Copper-free friction material and brake pad

A technology of friction materials and thermally conductive materials, applied in friction linings, gear transmission mechanisms, mechanical equipment, etc., can solve problems such as aggregation, uneven wear of brake discs, high temperature heat, and uneven deformation of brake discs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

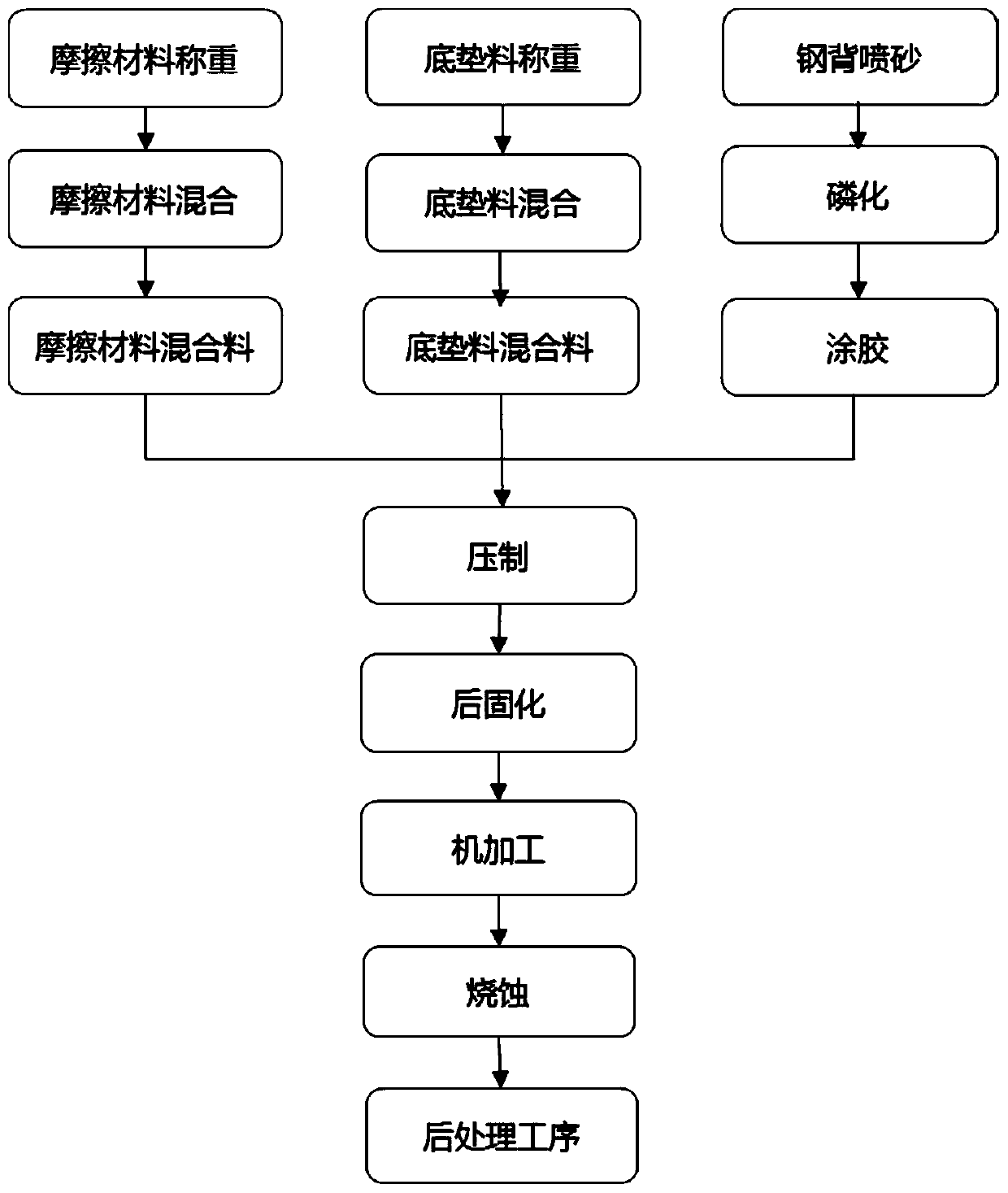

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0035] In order to achieve the above purpose, this solution adopts an optimized combination of anisotropic and isotropic heat-conducting materials. This combination of heat-conducting systems makes the brake pads have excellent thermal conductivity along the friction surface, while in the vertical direction Has relatively weak thermal conductivity. During the braking process, the brake pads can release the heat generated by braking in time, avoiding the formation of local hot spots on the brake pads or brake discs, so they have very good anti-fading, wear-resistant and anti-vibration characteristics while meeting requirements of environmental regulations.

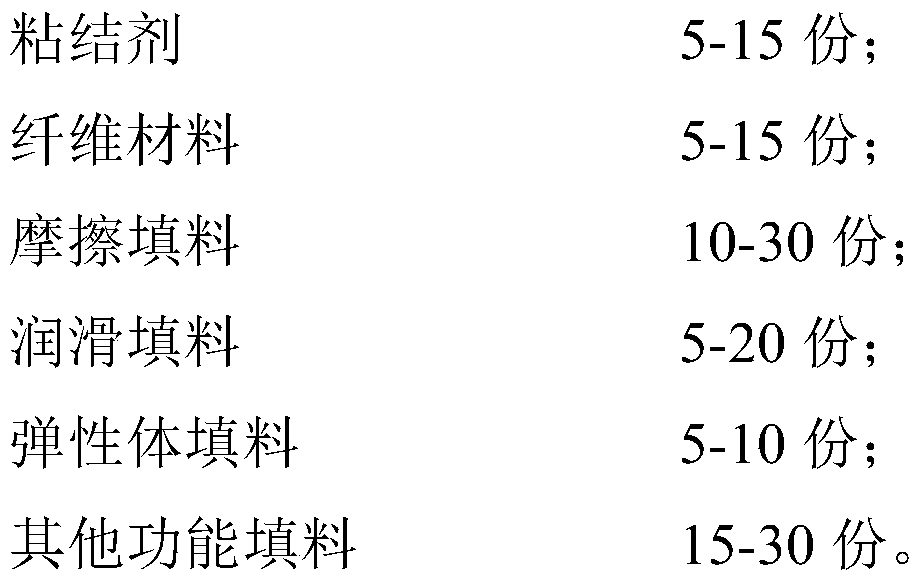

[0036] Specifically, the anisotropic thermally conductive material includes: flaky graph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com