Grinder tool machine analytic system

An analysis system and machine tool technology, which is applied in the direction of manufacturing tools, grinding machine parts, metal processing equipment, etc., can solve problems such as poor stability and reliability, general debugging effect, and low efficiency, so as to improve accuracy and debug Good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

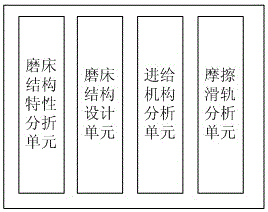

[0023] In Embodiment 1, a grinding machine tool analysis system is provided, please refer to figure 1 , the system includes:

[0024] The structural characteristic analysis unit of the grinder, the structural characteristic analysis unit of the grinder is used to analyze the structural characteristics of the grinder;

[0025] A grinder structure design unit, the grinder structure design unit is used to design the structure of the grinder;

[0026] A feed mechanism analysis unit, the feed mechanism analysis unit is used to analyze the feed mechanism of the grinding machine;

[0027] The friction slide rail analysis unit is used for analyzing the friction force between the workbench and the slide rail.

[0028] Wherein, in the embodiment of the present application, the structural characteristic analysis unit of the grinding machine is specifically to use ANSYS finite element software to analyze various structural characteristics of the grinding machine, including: structural s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com