Drum boiler pipe blowing debugging method and system

A technology of drum boiler and debugging method, which is applied in the field of combustion boilers, and can solve problems such as inability to ensure the effect of drum blowing and debugging of drum boilers, and affecting the safe operation of generator sets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

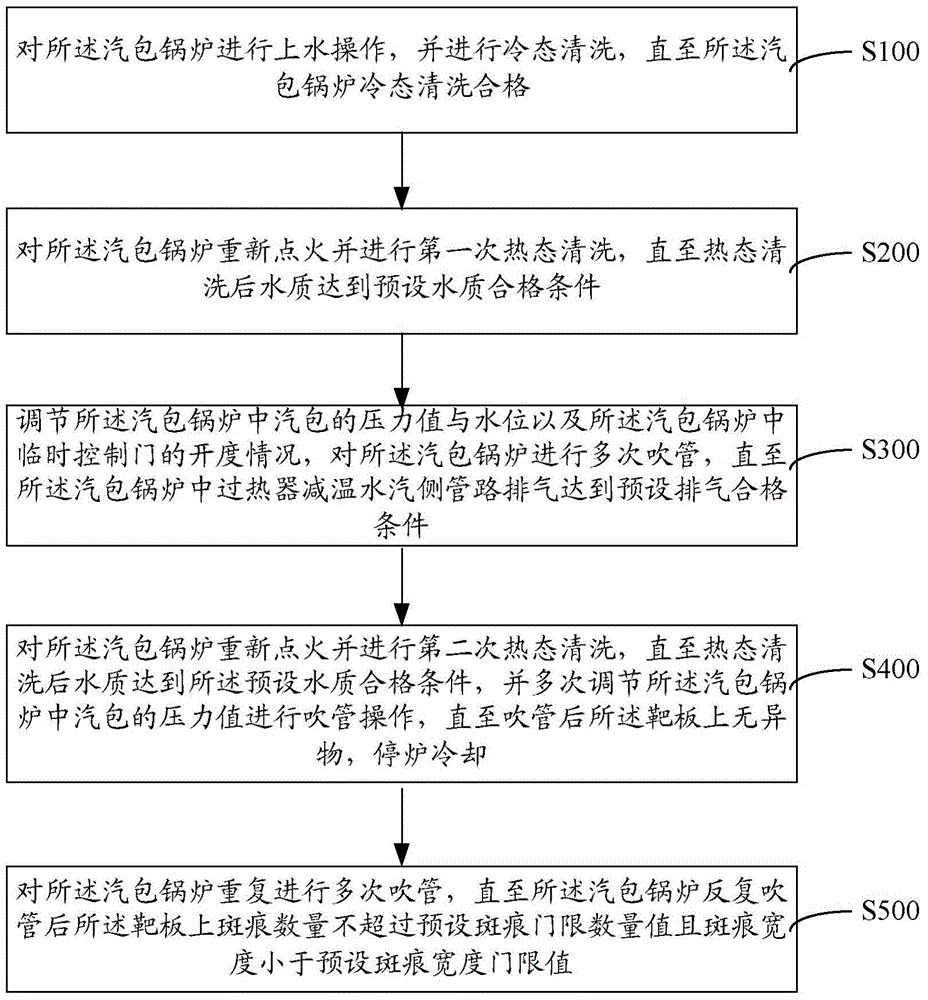

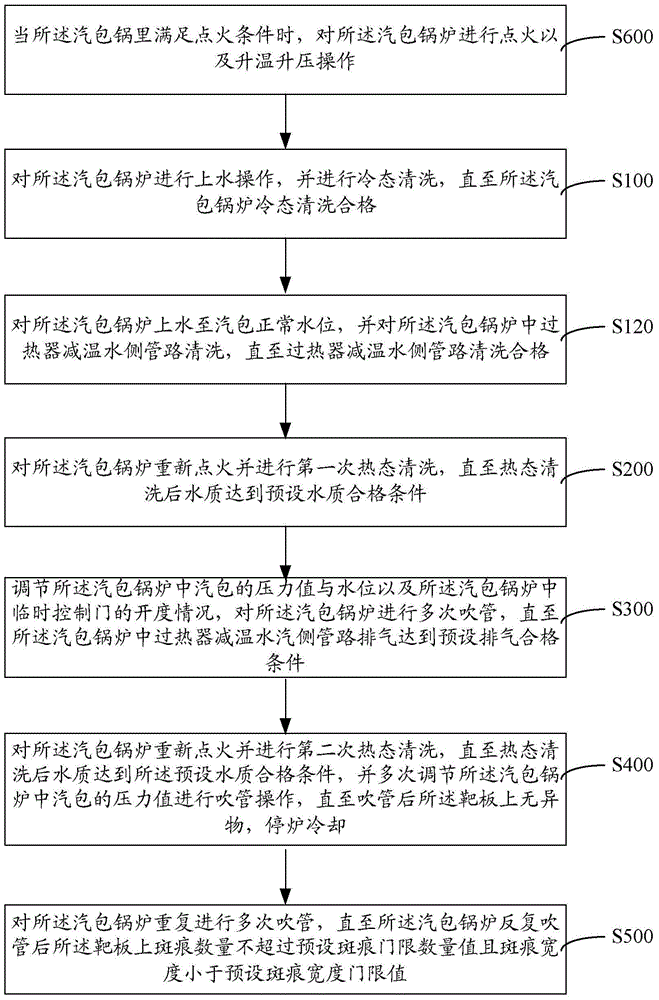

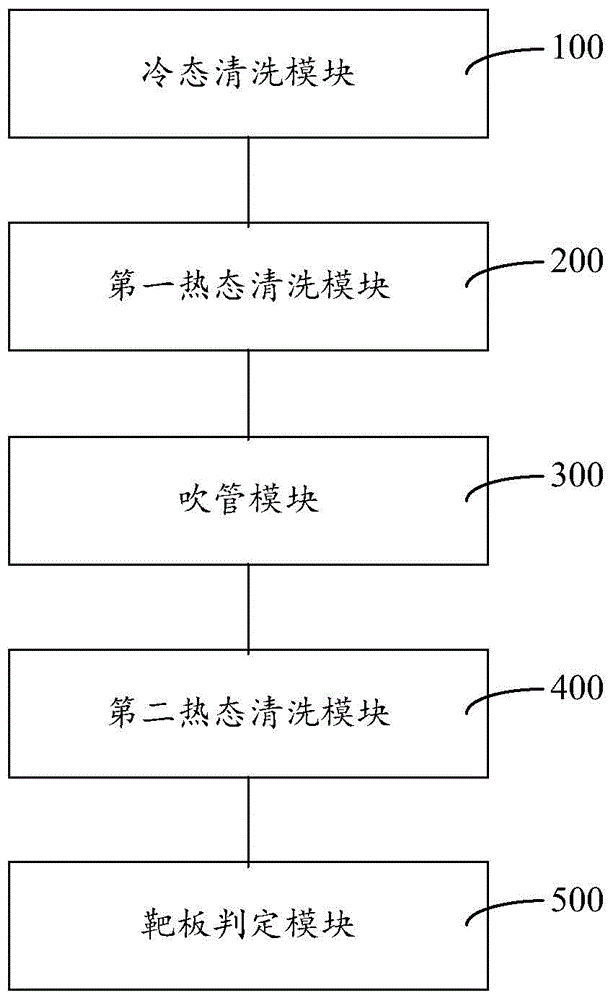

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain in detail the technical solution and beneficial effect of the drum boiler blowpipe debugging method of the present invention, in the following explanation, an existing drum boiler will be mainly used as the research object for description. This type of drum boiler is specifically manufactured by Dongfang Boiler Factory, with medium pressure parameters, natural circulation, single furnace, pulverized coal swirl burner arranged on the front wall, micro positive pressure combustion, double flue at the rear (along the furnace width direction), and adopts Tubular air preheater, all-steel frame Π-shaped drum furnace. The boiler model is DG38.5 / 3.82-II1. There are three swirl burners arranged in a font on the front wall of the boiler. The primary air is DC air, and the peripheral secondary air is swirl air.

[0026] In actual operation, some preparatory work needs to be done before the blowpipe debugging of the drum boiler, so that the blowpipe debugging ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com