is uniformly mixed to obtain a mixture; then the mixture material is put into an open mill for opening for 30 minutes, and the opening temperature is 135 ° C to obtain a flexible composite phase change material;

[0084] The flexible composite phase change material was vulcanized at 135°C to obtain a heating pad with a thickness of 3 mm.

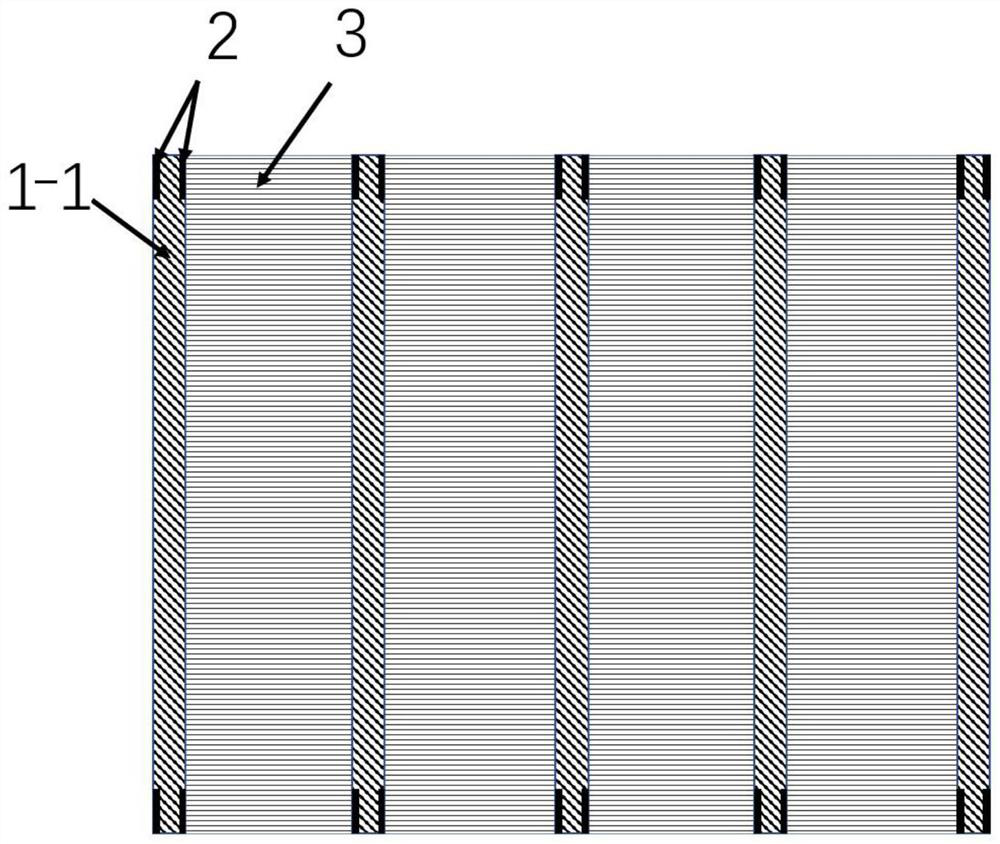

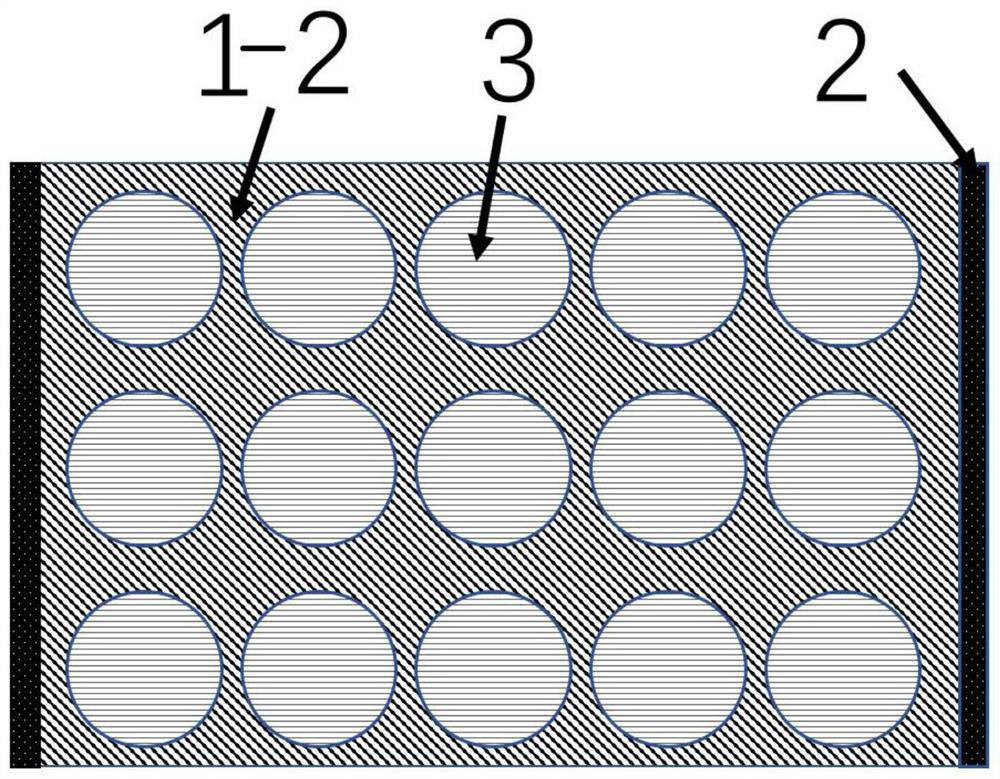

[0085] The heating pad prepared in this example is used for low-temperature preheating of a square lithium-ion battery pack. figure 1 Shown is a cross-sectional view of the low-temperature thermal management system for a square lithium-ion batte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com