Fast assembled machine cabinet

A component and cabinet technology, which is applied in the field of rapid assembly of cabinet components, can solve the problems of high assembly labor costs, many parts, and cumbersome and complicated assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

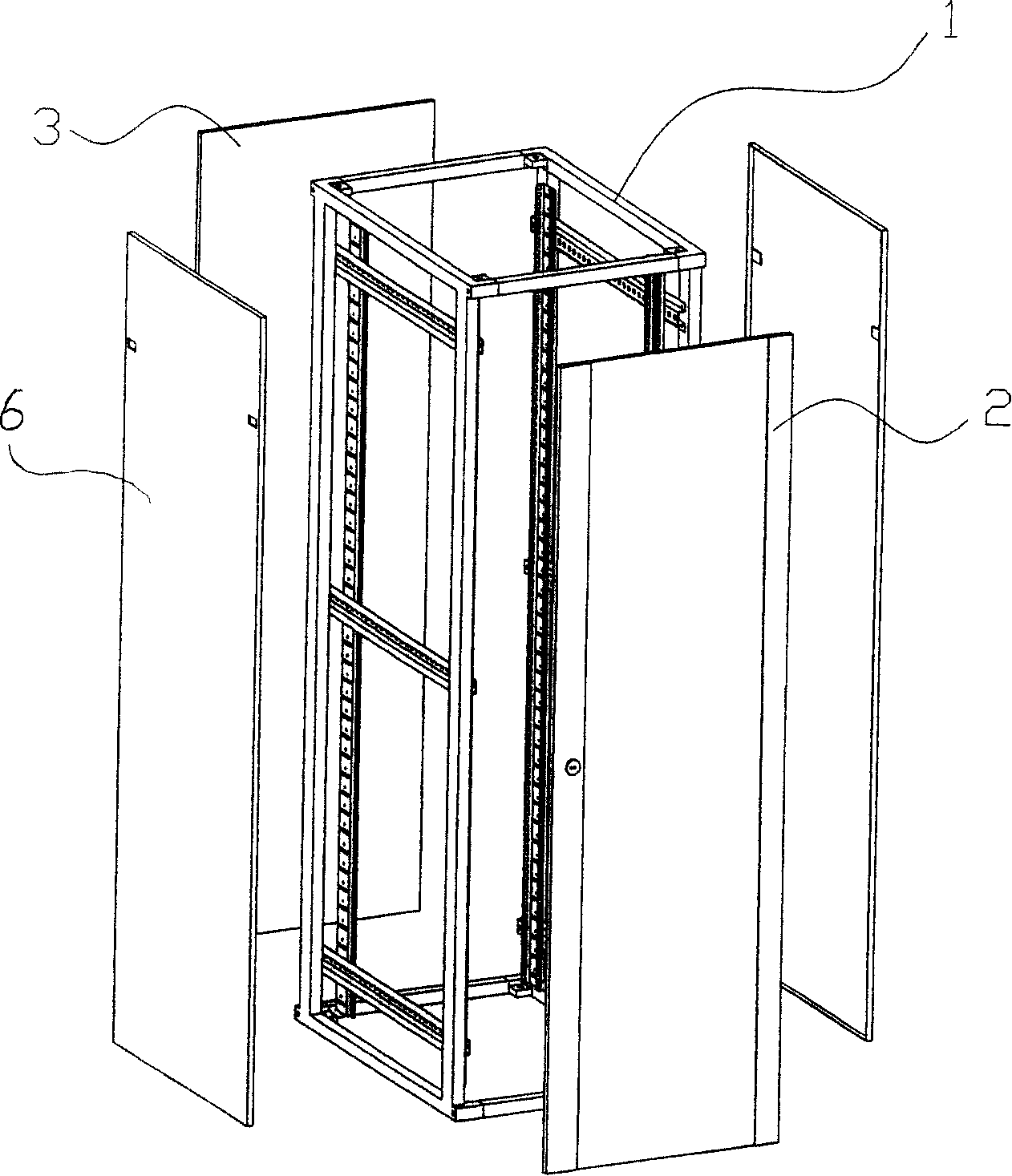

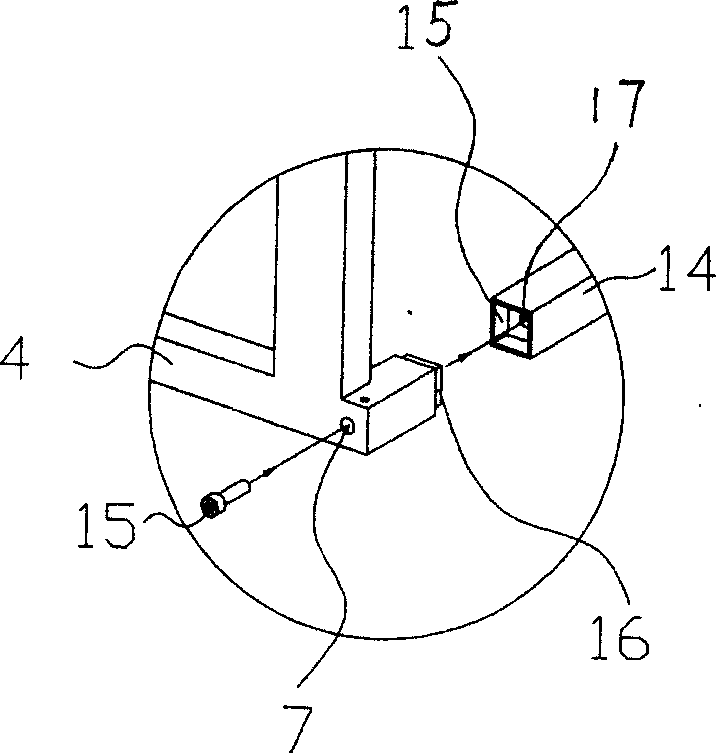

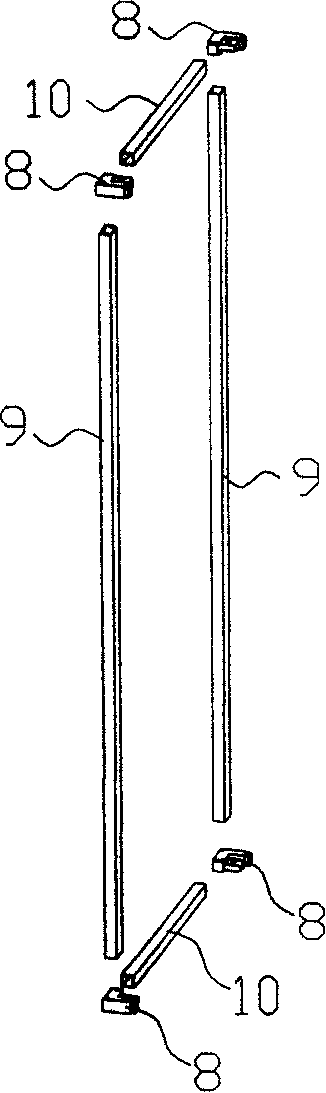

[0018] Example: such as figure 1 As shown, the quick-assembled cabinet assembly is composed of a frame assembly 1, a cabinet door 2, and a back panel 3; the frame 1 is composed of two enclosure assemblies 13, four connecting beams 14, and eight screws 15 (see Figure 3b ); in order to reduce the workload of on-site assembly, before the cabinet components leave the factory, parts such as door panels 6, equipment installation slats 11, and installation beams 12 are pre-assembled on the surrounding frame 4 (see Figure 2b ) to form the surrounding frame assembly 13; the surrounding frame 4 is composed of two columns 9 and two cross bars 10, connected by four connecting blocks 8 to form (see Figure 2a ), the exposed end of the connecting block 8 at the four corners of the corresponding side of the surrounding frame 4 is an embedded head 16 that can be mated with the counterbore at the end of the connecting beam 14 (see Figure 4 a); The four corners of the four sides of the surr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com