Method for debugging secondary equipment of transformer substation

A technology for secondary equipment and substations, applied in the field of secondary equipment commissioning in substations, can solve the problems of low level of commissioning automation, affecting the efficiency and quality of commissioning, and inability to visualize and track the progress of engineering commissioning in real time, so as to achieve automatic generation and improve commissioning. Effects and Quality of Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

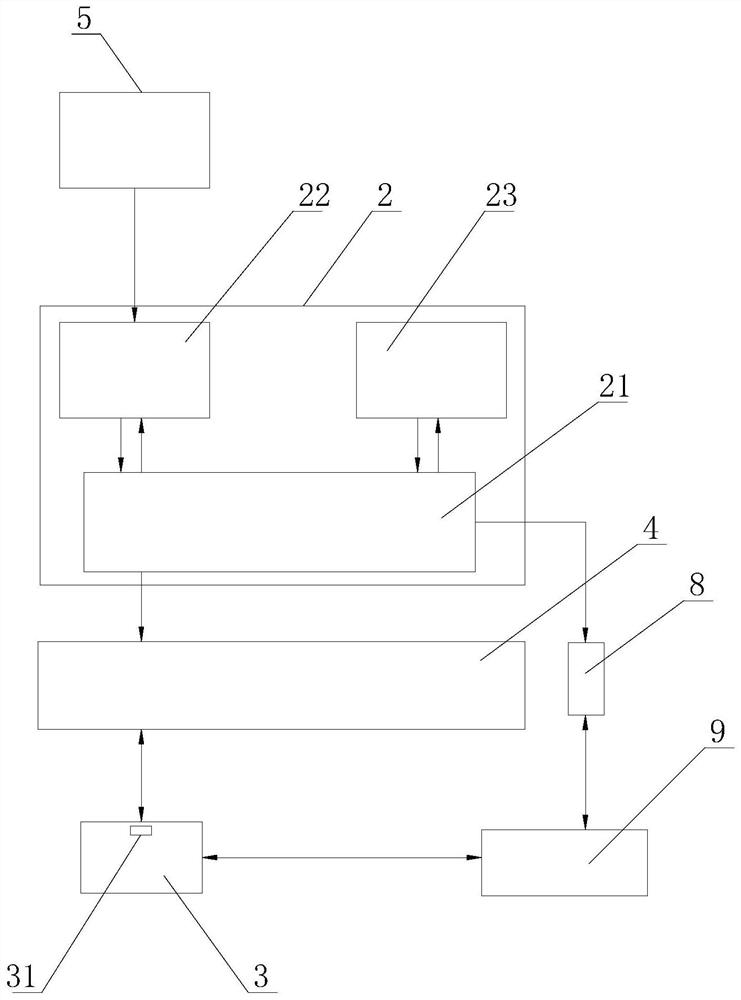

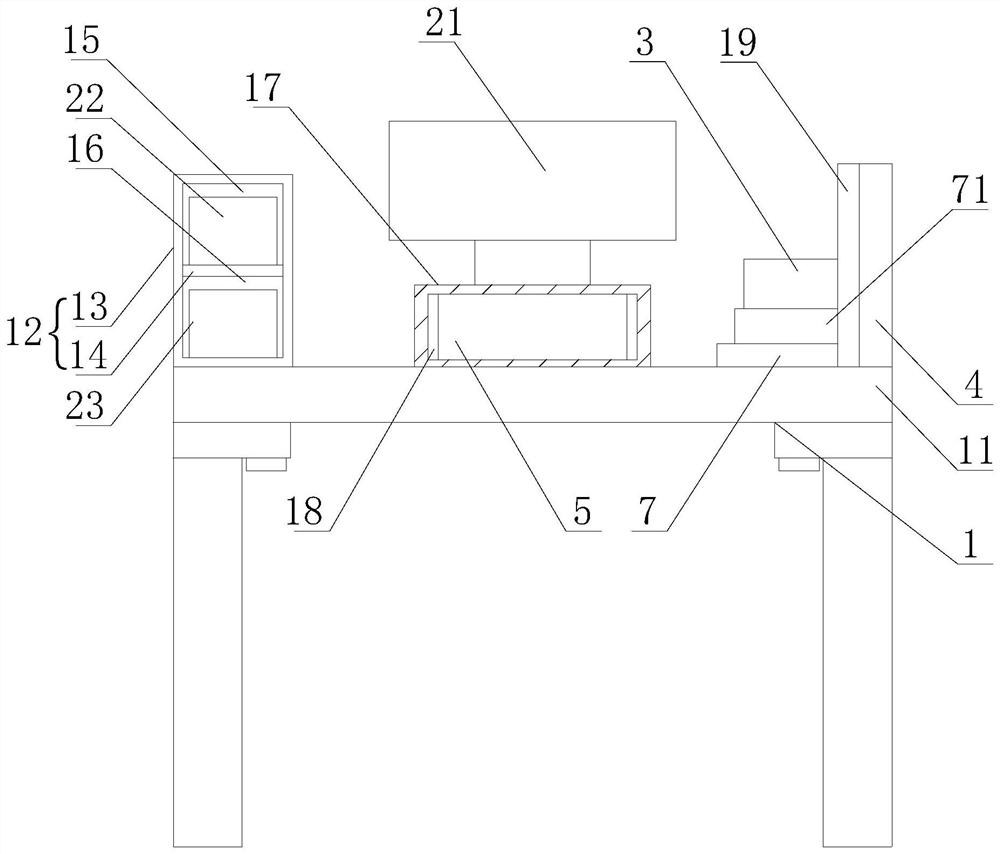

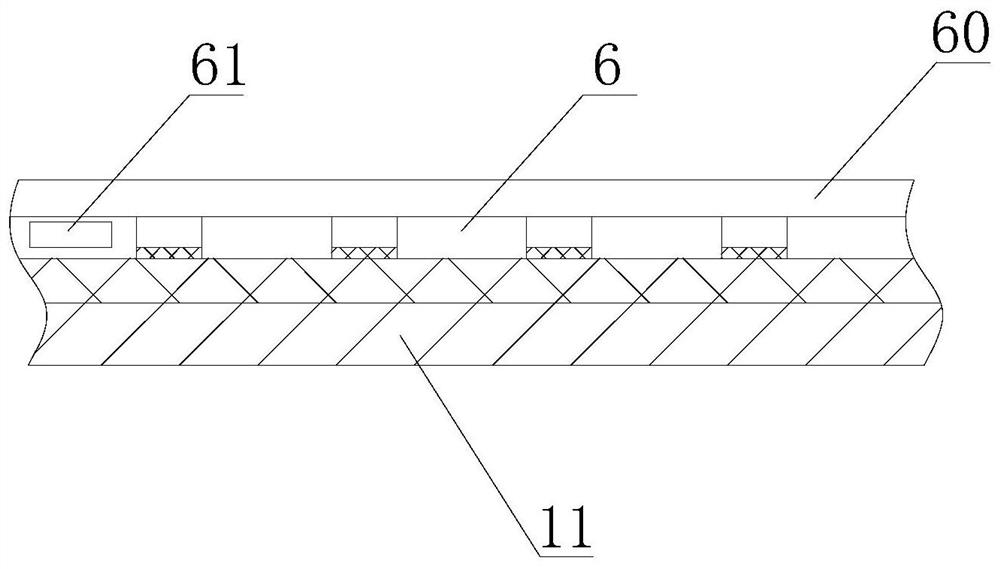

[0023] like figure 1 , figure 2 As shown, a method for debugging secondary equipment in substations, including a bracket 1, a debugging terminal 2, a debugging instrument 3 and a network switch 4, and the debugging terminal 2, debugging instrument 3 and network switch 4 are all installed on the bracket 1 , the device under test 8 is connected to the debugging terminal 2, the device under test 8 is connected to the debugging terminal 2 through the debugging instrument 3, the database server 5 for saving and protecting the original template is connected on the debugging terminal 2, and the debugging terminal 2 includes a For the control PC 21 responsible for the work scheduling and orderly connection of each subsystem, the first auxiliary PC 22 for debugging template generation, and the second auxiliary PC 23 for debugging result diagnosis, the method includes in sequence The following steps:

[0024] Step 1: Obtain the model of the device under test 8 by controlling the PC, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com