High-strength high-heat-conductive modified polycarbonate master batch and preparation method thereof

A polycarbonate, high-strength technology, applied in the field of modified high-strength, high thermal conductivity polycarbonate masterbatch and its preparation, can solve the problems of heat accumulation, limit the application range, affect the service life, etc., and achieve the improvement of mechanical properties, The effect of good thermal conductivity and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

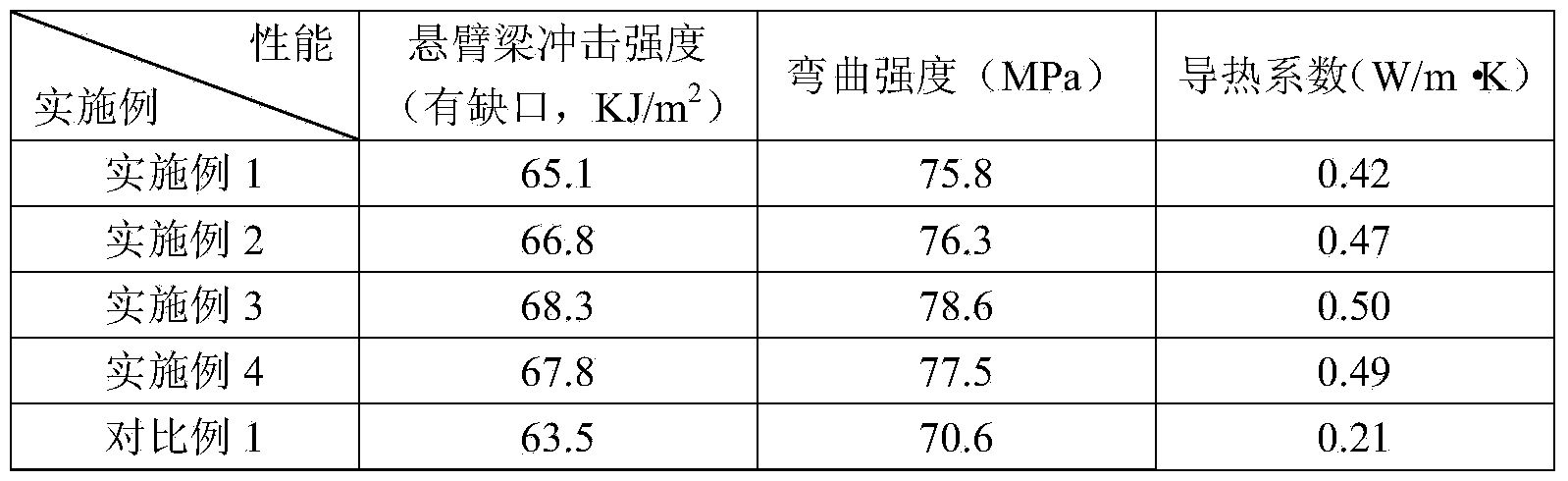

Examples

Embodiment 1

[0017] In parts by weight, 2 parts of graphene dry powder with a thickness of 1-2nm are placed in an electrostatic sprayer, the electrostatic output voltage is set to 10KV, the electrostatic output current is 5μA, and the powder output is controlled at 4g / min. The dry powder is sprayed on 100 parts of bisphenol A polycarbonate particles with a particle size of 10-15 mesh.

[0018] In parts by weight, the obtained graphene-modified polycarbonate particles, 5 parts of compatibilizer maleic anhydride grafted SEBS, 3 parts of toughening agent SEBS, 0.3 part of antioxidant tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl propionate] pentaerythritol ester and 0.3 parts of lubricant polyethylene wax are added to the high-speed mixer and mixed evenly, and then placed in a vacuum oven to dry. The mixed material is passed through the metering pump After that, it is sent into a twin-screw extruder for melting and kneading, and finally extruded through a die for granulation.

Embodiment 2

[0020] In terms of parts by weight, place 0.5 parts of graphene dry powder with a thickness of 1 to 2 nm in an electrostatic sprayer, set the electrostatic output voltage to 15KV, the electrostatic output current to 8μA, and control the powder output at 2g / min. The dry powder is sprayed on 100 parts of polycarbonate particles with a particle size of 100 mesh.

[0021] In parts by weight, the obtained graphene-modified polycarbonate particles, 6 parts of SEBS of compatibilizer maleic anhydride grafting, 7 parts of toughening agent SEBS, 0.3 part of antioxidant tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenyl propionate] pentaerythritol ester and 0.3 parts of lubricant polyethylene wax are added to the high-speed mixer and mixed evenly, and then placed in a vacuum oven to dry. The mixed material is passed through the metering pump After that, it is sent into a twin-screw extruder for melting and kneading, and finally extruded through a die for granulation.

Embodiment 3

[0023] In terms of parts by weight, place 0.01 part of graphene dry powder with a thickness of 1 to 2 nm in an electrostatic sprayer, set the electrostatic output voltage to 10KV, the electrostatic output current to 5μA, and control the powder output at 4g / min. The dry powder is sprayed on 100 parts of polycarbonate particles with a particle size of 80 mesh.

[0024] In parts by weight, the obtained graphene-modified polycarbonate particles, 8 parts of compatibilizer maleic anhydride grafted SEBS, 6 parts of toughening agent SEBS, 0.1 part of antioxidant tetrakis[β-(3,5- Di-tert-butyl-4-hydroxyphenylpropionate] pentaerythritol ester and 0.1 part of lubricant polyethylene wax are added to the high-speed mixer and mixed evenly, then placed in a vacuum oven to dry. The mixed material is passed through the metering pump After that, it is sent into a twin-screw extruder for melting and kneading, and finally extruded through a die for granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com