Patents

Literature

85results about How to "Good debugging effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

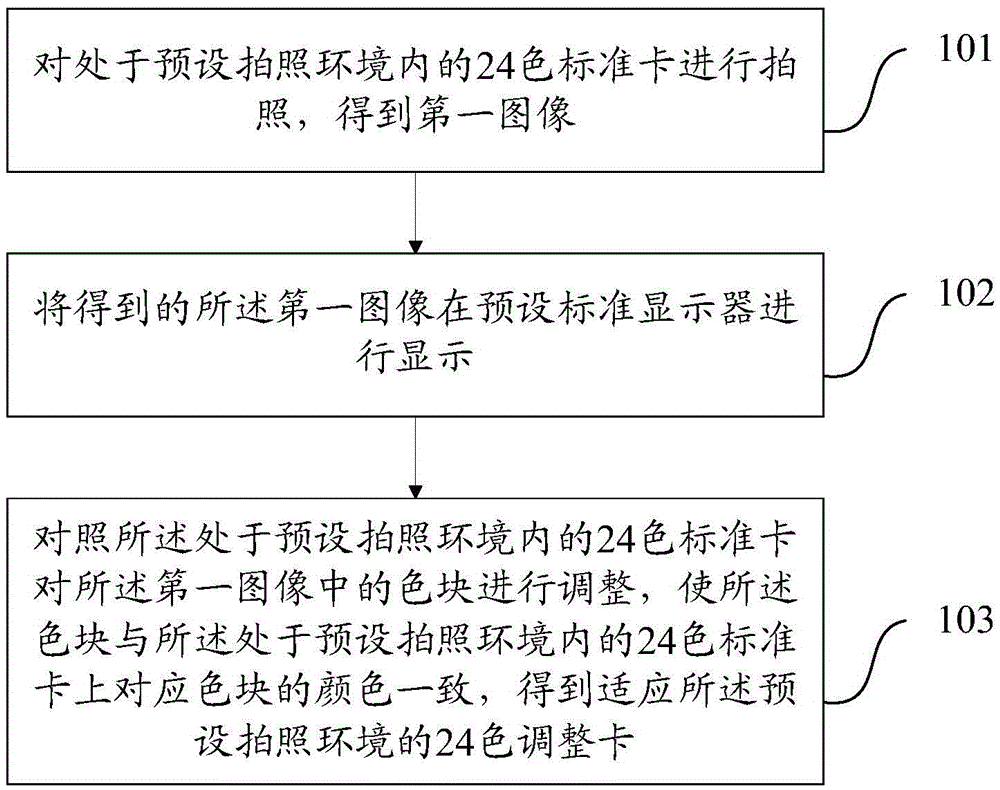

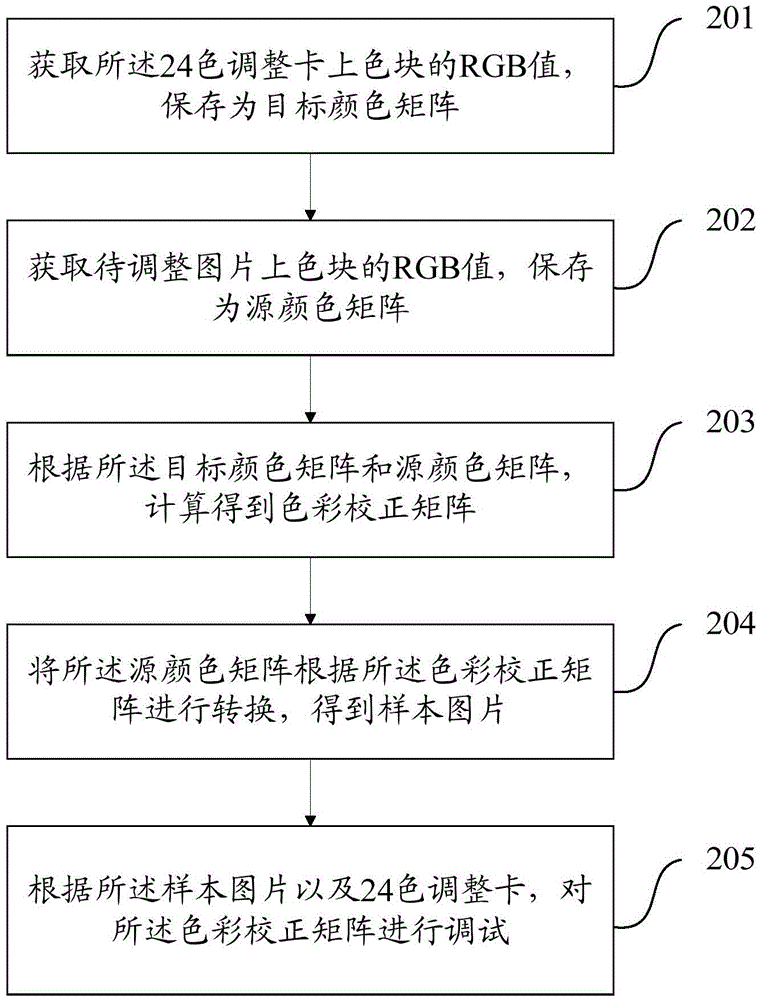

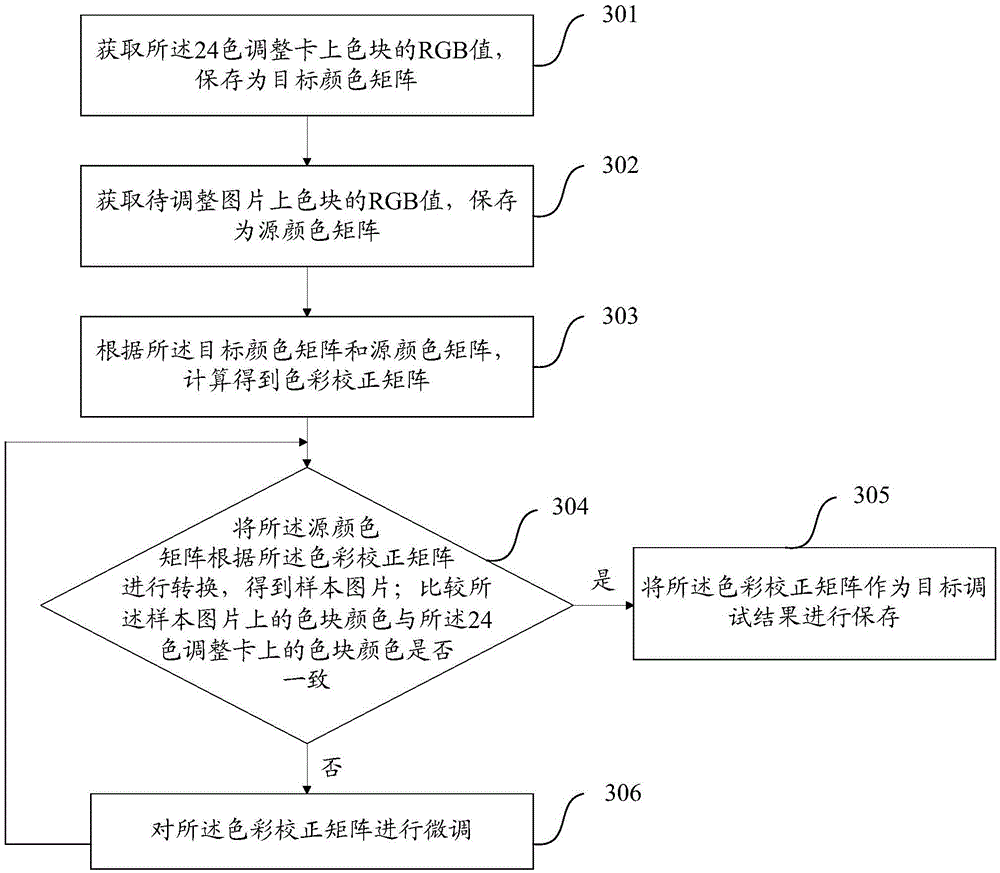

Adjustment card manufacturing method, system, color correction matrix debugging method and device

ActiveCN105827897ATrue colorGood debugging effectColor signal processing circuitsColor correctionSample image

The invention provides a method for debugging a color correction matrix. The method comprises the steps of acquiring the RGB values of color blocks on a 24-color adjustment card and storing the acquired RGB values as a target color matrix; acquiring the RGB values of color blocks on a to-be-adjusted picture and storing the acquired RGB values as a source color matrix; calculating to obtain a color correction matrix according to the target color matrix and the source color matrix; converting the color correction matrix according to the source color matrix to obtain a sample picture; according to the sample picture and the 24-color adjustment card, debugging the color correction matrix. The invention also provides an electronic device corresponding to the above method for debugging the color correction matrix. The invention also provides a method and a system for manufacturing the above 24-color adjustment card. According to the method for debugging the color correction matrix, the color correction matrix is debugged based on the 24-color adjustment card manufactured according to the manufacturing method, so that restored colors are closer to colors seen by human eyes. Therefore, the debugging effect of the color correction matrix is improved.

Owner:VIVO MOBILE COMM CO LTD

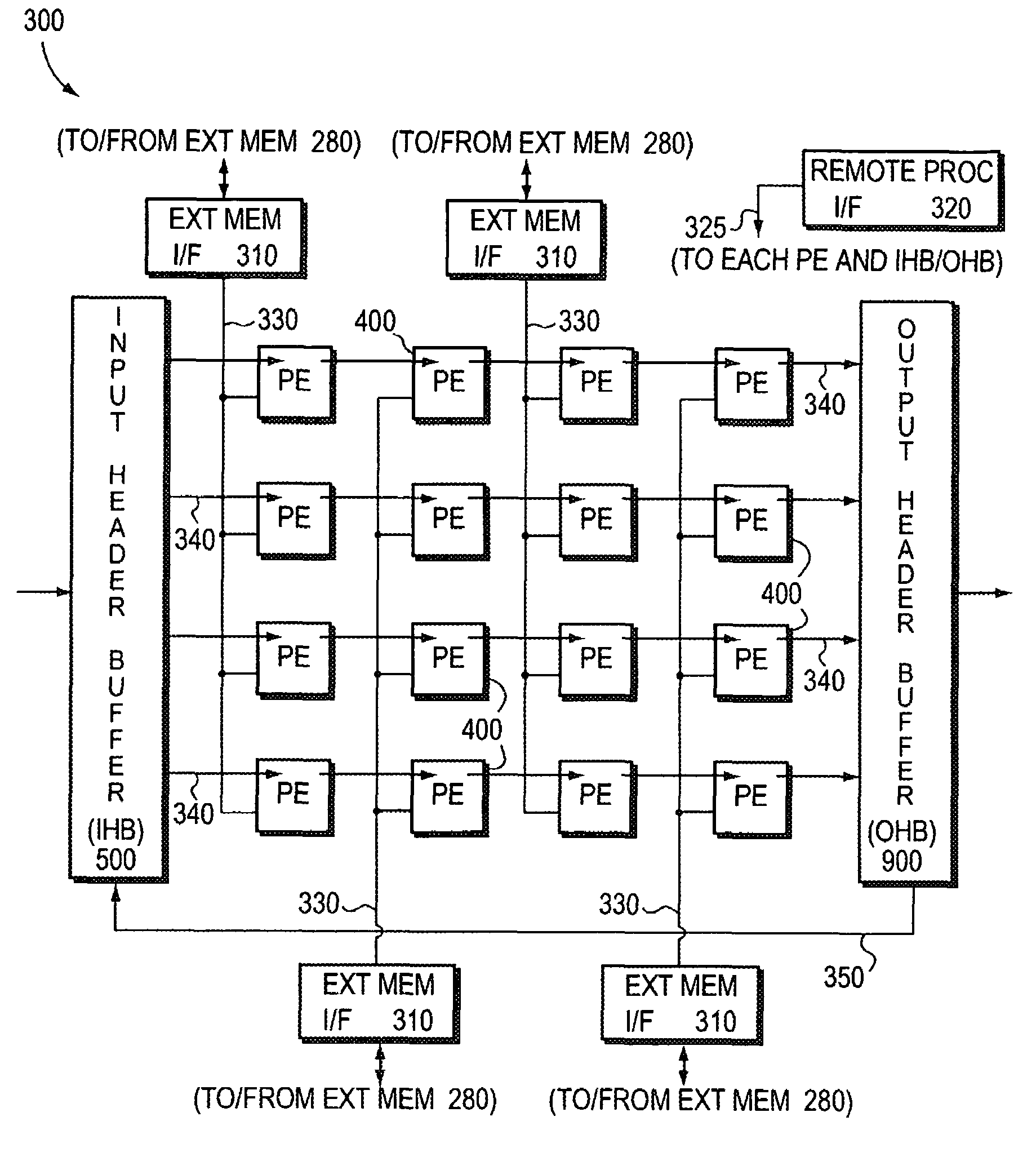

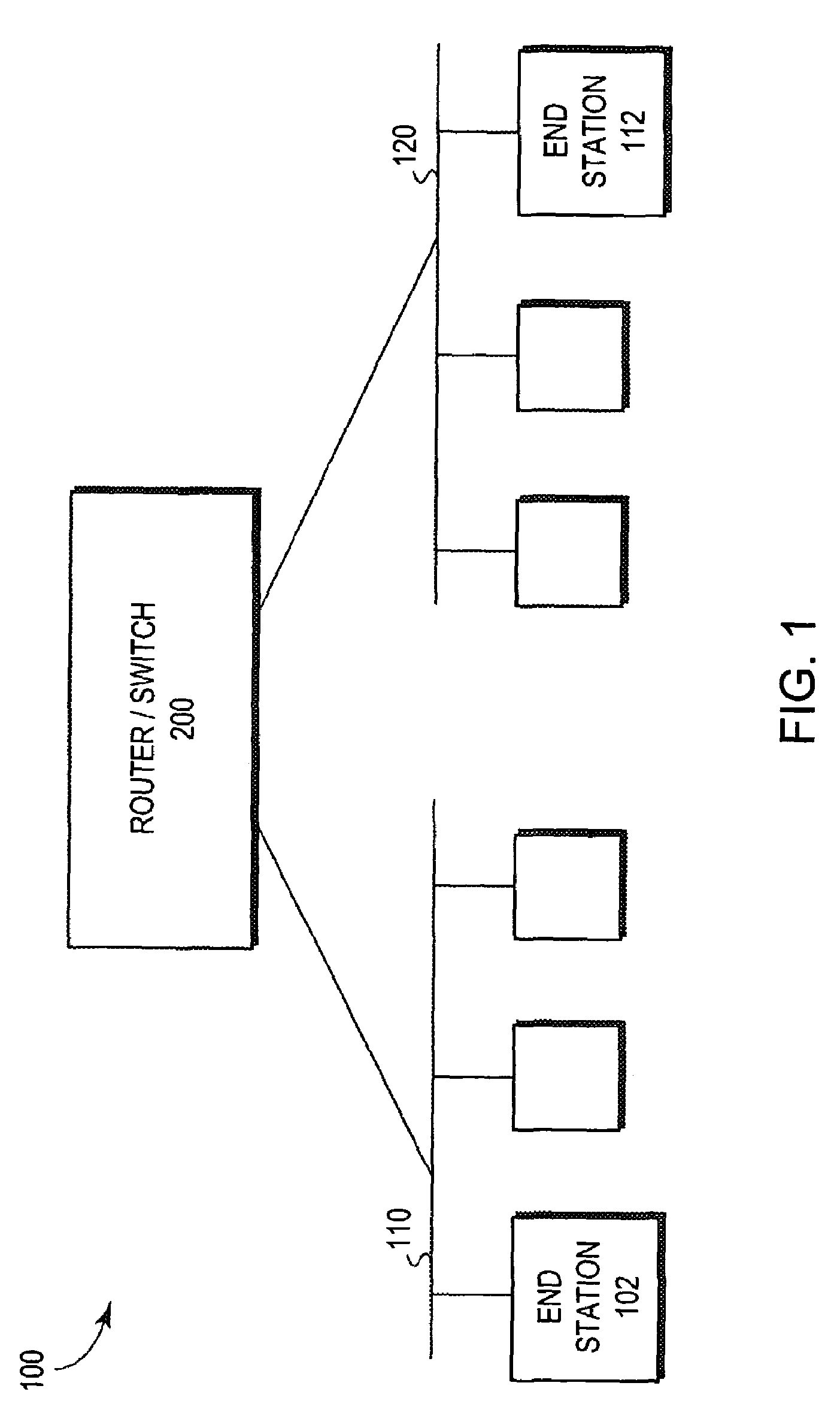

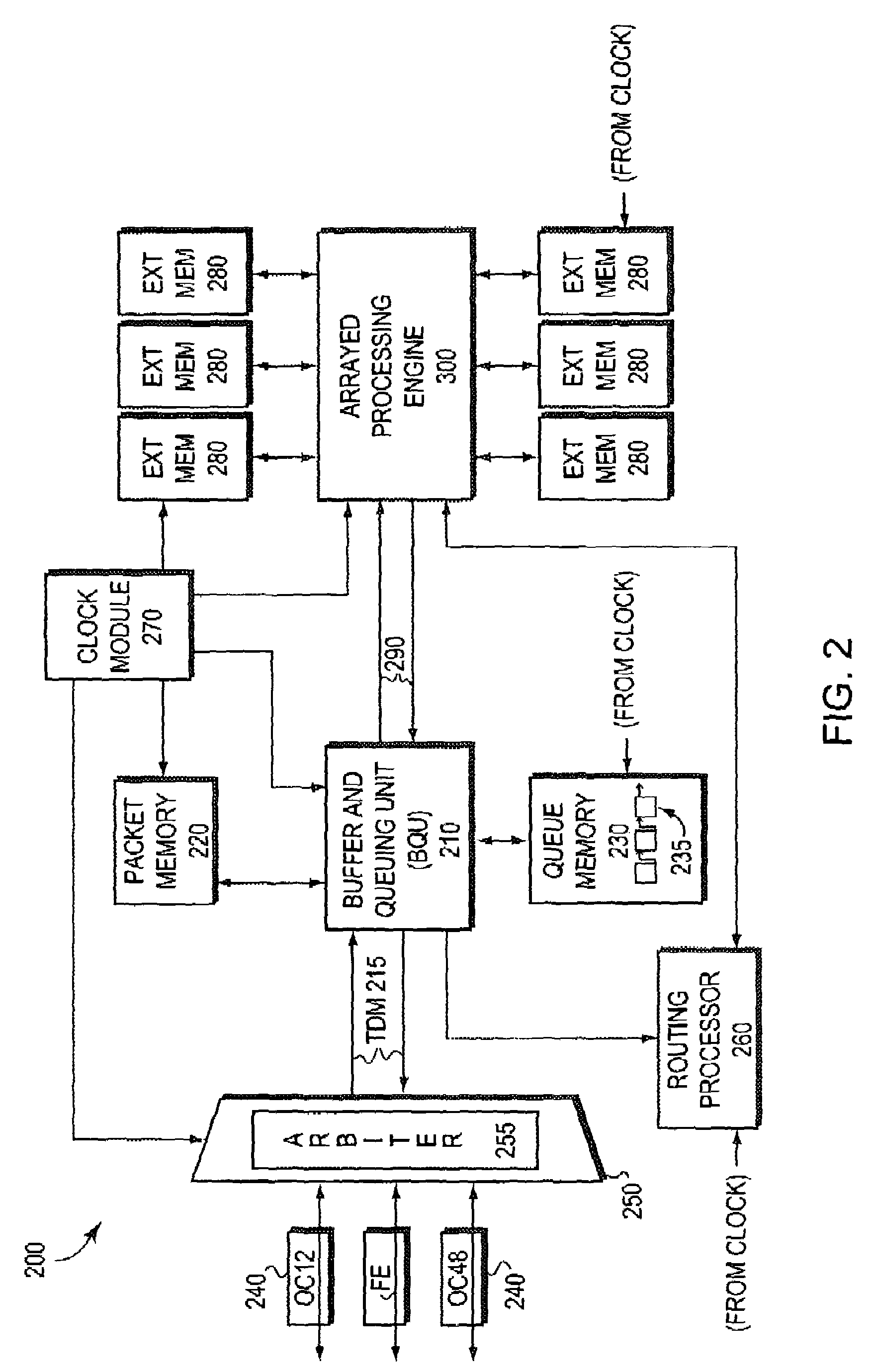

Processor isolation technique for integrated multi-processor systems

InactiveUS7185224B1Easy and fast commissioningImprove abilitiesFunctional testingMulti processorParallel computing

A processor isolation technique enhances debug capability in a multiprocessor circuit. A bypass register has a bit location which may indicate that a processor is to be bypassed. A code entry point is selected to permit a downstream processor to do the work of the bypassed processor. The processors may be arrayed in a pipeline.

Owner:CISCO TECH INC

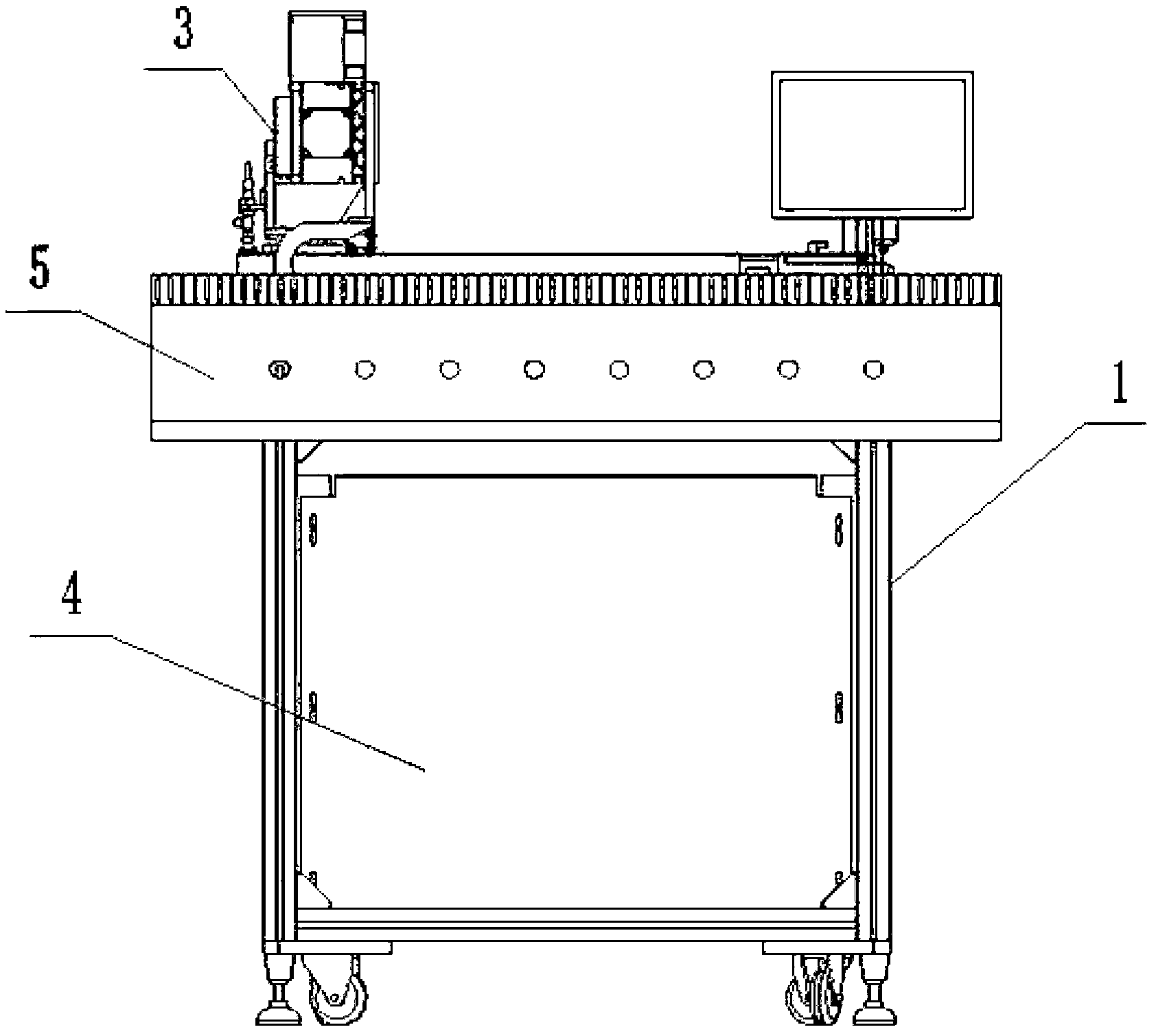

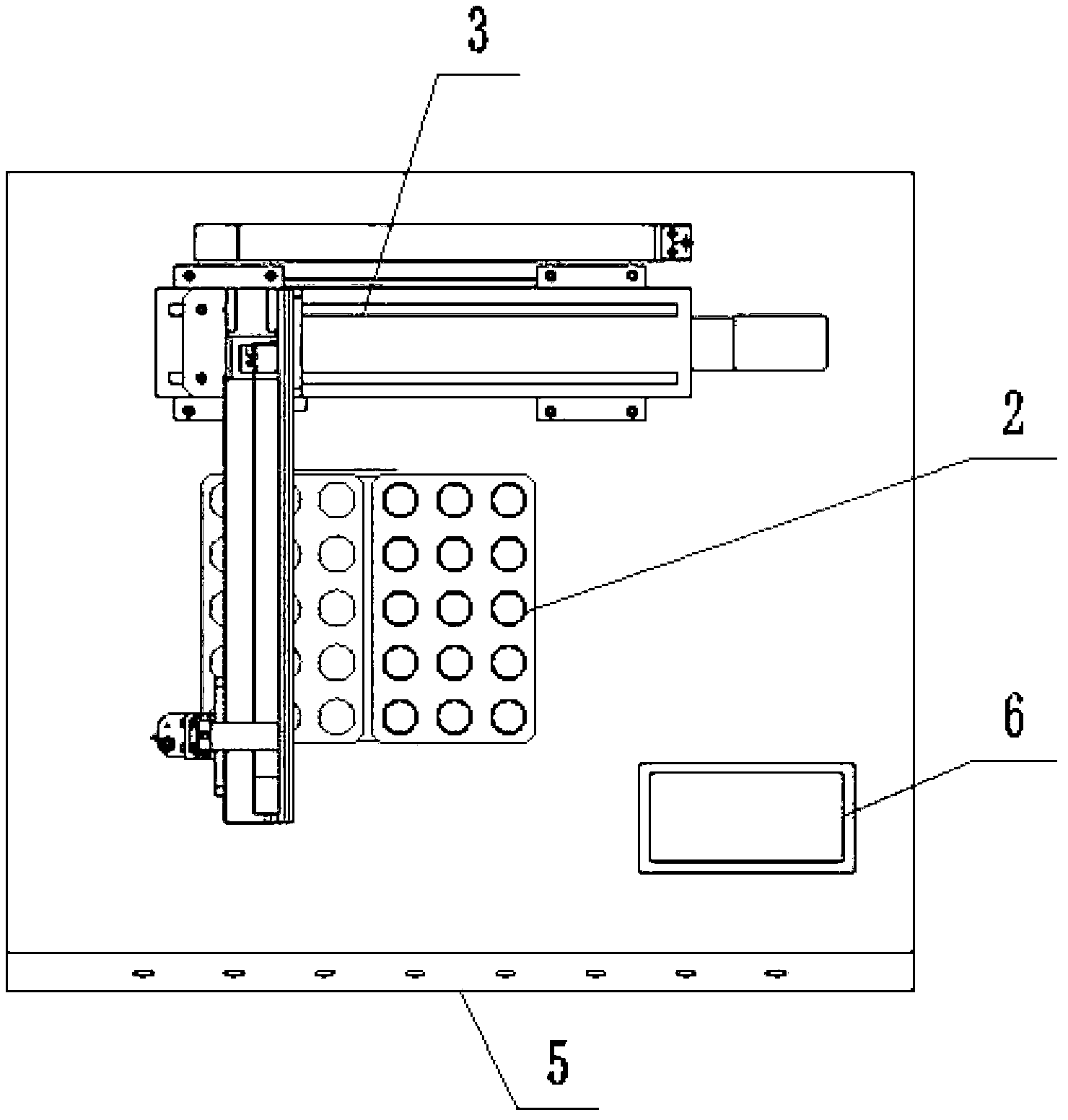

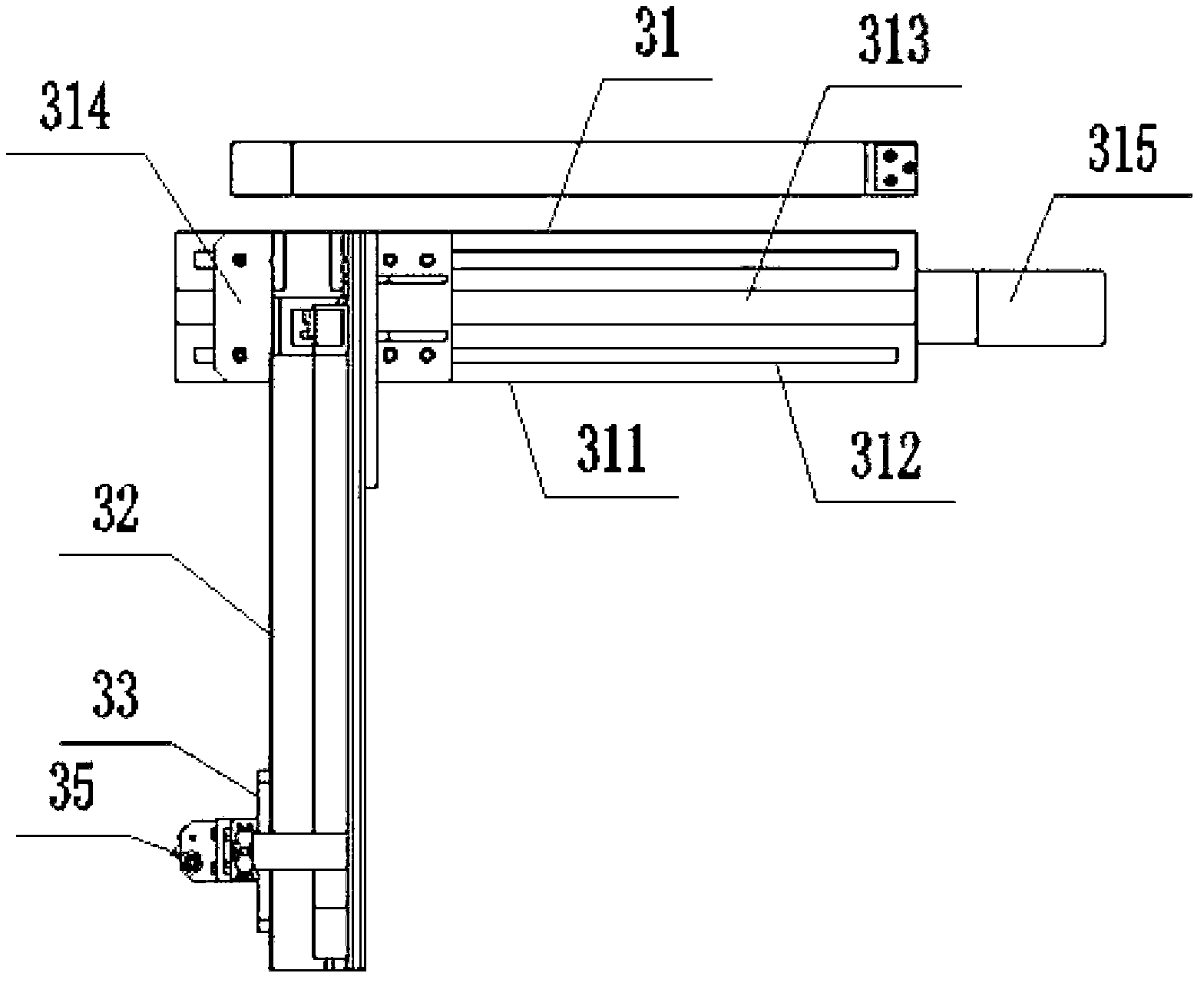

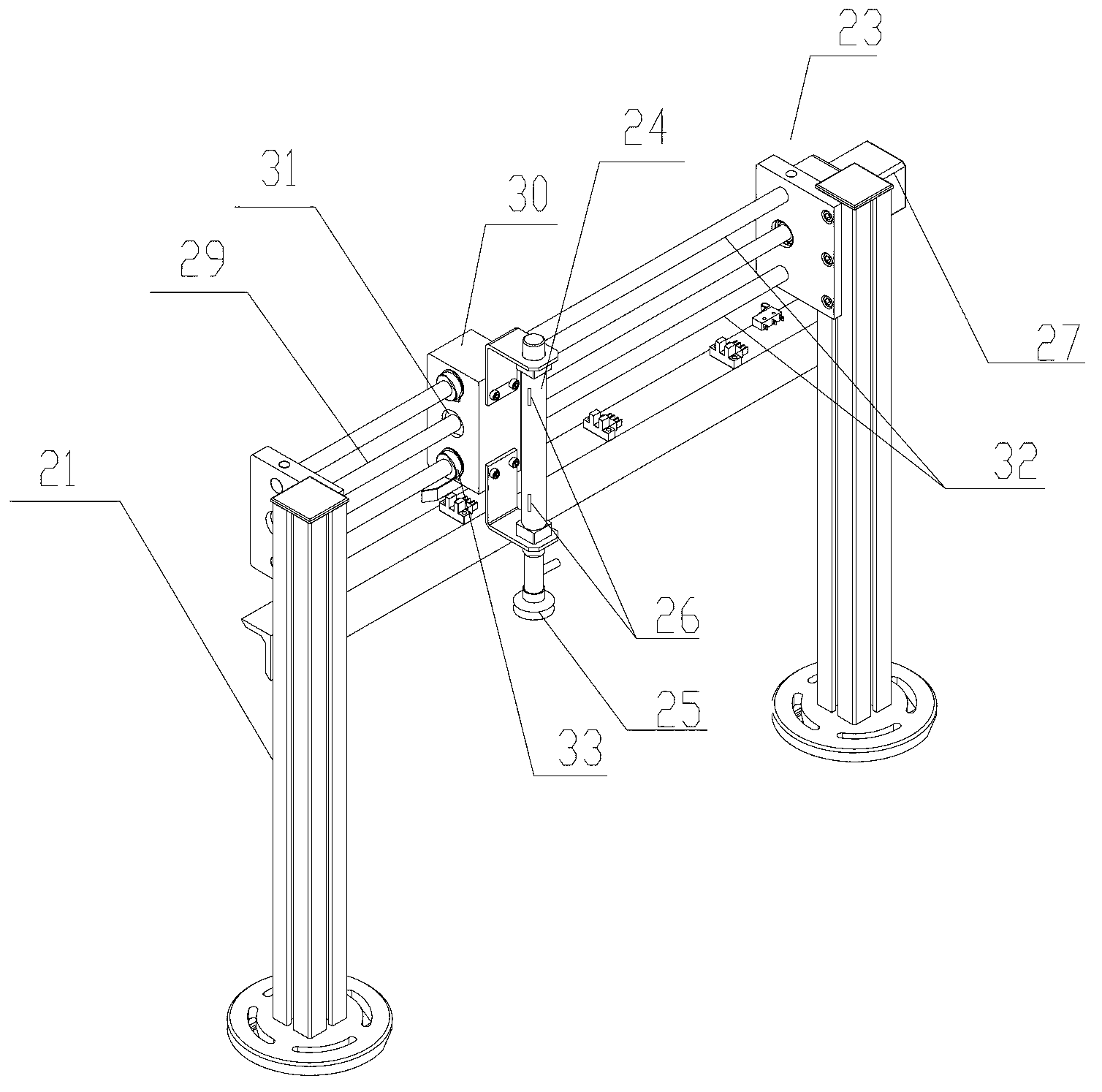

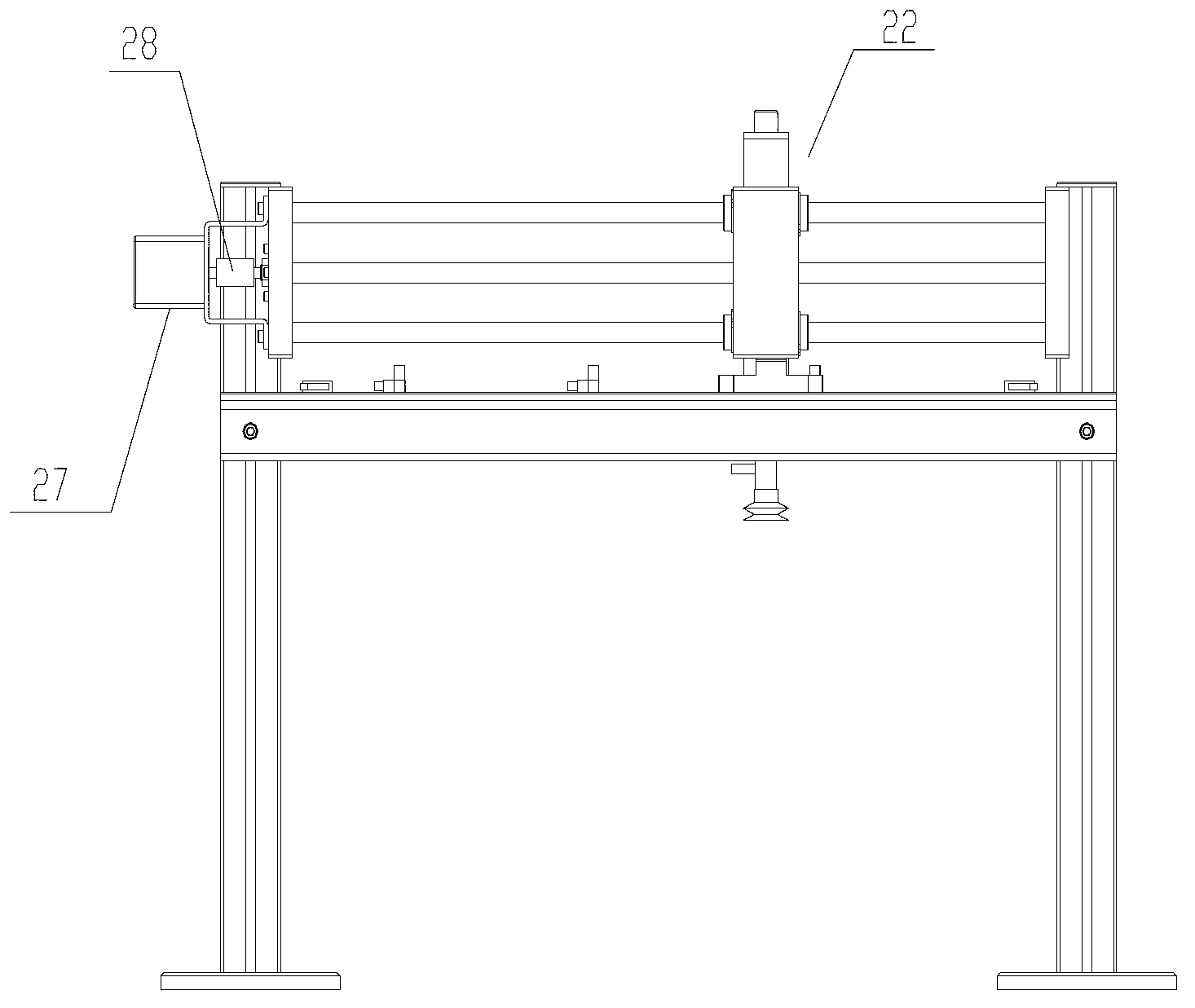

Three-freedom-degree table tennis carrying mechanical arm

InactiveCN103213121AFast assemblyGood debugging effectProgramme-controlled manipulatorGripping headsOrthogonal coordinatesControl system

Owner:JIANGSU HUIBO ROBOTICS TECH CO LTD

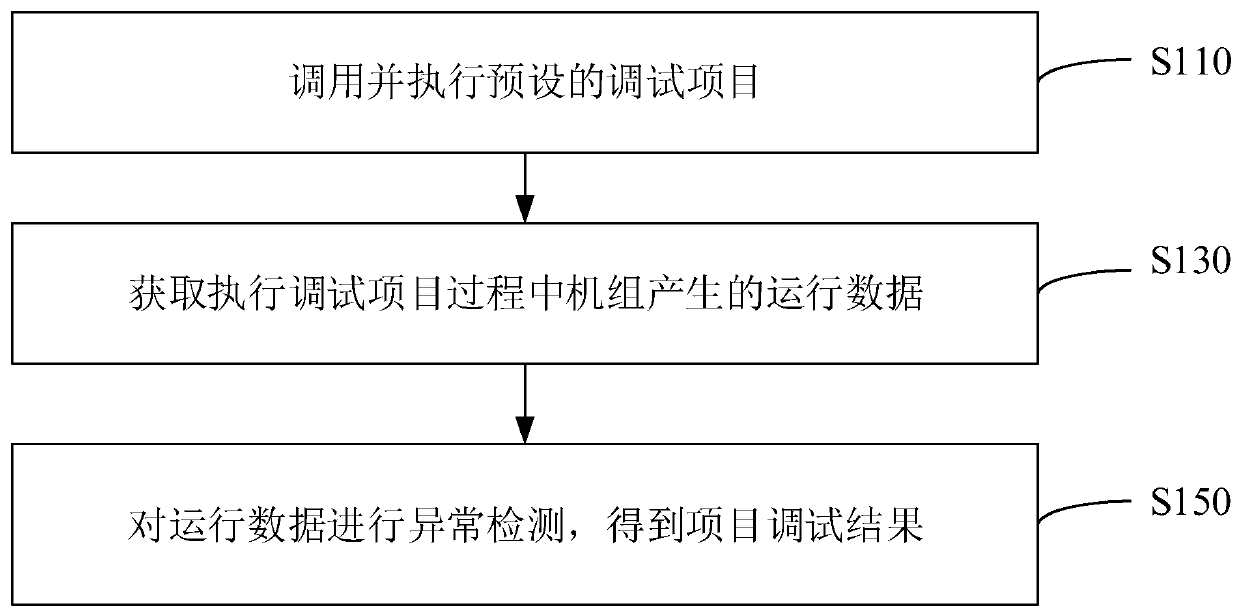

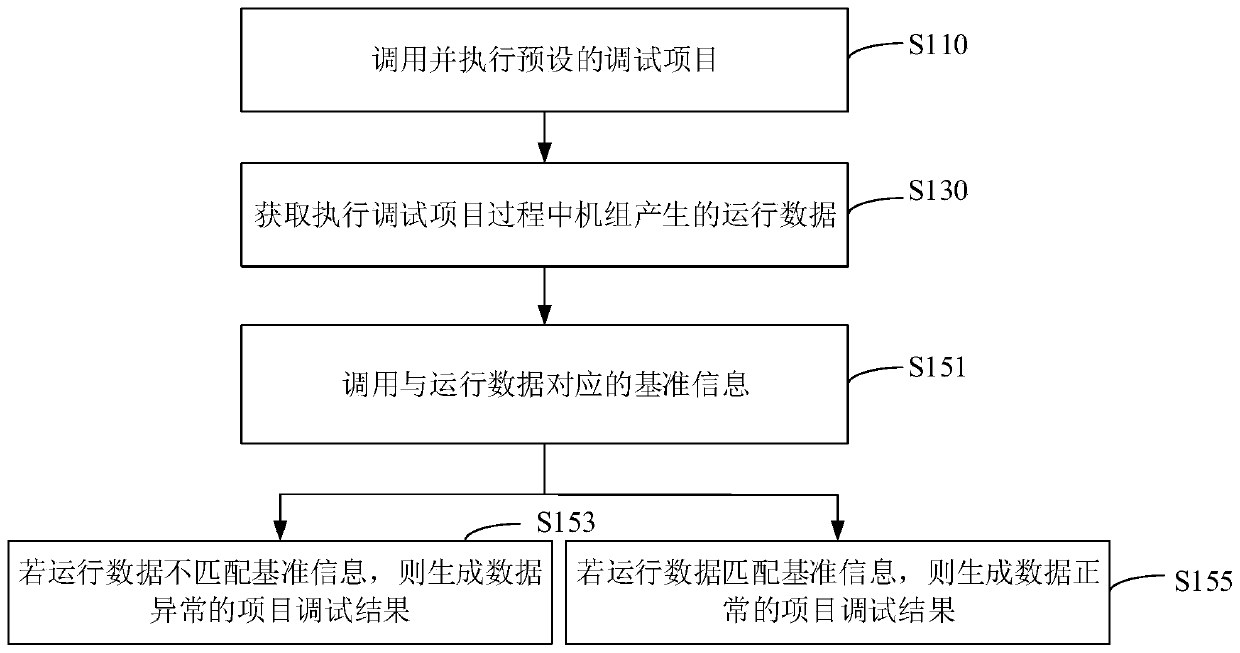

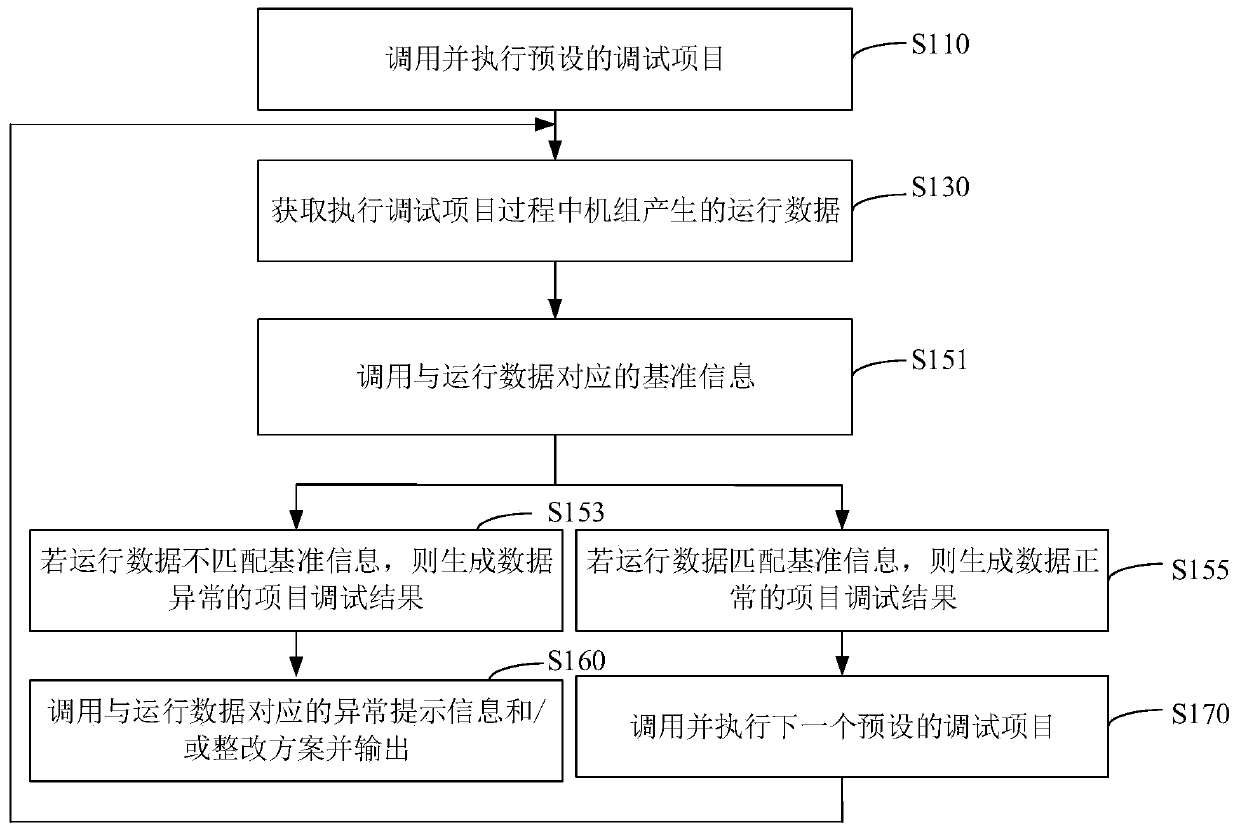

Unit debugging method, device, debugging equipment, medium and air conditioning system

InactiveCN110762769AImprove reliabilityExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsAnomaly detectionSoftware engineering

This application relates to a unit debugging method, a unit debugging device, debugging equipment, a medium and an air conditioning system. The method includes the following steps: invoking and executing a preset debugging item; obtaining operation data generated by the unit in the debugging item execution process; carrying out abnormal detection on the operation data to obtain the debugging result of the item. By adopting this application, the unit can be achieved for automatic debugging and debugging detection without the need of manual debugging, professional requirements for debugging personnel can be reduced, and the impact of manual operation on debugging effect can be reduced, and thus the debugging effect is improved.

Owner:GREE ELECTRIC APPLIANCES INC

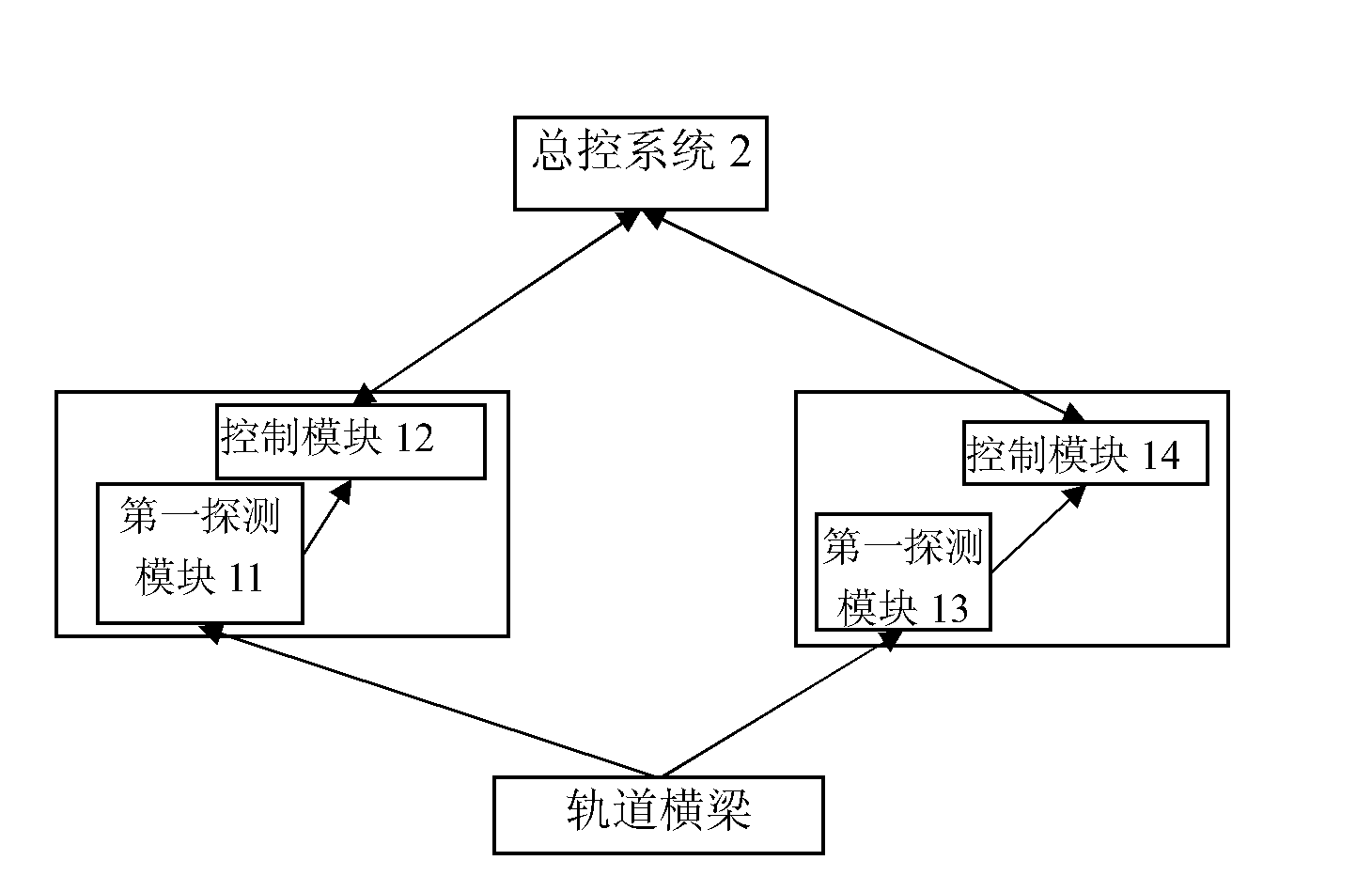

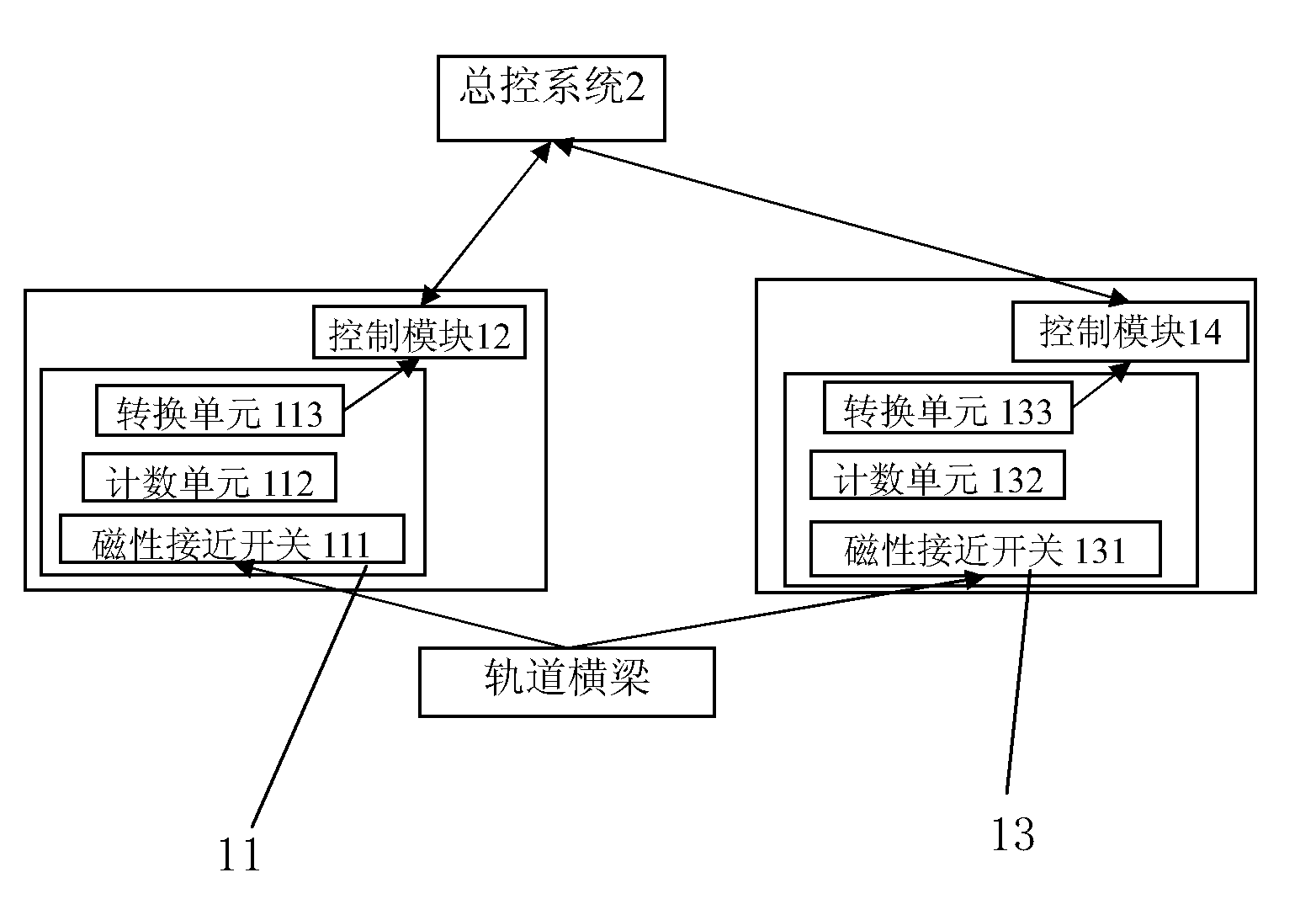

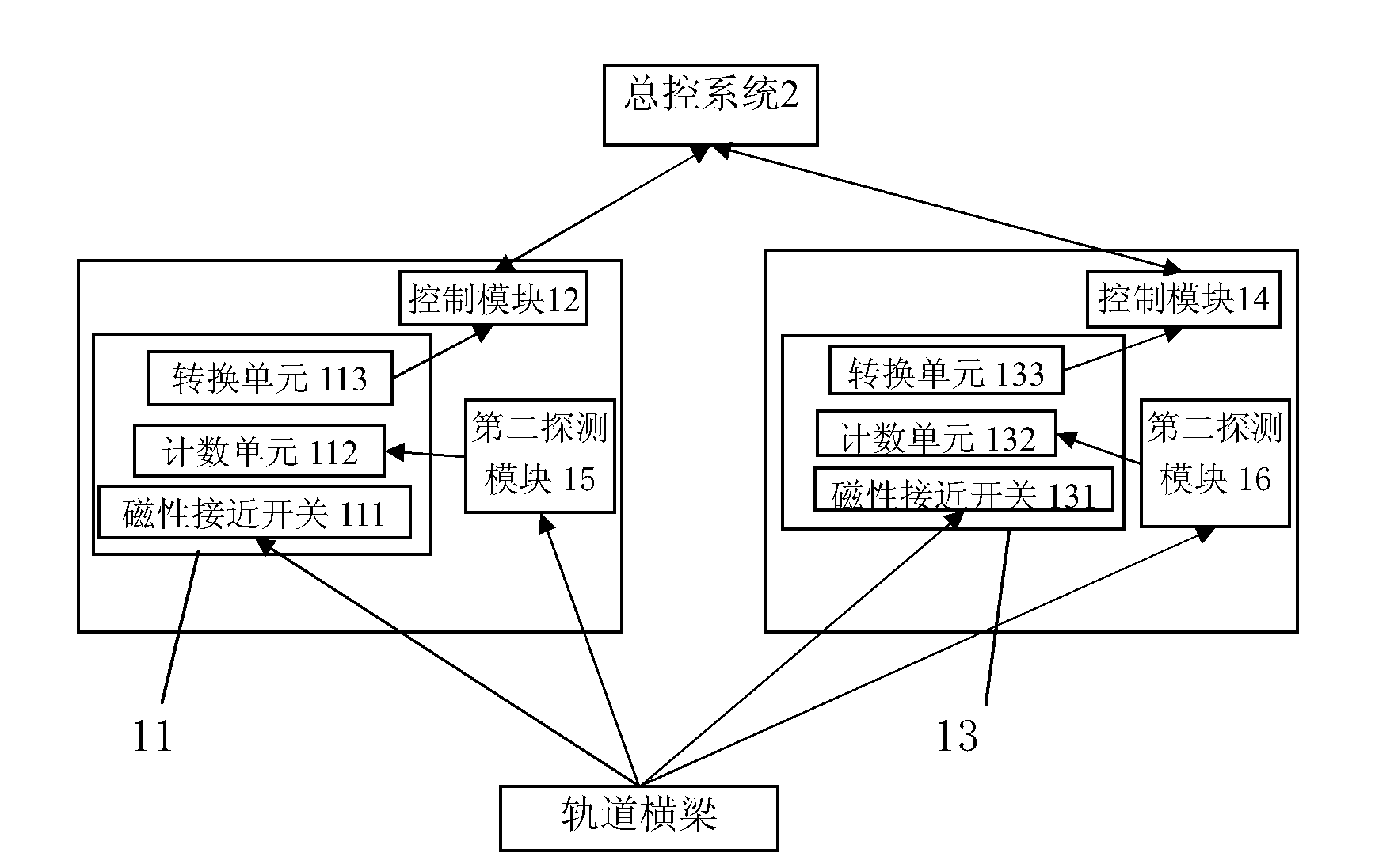

Anti-collision rail car system

ActiveCN102314162AAvoid colliding with each otherGood debugging effectTotal factory controlProgramme total factory controlControl systemEngineering

The invention relates to an anti-collision rail car system, which comprises a plurality of rail cars and a master control system. The rail cars run simultaneously on an independent track, the master control system are used for remotely monitoring the rail cars, the rail cars comprises a first detection module and a control module, the first detection modules are used for obtaining position information of the rail cars through detecting a plurality of crossbeams on the track, and the control modules are used for transmitting the position information to a control system and controlling the rail cars according to feedback of the master control system. The first detection modules can obtain the position information of the rail cars through detecting the number or properties of the crossbeams on the track and comprise a magnetic proximity switch, a counting unit and a conversion unit, the magnetic proximity switches are used for detecting whether the track is provided with the crossbeams, the counting unit is used for calculating the number of the crossbeams according to the ON / OFF states of the magnetic proximity switches, and the conversion units are used for converting counting results of the counting unit into the position information. When the anti-collision rail car system is adopted, multiple cars can run simultaneously on the independent track, dynamic interference and real-time adjustment of the cars can be achieved, and collision of the cars can be avoided.

Owner:SHENZHEN HUANGQIANG CULTURE TECH GROUP

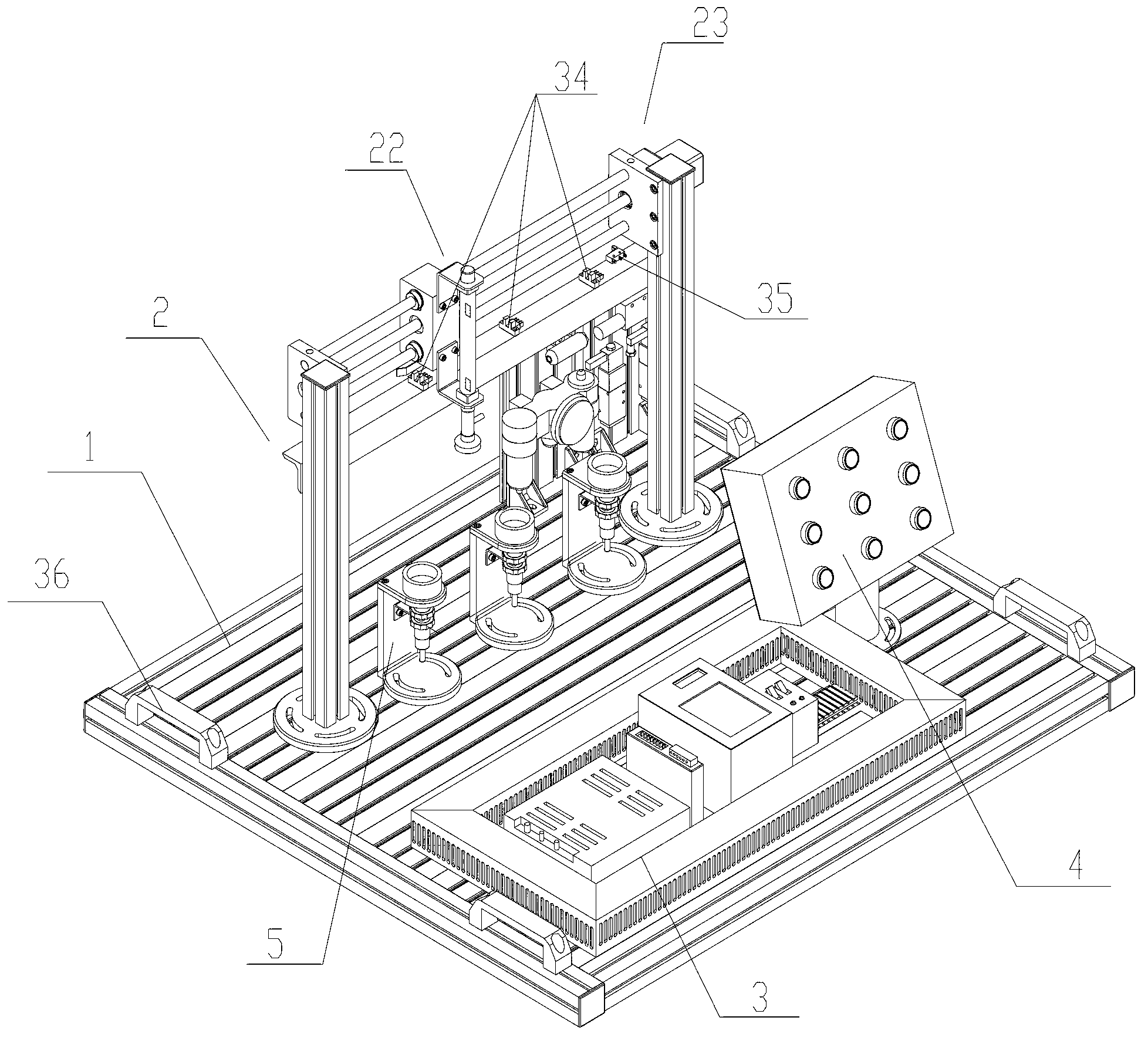

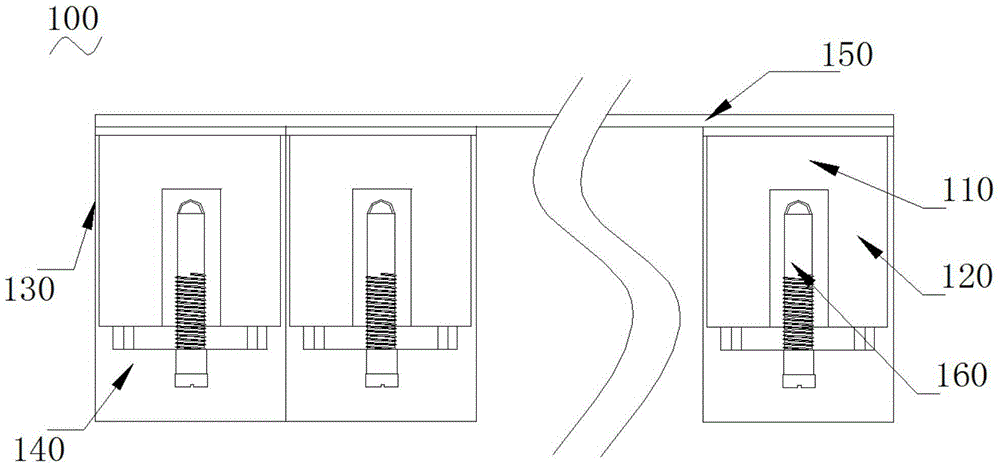

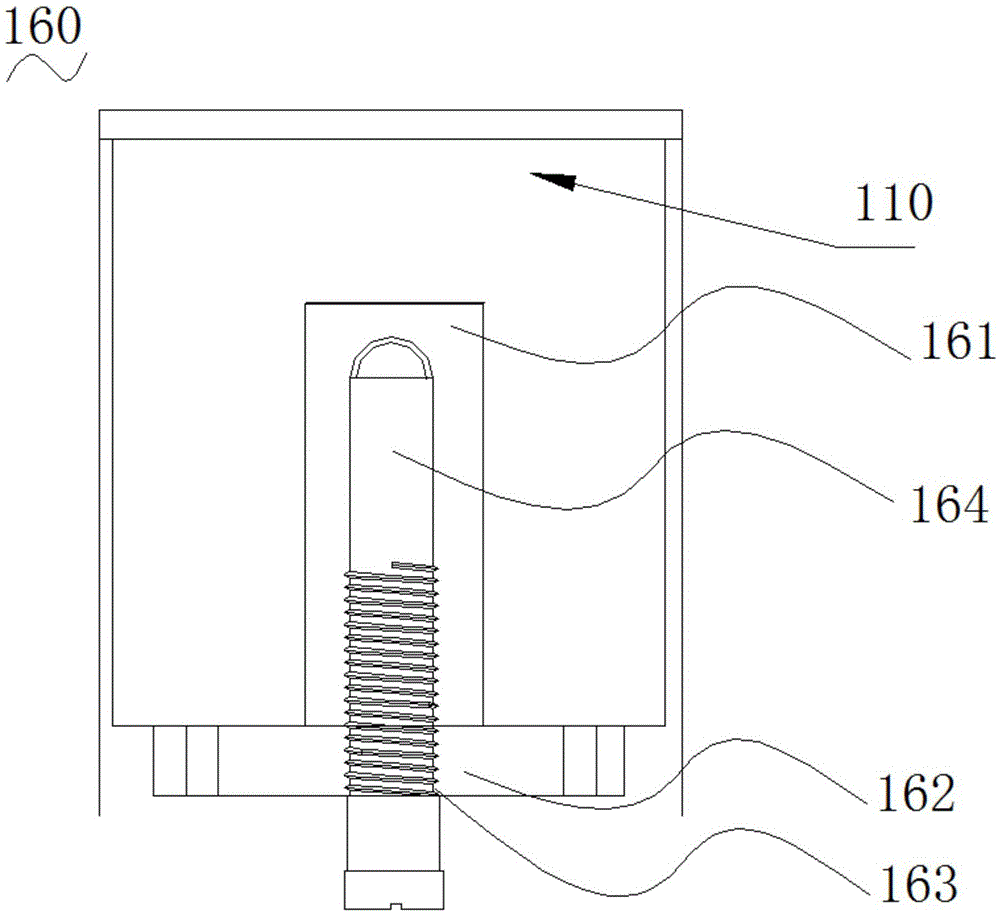

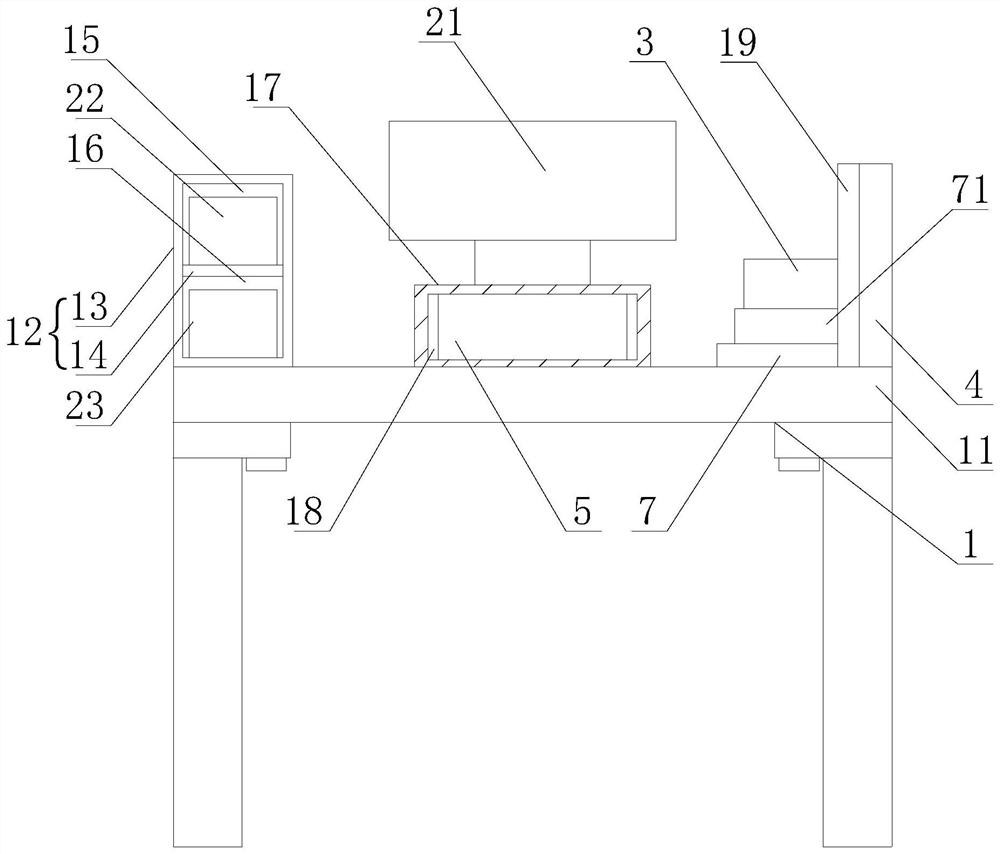

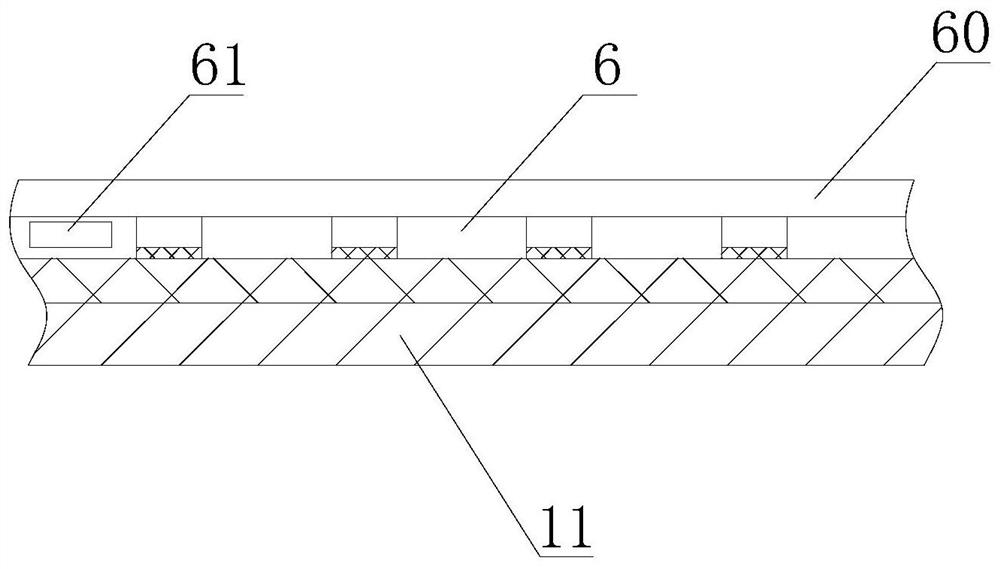

Uniaxial motion control practice training device and feeding and discharging method

ActiveCN103231367AGood pickupFully understand the designProgramme-controlled manipulatorEducational modelsElectricityEngineering

The invention discloses a uniaxial motion control practice training device and a feeding and discharging method. The device comprises an experiment table, a feeding and discharging mechanism, a detecting mechanism used for detecting the position of a sample, and a control mechanism, wherein the detecting mechanism is electrically connected with the control mechanism, brackets used for placing the sample are correspondingly arranged below the feeding and discharging mechanism, and at least two brackets are arranged; and the control mechanism of the device is used for driving a mechanical arm to operate so as to move the sample from the former bracket to the latter bracket, the detecting mechanism is used for facilitating the mechanical arm to conveniently pick up and accurately locate the sample, and the device has the characteristics of simple structure, convenience and flexibility in operation, high reliability, high speed, high precision and low application cost, thereby capable of being used for teaching for a long time without maintenance, facilitating students in fully mastering the working principle of a robot and the selection and design of mechanism components and improving the designing, assembling and debugging capabilities of the students on electromechanical systems.

Owner:SUZHOU UNIV

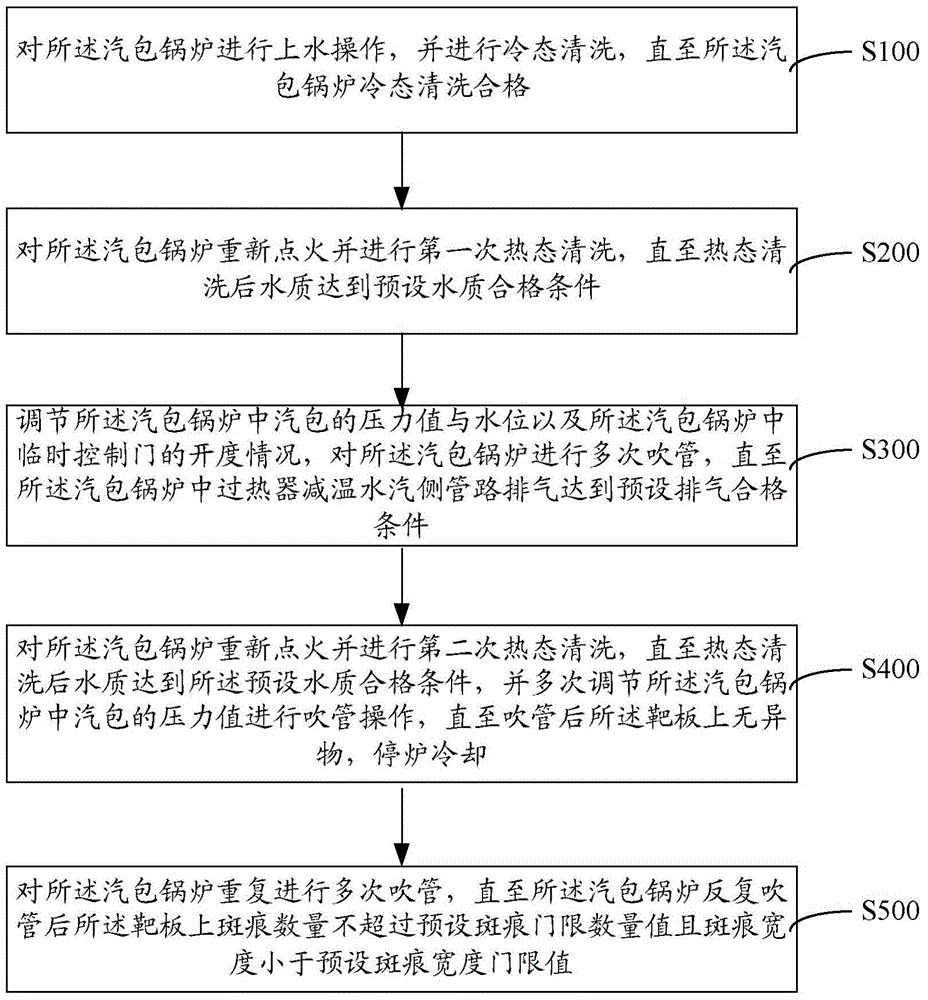

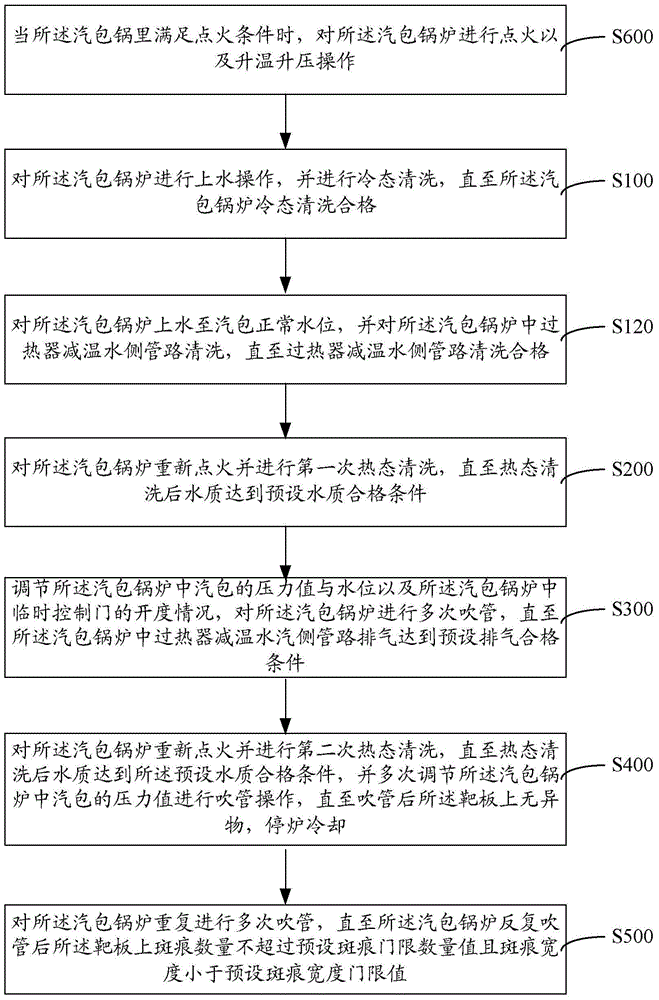

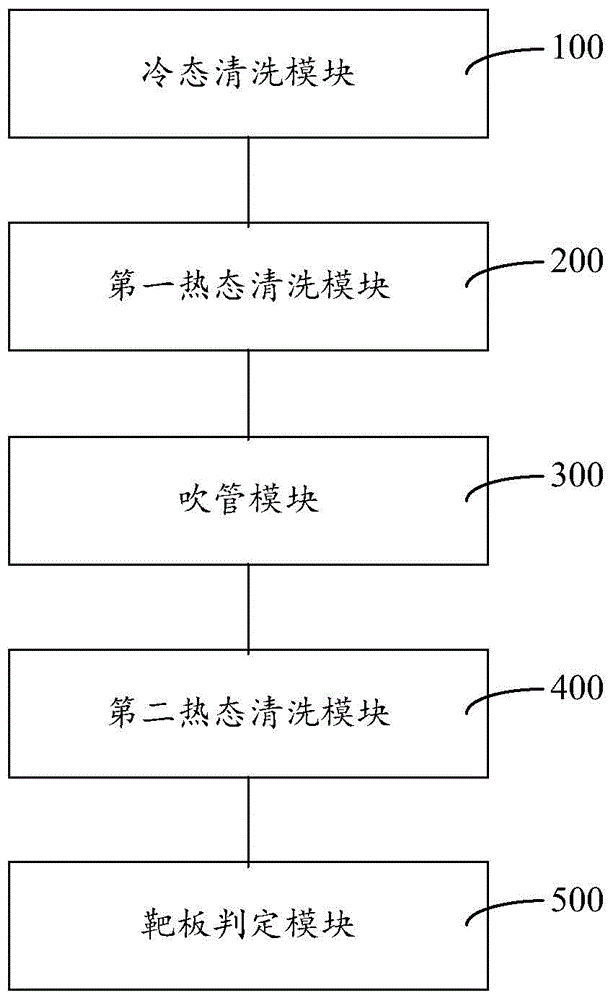

Drum boiler pipe blowing debugging method and system

InactiveCN104896490AGood blowpipe debugging effectGood debugging effectSolid removalWater vaporEngineering

The invention provides a drum boiler pipe blowing debugging method and system. The drum boiler pipe blowing debugging method comprises performing water filling operation and cold state cleaning on a drum boiler; performing first heat state cleaning on the drum boiler; adjusting a pressure value and the water level of a drum in the drum boiler and the opening condition of a temporary control door and performing multiple pipe blowing until the pipeline exhaust of the superheater desuperheating water vapor side meets the preset exhaust qualified conditions; performing second heat state cleaning and performing multiple adjustment on the pressure value of the drum in the drum boiler and performing the pipe blowing operation until a target plate is free of foreign body after the pipe blowing; performing the multiple pipe blowing on the drum boiler repeatedly until the number of blackspots on the target plate does not exceed a number value of the blackspot threshold and the width of every blackspot is smaller than a preset threshold value of the width of every blackspot after the repeated pipe blowing on the drum boiler. According to the drum boiler pipe blowing debugging method and system, guidance and control are performed on the drum boiler pipe blowing debugging process in the integral process and accordingly the good drum boiler pipe blowing debugging effect is implemented and the safe operation of a power generation unit is ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

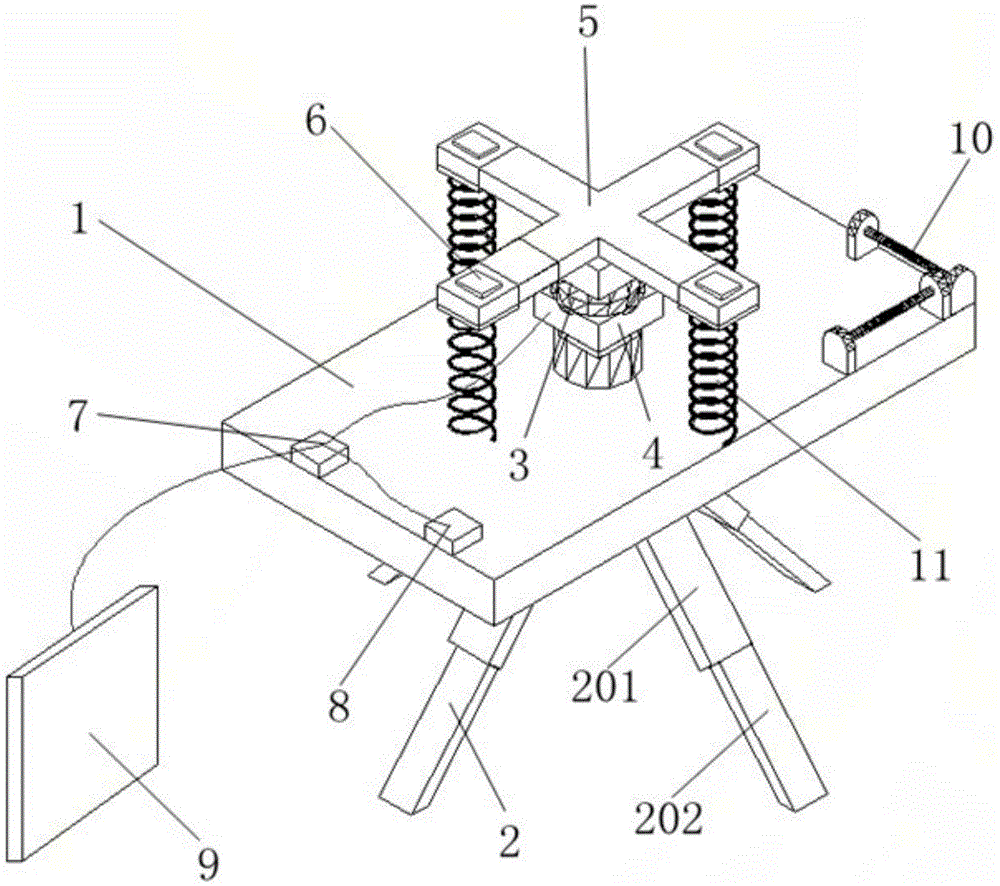

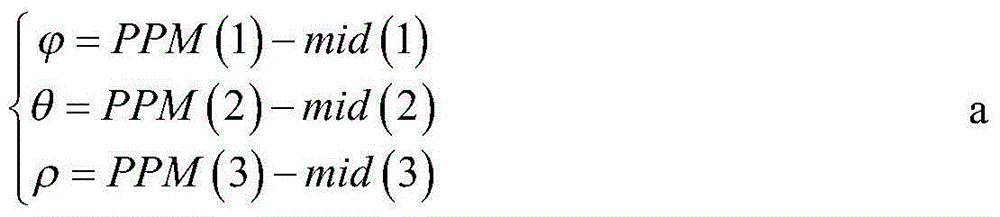

Mechanical failure debugging device for rotor craft

InactiveCN103984339AThe effect of reducing control accuracyHigh control precisionElectric testing/monitoringSurface mountingRemote control

The invention discloses a mechanical failure debugging device for a rotor craft. According to the device, the debugging effect can be improved. The debugging device comprises a base, wherein the base is supported through a telescopic support, a spherical surface cardan joint is installed on the upper surface of the base, an encoder is connected to the spherical surface cardan joint, the spherical surface cardan joint is provided with a moment arm fixing rack, and a pressure sensor is installed on each moment arm. The debugging device further comprises a controlling and processing chip, a remote control signal adaptor and a display device. By the adoption of the debugging device, detection of the direction and distance of each path of signal of a remote controller can be realized, whether a sensor or a rotor wing of the rotor craft works normally can be detected, whether the axis of rotation of the rotor wing is overlarge can be detected preliminarily, further debugging can be conducted on a control system of the craft according to detection results, the influence of mechanical installation errors on rotor craft control accuracy is reduced, and the debugging effect is good. The debugging device is suitable for being popularized and applied in the field of craft debugging equipment.

Owner:SOUTHWEST JIAOTONG UNIV

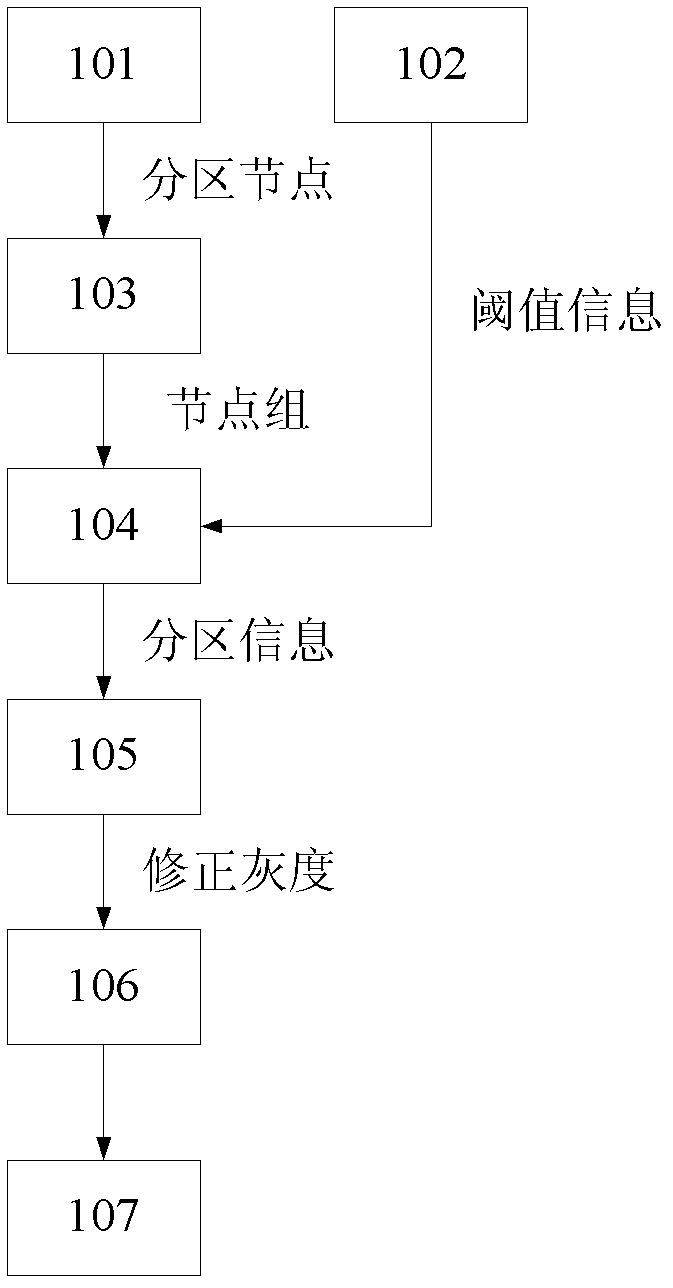

Histogram debugging method of colored image and debugging system thereof

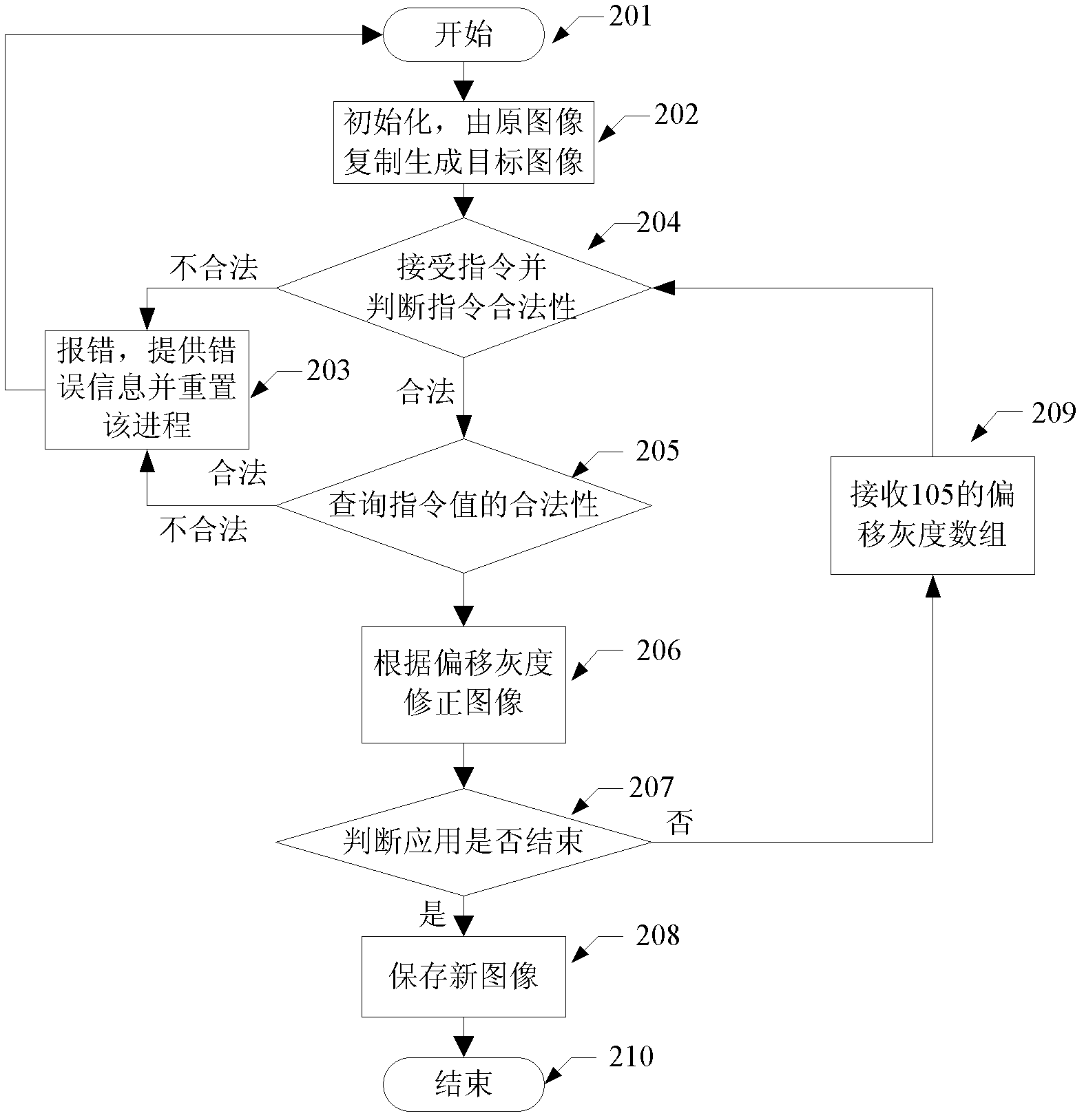

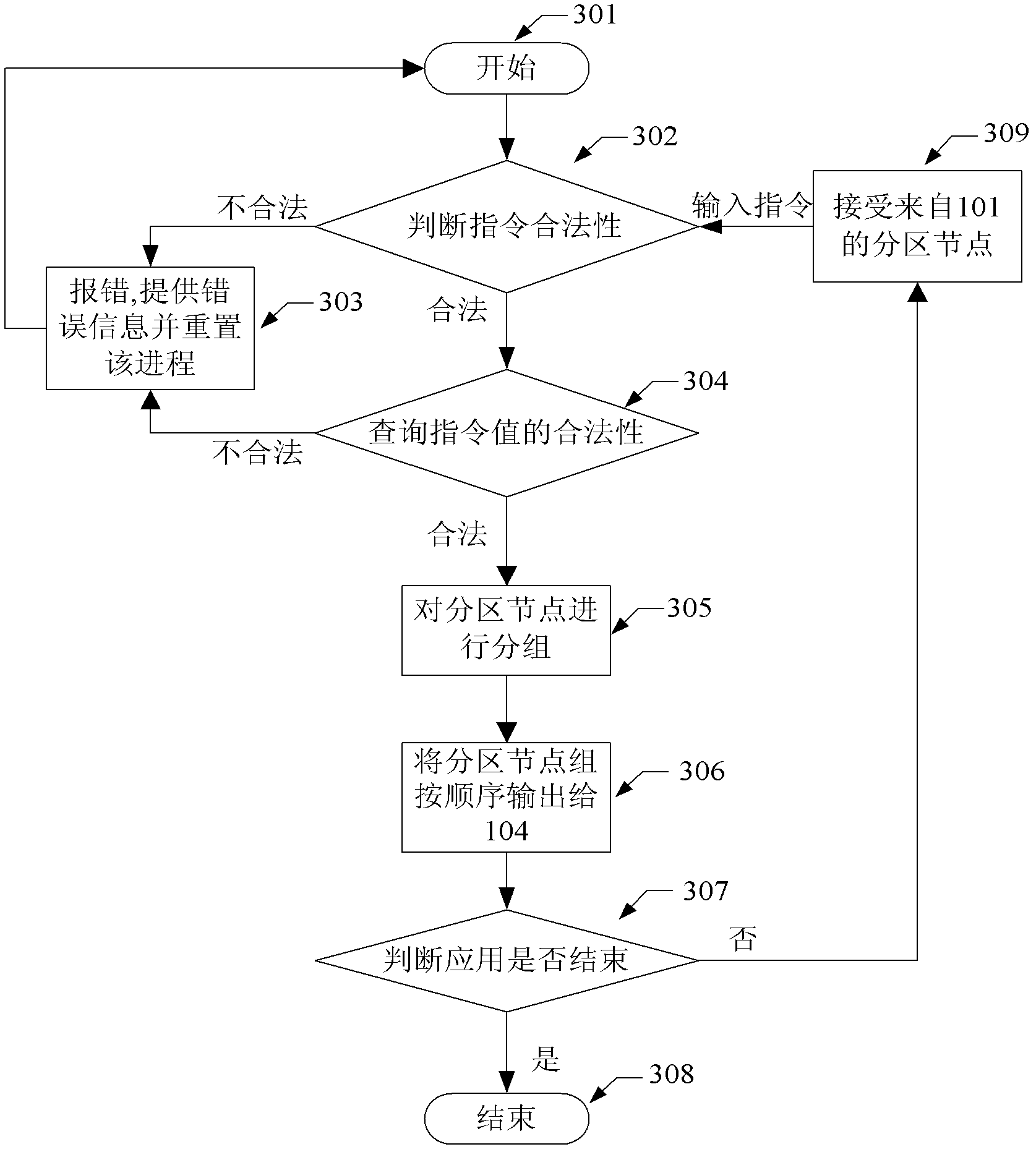

InactiveCN102306380AWith gray equalizationGuaranteed Smooth TransformationImage enhancementRgb imageImage correction

The invention relates to a histogram debugging method of a colored image and a debugging system thereof. According to the method, subarea nodes and subarea thresholds of a histogram of a colored image are arranged; according to an obtained node group with the thresholds, weighted translation calculation is carried out on each gray scale to obtain offset gray scales; and then each the gray scale of the colored image is replaced into each the offset gray scale. In addition, the system comprises a subarea node module, a subarea threshold module, a histogram subarea module, a threshold setting module, a gray scale transformation module and an image correction module. According to the invention, the following advantages are provided: novel functions, simple realization, low cost, and obvious debugging effect and the like. Moreover, according to the invention, a histogram is utilized to realize debugging on RGB image gray scale by a user. Therefore, a limitation on a gray scale debugging function of preset software can be broken through and furthermore, the user can set a random interval of a histogram of an image and a random threshold in the interval according to own needs of the user, thereby embodying strong interactivity, flexibility and generality. Therefore, the invention has a wide application prospect.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Bottom-debugging cavity filter

InactiveCN105552495AEasy to processGood debugging effectWaveguide type devicesEngineeringElectrical conductor

Owner:李登峰

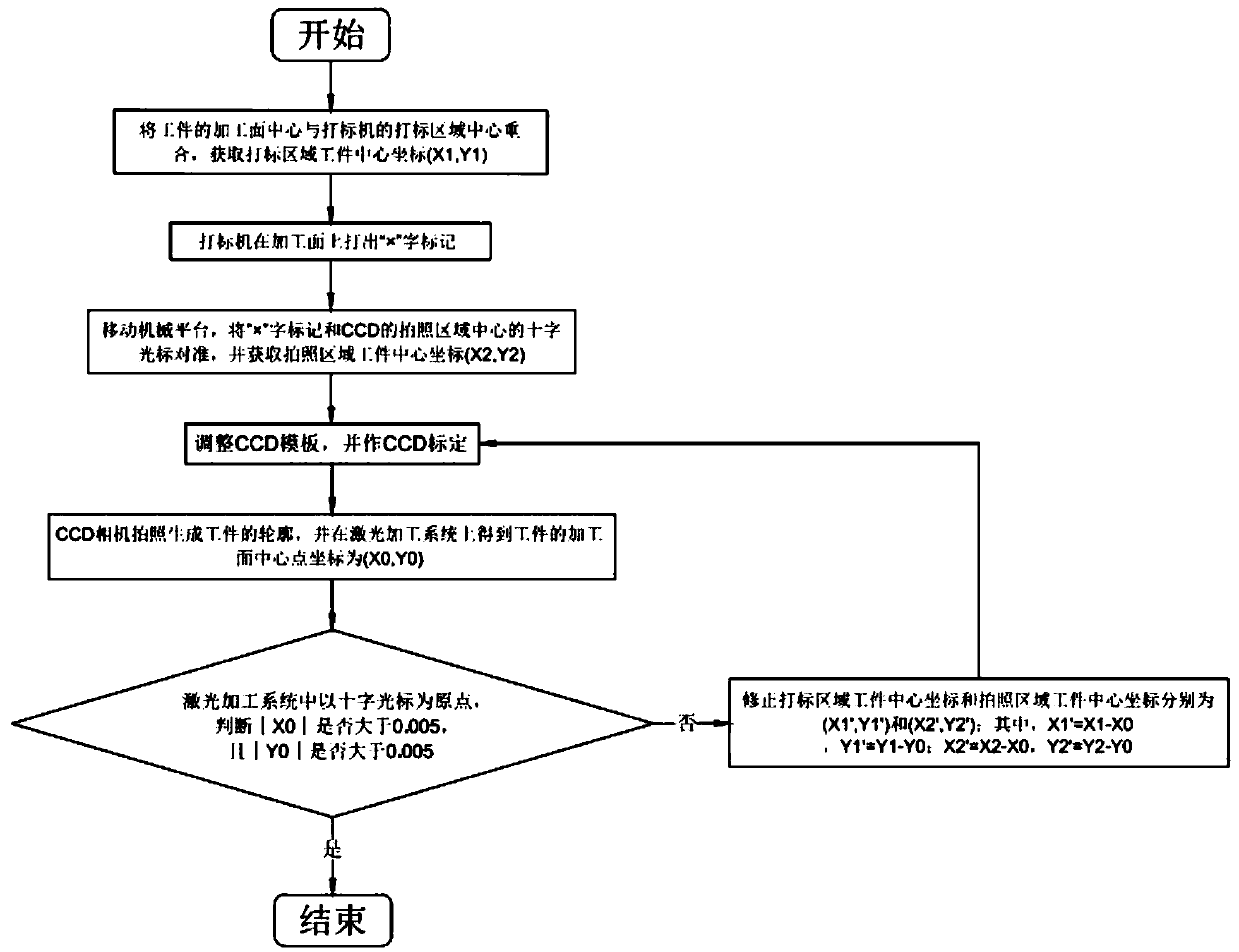

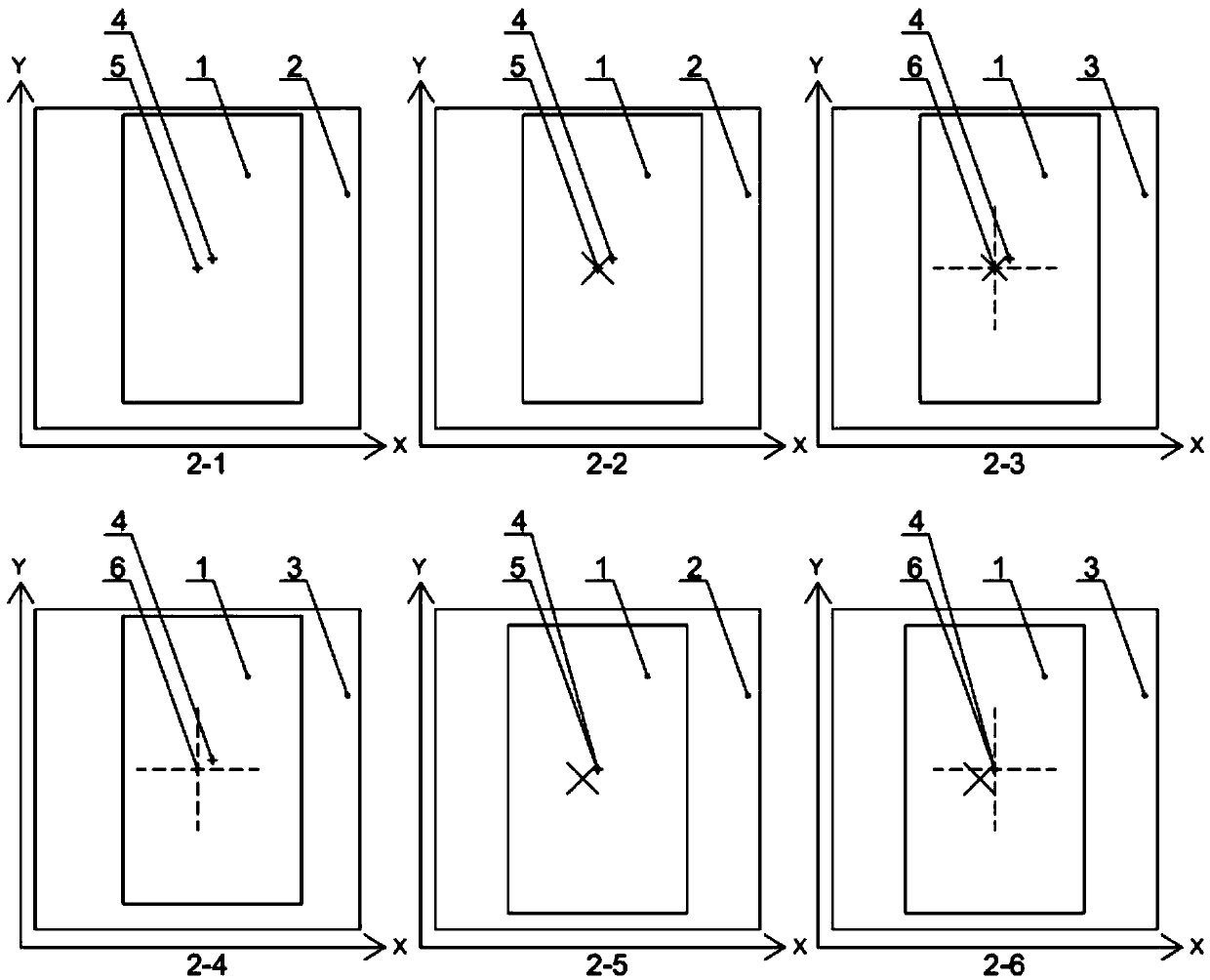

Method for improving debugging precision of laser marking system

InactiveCN109570749AHigh precisionGood debugging effectLaser beam welding apparatusLaser processingComputer science

The invention relates to the field of laser processing, in particular to a method for improving the debugging precision of a laser marking system. The method for improving the debugging precision of the laser marking system is used for laser marking equipment needing for large-format high-precision processing. The method for improving the debugging precision of the laser marking system comprises the steps that the processing surface center is coincident with a marking area center, an x mark is coincident with a cross cursor of the CCD photographed area center, and coarse standardization of a marking area workpiece center coordinate and a photographed area workpiece center coordinate; and then, a center point coincident of the coarse standardization and a cross cursor original point in a laser processing system are judged and fed back to be optimized back and forth, so that a processing surface center point is located at a center point of laser processing and image collecting, the situation of improving the processing effect of the edge position of a workpiece being consistent with the center position is facilitated, reduction of negative effects of lens distortion on processing precision is further facilitated, the precision of CCD collected images is improved, careful debugging of engineers does not depended on, and the debugging effect and efficiency are improved.

Owner:HANS LASER TECH IND GRP CO LTD

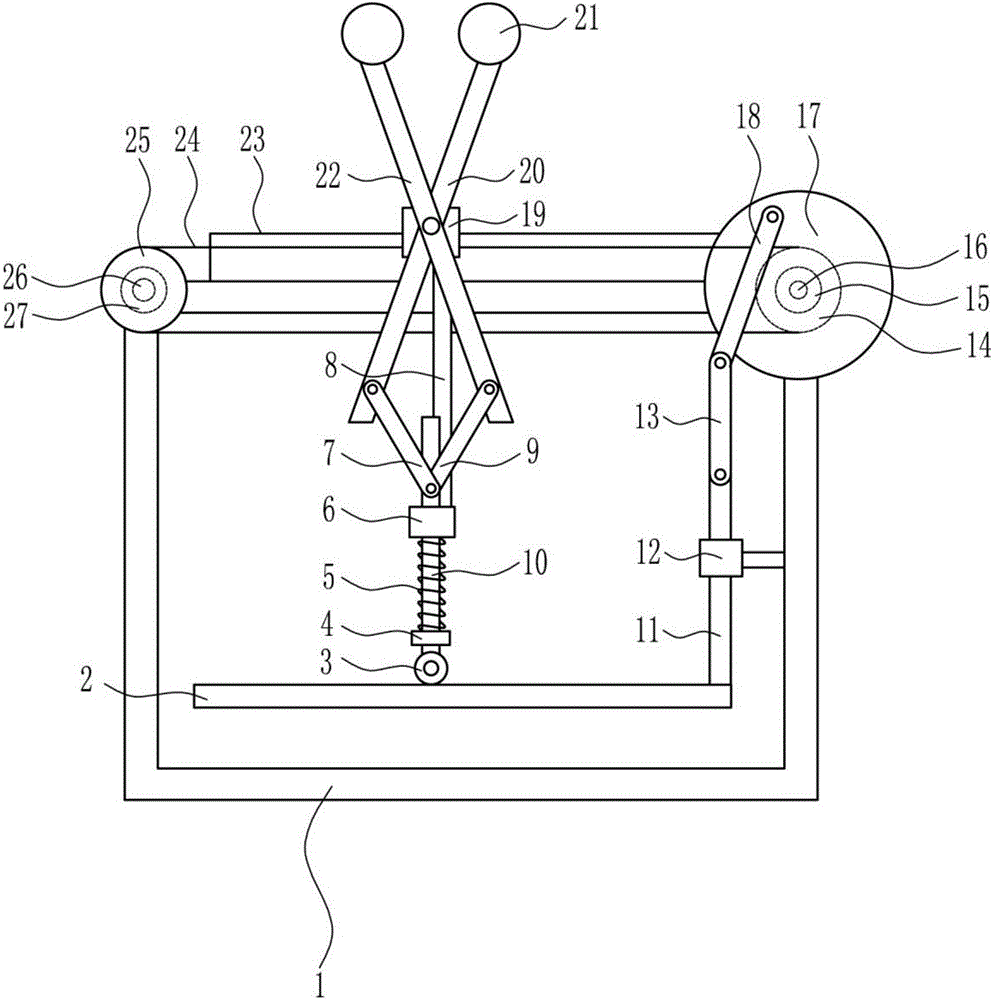

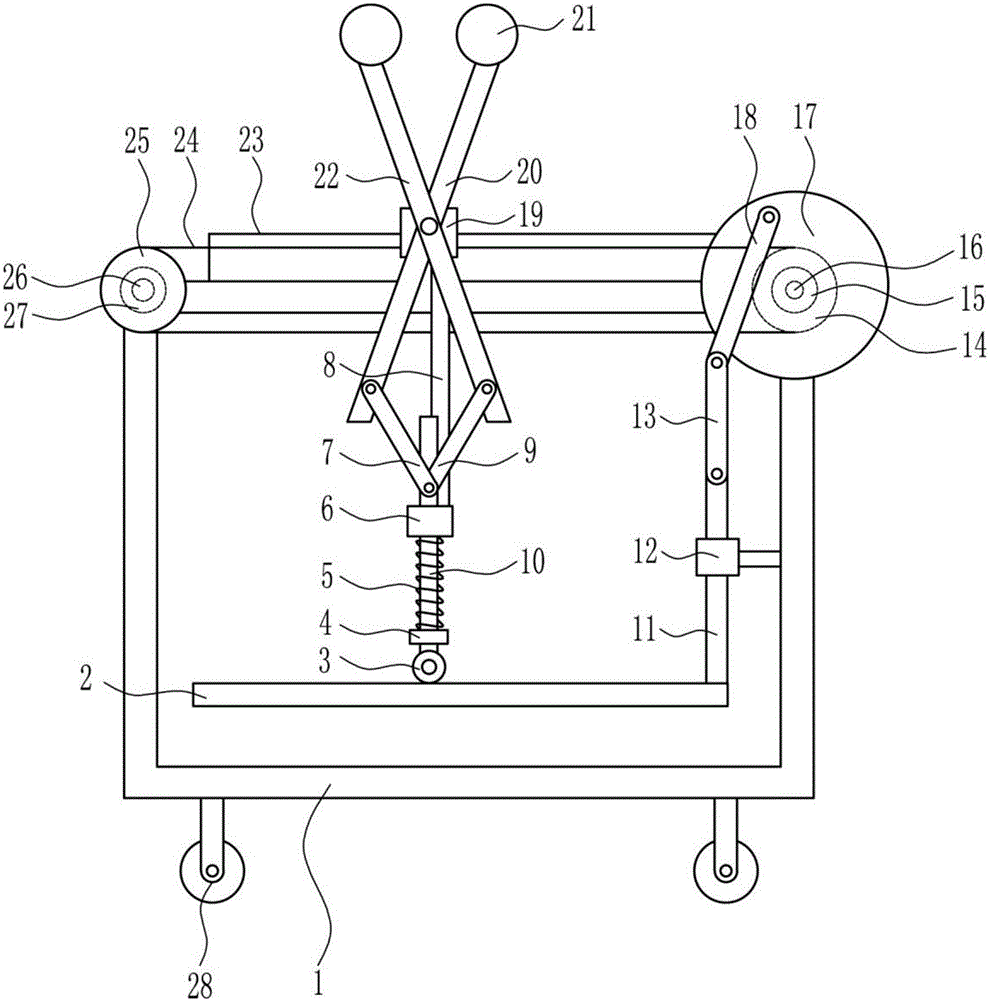

Auxiliary water spraying equipment for fire protection

The invention relates to water spraying equipment, in particular to auxiliary water spraying equipment for fire protection. The auxiliary water spraying equipment for fire protection aims at achieving the technical effects of being large in spraying range, high in reliability and good in adjusting performance. In order to achieve the technical effects, the auxiliary water spraying equipment for fire protection is provided and comprises a fixing frame, an installation plate, rolling wheels, a fixing check block, a first spring, a first guide rail, a first connection rod, a first fixing rod, a second connection rod, a first lifting rod and the like. A second guide rail is arranged in the middle on the right wall inside the fixing frame. A second lifting rod is arranged in the second guide rail. The installation plate is arranged at the bottom of the second lifting rod. The top of the second lifting rod is rotationally connected with a third connection rod. The auxiliary water spraying equipment achieves the effects of being high in reliability and good in adjusting performance, can better assist firemen in work and reduce the labor intensity of firemen, is safe and reliable to use and convenient to maintain, and improves working efficiency.

Owner:日照鑫锐安全设备有限公司

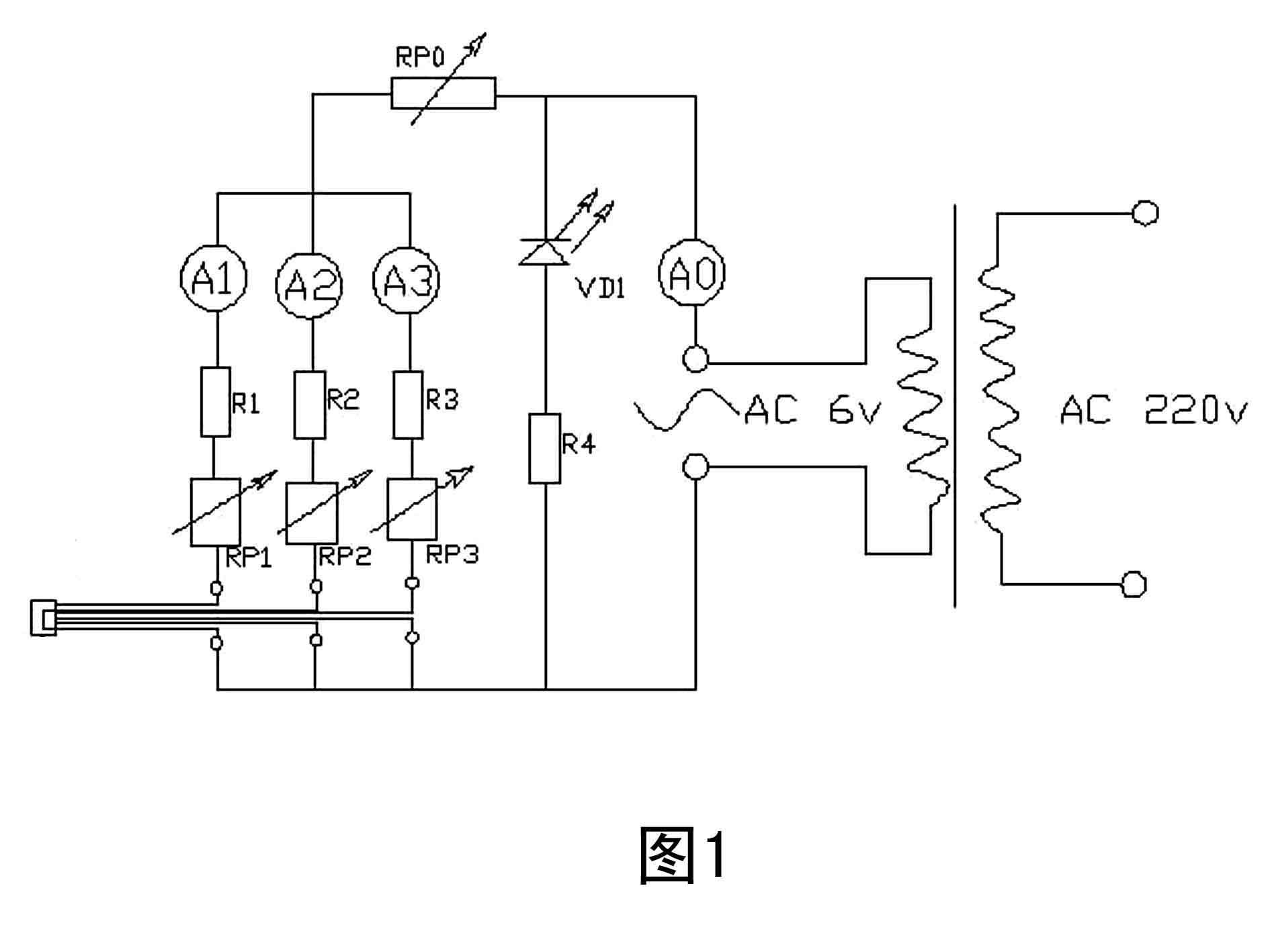

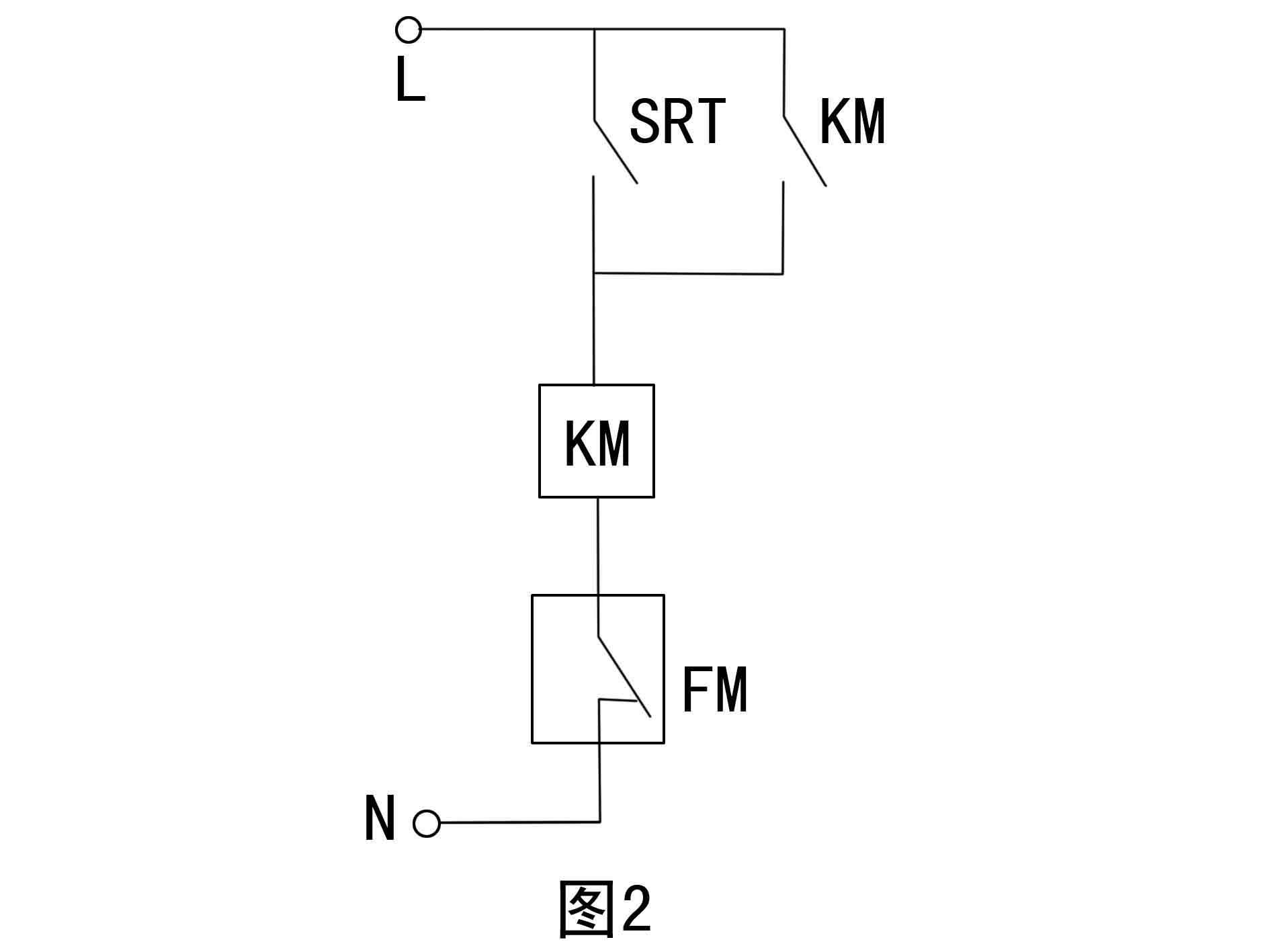

Small current generator

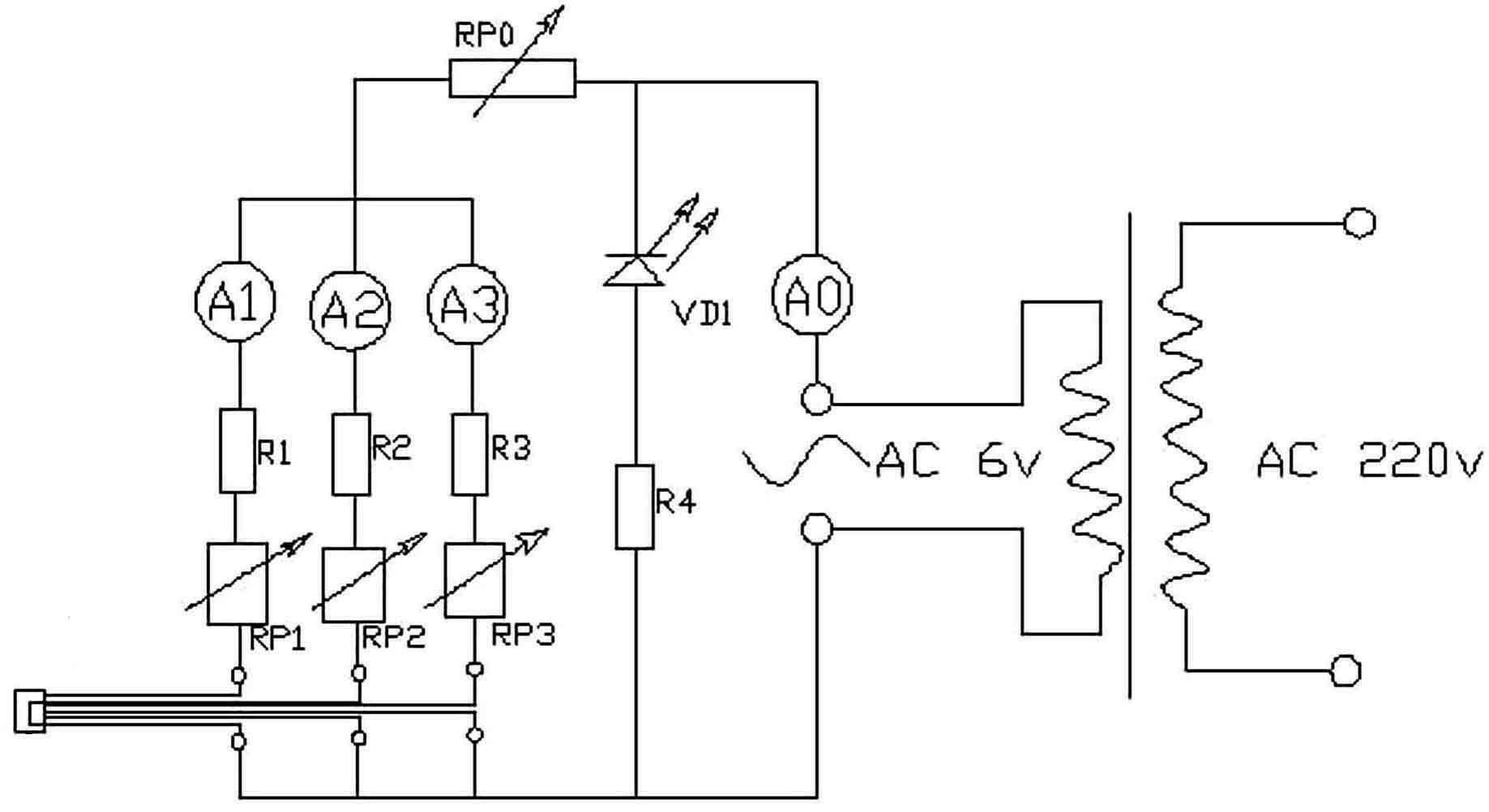

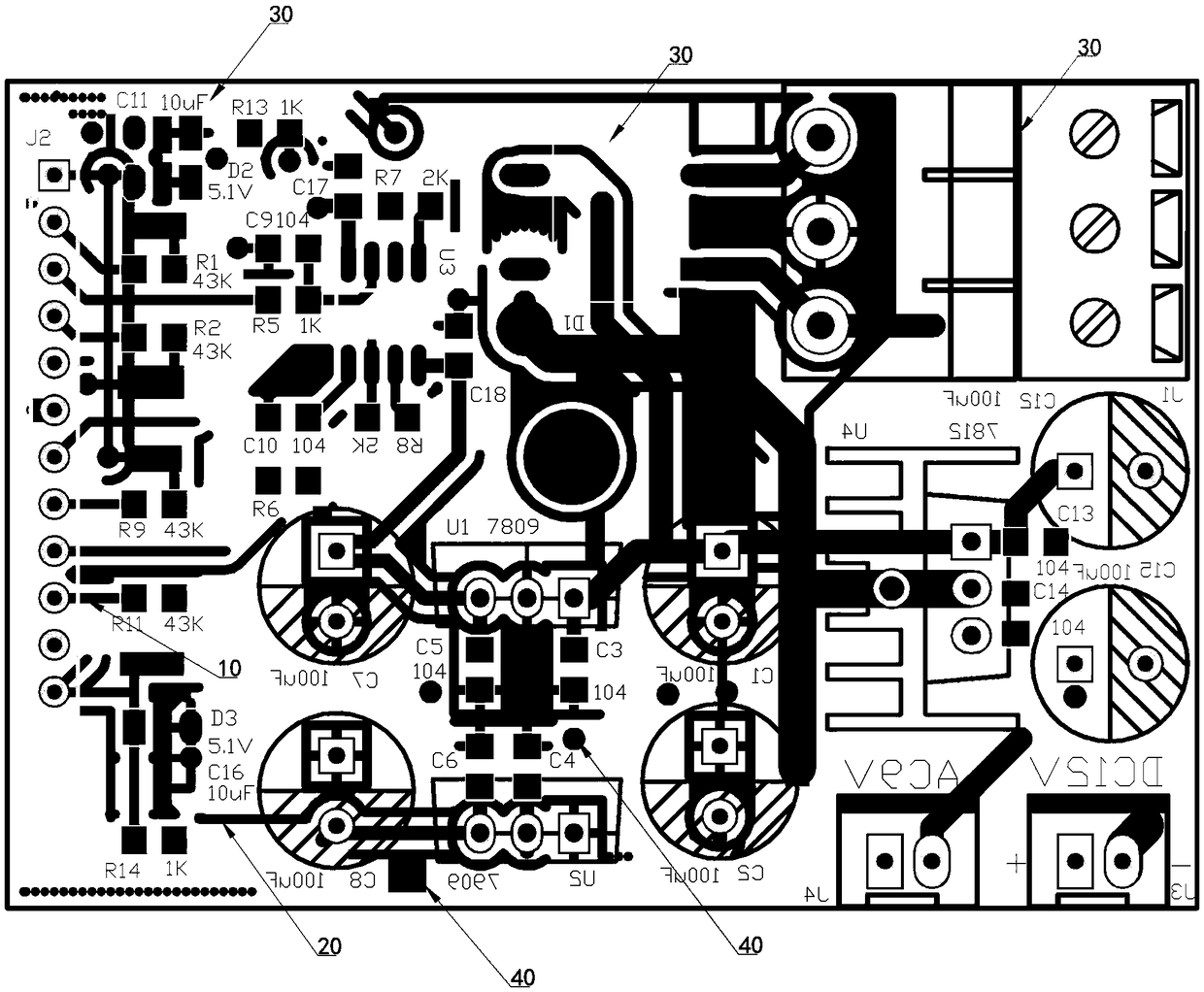

InactiveCN102495249AReduce volumeEasy to operateElectrical measurement instrument detailsDynamo-electric machine testingCurrent meterPower flow

The invention discloses a small current generator. A branch circuit consisting of a current meter A1, a resistor R1 and an adjustable potentiometer RP1 which are connected in series with one another, a branch circuit consisting of a current meter A2, a resistor R2 and an adjustable potentiometer RP2 which are connected in series with one another and a branch circuit consisting of a current meter A3, a resistor R3 and an adjustable potentiometer RP3 which are connected in series with one another are connected in parallel with one another to form a parallel branch circuit; a branch circuit consisting of the parallel branch circuit and an adjustable potentiometer RP4 which are connected in series with each other and a branch circuit consisting of a light emitting diode VD1 and a resistor R4 which are connected in series with each other are connected in parallel with each other; one end of the output end of a transformer is connected with a current meter A0, and the other end of the output end of the transformer is connected with one end of the resistor R4, which is not connected with the light emitting diode VD1; the other end of the output end of the transformer is connected to three interfaces on the lower row of a network interface RJ45; three interfaces on the upper row of the network interface RJ45 are connected to the interfaces of the adjustable potentiometers RP1, RP2 and RP3, which are not connected with the resistors R1, R2 and R3 respectively; and the output end of the network interface RJ45 outputs small current. The small current generator is small in debugging current, simple in wire connection operation, high in safety reliability, short in working time, and low in cost, and is convenient to construct.

Owner:THE THIRD CONSTR CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Grinder tool machine analytic system

The invention discloses a grinder machine tool analysis system comprising: a grinder structural characteristic analysis unit for analyzing the grinder structural characteristic; a grinder structural design unit for the grinder structural design unit The structure of the grinding machine is designed; the feed mechanism analysis unit is used to analyze the feed mechanism of the grinder; the friction slide analysis unit is used to analyze the workbench and slide The friction force between the rails realizes the reasonable system design, the comprehensive analysis and debugging of the grinding machine, the efficiency is high, and the debugging effect is good, which improves the technical effect of the precision, reliability and stability of the grinding machine.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

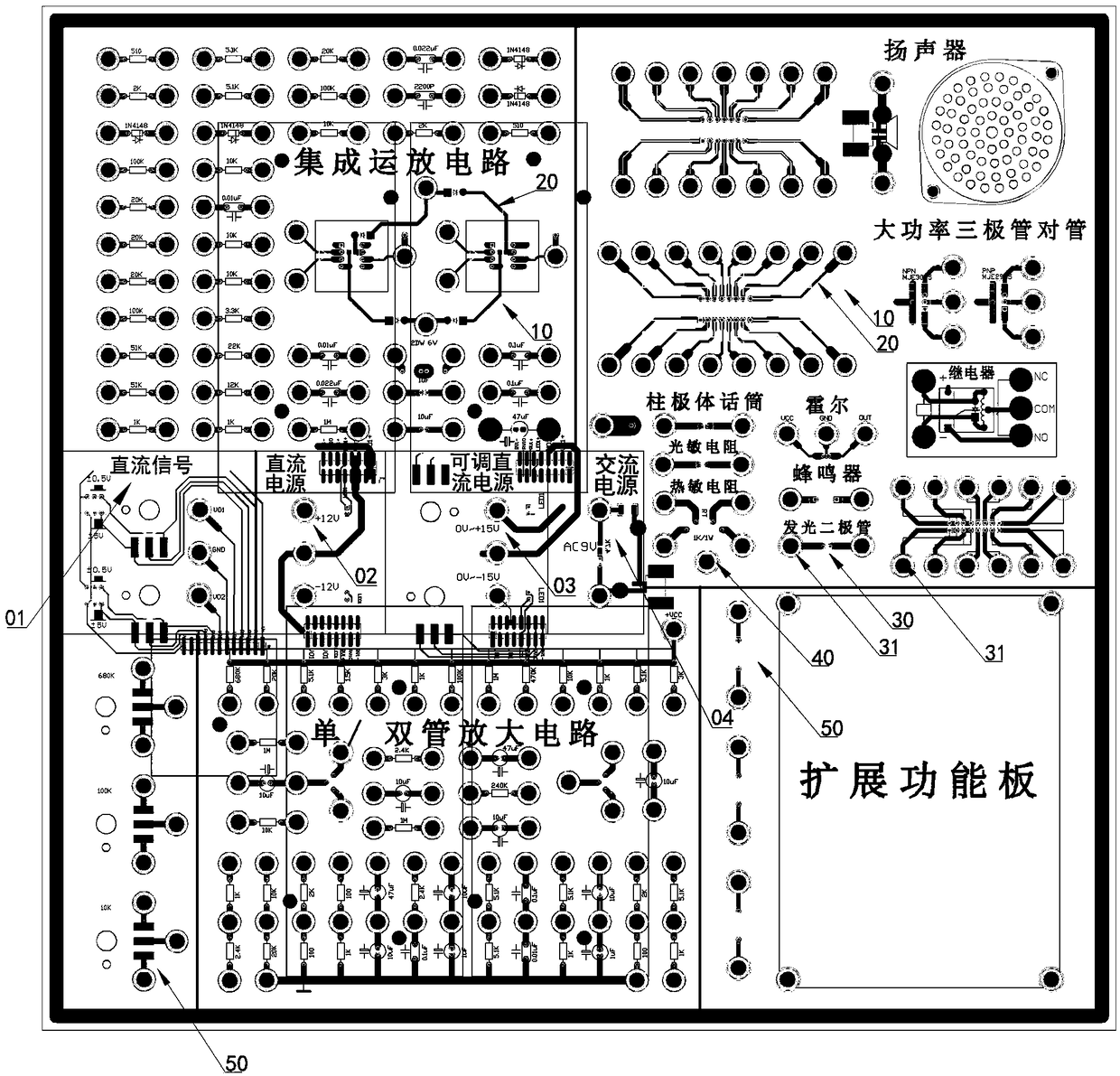

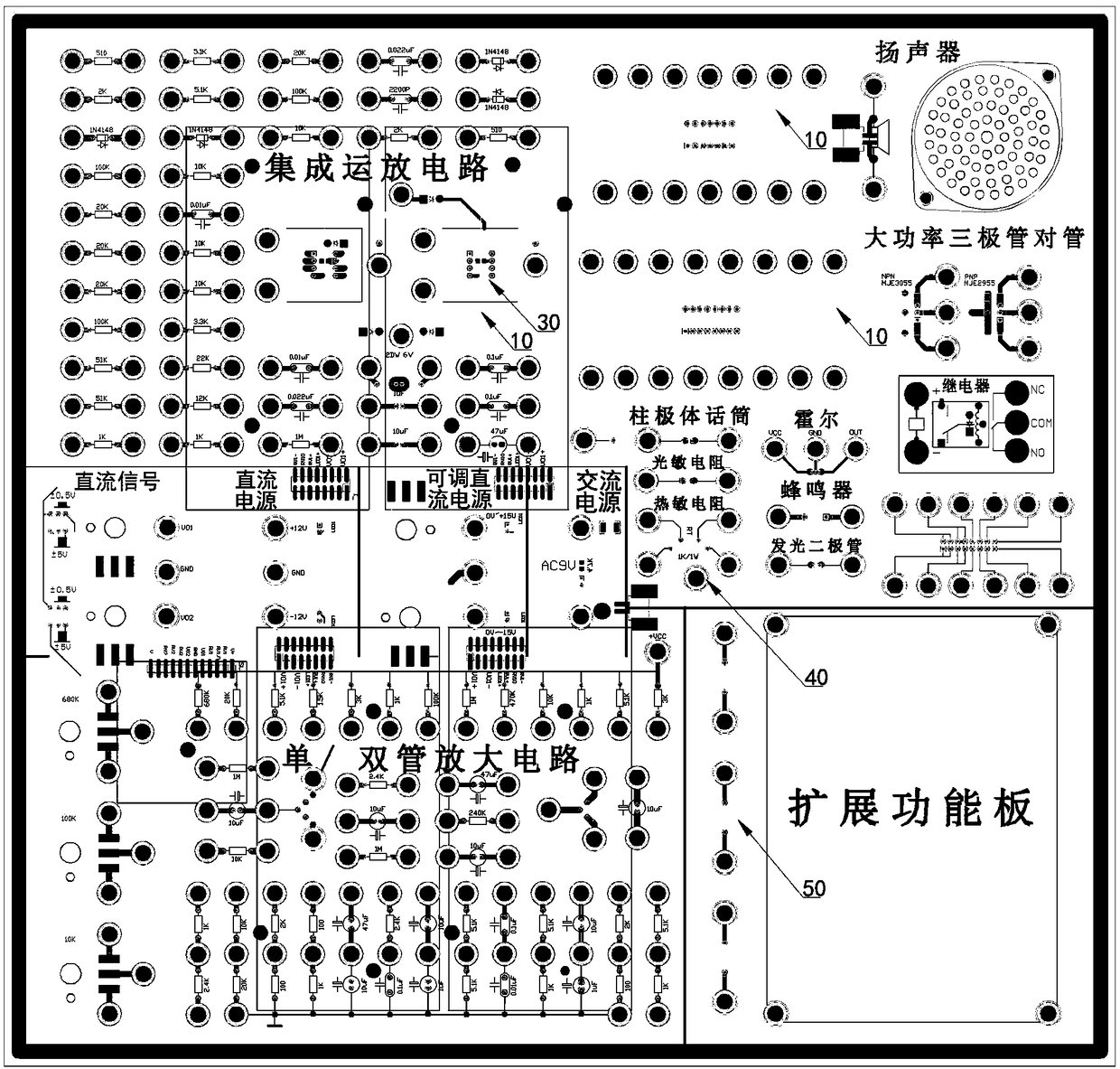

Analog circuit teaching experimental box

PendingCN108922348AClear and profound teaching experiment cognitive masteryImprove design hands-on abilityEducational modelsScreen printingComputer module

The invention discloses an analog circuit teaching experimental box. The analog circuit teaching experimental box is configured with a plurality of analog circuit modules mounted and welded to independent PCBs corresponding to the analog circuit modules correspondingly; the PCB of each analog circuit module is at least provided with a wiring layer and a screen printing layer; the screen printing layers comprise top face screen printing layers and / or bottom face screen printing layers, wherein the top face screen printing layers and / or the bottom face screen printing layers comprise circuit principle connecting screen printing layers for a teaching circuit connection schematic diagram, and text symbol screen printing layers for teaching recognition of used component information; the circuitprinciple connecting screen printing layers are used for teaching experiment showing of the electrical connection principle of all components constituting the analog circuit modules; the multiple analog circuit modules comprise but are not limited to main panel modules; and the main panel modules are provided with various sensor circuit interfaces, extended function boards and a plurality of independent circuit debugging units with an independent circuit function and / or a multiple independent component function. Application skills of circuit design operational capability, component recognition capability and design capability in circuit layout of students are improved, and the experimental teaching effect is improved.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

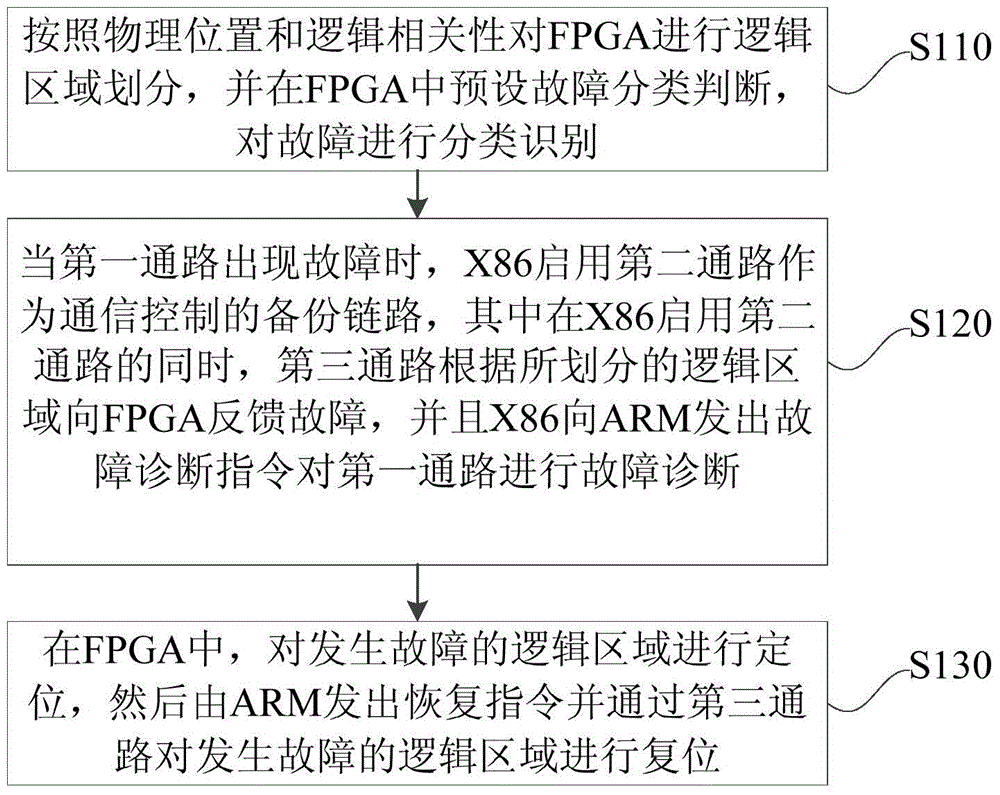

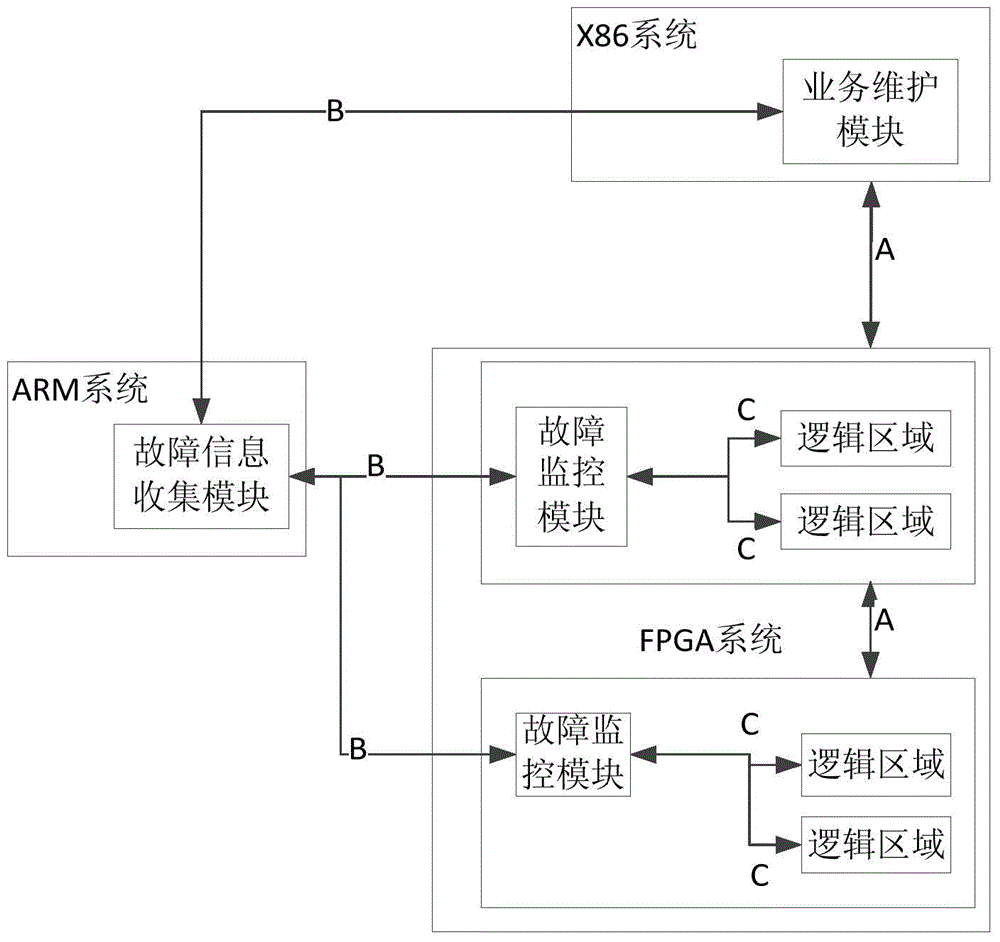

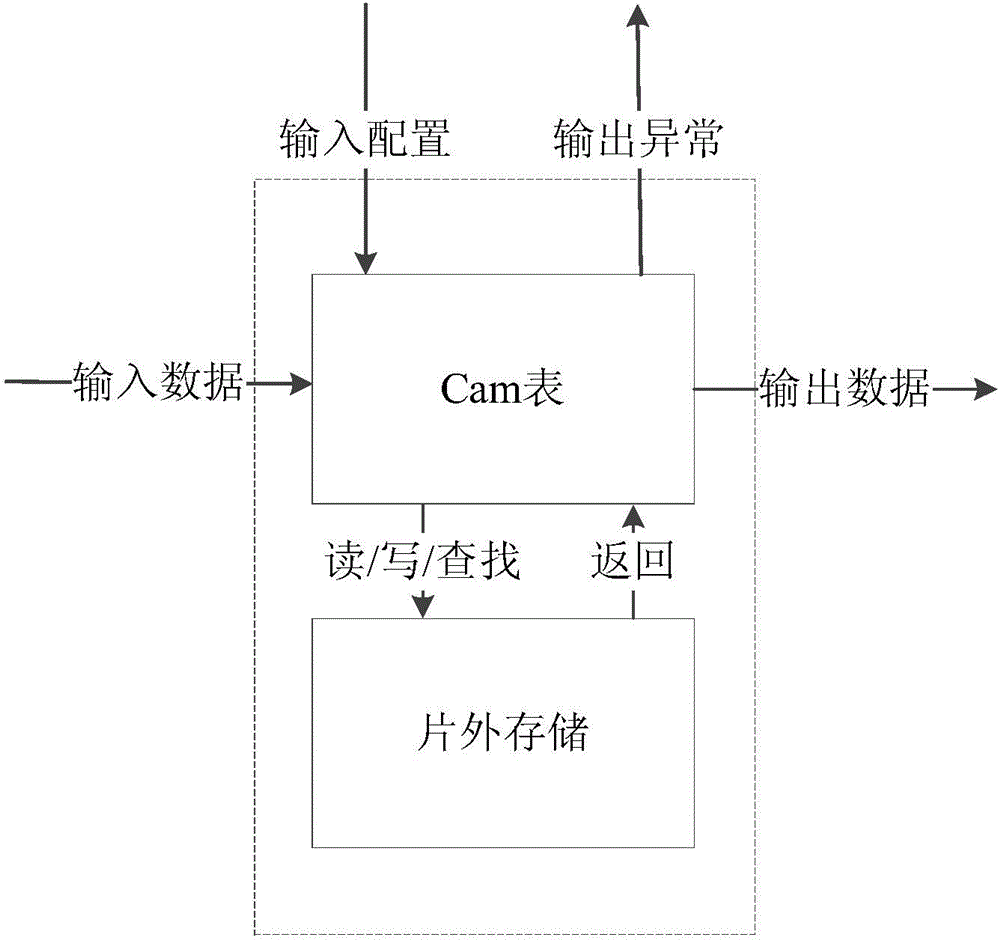

Fault diagnosis and recovery method and device for heterogeneous system

ActiveCN103605593AGood debugging effectGuaranteed uptimeDetecting faulty computer hardwareSpecial data processing applicationsX86Failure diagnosis

The invention provides a fault diagnosis and recovery method and device for a heterogeneous system. The method includes the steps that in the heterogeneous system formed by an X86 and an FPGA, logic area division is performed on the FPGA according to the physical position and the logic relevancy, and fault classification judgment is preset in the FPGA for fault recognition; when a first access breaks down, a second access is started to be used as a backup link in the X86, a third access feeds the fault category back to the FPGA according to divided logic areas, and fault diagnosis is performed on the first access in the mode that the X86 sends fault diagnosis instructions to an ARM; in the FPGA, the broken-down logic area is located, then the ARM sends out recovery instructions, and recovery is performed on the broken-down logic area through the third access so as to complete elimination of faults of the heterogeneous system. The fault diagnosis and recovery method and device for the heterogeneous system can achieve the communication control link between the backup FPGA and the X86, obtain fault diagnosis information, eliminate accidental faults, and improve the fault debugging capacity and the stable operation capacity of the system.

Owner:NEUSOFT CORP

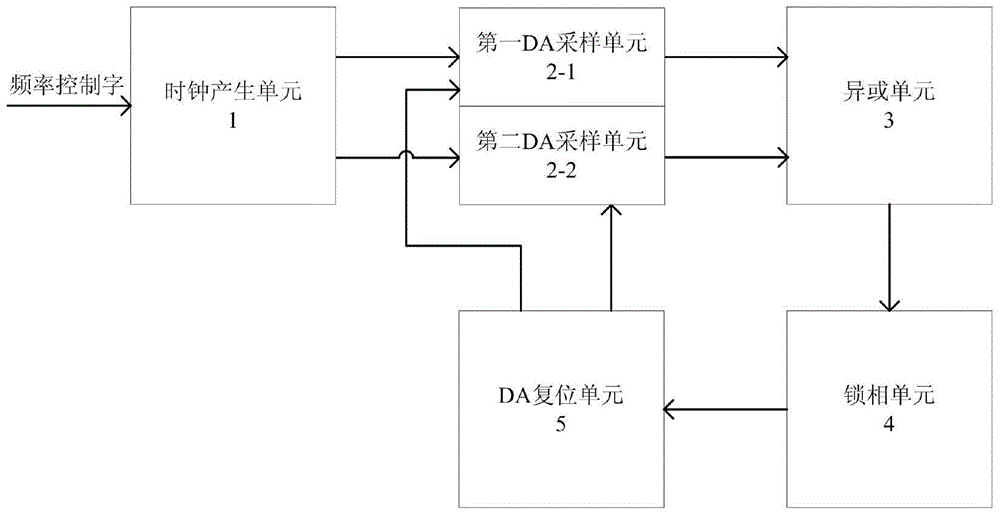

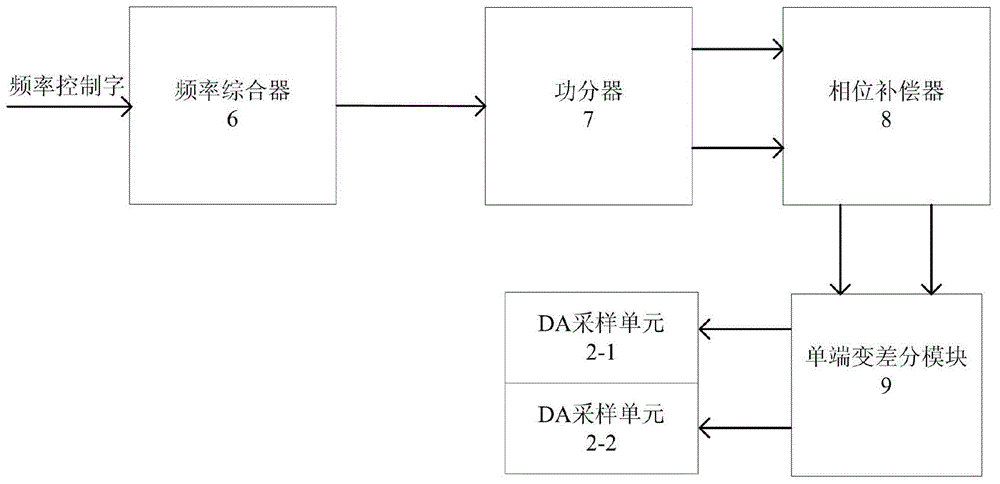

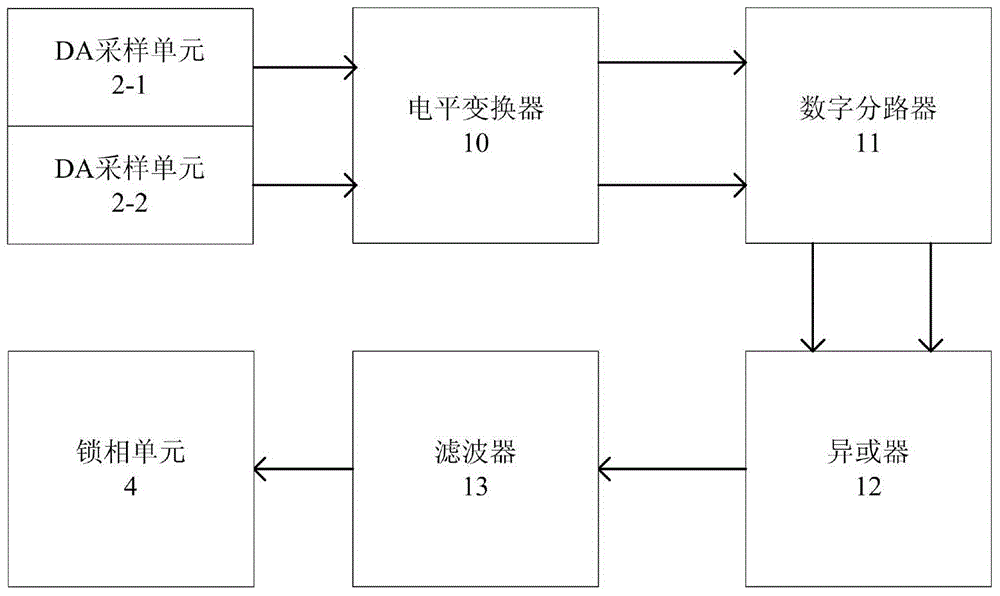

Double-DA synchronous sampling device

ActiveCN104868912AImprove reliabilityGood debugging effectPulse automatic controlComputer sciencePhase-locked loop

The invention discloses a double-DA synchronous sampling device which comprises a clock generate unit, a first DA sampling unit, a second DA sampling unit, an XOR unit, a phase-lock unit and a DA reset unit. According to the invention, clock signals are generated according to externally input frequency control words and are respectively adopted as sampling clocks of two DAs, four frequency division clocks respectively output by the two DAs are subjected to XOR treatment, then, signals output through XOR are input into a phase-lock loop, a phase-lock index signal is generated through the phase-lock loop, finally, the phase-lock index signal is sent into the DA reset unit, the DA reset unit performs judgment after the wobble elimination of the input phase-lock index signal wobble elimination is completed, and the two DAs are respectively reset if the result indicates that the two DAs are not synchronous in operation. According to the invention, from the aspect of XOR output signal duty ratio, the interference of peripheral circuits to extraction of synchronous signals is reduced, and the accuracy and reliability of operation of the double-DA synchronous sampling device are improved.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

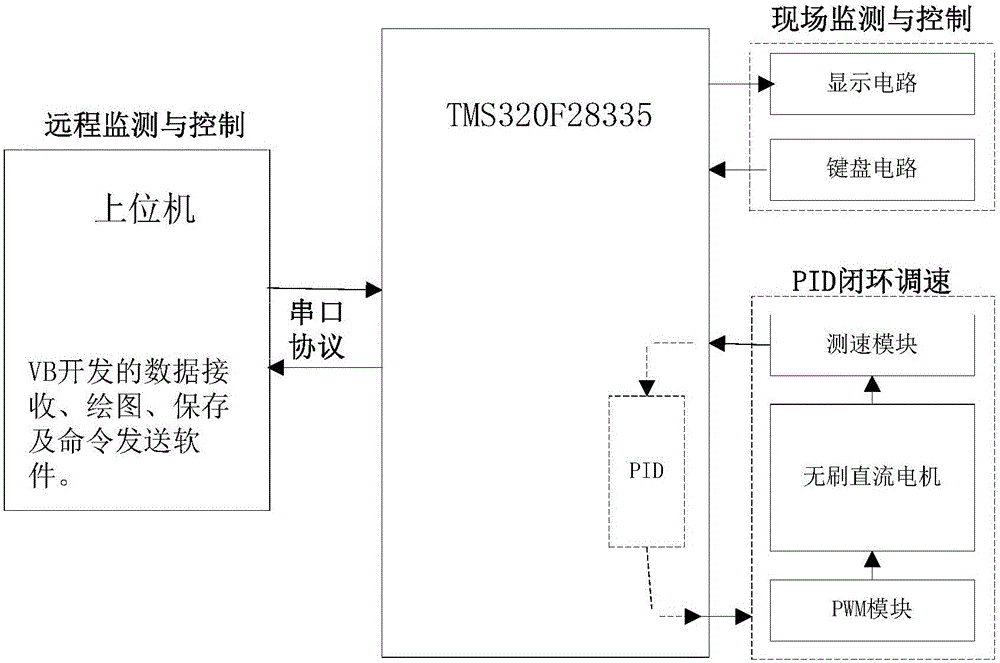

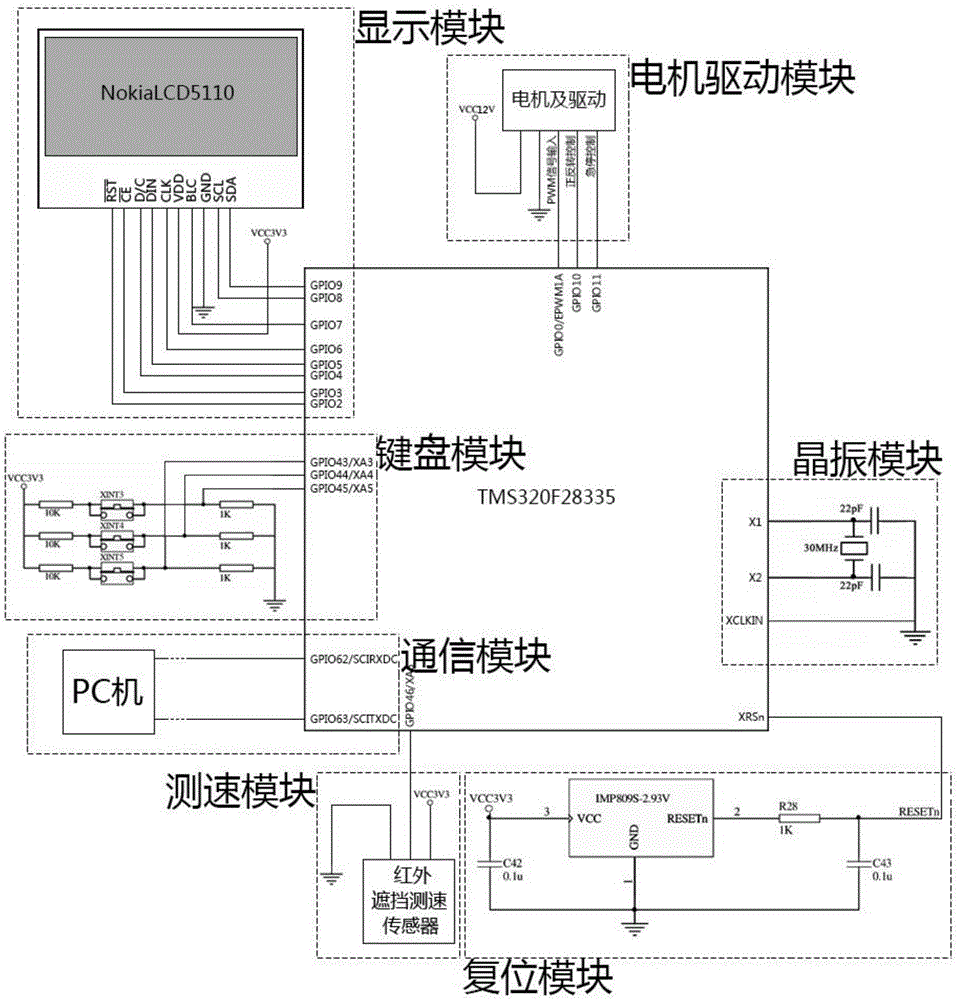

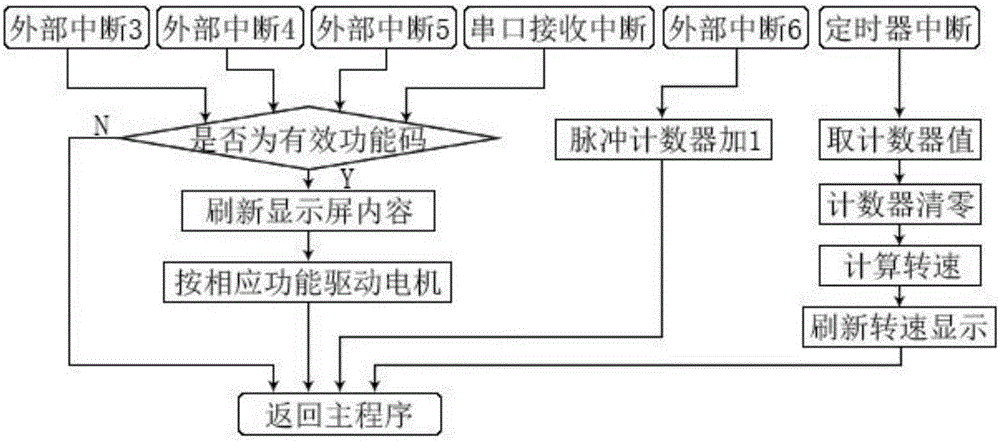

Online debugging system of brushless DC motor

InactiveCN106253780AEasy to detectEasy to controlElectronic commutation motor controlVector control systemsFar distanceHall element

The invention discloses an online debugging system of a brushless DC motor (BLDC), and the online debugging system relates to the technical field of brushless DC motors. The online debugging system comprises a PID closed-loop speed regulating unit, a motor work site monitoring and control unit, an upper computer remote monitoring and control unit and a lower computer unit, wherein the PID closed-loop speed regulating unit comprises a controller module, a Hall element module, a speed measuring module, a PWM module and a PID speed regulating module; the motor work site monitoring and control unit comprises a keyboard circuit module and a display circuit module; and the upper computer remote monitoring and control unit is used for sending a command to the lower computer unit and receiving data fed back by the lower computer unit. The online debugging system of the brushless DC motor has the beneficial effects that: 1, the BLDC online PID parameter debugging method is simple in operation, and can realize detection and control of operating data of the BLDC in an industrial site and at far distance; 2, and the relevant parameters of BLDC operation can be displayed on an upper computer in the form of curves.

Owner:SICHUAN NORMAL UNIVERSITY

Primary loop heating and humidifying system and method for high-temperature gas cooled reactor nuclear power station

PendingCN108278586AFast heatingShorten the construction periodSteam generation using mechanical energyNuclear energy generationEvaporatorEngineering

The invention provides a primary loop heating and humidifying system and a primary loop heating and humidifying method for a high-temperature gas cooled reactor nuclear power station. The system comprises an evaporator inlet isolating valve, an evaporator, a main steam valve, a drain valve, a pressure vessel and an external steam charging valve unit, wherein the evaporator inlet isolating valve, the evaporator and the main steam valve are connected in sequence; the drain valve is arranged between the evaporator inlet isolating valve and the evaporator; and a pipeline between the evaporator andthe main steam is connected with the external steam charging valve unit. According to the method provided by the invention, external steam is charged to a secondary side of the evaporator via the external steam charging valve unit, and a working medium in a primary loop is heated inside the evaporator, so the temperature of the primary loop is increased, and the requirements of heating and dehumidification of the primary loop are met.

Owner:XIAN THERMAL POWER RES INST CO LTD

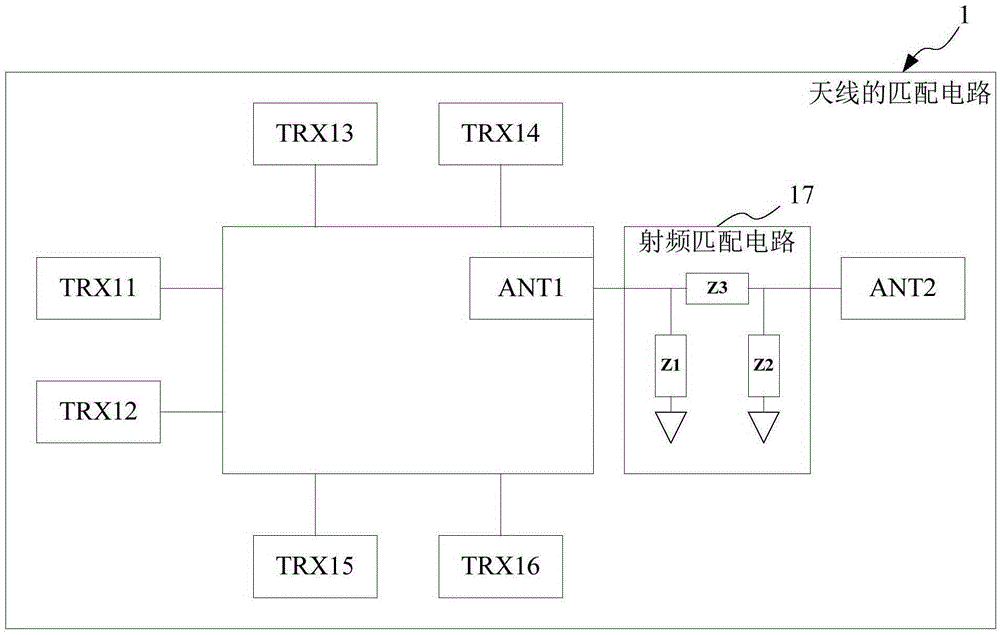

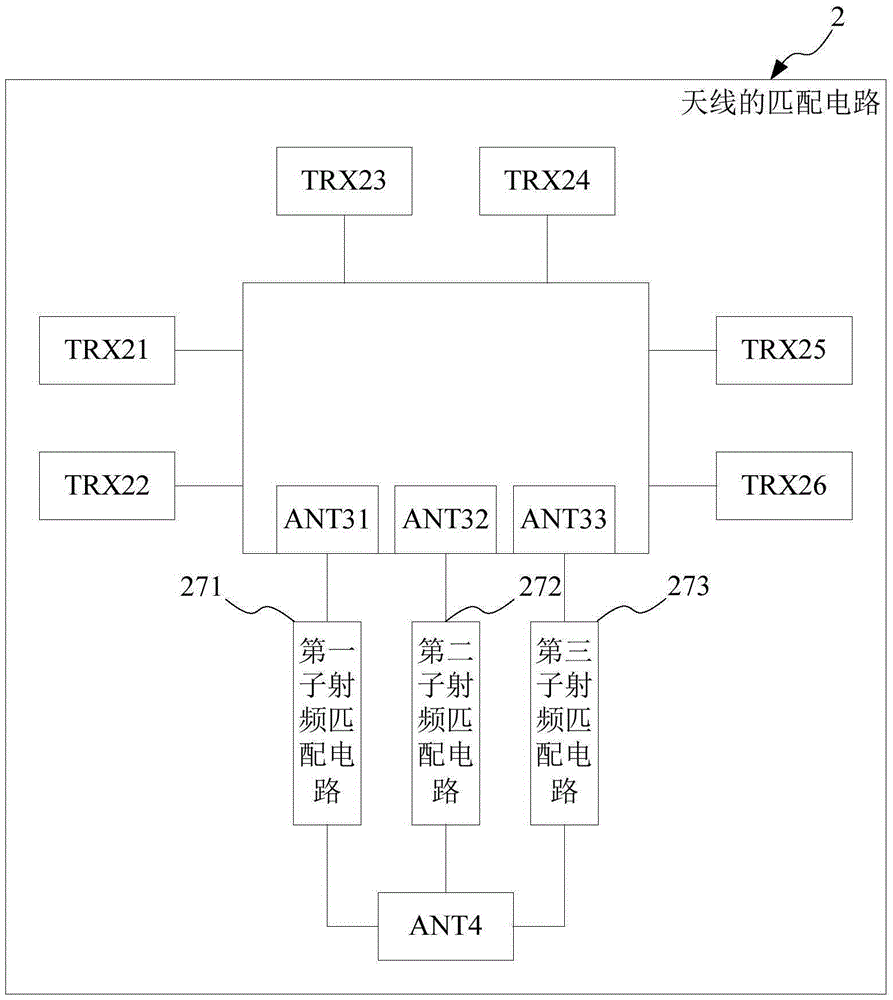

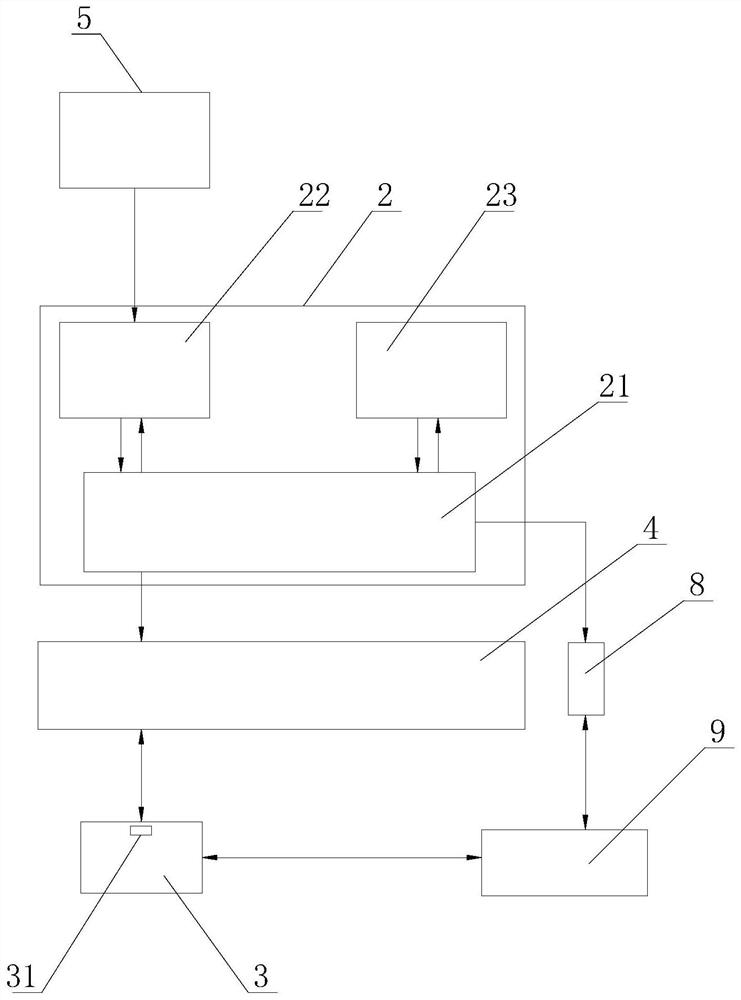

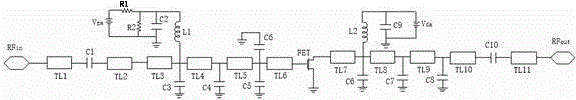

Radio frequency matching circuit, and method for debugging radio frequency matching circuit

InactiveCN105391457AReduce convergenceFast convergenceTransmitters monitoringReceivers monitoringSmith chartRadio frequency

The invention provides a radio frequency matching circuit and a method for debugging the radio frequency matching circuit. The radio frequency matching circuit includes more than two sub radio frequency matching circuits, one end of each sub radio frequency matching circuit is connected with a sub signal output end, and the other end is connected with an input end of an antenna; and a signal output by each of the sub signal output ends has a different frequency range. Thus signals output by an output end of a radio frequency converter are output through more than two sub signal output ends according to difference of the frequency ranges, then impedance in the corresponding frequency range is debugged through the sub radio frequency matching circuit connected with the sub signal output end, so that a radio frequency engineer can perform matching debugging in a relatively small frequency range, the debugging difficulty is lowered, the degree of convergence of a Smith chart is improved, the reflection power is reduced, and a debugging effect is improved, thereby improving the radio frequency performance of a mobile terminal.

Owner:PHICOMM (SHANGHAI) CO LTD

Method for debugging secondary equipment of transformer substation

PendingCN111654101AImplement IntelliSenseRealize intelligent diagnosisCircuit arrangementsInformation technology support systemData streamStation

The invention relates to a method for debugging secondary equipment of a transformer substation. The method comprises a bracket, a debugging end, a debugging instrument and a network switch, and sequentially comprises the following steps: generating a debugging strategy, debugging tested equipment, generating a debugging report and analyzing a debugging result. The method has the advantages that the tested equipment is debugged through a debugging strategy generation method, a tested equipment debugging operation method, a debugging report generation method and a debugging result analysis method. Intelligent generation of a debugging template and intelligent perception and intelligent diagnosis of a debugging result are realized. Intelligent debugging of secondary equipment of the whole station and automatic generation of a debugging report are realized. The control PC and the debugging instrument are core carriers of the whole debugging system, the control PC is connected with the debugging instrument and the tested equipment, seamless transmission from operation information flow to debugging data flow and then to debugging control and feedback flow is achieved, and therefore automatic debugging is conducted on secondary equipment of a transformer substation, and the debugging effect and quality are improved.

Owner:温州电力建设有限公司 +1

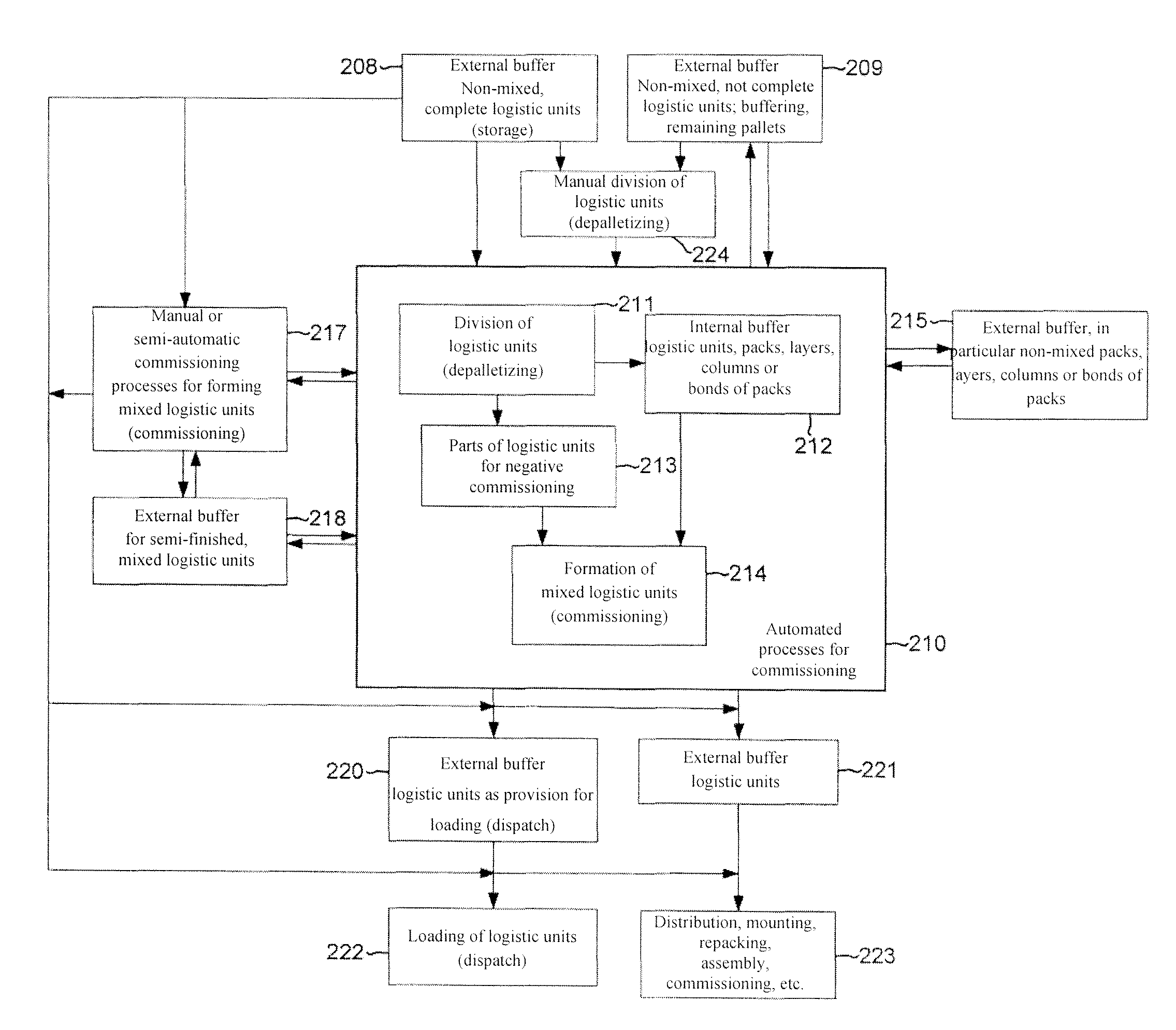

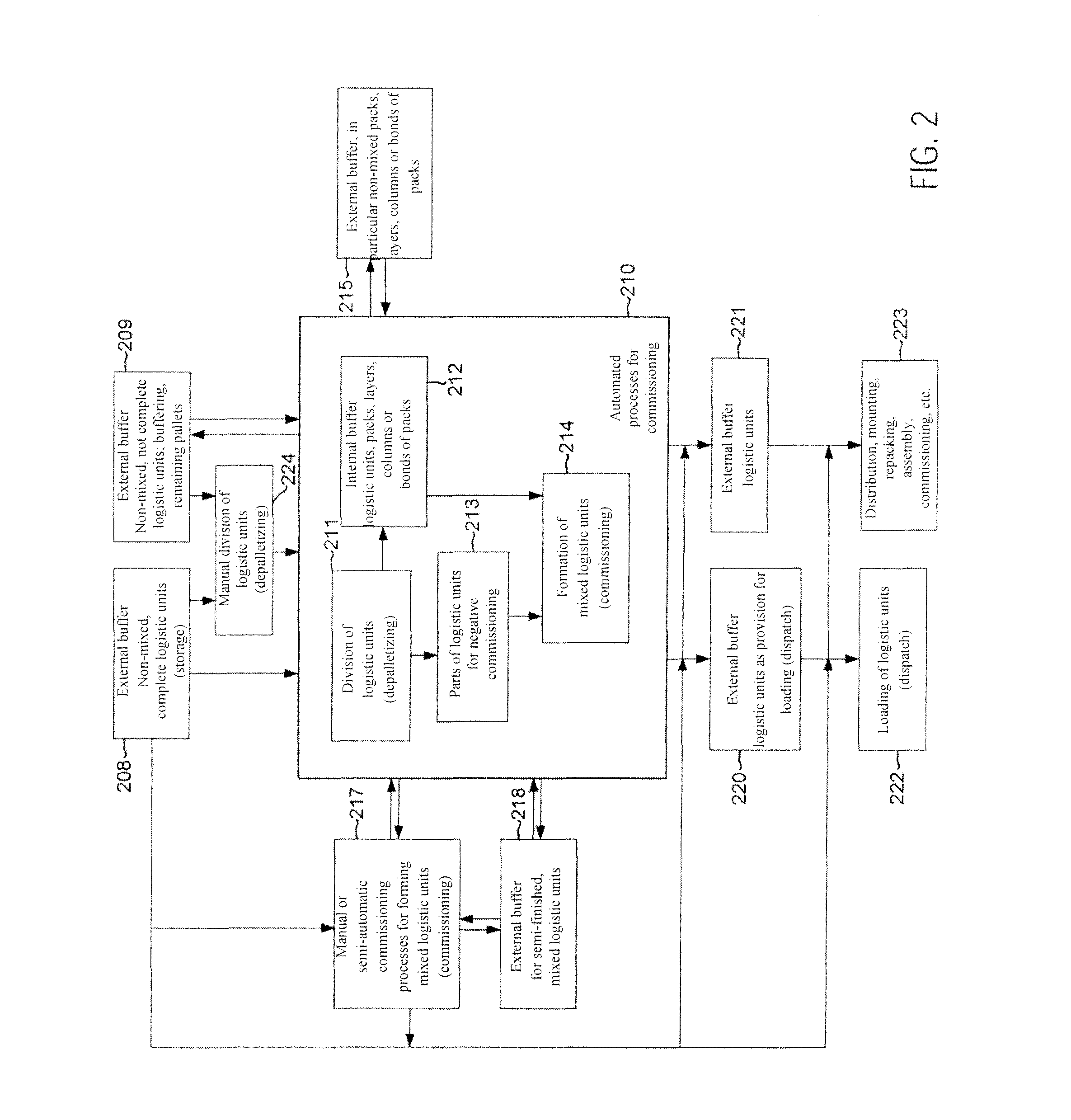

Device and Method for the Partially or Completely Automatic Commissioning of Packs

InactiveUS20110125694A1Good debugging effectImprove performanceKnowledge representationStorage devicesEngineeringPackaging and labeling

Owner:ALLIACENSE LIMITED

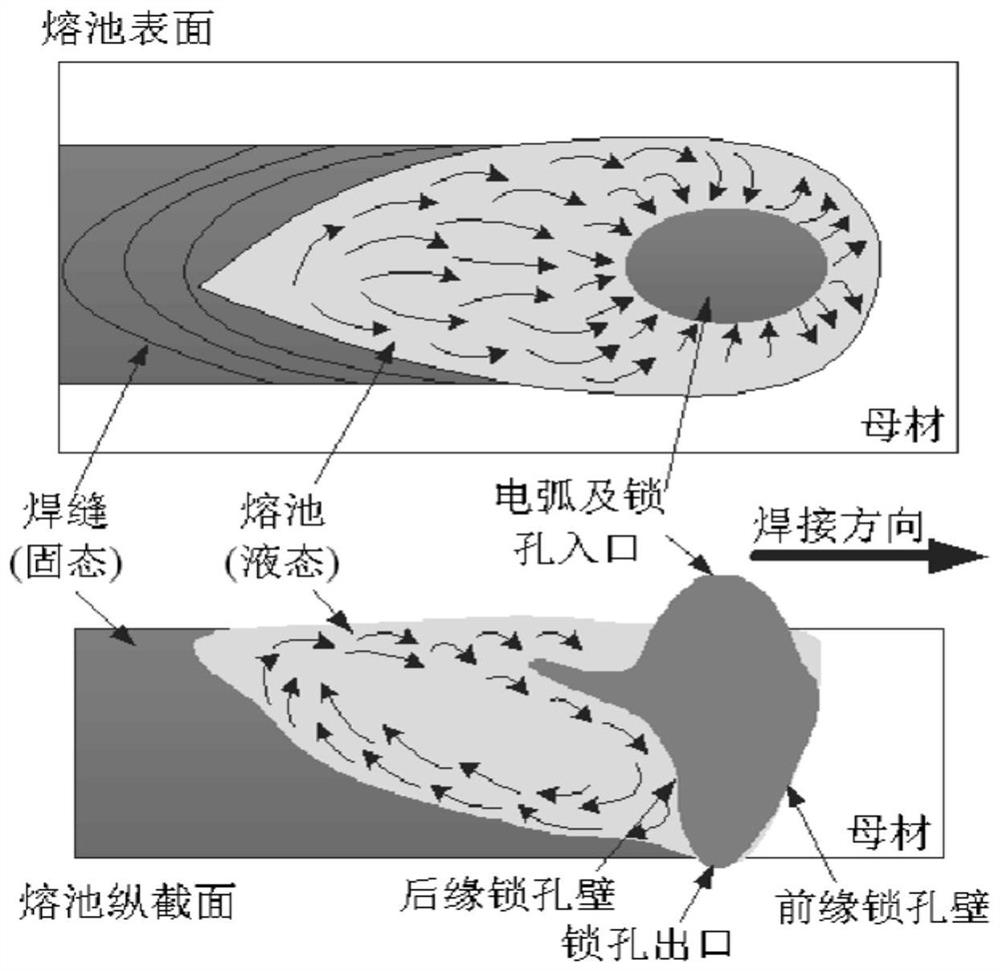

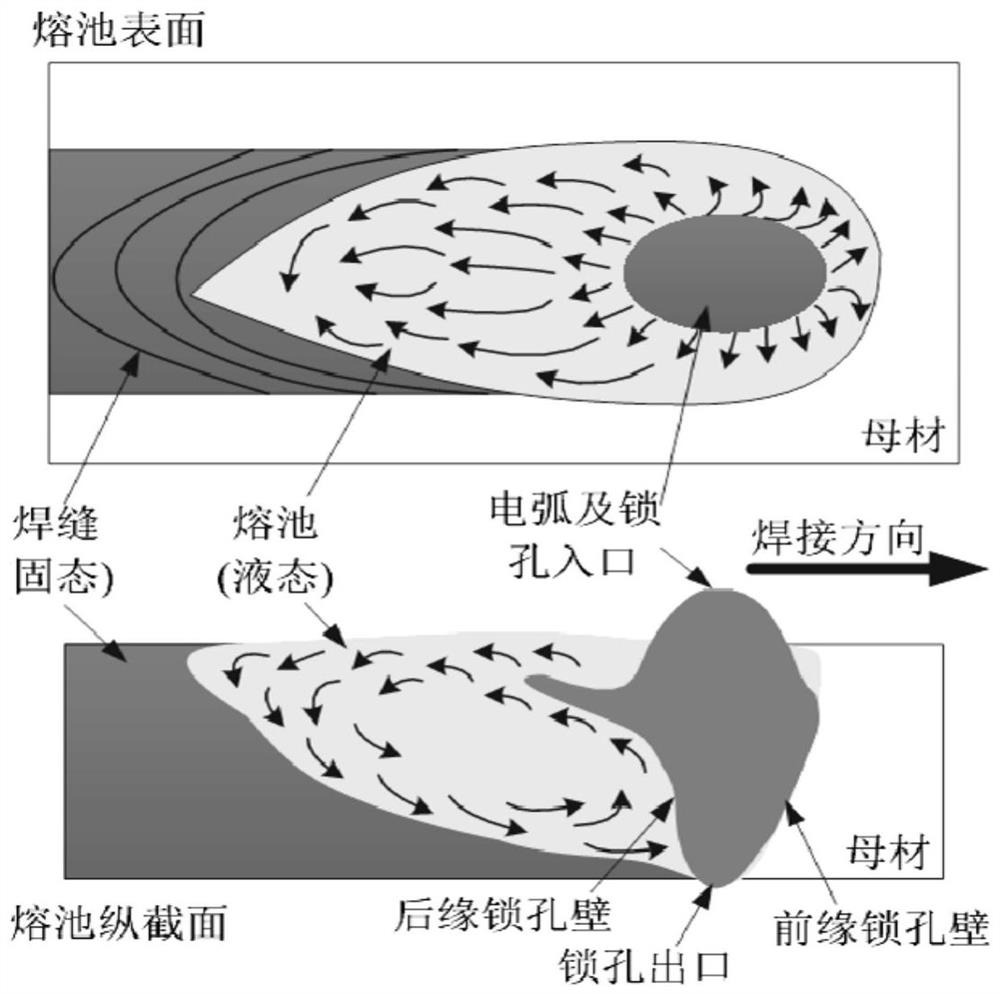

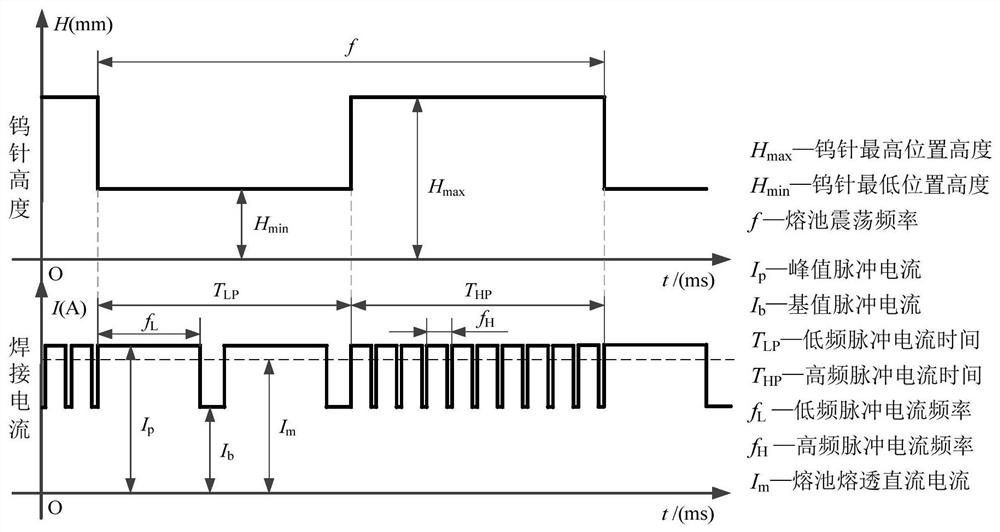

Method for controlling stirring and balanced oscillating of deep penetration K-TIG welding pool

ActiveCN113369640ARealize the effect of stirring and shakingLow costArc welding apparatusWelding power supplyLiquid metal

The invention relates to a method for controlling stirring and balanced oscillating of a deep penetration K-TIG welding pool. A tungsten needle is controlled to do axial motion to adjust the distance between the tungsten needle and a weldment while the tungsten needle moves along the welding direction, the motion state of the tungsten needle between the lowest position and the highest position in the axial motion is adjusted, and the welding current output by a welding power supply system is synchronously adjusted, so that the stress state and the heat transfer state of a welding pool are continuously changed, the radial and axial motion states of liquid metal in the welding pool are further changed, and the stirring and oscillating effects are formed in the welding pool. According to the method provided by the invention, peripheral auxiliary welding equipment does not need to be added, and on the basis of original deep penetration K-TIG welding equipment, the state of the welding pool is changed by coupling tungsten needle height changes and welding current changes, so that the stirring and oscillating effects of the welding pool are achieved, the welding process of single-face welding and double-face forming is achieved with lower heat input energy, and the welding pool is good in penetration performance and program transferability.

Owner:SOUTH CHINA UNIV OF TECH

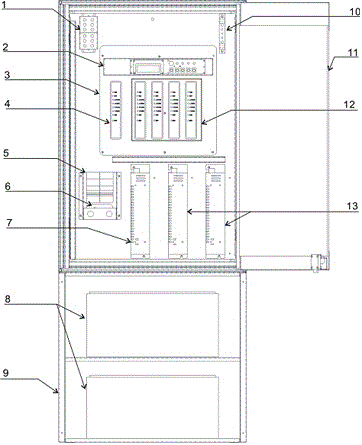

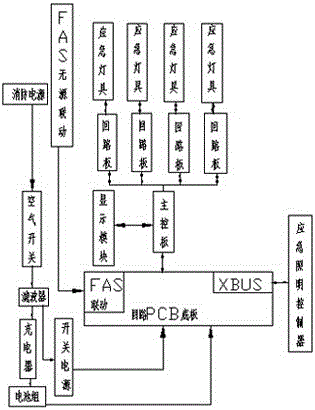

Intelligent fire-fighting emergency illumination and dispersion indication system

InactiveCN105764216AQuick positioning replacementImprove satisfactionElectrical apparatusElectric light circuit arrangementMiniaturizationEmergency situations

The invention relates to an intelligent fire-fighting emergency illumination and dispersion indication system comprising a power supply unit, an emergency dispersion control unit, a distribution detection unit, and an emergency illumination unit. The power supply unit provides power for the distribution detection unit; the distribution detection unit is divided into two paths of circuits; and one path of circuit is connected with the emergency illumination unit and the other path of circuit is connected with the emergency dispersion control unit. On the basis of the technical scheme, power unit miniaturization can be realized; installation at a nearest place for power taking can be realized; and the cost is lowered. Application of the intelligent fire-fighting emergency illumination and dispersion indication system is possible for a small occasion.

Owner:浙江台谊消防股份有限公司

Processor chip emulator with nonvolatile memory

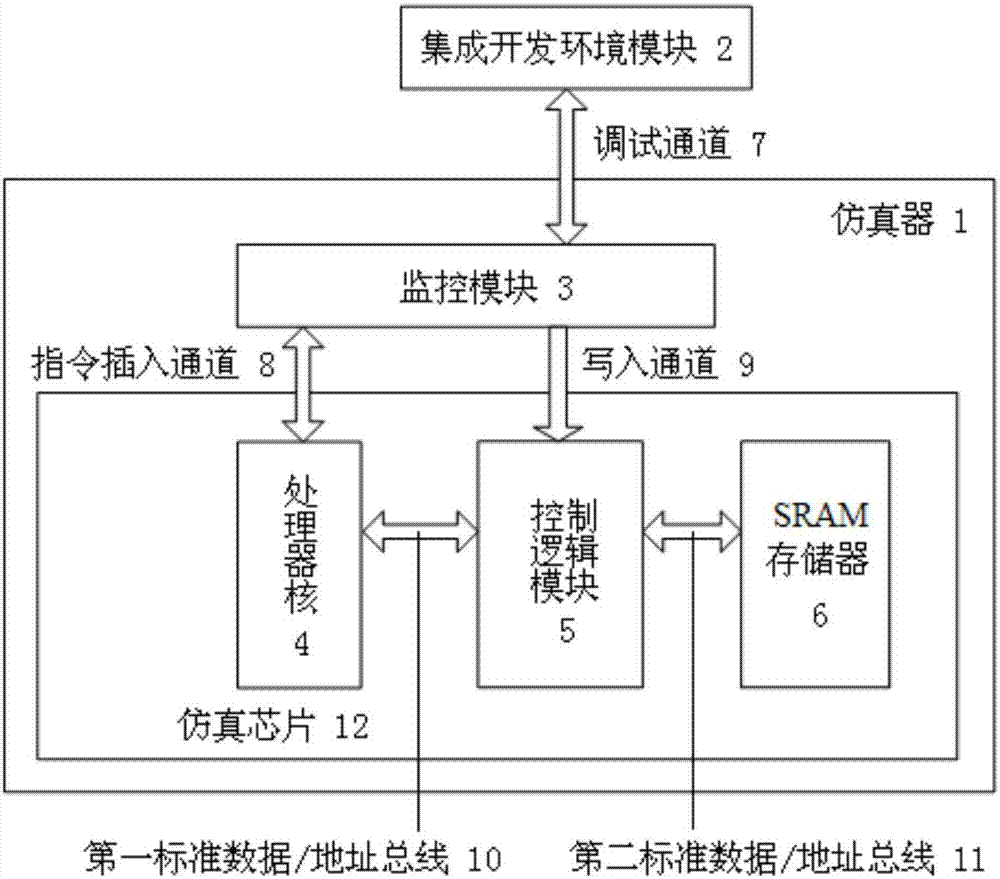

PendingCN107577520APerformance consistencyImprove usabilityMemory adressing/allocation/relocationFunctional testingCode coverageComputer module

The invention discloses a processor chip emulator with a nonvolatile memory. Code coverage configuration is written to a control logic module by a monitoring module through a write channel; accordingto the code coverage configuration, if a received write operation target address is in the code coverage configuration, the control logic module performs a transparent channel function and directly connects a first standard data / address bus connected with a processor core with a second standard data / address bus connected with an SRAM equivalently in terms of function and performance; if the received write operation target address is not in the code coverage configuration, the control logic module can emulate a write operation sequential control function and write operation sequential control performance of an equivalent nonvolatile memory and can be used in cooperation with the SRAM to be equivalent to a write operation time sequence and function and write operation performance of the nonvolatile memory in a product chip. According to the processor chip emulator, not only is the consistency of the function and the performance of the emulator guaranteed, but achievement and usage modesof a system are simplified.

Owner:SHANGHAI INFORMATION NETWORK

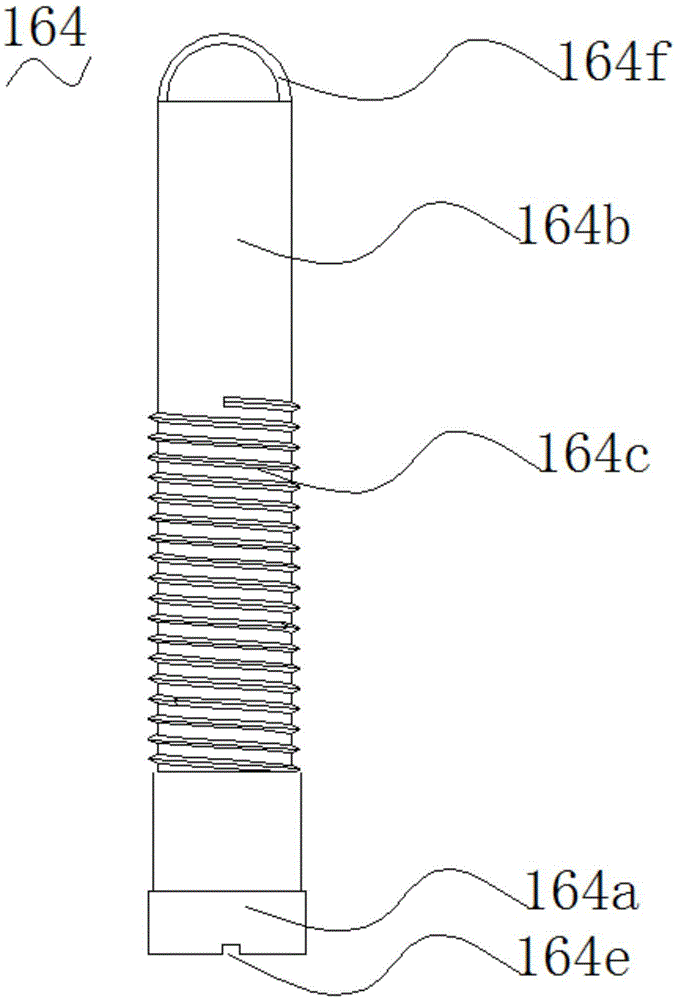

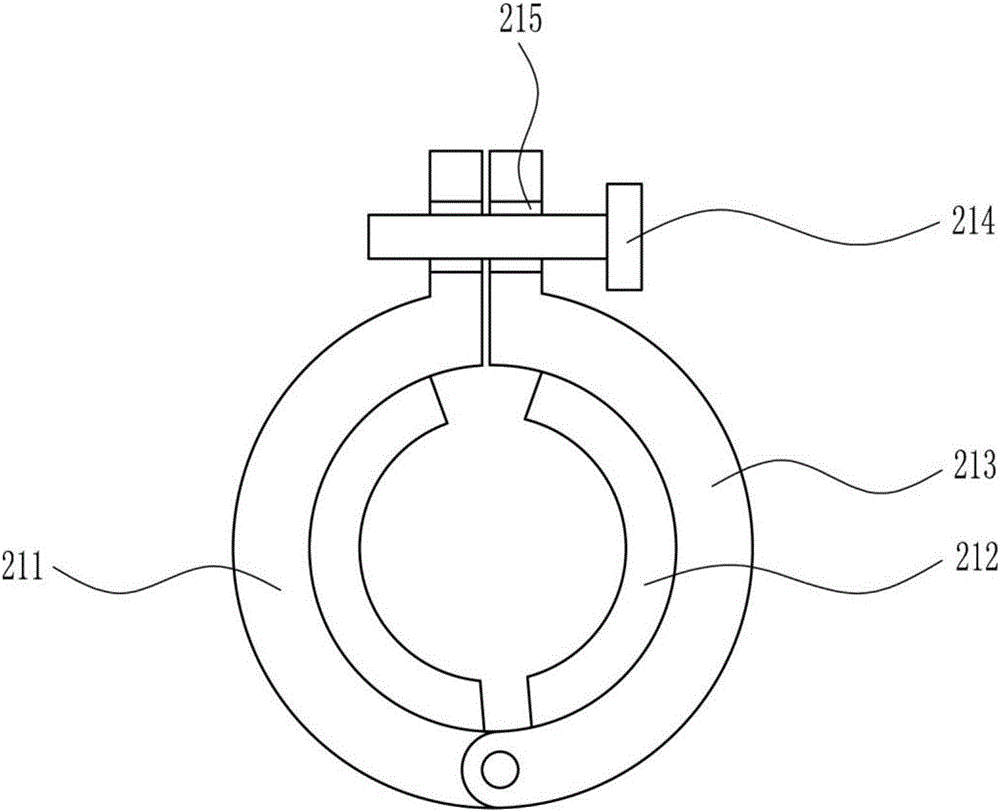

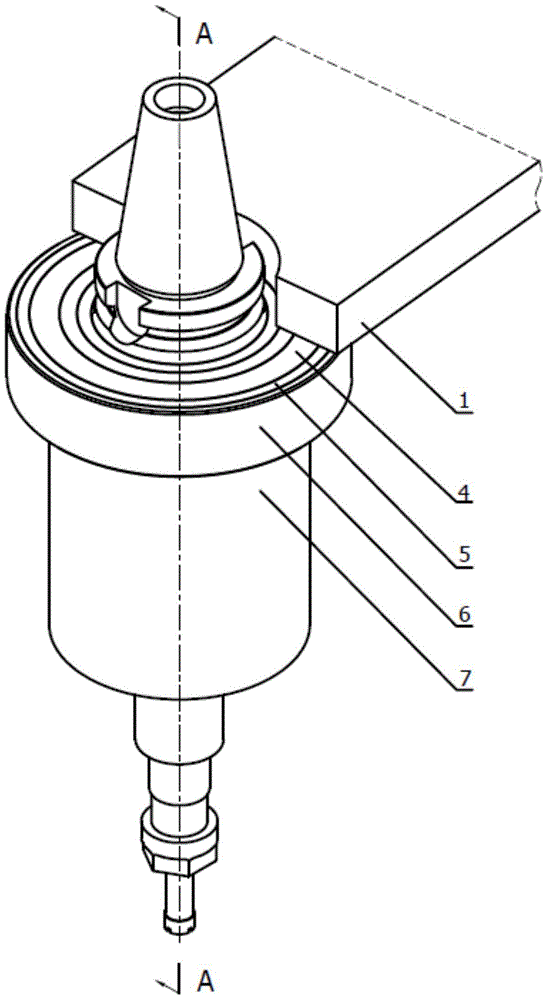

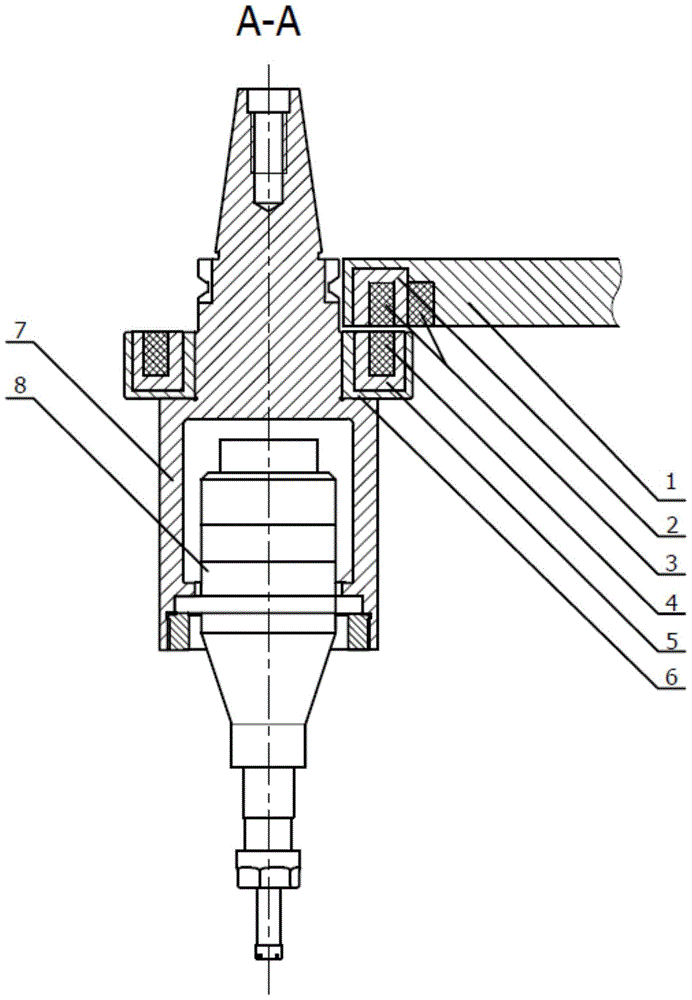

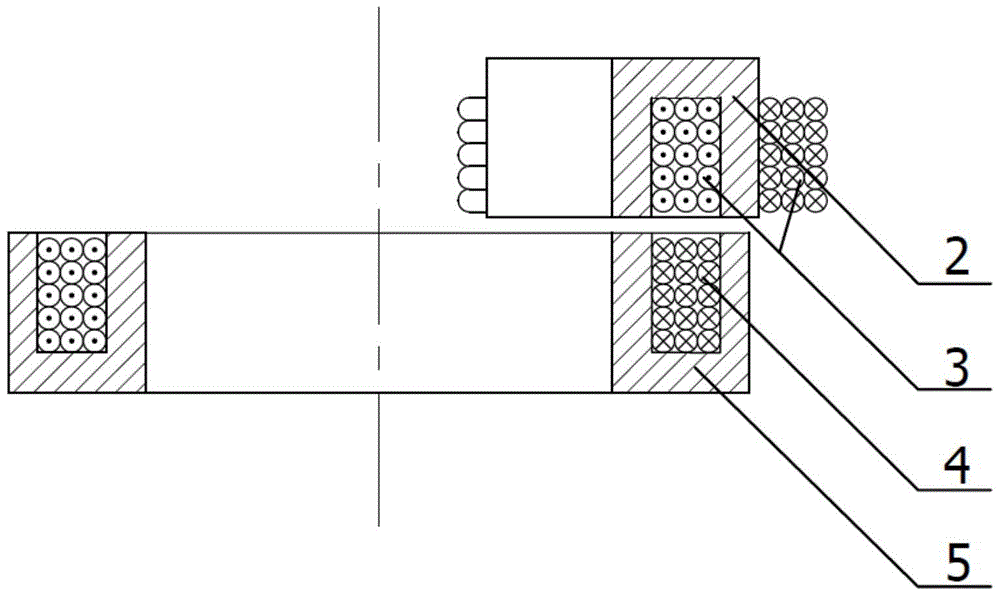

A non-contact energy transfer device for rotary ultrasonic machining

ActiveCN104439348BEasy accessAvoid interferenceMechanical vibrations separationChucksEngineeringAutomation

The invention discloses a non-contact energy transmission device for rotary ultrasonic processing. The non-contact energy transmission device comprises a fixed end and a rotating end. The opposite positions of the fixed end and the rotating end are each of an axial opened type or a radial opened type. When the opposite positions of the fixed end and the rotating end are of the axial opened type, a magnetic core of the fixed end is a part cut from a tank type magnetic core, and the central angle of the part cut from the tank type magnetic core is smaller than or equal to 180 degrees; a magnetic core of the rotating end is a complete tank type magnetic core. When the opposite positions of the fixed end and the rotating end are of the radial opened type, the magnetic core of the fixed end is a part cut from an annular inner groove magnetic core, and the central angle of the part cut from the annular inner groove magnetic core is smaller than or equal to 180 degrees; a magnetic core of the rotating end is a complete annular outer groove magnetic core. By means of the non-contact energy transmission device, the processing efficiency and automation level can be improved, the improvement cost and capital investment can be saved, the safety and applicability of an ultrasonic processing device can be improved, and the installation performance and adjustment performance are good.

Owner:DALIAN UNIV OF TECH

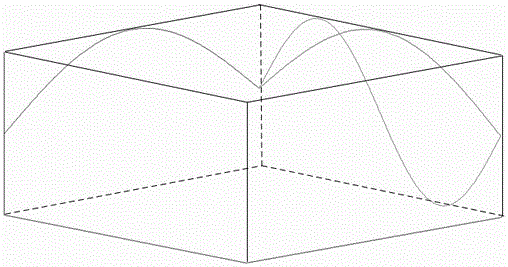

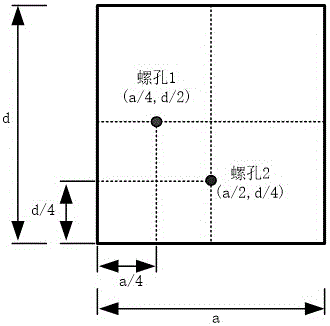

Adjustable electromagnetic shielding cover and radio frequency circuit optimization method

InactiveCN105934143AMake up for performance differencesReduce debugging workloadMagnetic/electric field screeningResonatorsMicrowaveCavity resonance

The invention discloses an adjustable electromagnetic shielding cover and a radio frequency circuit optimization method. The electromagnetic shielding cover comprises a metal shielding cover and a circuit structure arranged therein, and tuning screws are arranged at sensitive positions of a cavity effect in the metal shielding cover. According to the method, through establishing a cavity model, an influence exerted by a shielding cover cavity on a microwave and radio frequency circuit is analyzed; the specially optimized tuning screws are additionally arranged on the shielding cover of the microwave and radio frequency circuit, slits between the tuning screws and the circuit are adjusted, and an equivalent circuit of a cavity between the circuit and the shielding cover is changed; and the adjustable electromagnetic shielding cover can obviously inhibit cavity resonance, adjusts the cavity effect and improves performance of the circuit.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

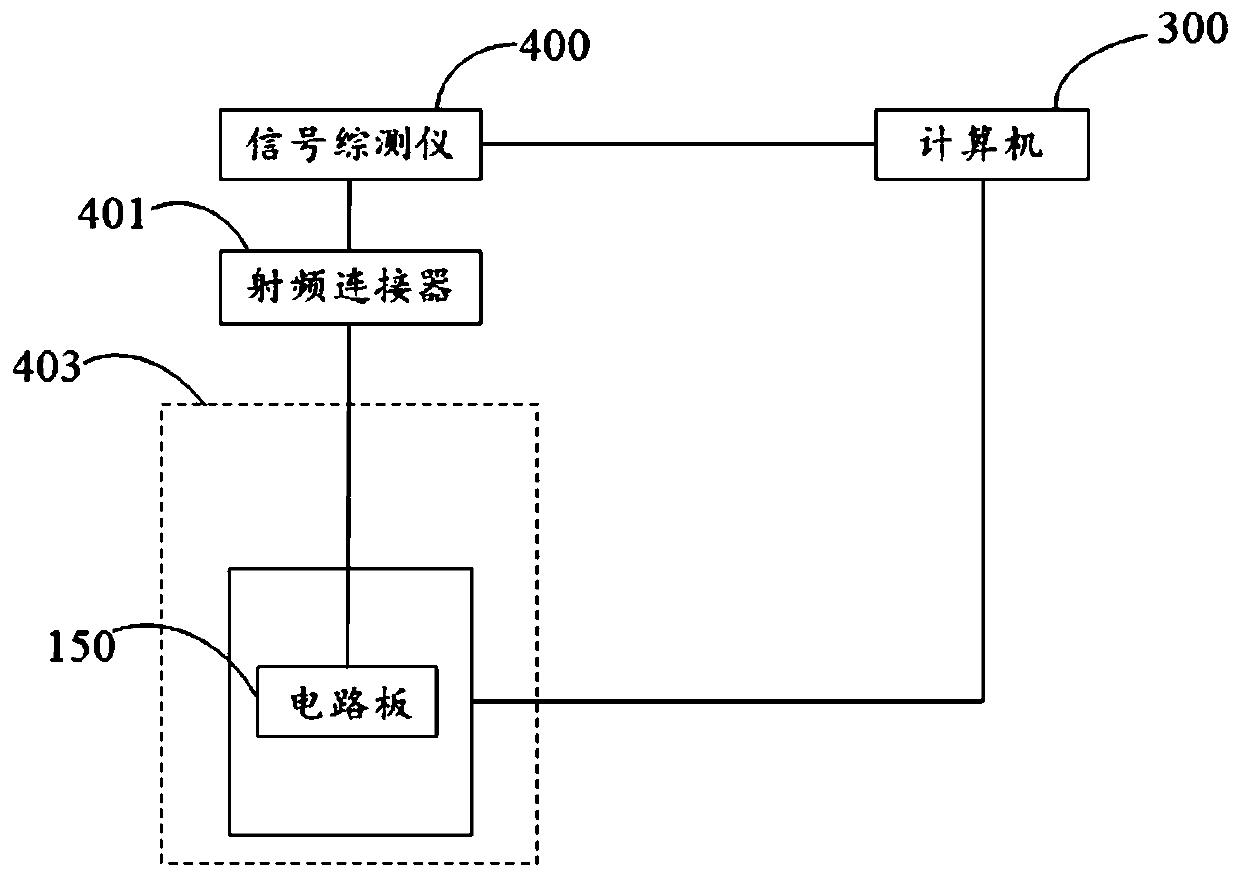

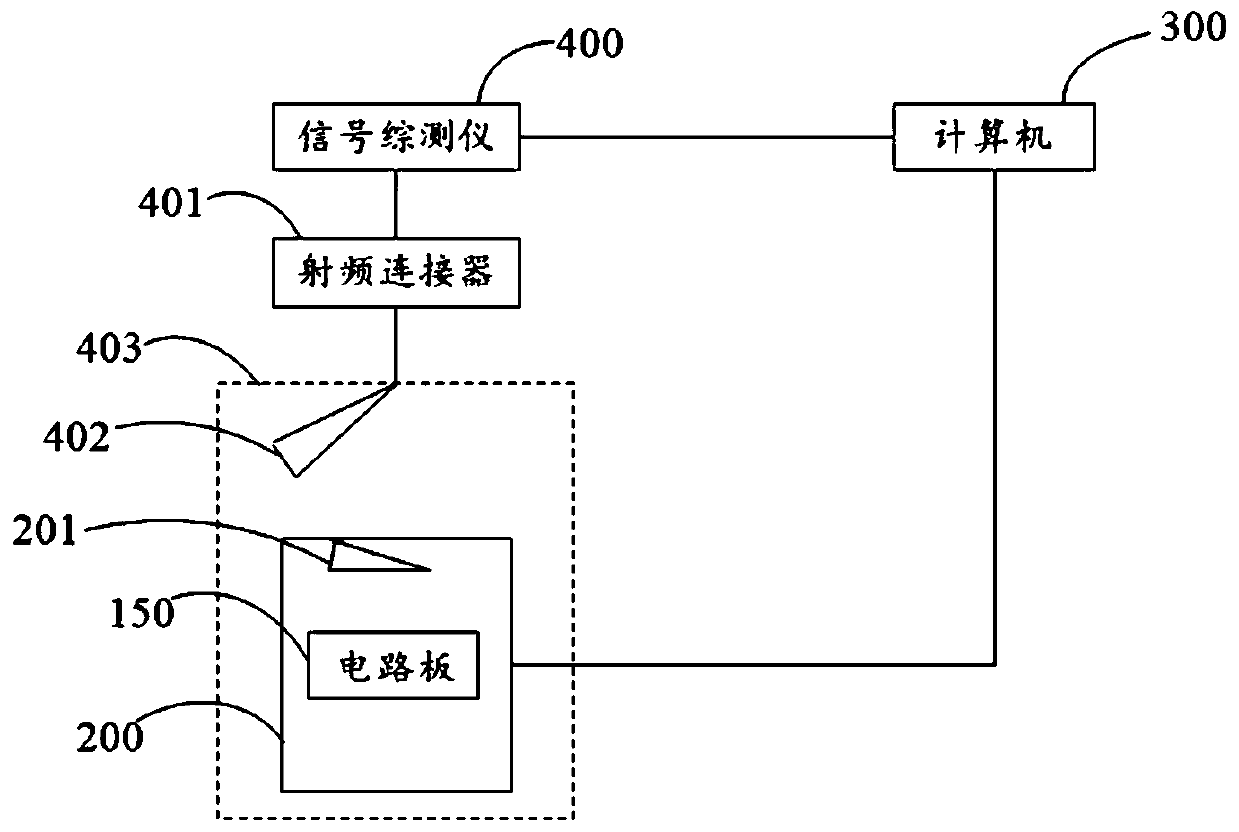

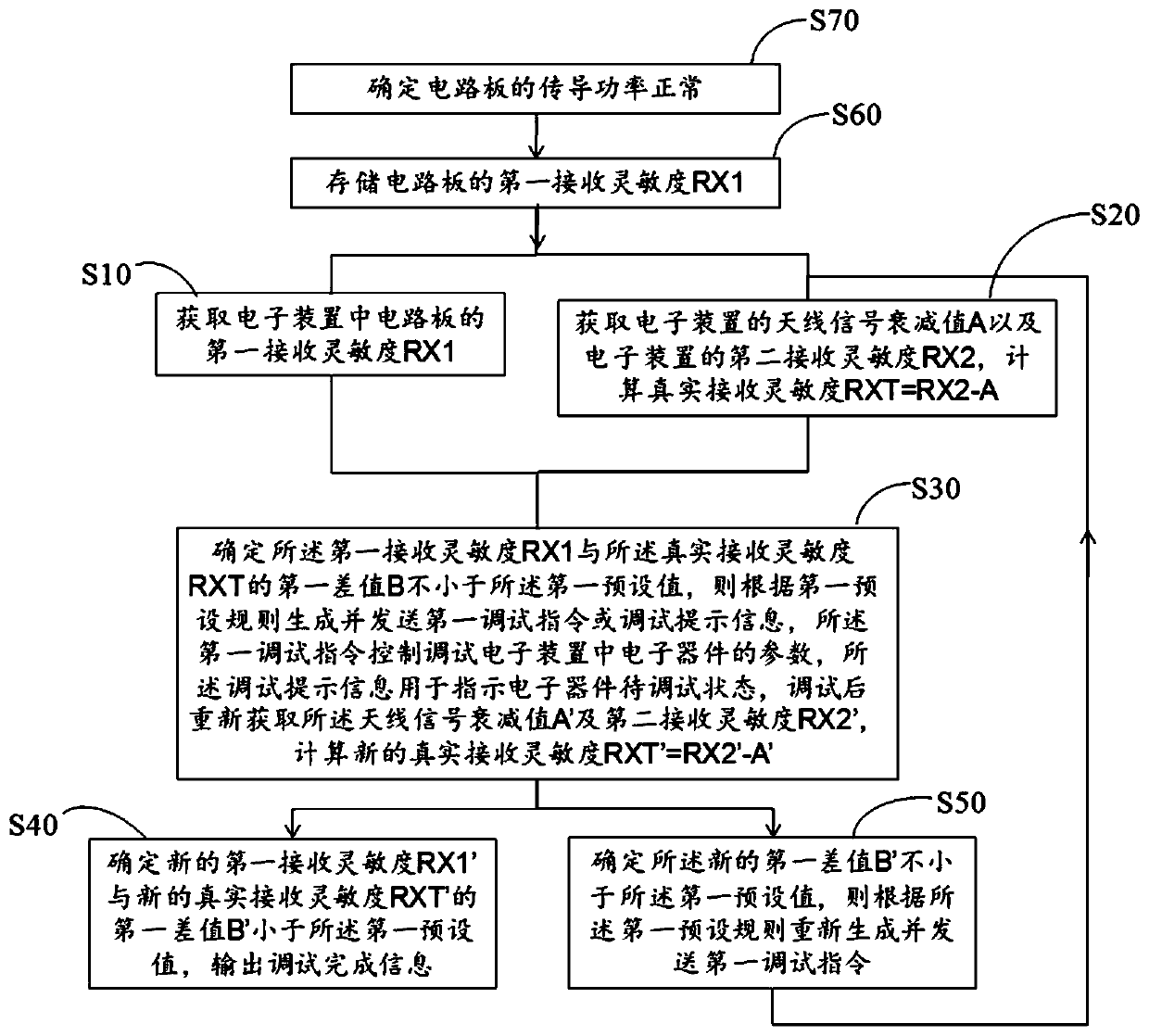

Signal interference debugging method, signal interference debugging device, computer equipment and storage medium

ActiveCN110958061AReduce distractionsMeet the practical applicationReceivers monitoringComputer hardwareSoftware engineering

The invention discloses a signal interference debugging method. The method comprises the following steps: acquiring first receiving sensitivity of a circuit board; acquiring an antenna signal attenuation value of an electronic device and second receiving sensitivity of the electronic device, and calculating real receiving sensitivity; if it is determined that a first difference value between the first receiving sensitivity and the real receiving sensitivity is not less than a first preset value, generating and sending a first debugging instruction or debugging prompt information according to afirst preset rule, wherein the first debugging instruction controls and debugs parameters of electronic components in the electronic device, the debugging prompt information is used for indicating the to-be-debugged states of the electronic components; obtaining the antenna signal attenuation value and the second receiving sensitivity again after debugging, and calculating the new real receivingsensitivity; and determining that the first difference value between the new first receiving sensitivity and the new real receiving sensitivity is smaller than the first preset value, and outputting debugging completion information. The method is simple and accurate in debugging. The invention further provides a debugging device, computer equipment and a storage medium.

Owner:恒大恒驰新能源汽车研究院(上海)有限公司

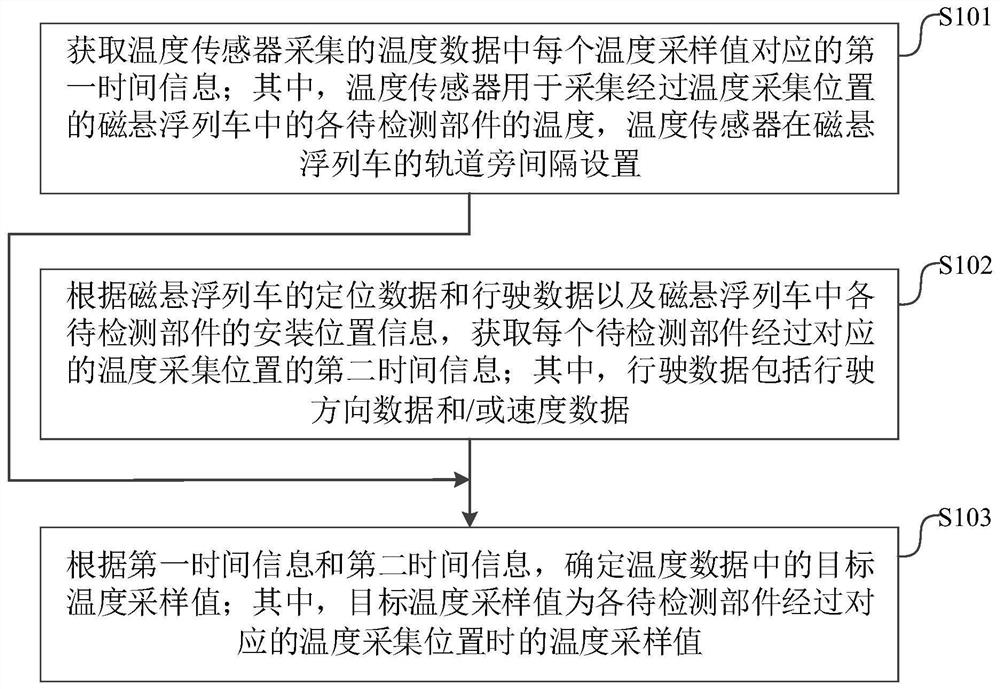

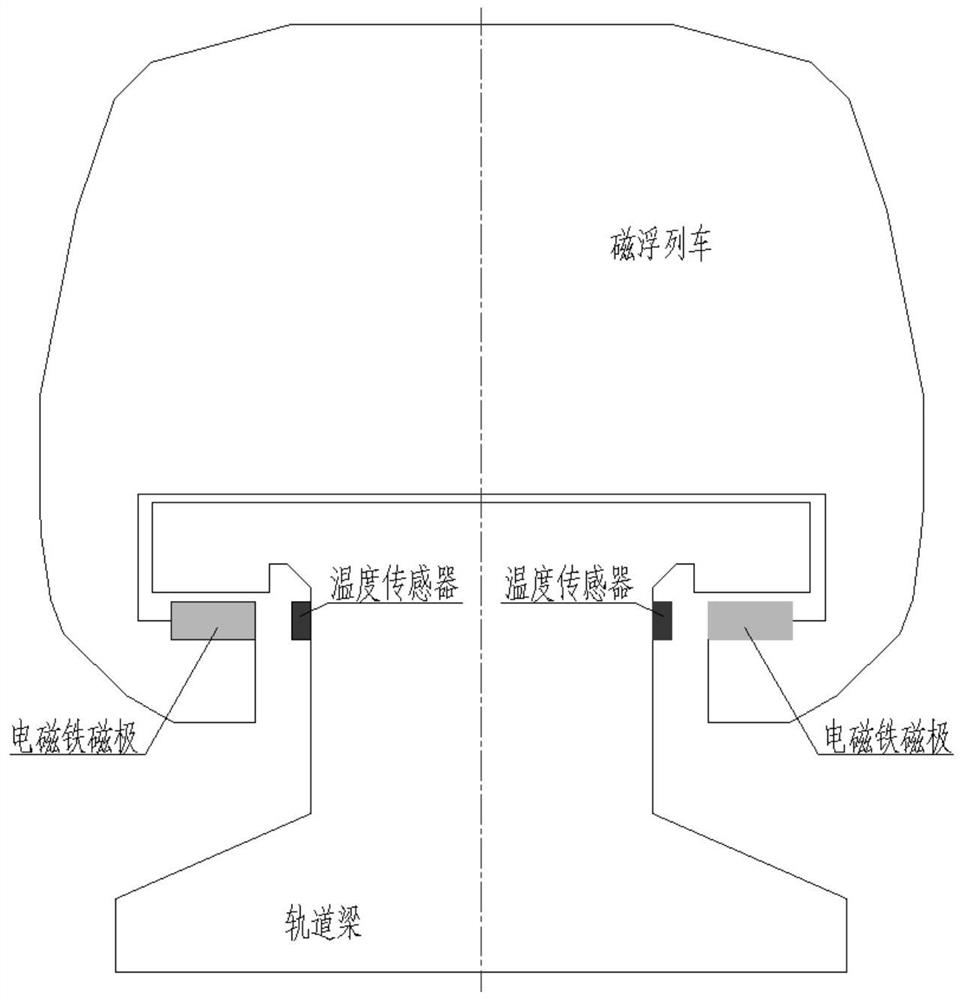

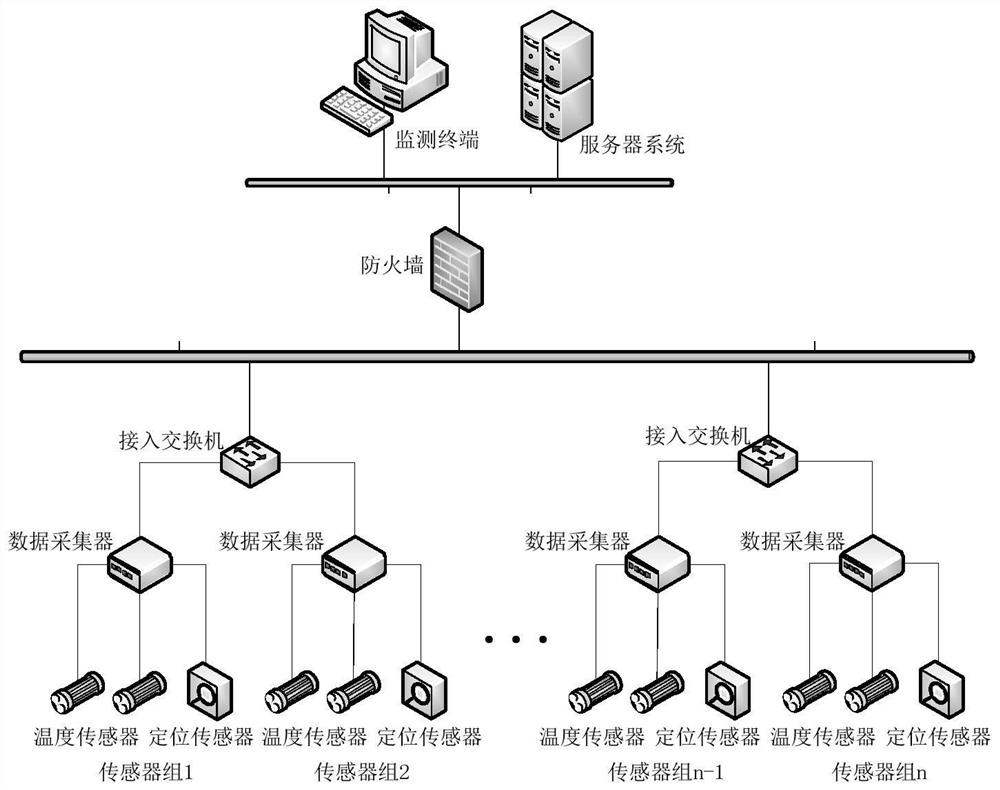

Temperature detection method, device and system for magnetically levitated train and server

PendingCN114674458AAccurate detectionAvoid weightThermometer applicationsTime informationEngineering

The invention discloses a temperature detection method, device and system for a maglev train and a server. The method comprises the steps that first time information corresponding to each temperature sampling value in temperature data collected by a temperature sensor is obtained; according to the positioning data and the driving data of the magnetically levitated train and the installation position information of each to-be-detected component in the magnetically levitated train, obtaining second time information of each to-be-detected component passing through the corresponding temperature acquisition position; determining a target temperature sampling value in the temperature data according to the first time information and the second time information; according to the invention, through comparative analysis of the time information of the temperature sampling value collected by the temperature sensor and the time information of the to-be-detected part passing through the temperature collection position, the accurate temperature value collected by the temperature sensor when the to-be-detected part passes through the temperature collection position is extracted; therefore, the temperature of the electromagnet of the maglev train can be accurately detected in a non-contact manner, and the influence on the wiring design and weight control of the train is avoided.

Owner:CRRC QINGDAO SIFANG CO LTD

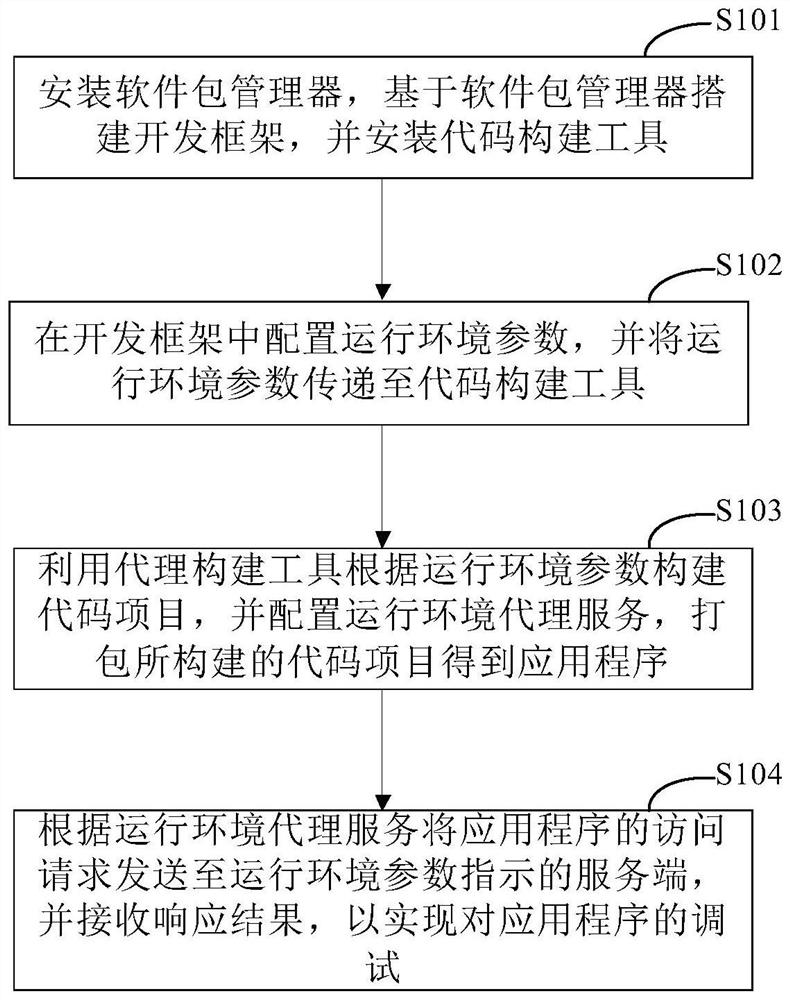

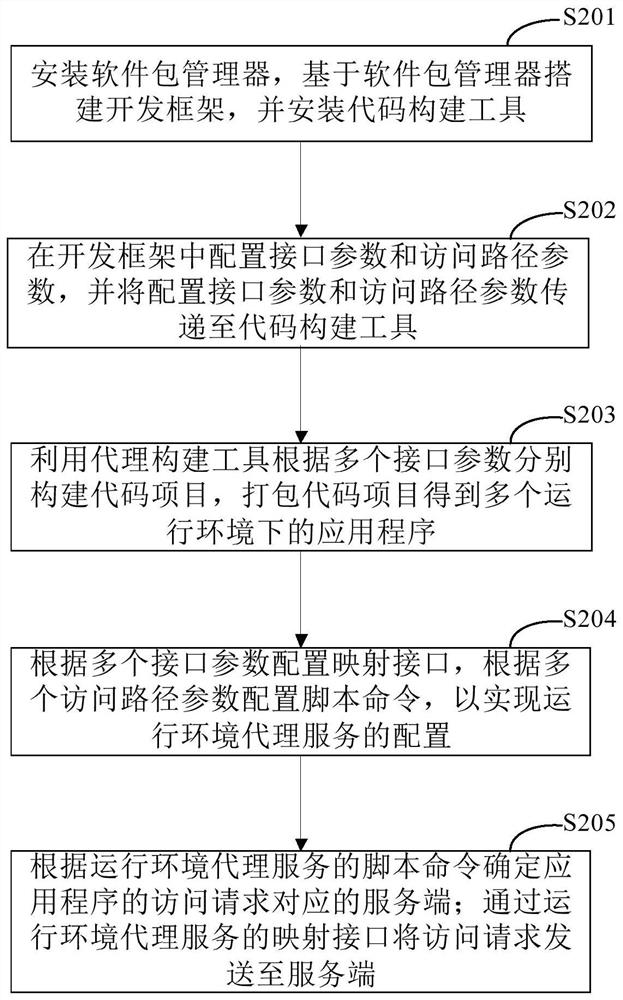

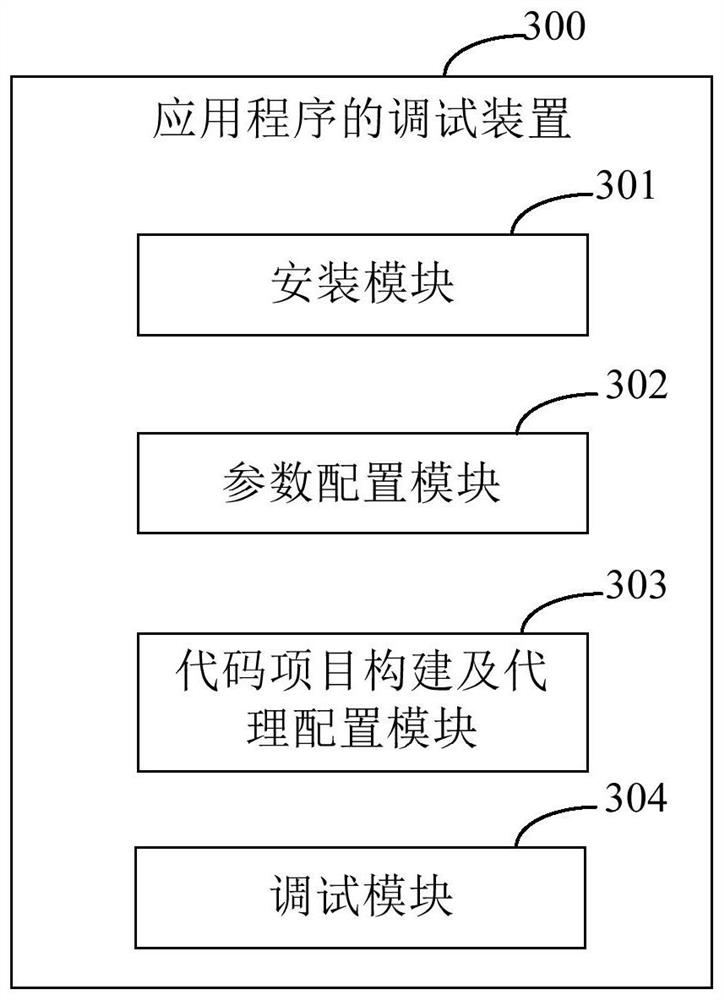

Application program debugging method and device, electronic equipment and computer readable medium

ActiveCN113468067AOvercoming the time-consuming debuggingImprove debugging efficiency and debugging effectSoftware testing/debuggingProxy serviceComputer programming

The invention discloses an application program debugging method and device, electronic equipment and a computer readable medium, which relate to the technical field of automatic program design. A specific embodiment of the method comprises the following steps of installing a software package manager, establishing a development framework based on the software package manager, and installing a code construction tool, configuring operation environment parameters in the development framework, and transmitting the operation environment parameters to the code construction tool, constructing a code project according to the running environment parameters by utilizing an agent construction tool, configuring a running environment agent service, and packaging the constructed code project to obtain an application program, and sending an access request of the application program to a server indicated by the running environment parameters according to the running environment proxy service, and receiving a response result so as to debug the application program. According to the embodiment, the debugging efficiency and the debugging effect are improved, and the application scene of debugging is expanded.

Owner:CHINA CONSTRUCTION BANK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com