Mechanical failure debugging device for rotor craft

A technology for rotorcraft and mechanical failure, applied in electrical testing/monitoring and other directions, can solve the problems of not considering the mechanical installation accuracy of the rotorcraft, wiring errors, errors, etc., and achieves good debugging effect, convenient operation, and improved control accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

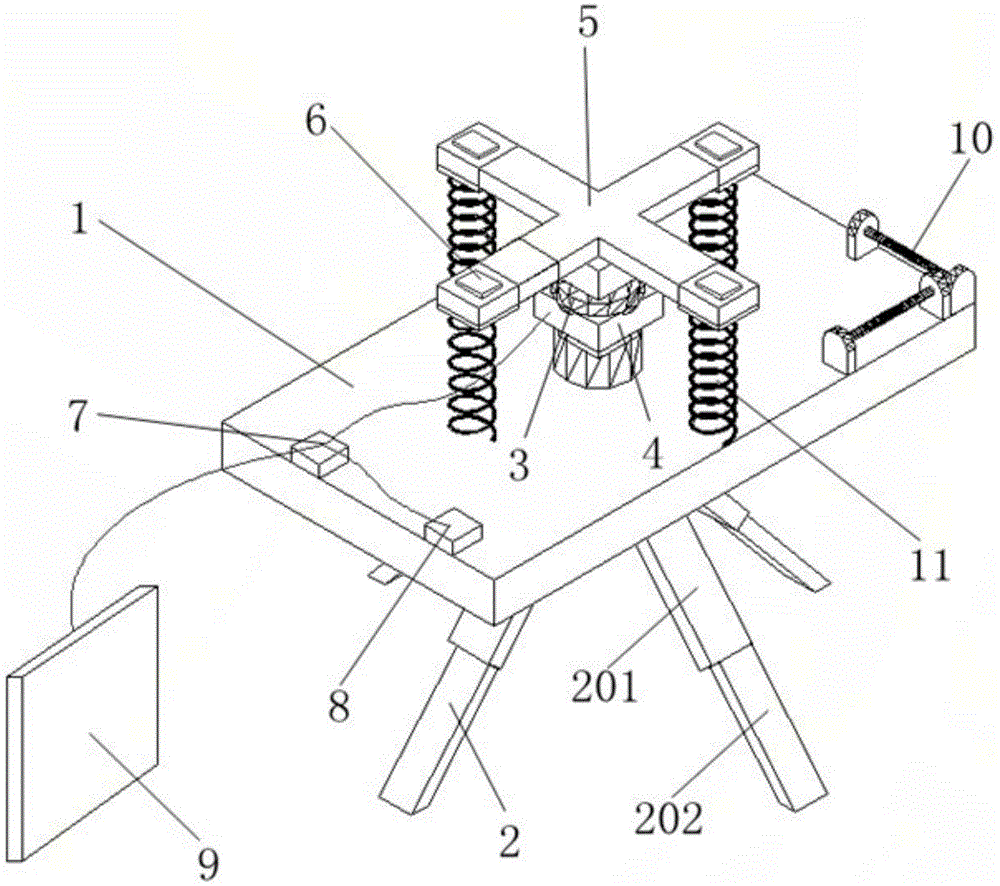

[0017] Such as figure 1 As shown, the mechanical failure debugging device for rotorcraft includes a base 1, the base 1 is supported by a telescopic tripod 2, and a spherical universal joint 3 is installed on the upper surface of the base 1, and the The spherical universal joint 3 is connected with an encoder 4 for obtaining the three-dimensional attitude data of the spherical universal joint 3, and the spherical universal joint 3 is equipped with a force arm fixing frame 5, and the force arm quantity of the force arm fixing frame 5 is the same as The rotor support quantity of rotorcraft is corresponding, and pressure sensor 6 is all installed on described each arm of force, when rotorcraft is installed on the arm fixed frame 5, described pressure sensor 6 is positioned at the arm of force and the rotor support of rotorcraft The room is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com