Online debugging system of brushless DC motor

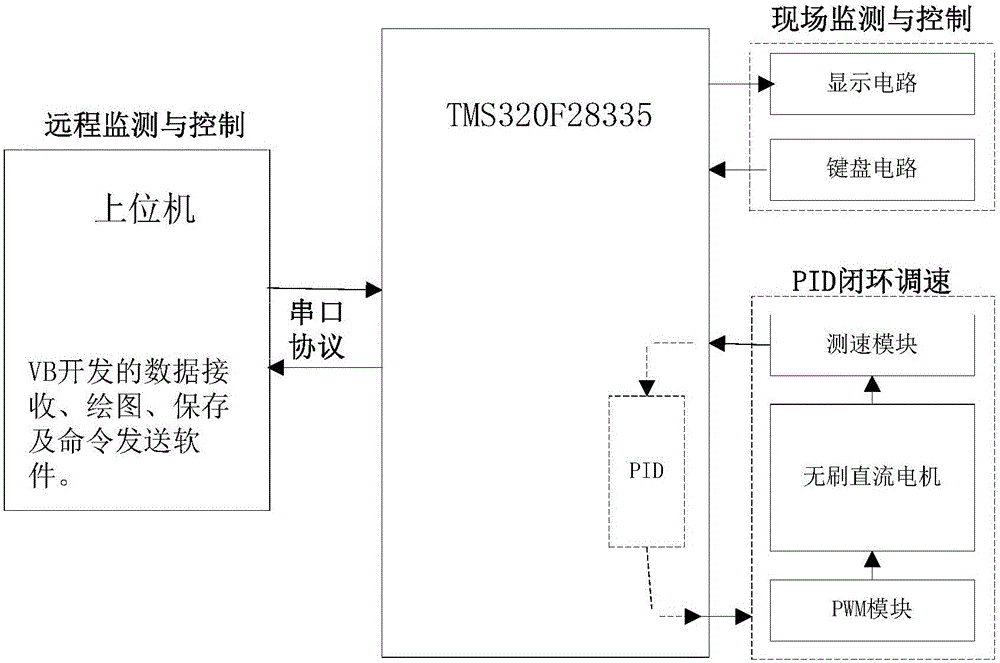

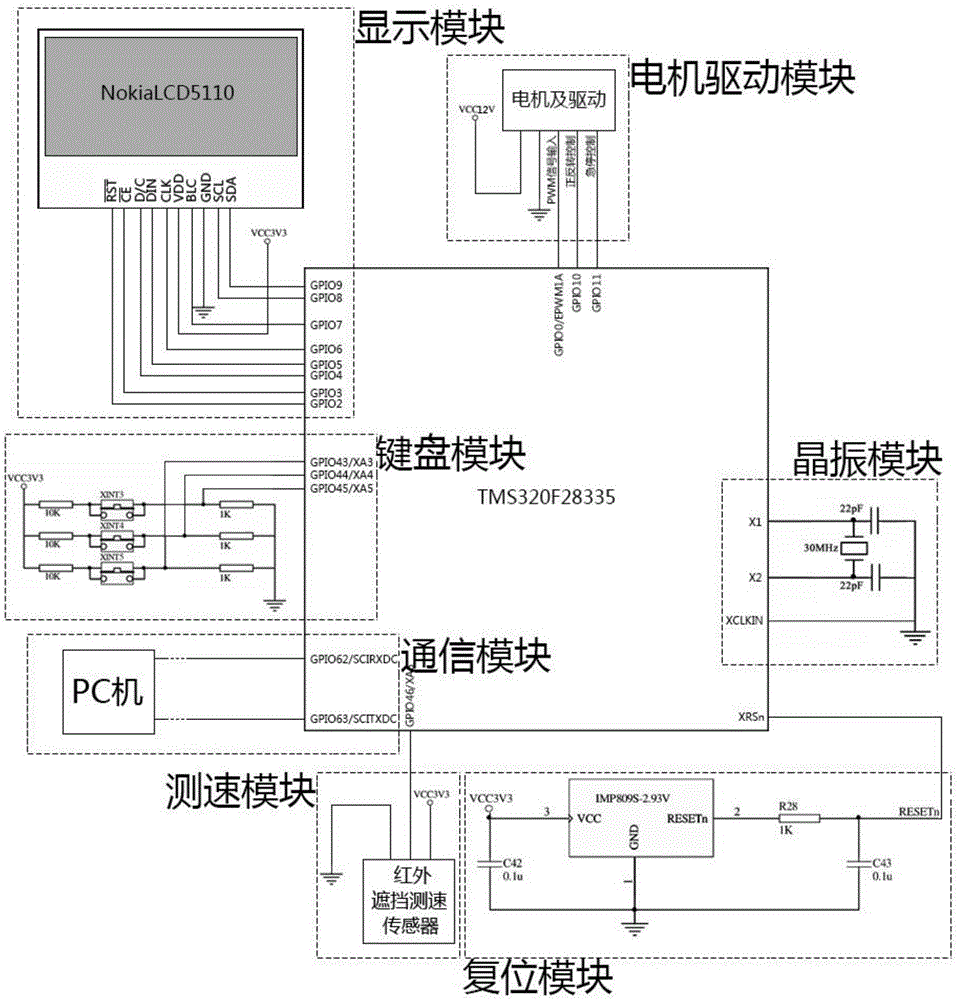

A technology of brushing DC motor and debugging system, applied in control system, control generator, vector control system, etc., can solve problems such as large error, and achieve the effect of fast control response, easy and timely regulation, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

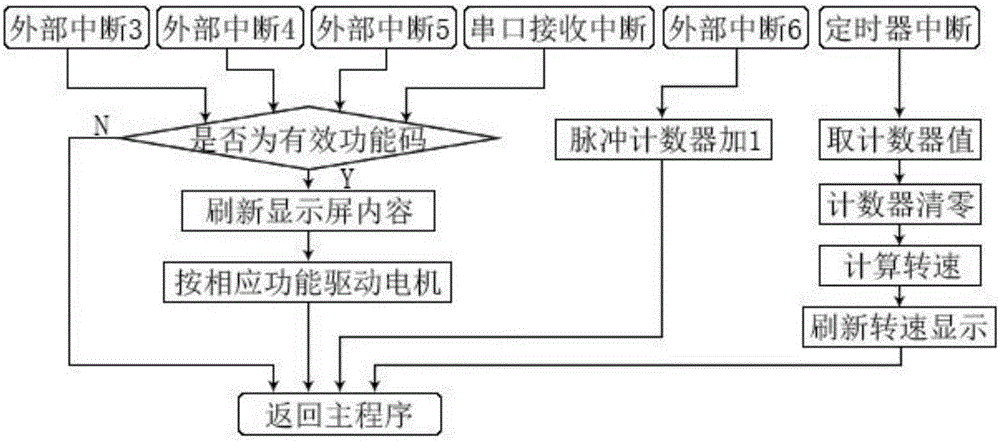

[0059] Embodiment: For example, the motor speed needs to be stabilized to 1200 rpm through the PID link, and the current Kp, Ti, and Td values are all 0.000, that is, the PID link has not played a substantial role for the time being.

[0060] When debugging, start with Kp first, for example, give Kp=0.05 to get the real-time speed curve, but now I don’t know whether this value is too large or too small, and then try to give a larger value Kp=0.2 to get such Image 6 In the curve (below), it is obvious that the rotational speed value has already oscillated violently, and the static stability is very poor. Comparing the results of these two times, we can see that Kp=0.2 is too large. Then try Kp=0.1, a value between 0.05 and 0.2, to get as Image 6 (Above) curve, the result is relatively good, and a relatively fast response speed and good stability are obtained. Therefore the Kp parameter is determined as Kp=0.1.

[0061] Then adjust the differential parameter Td. Similar ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com