Workpiece positioning and clamping device for thread cutting machine

A thread processing and clamping device technology, applied in positioning devices, metal processing machinery parts, metal processing equipment, etc., can solve problems such as errors, large deviations in processing or measurement results, etc., to overcome torsion and bending deformation, clamping Positioning is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the drawings and embodiments.

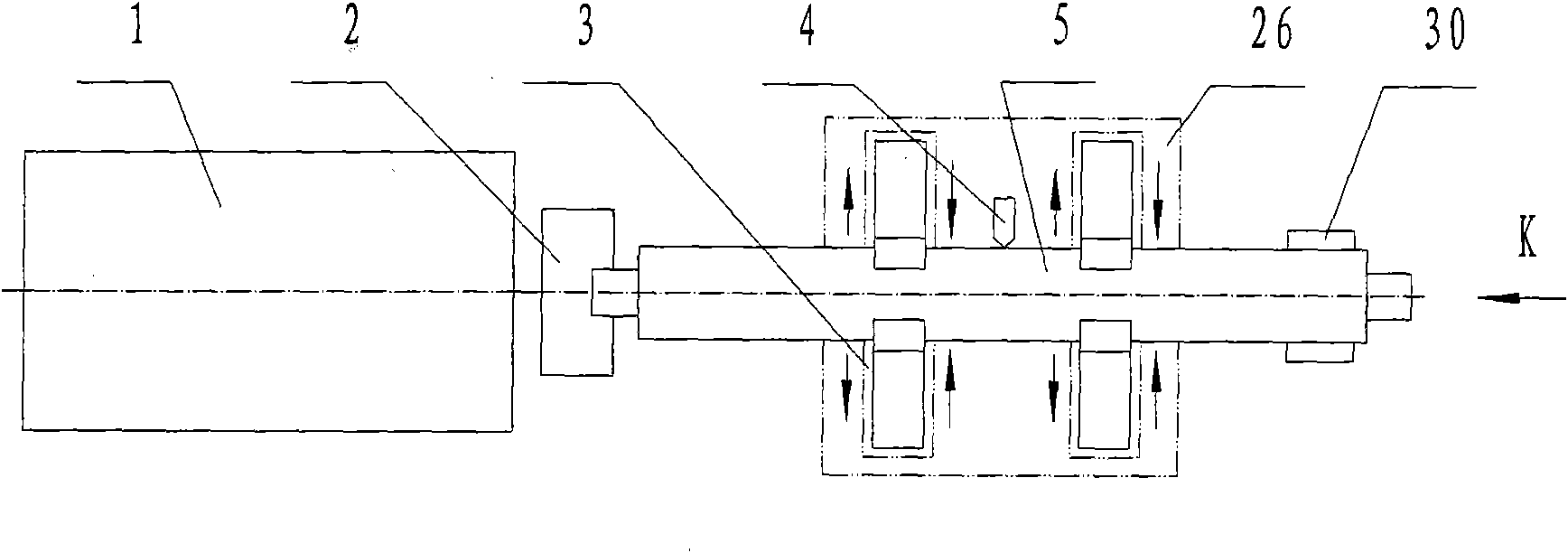

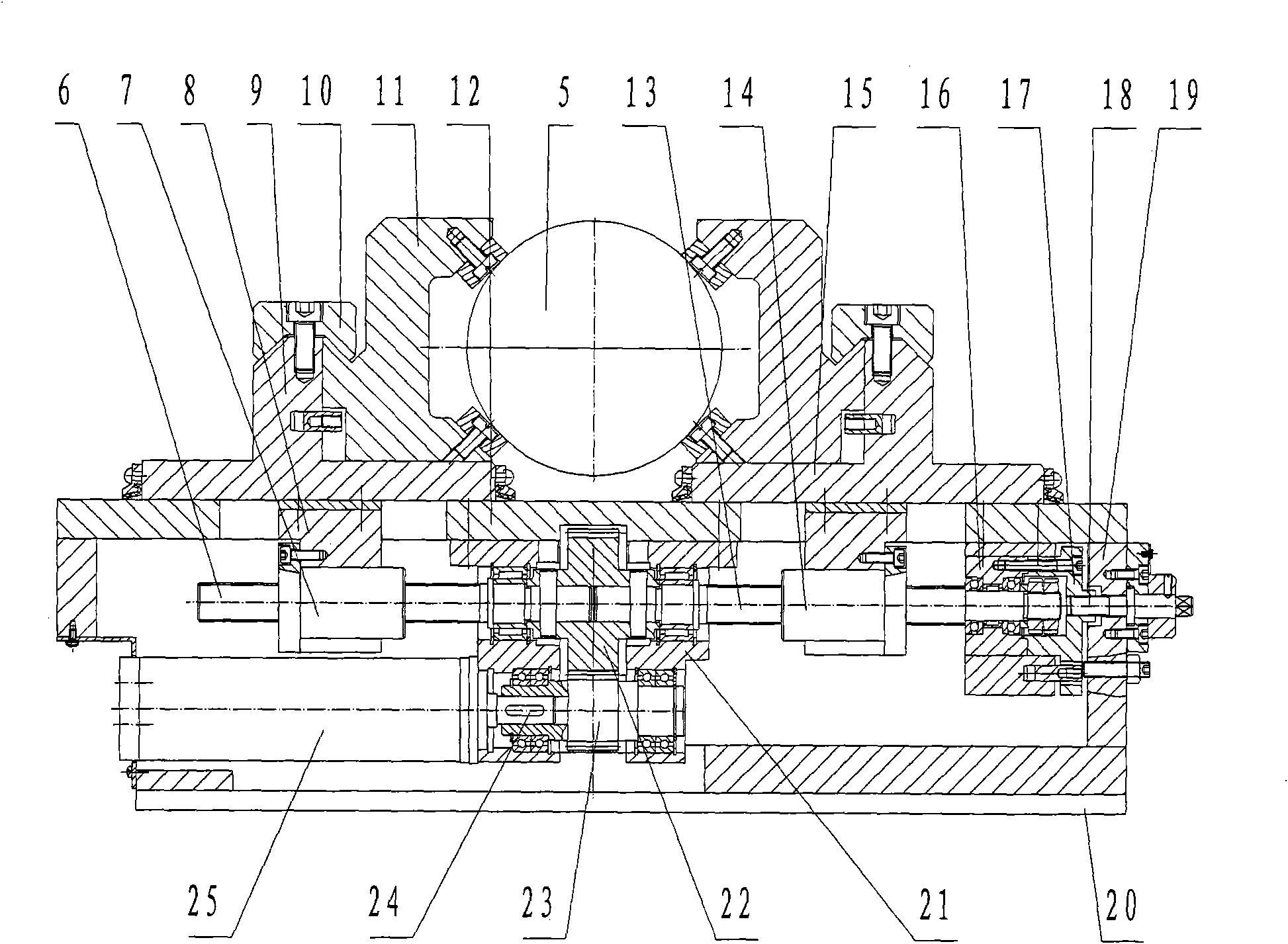

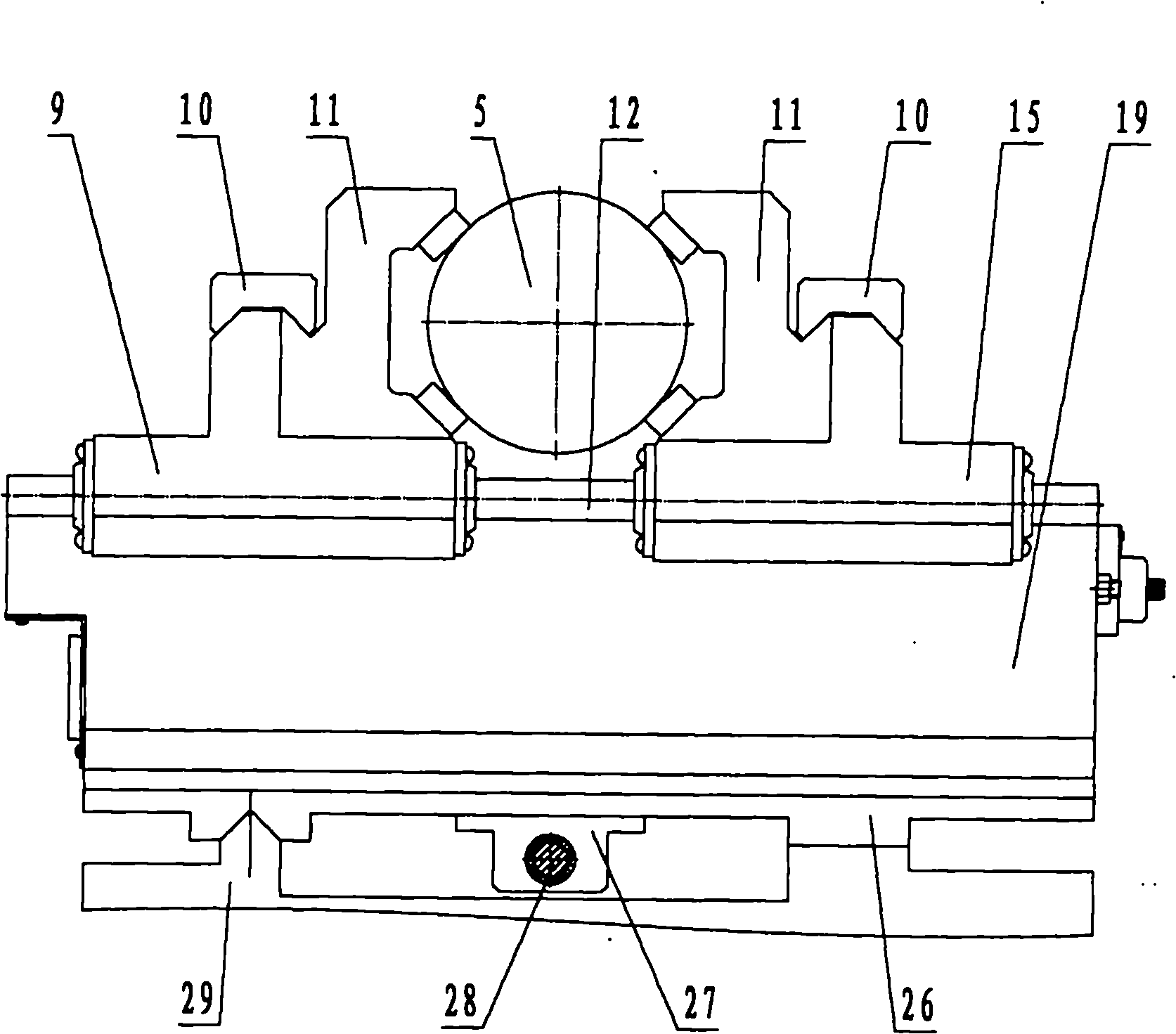

[0016] The thread processing machine tool workpiece positioning and clamping device of the present invention is composed of a support, a running mechanism fixedly installed on the upper part of the support, and a transmission mechanism installed in the inner cavity of the support. The transmission mechanism converts rotary motion into linear motion and drives the running mechanism to work. This device is used in pairs, and is fixed on the longitudinal carriage 26 of the machine tool together with the machine tool system. The tool system 4 is located at the center of the longitudinal carriage 26. A set of this device is installed on each side of the longitudinal carriage 26. The longitudinal carriage 26 is located On the guide rail of the machine bed 29, such as figure 1 image 3 Shown. During thread cutting, the machine tool headstock chuck 2 clamps one end of the work ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com