Fuel cell bipolar plate

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problem that the cooling water cannot be connected as a whole, so as to avoid the uncontrollable reaction gas pressure, improve the area utilization rate, and evenly distribute Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

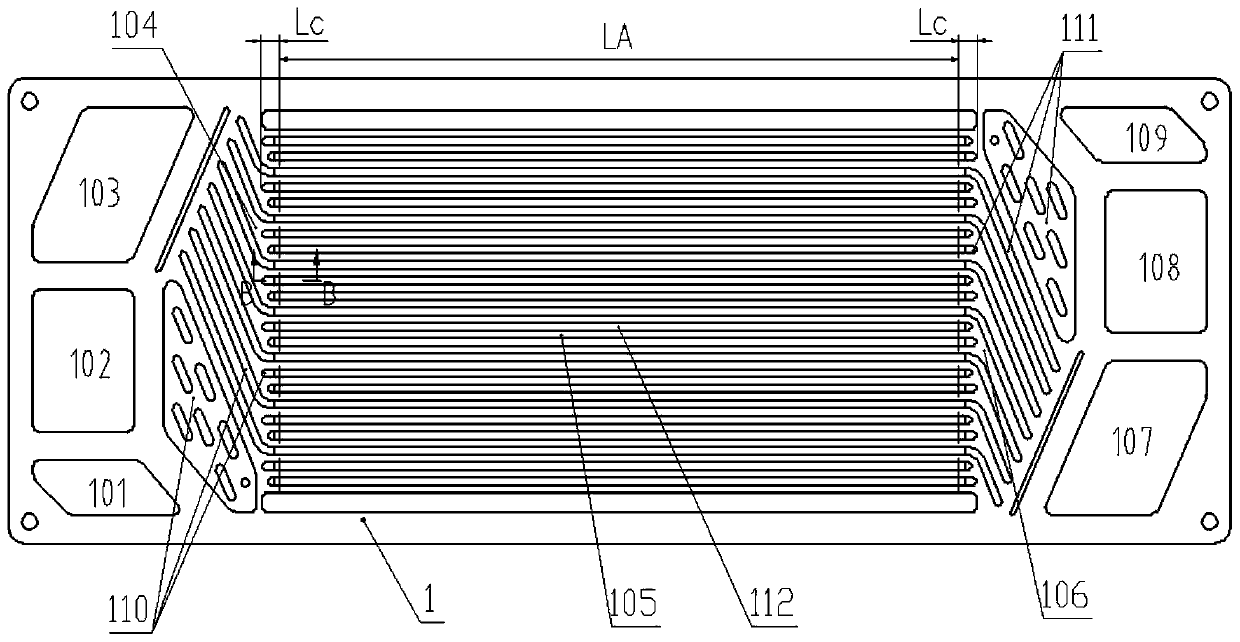

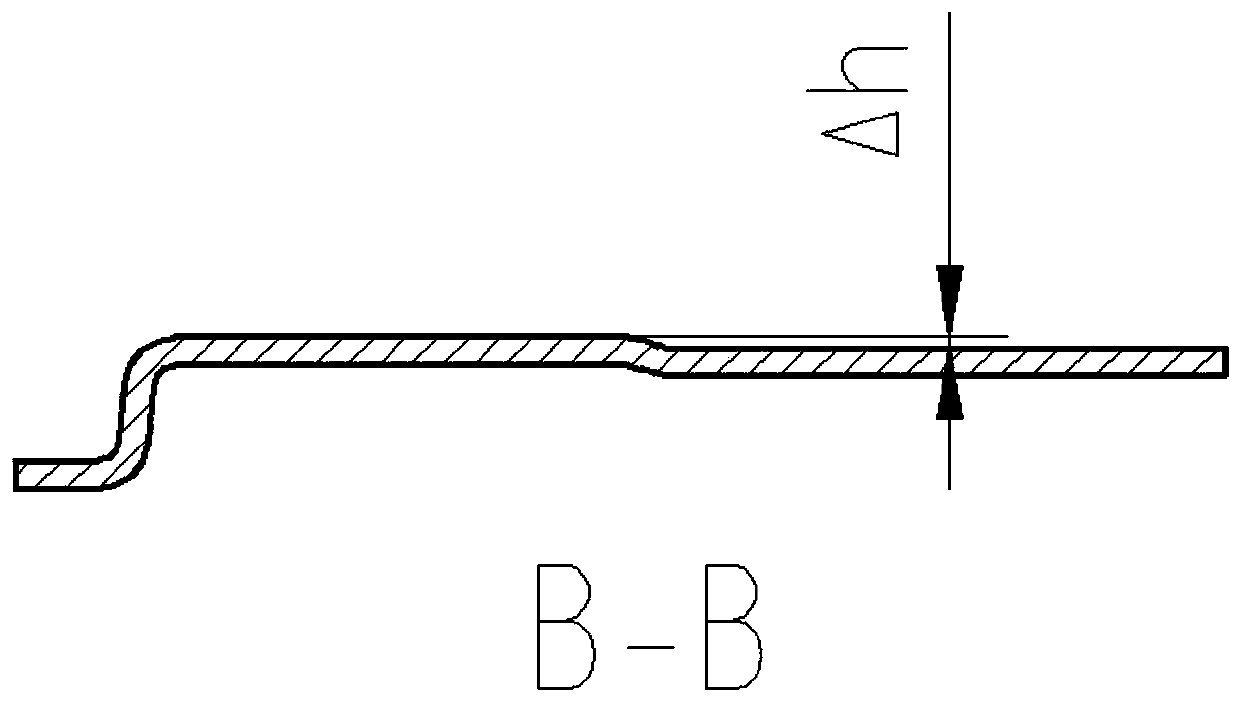

[0049] Such as Figure 1-5 As shown, on the basis of the above technical solution, in this embodiment, the cathode plate 1 and the anode plate 2 are stamped from a 0.1 mm thick stainless steel sheet.

[0050] In this embodiment, the flow field structure in the distribution area has a branched flow field structure, flow channels are set in the flow field of the distribution area, and each flow channel period is branched to correspond to 1- 50 flow channel cycles; the flow field structure in the distribution area has discontinuities along the direction of fluid flow, and the discontinuity refers to changes in the flow field structure in its height direction; not all flow fields in the distribution area It is an intermittent boss and pit structure; each flow channel period includes a groove and a ridge;

[0051] Further, the flow fields in the distribution area of the cathode plate 1 and the anode plate 2 are not all discontinuous bosses and pits, but can be continuous uninter...

Embodiment 2

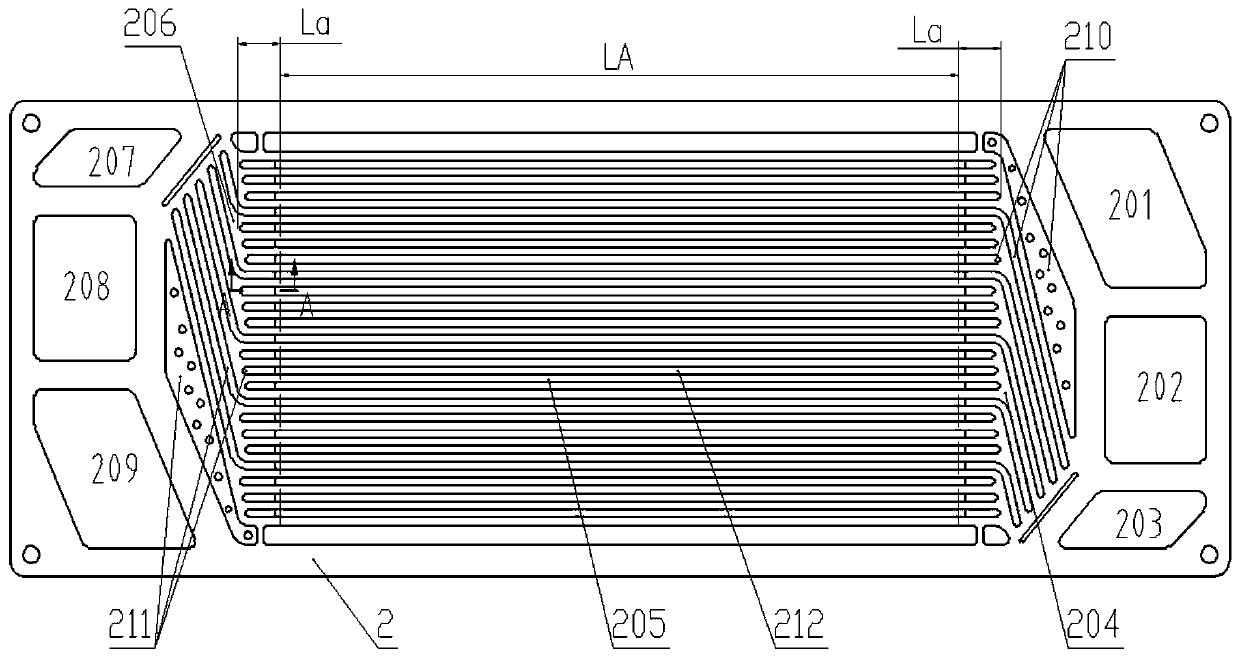

[0068] The difference between this embodiment and Embodiment 1 is that in order to ensure the smooth flow of cooling water in the bipolar plate, in the cathode plate and the anode plate that make up the bipolar plate, the cooling water active area corresponding to one of the plates flows The flow channel in the field extends to the range covered by the flow field of the cooling water distribution area corresponding to the other plate, and is used for introducing cooling water.

[0069] Further, when the flow channel in the flow field of the cooling water active zone corresponding to one of the pole plates extends to the range covered by the flow field of the cooling water distribution zone corresponding to the other pole plate for introducing cooling water, the above flow The extension length of the channel is greater than or equal to one channel period of the flow field of the cooling water distribution area of the other plate; The internal flow channel is connected to real...

Embodiment 3

[0072] In the fuel cell bipolar plate provided in this embodiment, the flow field in the distribution area corresponding to the cathode plate 1 and the anode plate 2 adopts a discontinuous convex platform and pit-like structure, and the cathode plate 1 or the anode plate 2 The flow channel in the flow field of the cooling water active area corresponding to the anode plate 2 extends to the range covered by the flow field of the cooling water distribution area corresponding to the other plate for introducing cooling water; or, the cathode plate 1 The flow channels in the cooling water active zone flow field corresponding to the anode plate 2 all extend to the range covered by the cooling water distribution zone flow field corresponding to the other polar plate, and the above-mentioned flow channels corresponding to the two polar plates The lengths of the channel extensions are not equal, and the above-mentioned flow channels with longer extension lengths are used to introduce coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com