Flue gas cooling system and method

A technology of flue gas cooling and flue gas cooler, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as damage to adsorption towers, combustion, and failure of activated carbon or activated coke, so as to avoid failure and avoid hotspot effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

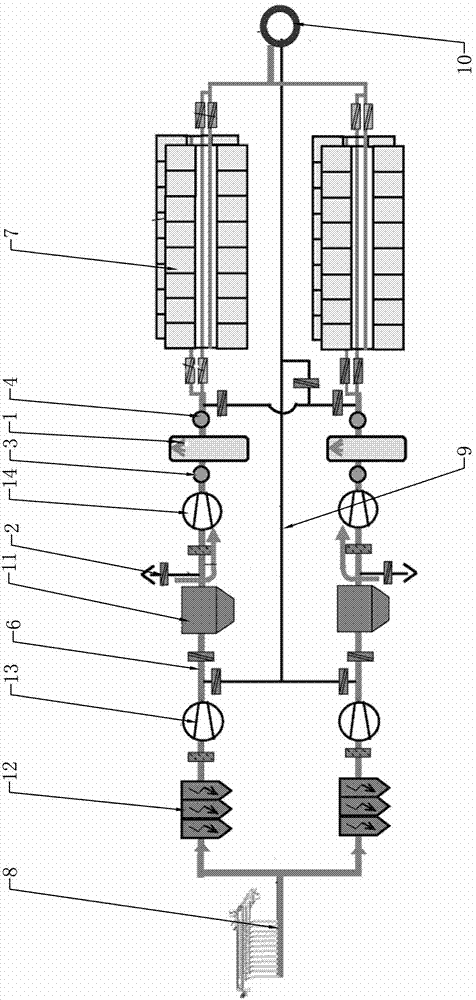

[0023] When the flue gas enters the adsorption tower 7 continuously at a temperature above 150°C, the activated carbon becomes overheated from a certain point in the adsorption tower and forms a small fire, which starts to transfer to other activated carbons in the module. Time will be in a stopped state where adsorption and catalytic activities cannot be performed. Therefore, in order for activated carbon to maintain its normal and optimal function below 150°C, and the adsorption tower will not reduce the operation and efficiency of the entire system due to "hot spots", it is necessary to use the following system to cool the temperature of the flue gas entering the adsorption tower, Keep it below 150°C.

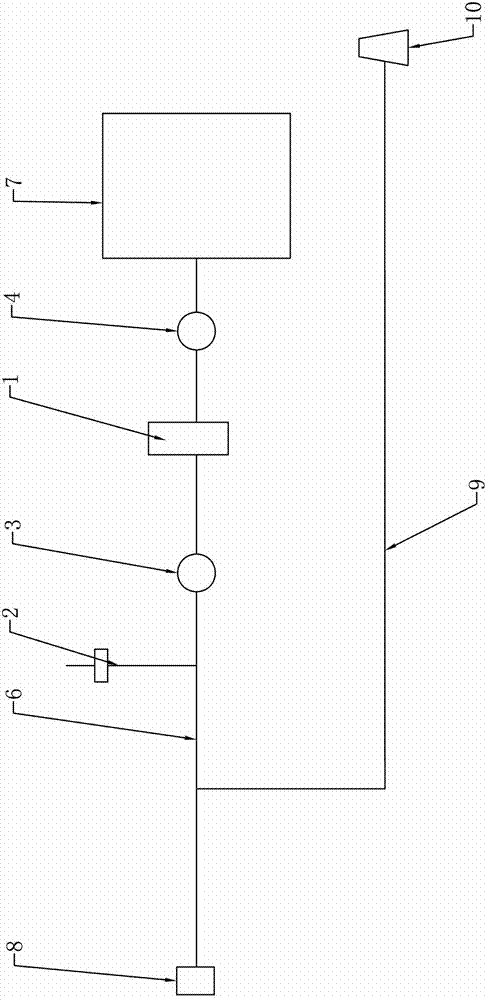

[0024] Such as figure 1 As shown, the flue gas cooling system of the present invention includes a flue gas cooler 1, an external air cooler 2, a first temperature sensor 3, a second temperature sensor 4, a third temperature sensor, a first flue gas pipe 6 and a second flue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com