Air-Operated Pump

a technology of air motor and pump, which is applied in the direction of piston pump, positive displacement liquid engine, non-mechanical valve, etc., can solve the problems of inconvenient options, inability to isolate the problem component, etc., and achieve the effect of facilitating the servicing of the air valve system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

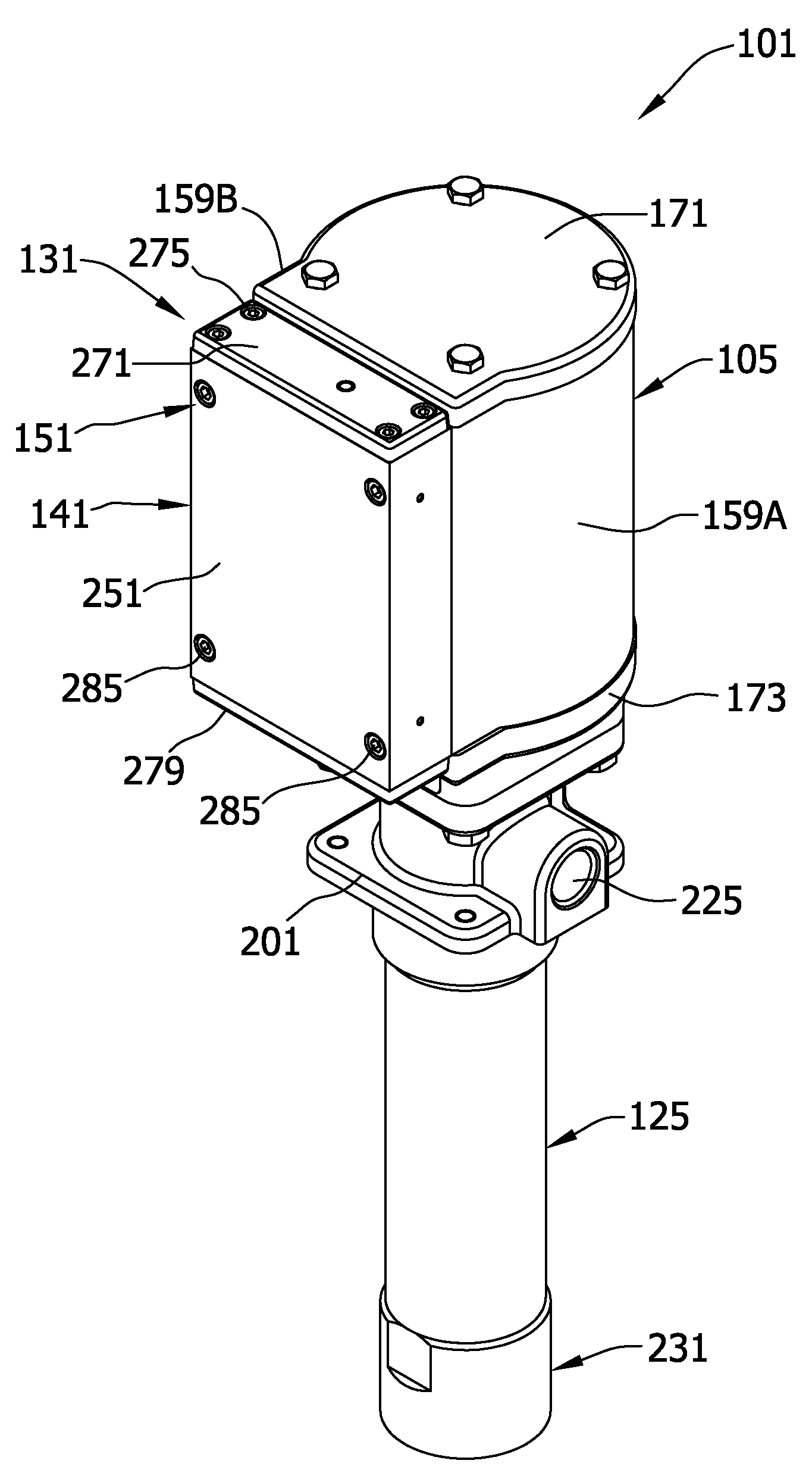

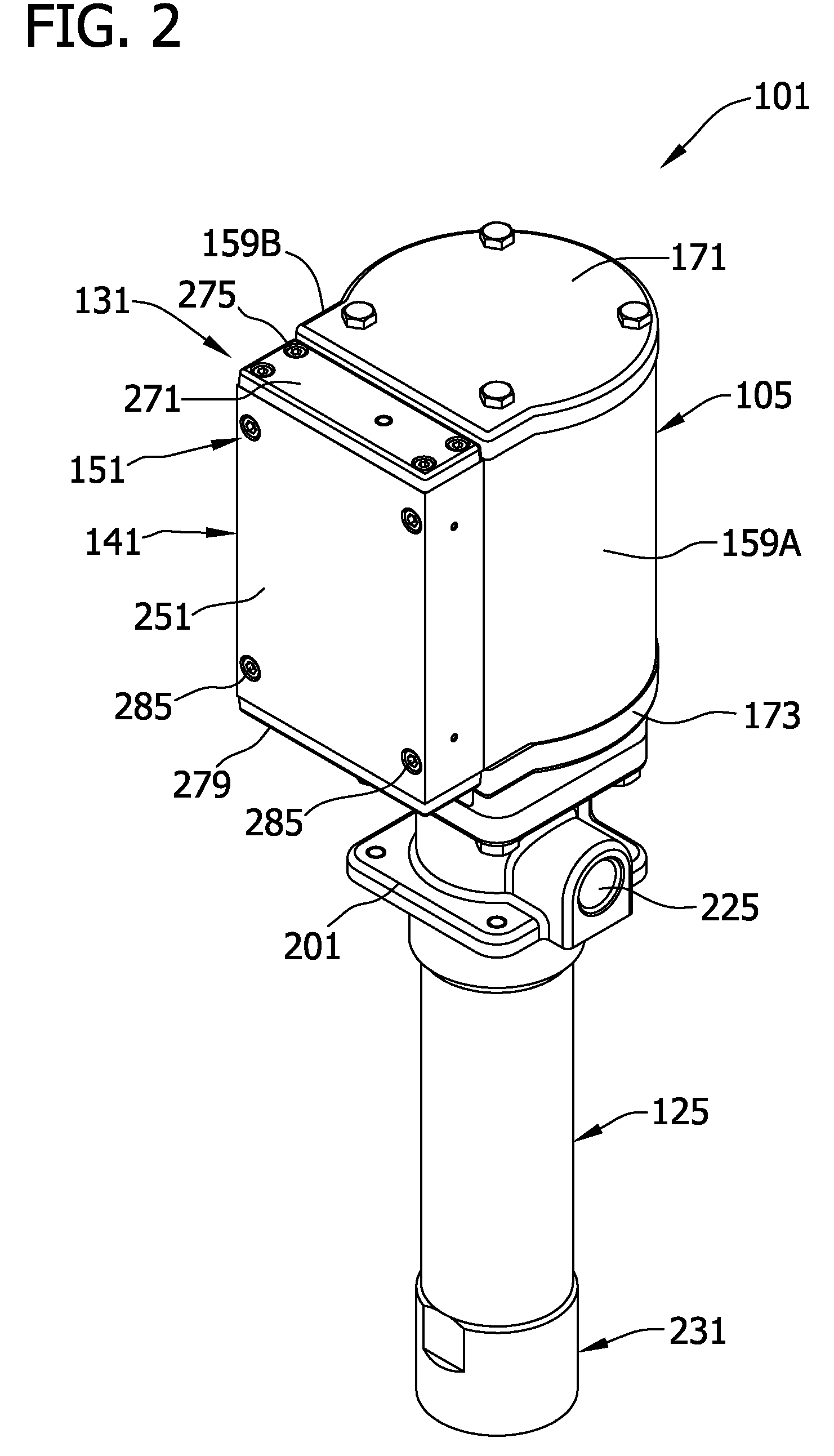

[0024]FIGS. 2-15 illustrate one embodiment of an air-operated pump of this invention, designated in its entirety by the reference number 101. The pump is operable for pumping material, particularly a lubricant such as oil or grease, from a source of such material such as a container (not shown). The pump 101 of this particular embodiment is particularly adapted for pumping oil.

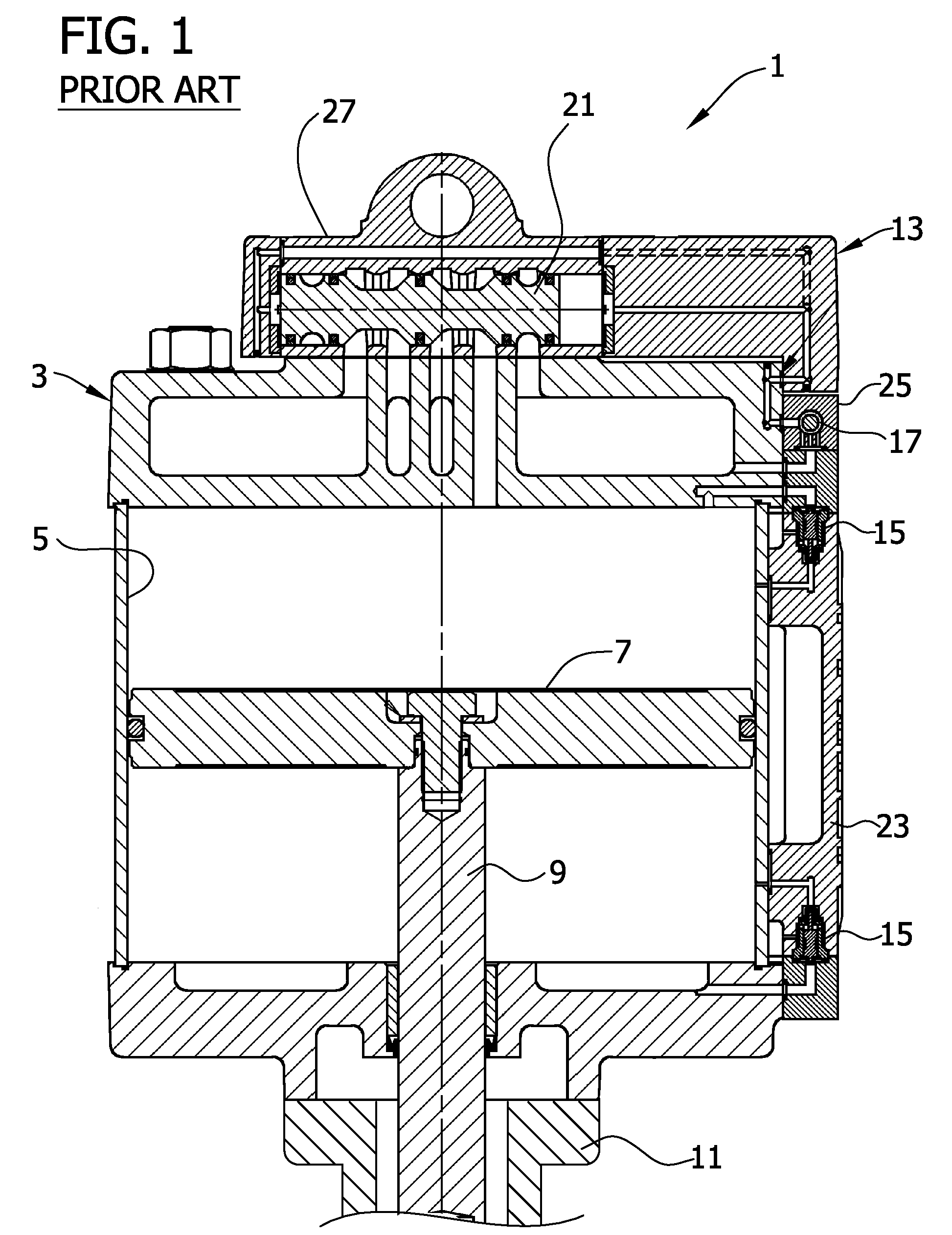

[0025]In general, and referring to FIGS. 1-7 the pump comprises a pump head 105 defining a cylinder 107 and a piston 111 reciprocal up and down in the cylinder. The cylinder 107 is divided into a first expansible chamber 115 at one side of the piston (the upper side as shown in FIG. 5) and a second expansible chamber 117 at the opposite side of the piston (the lower side as shown in FIG. 6). A pump plunger 121 extends down from the piston 111 generally co-axial with the cylinder 107. The plunger 121 has an upper end connected to the piston 111 and a lower end. An elongate pump tube 125 is connected to the head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com