Air tool

a technology of air tools and air-powered tools, which is applied in the direction of electric generator control, magnetic circuit shape/form/construction, magnetic circuit rotating parts, etc., can solve the problems of reducing the electrical output of the generator, reducing the energy of the magnetic circuit, and overheating the coil, so as to achieve less vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

An integral air motor generator (IAMG) converts compressed air into rotary torque and electricity. The inventive IAMG utilizes an improved sidepole stator and rotor arrangement.

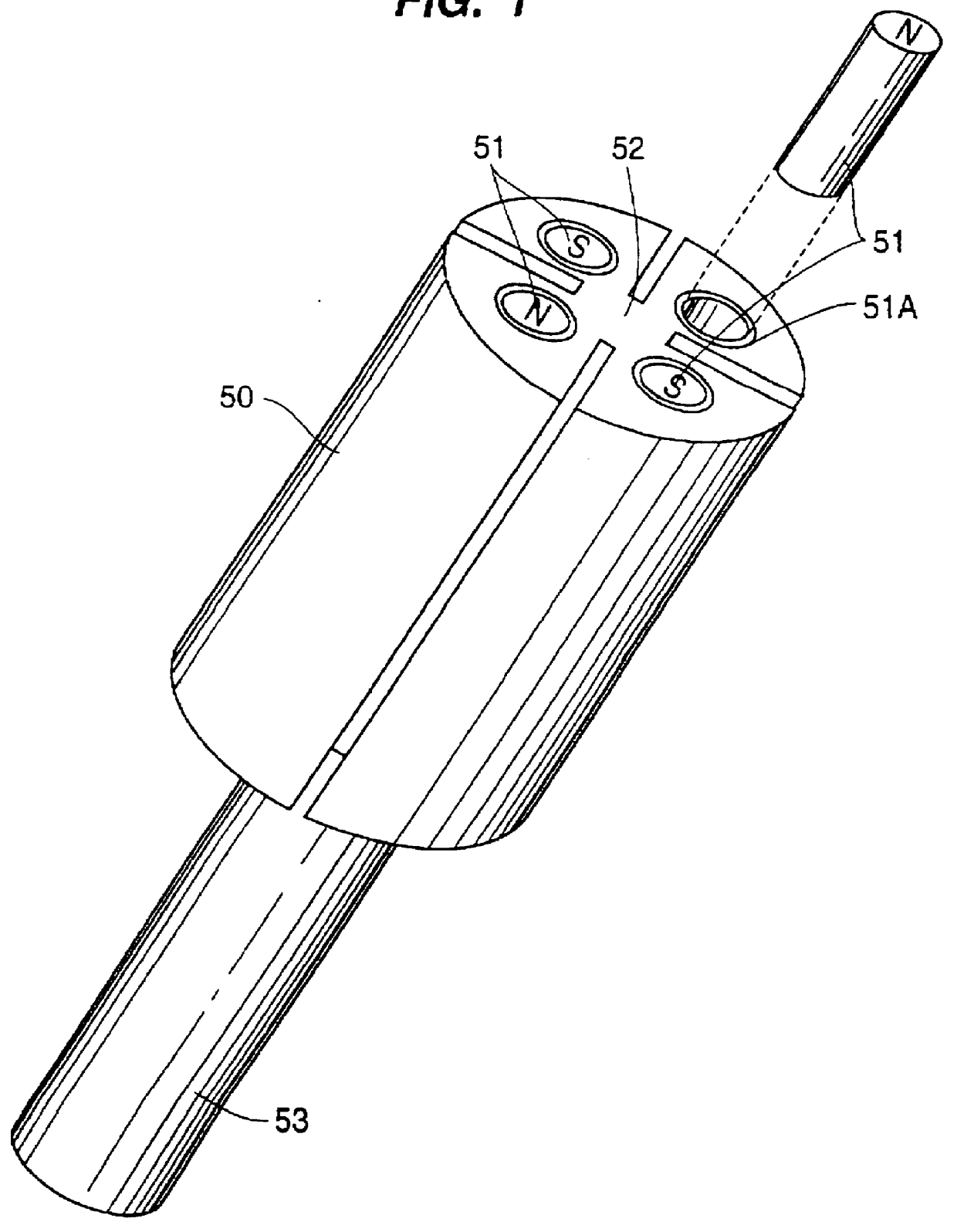

FIG. 1 shows a modified rotor body 50 referred to as a cantilever rotor. The cantilever rotor design improves magnetic induction and decreases the required amount of space, thereby allowing the incorporation of the IAMG into small air powered tools. Significantly improved magnetic induction in the electromagnetic circuit of the generator has been achieved through the incorporation of the magnetic elements 51 into the air motor rotor body 50 (or a segment of the same) in a sidepole arrangement as shown and utilizing nonmagnetic material for the shaft 53 and rotor body 50 (such as stainless steel carbon fiber reinforced thermoplastic or glass fiber reinforced thermoplastic).

An improved permanent magnet 51 is made of a metallic compound consisting of the element neodymium (Symbol Nd, Atomic number, 60, Atomic we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com