Adjustment card manufacturing method, system, color correction matrix debugging method and device

A technology of color correction and production method, applied in the direction of color signal processing circuit, image communication, electrical components, etc., can solve the problem that the color cannot be close to the color seen by the human eye, and achieve the effect of improving the debugging effect and the true color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

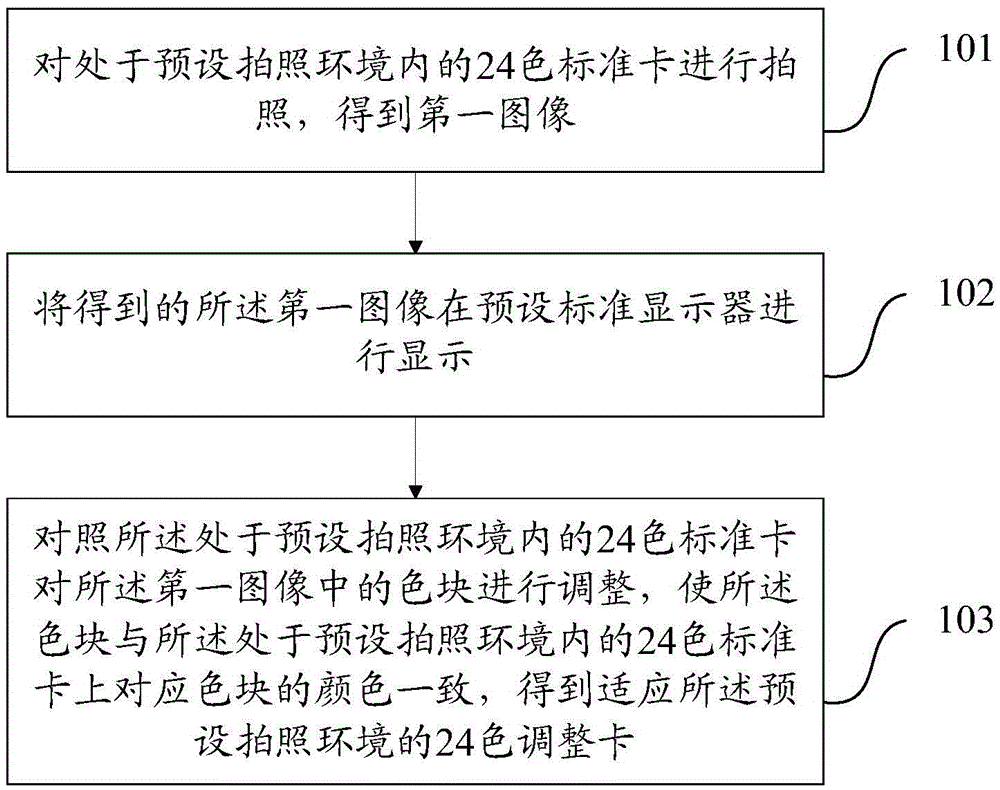

[0037] Such as figure 1 As shown, the first embodiment of the present invention provides a method for making a 24-color adjustment card, and the method includes:

[0038] Step 101: Take a photo of a 24-color standard card in a preset photo environment to obtain a first image.

[0039] Wherein, the preset photographing environment is preferably an environment illuminated by a light box.

[0040] Step 102: Display the obtained first image on a preset standard display.

[0041] Wherein, the preset standard display is preferably a display with a color difference less than 0.5 and a saturation greater than 99% and less than or equal to 100%.

[0042] Step 103: Adjust the color blocks in the first image according to the 24-color standard card in the preset photographing environment, so that the color blocks are on the same level as the 24-color standard card in the preset photographing environment The colors of the corresponding color blocks are consistent, and a 24-color adjust...

no. 2 example

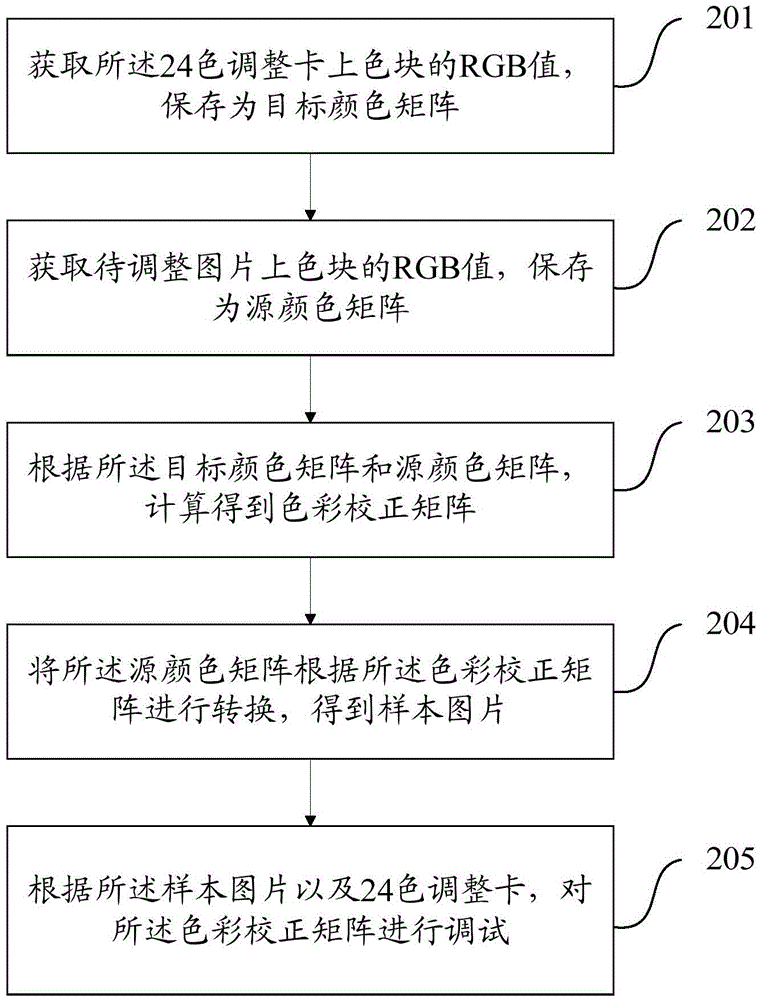

[0047] Such as figure 2 As shown, the second embodiment of the present invention provides a method for debugging the color correction matrix using the 24-color adjustment card produced by the production method described in the first embodiment above, the method comprising:

[0048] Step 201: Obtain the red, green and blue color RGB values of the color blocks on the 24-color adjustment card, and save them as a target color matrix;

[0049] Among them, the 24-color adjustment card is arranged as a 4×6 color block matrix, and the color blocks in the last row are white, gray and black, but the brightness is different, so you can only obtain the RGB values of the color blocks in the upper three rows, and correspondingly adjust the image to be adjusted. The RGB values corresponding to the color blocks, that is, the target color matrix may be a 3×6 matrix.

[0050] Step 202: Obtain the RGB value of the color block on the image to be adjusted, and save it as a source color m...

no. 3 example

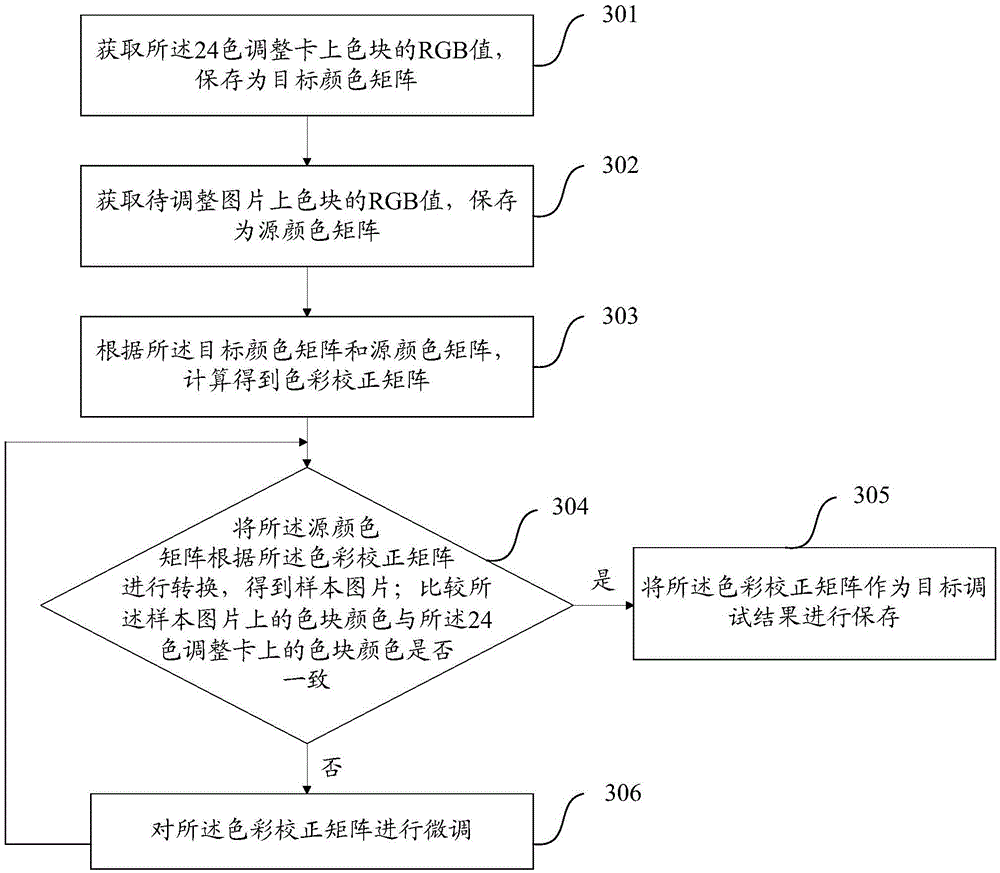

[0063] Based on the above-mentioned second embodiment, the method for debugging the color correction matrix of the 24-color adjustment card produced by the production method described in the above-mentioned first embodiment includes: obtaining the RGB values of the color blocks on the 24-color adjustment card, and saving them as the target Color matrix; obtain the RGB value of the color block on the picture to be adjusted, and save it as a source color matrix; calculate and obtain the color correction matrix according to the target color matrix and the source color matrix; correct the source color matrix according to the color The matrix is converted to obtain a sample picture; when the color block color on the sample picture is consistent with the color block color on the 24-color adjustment card, the color correction matrix is saved as the target debugging result; in the sample When the color of the color blocks on the picture deviates from the color of the color blocks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com