Fast assembled machine cabinet

A kind of cabinet and fast technology, applied in the direction of cabinet/box/drawer parts, instrument parts, electrical equipment shell/cabinet/drawer, etc., can solve the problem of many parts, high assembly labor cost and cumbersome assembly process complex issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

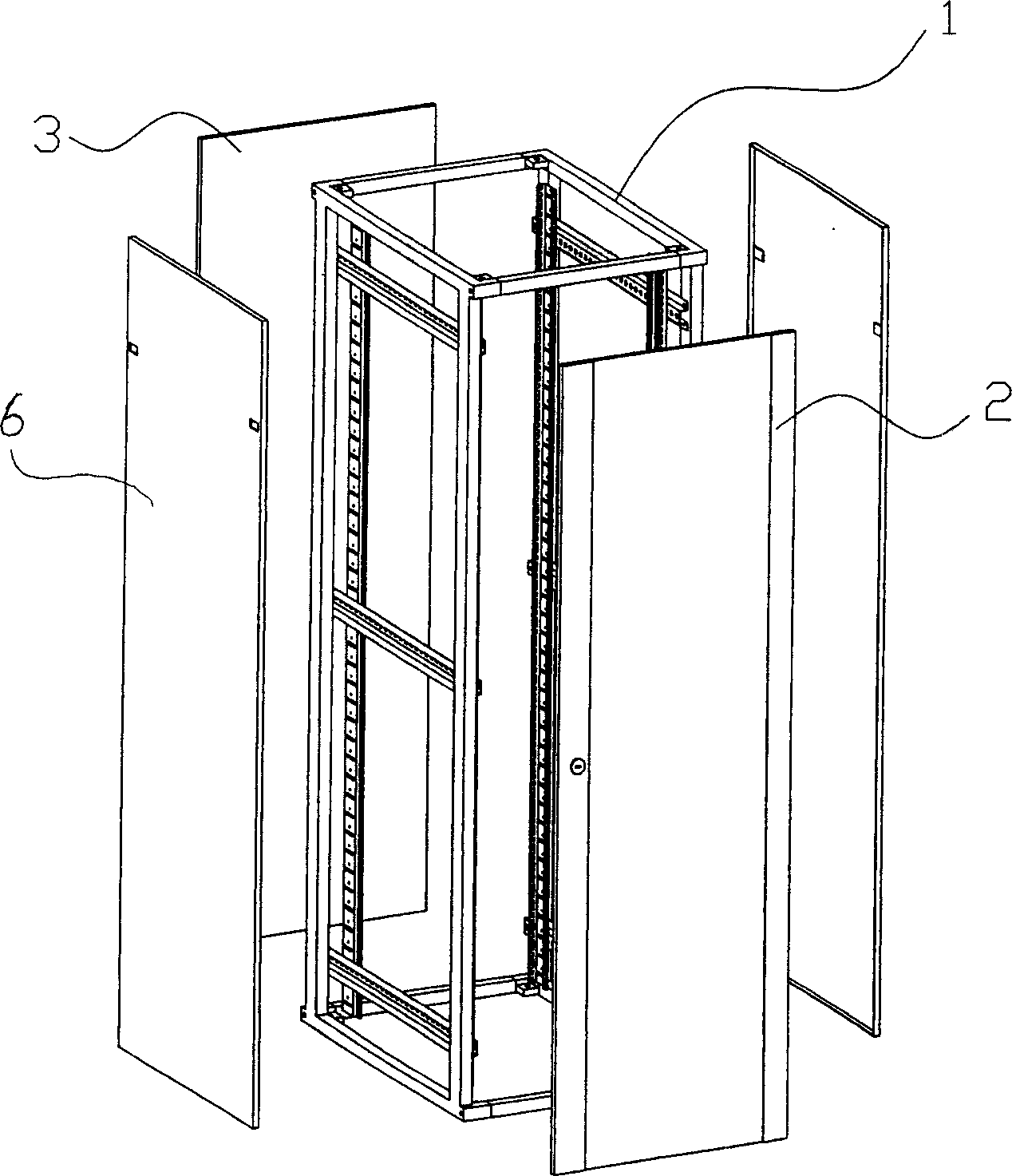

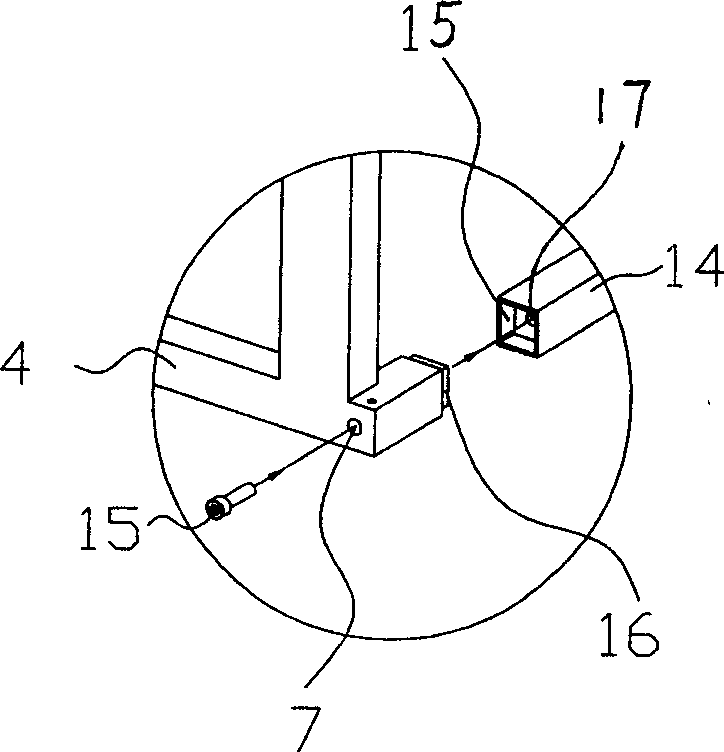

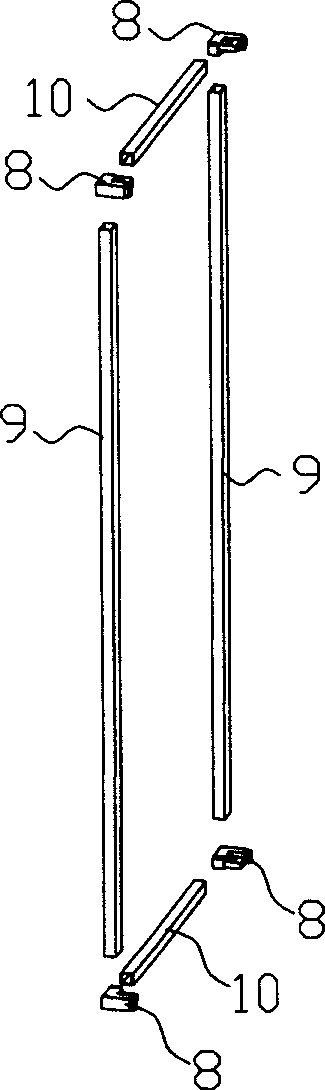

[0020] Example: such as figure 1 As shown, the cabinet is composed of a frame 1, a cabinet door 2, a backboard 3, and a panel 6; the frame 1 is composed of two enclosure components 13, four connecting beams 14 and eight screws 5 (see Figure 3a ); the frame assembly 13 is made of parts such as the frame 4 and the panel 6 installed thereon, the equipment installation slat 11 , the installation beam 12 , and the panel 6 , equipment installation slat 11 , installation beam 12 etc. Parts are pre-assembled onto frame 4 (see Figure 2b ) to form the frame assembly 13 (see Figure 2c ); the surrounding frame 4 is composed of two columns 9 and two cross bars 10, which are connected by four connecting blocks 8 (see Figure 2a ), the exposed end of the connecting block 8 at the four corners of the corresponding side of the surrounding frame 4 is an embedded head 16 that can be mated with the counterbore at the end of the connecting beam 14 (see Figure 4 ); the four corners of the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com