Method for controlling stirring and balanced oscillating of deep penetration K-TIG welding pool

A technology of welding molten pool and control method, applied in welding equipment, manufacturing tools, arc welding equipment, etc., can solve problems such as low efficiency, increased equipment complexity, equipment cost, and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

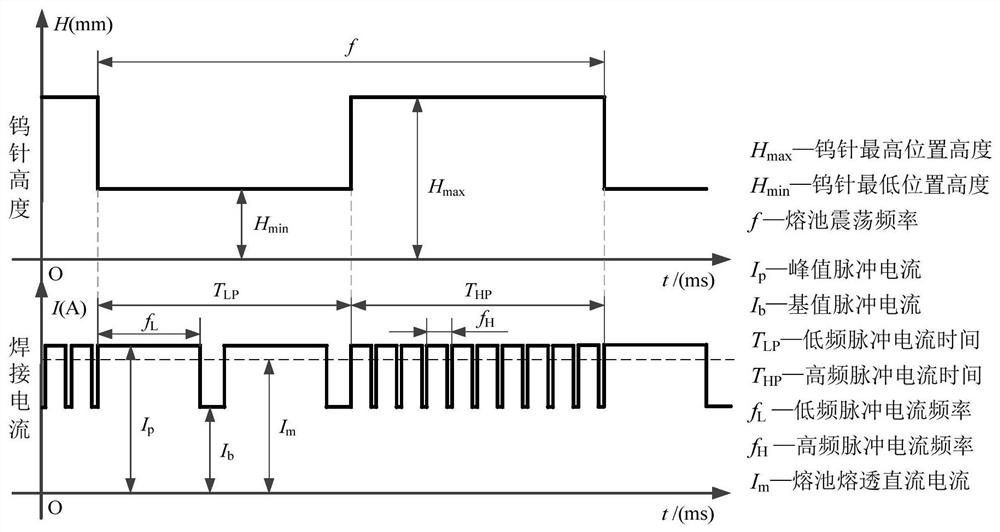

[0046] Such as figure 2 As shown, when the tungsten needle jumps from the highest position to the lowest position, the tungsten needle is in the low position area, and the welding power system outputs low-frequency pulse current; when the tungsten needle jumps from the lowest position to the highest position, the tungsten needle is in the high position area, and the welding The power system outputs high-frequency pulse current.

Embodiment 2

[0048] Such as image 3 As shown, when the tungsten needle gradually moves from the lowest position to the highest position, the tungsten needle enters the high position area from the low position area. When the tungsten needle is in the low position area, the welding power system outputs low-frequency pulse current; when the tungsten needle is in the high position When the tungsten needle jumps from the highest position to the lowest position, the tungsten needle enters the low position area from the high position area, and the welding power system outputs low frequency pulse current.

Embodiment 3

[0050] Such as Figure 4 As shown, when the tungsten needle gradually moves from the lowest position to the highest position, the tungsten needle enters the high position area from the low position area. When the tungsten needle is in the low position area, the welding power system outputs low-frequency pulse current; when the tungsten needle is in the high position When the tungsten needle moves from the highest position to the lowest position gradually, the tungsten needle enters the position area from the high and low position area, and when the tungsten needle is in the high position area, the welding power system outputs high Frequency pulse current; when the tungsten needle is in the low position area, the welding power system outputs low frequency pulse current.

[0051] In the above-mentioned first, second and third embodiments, when the welding power supply system outputs low-frequency pulse current, the distance between the tungsten needle of the welding torch and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com