Integrated commercial vehicle AMT rear auxiliary synchronizer and control method

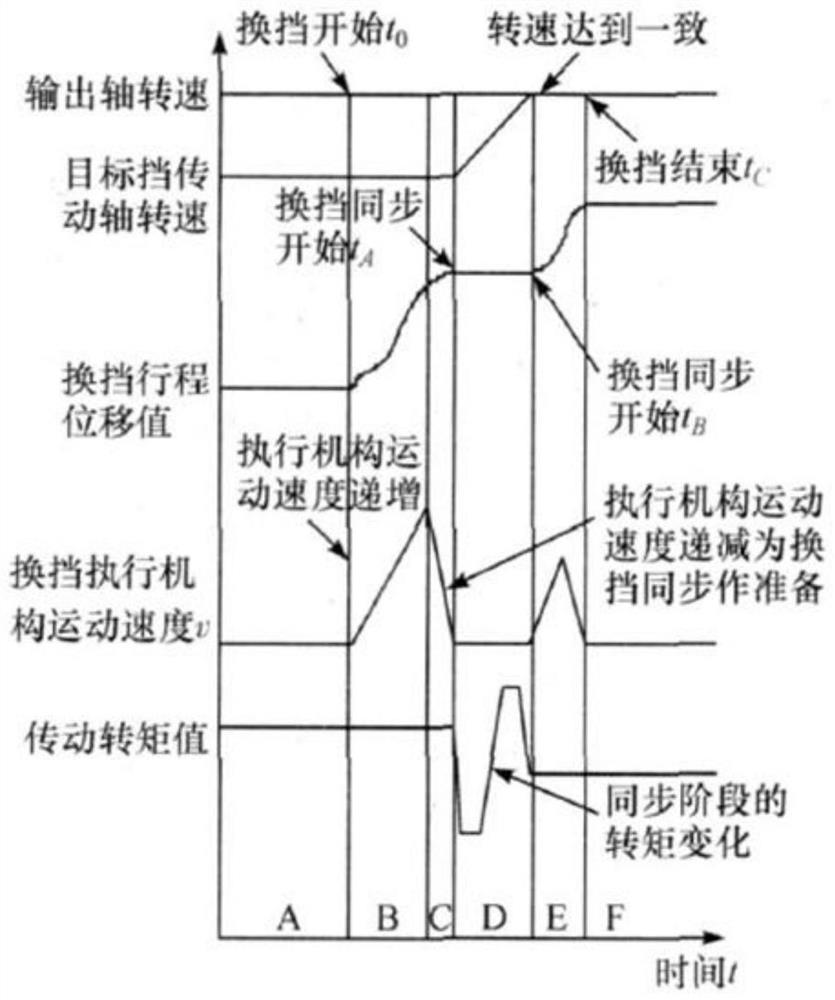

An integrated, commercial vehicle technology, applied in the control device, transmission control, clutch and other directions, can solve the problems of improper control, shifting shock, asynchronous shock, etc., to reduce the number of parts and reduce the effect of shifting shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

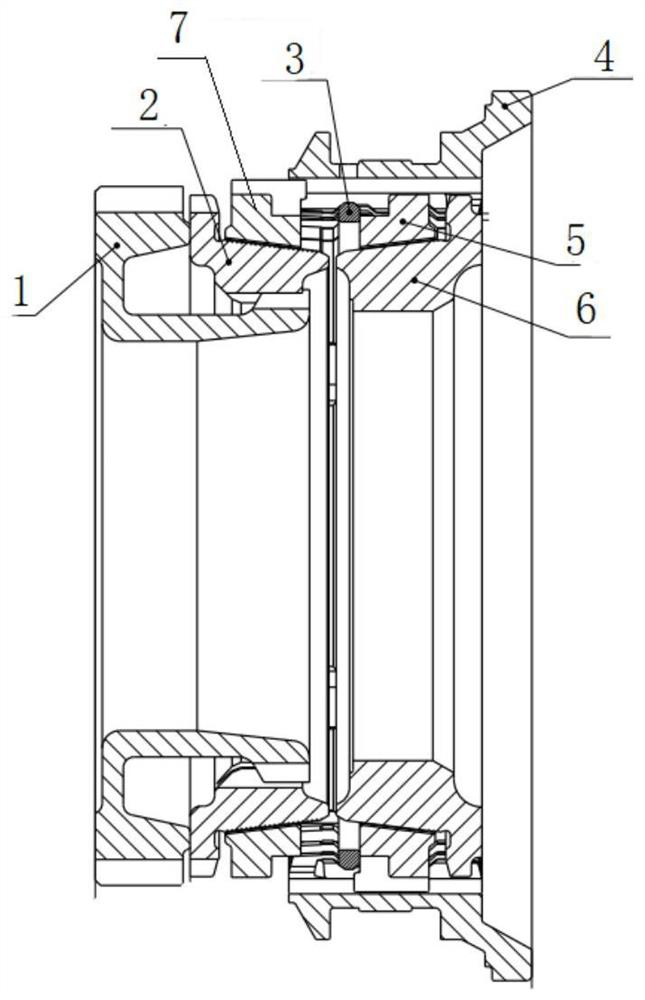

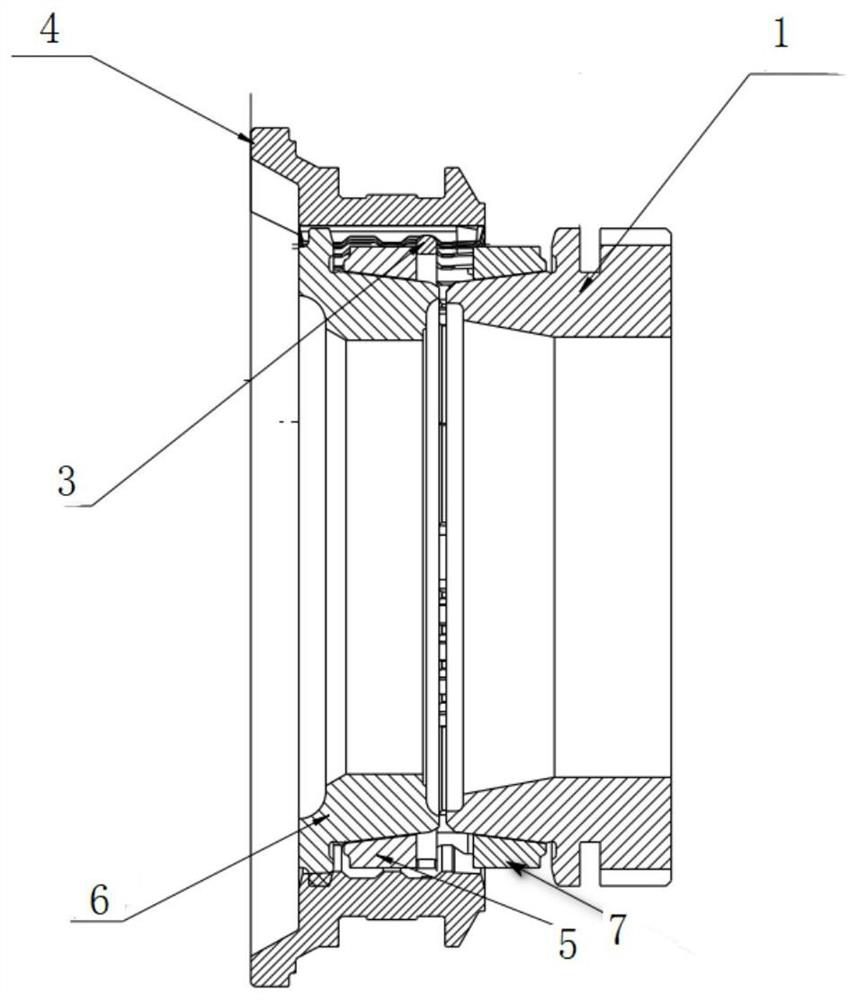

[0015] Such as figure 1 As shown, the existing rear sub-box synchronizer realizes the high / low gear switching of the rear sub-box, and the rear sub-box synchronizer assembly includes two sets of cone rings (low-grade cone ring 2 and high-grade cone ring 6), two sets of synchronization rings ( High-grade synchronous ring 5 and low-grade synchronous ring 7), a sliding sleeve (sliding tooth sleeve 4) and a low-grade conical hub (low-grade conical hub 1), this assembly is assembled on the gearbox output shaft (ie planet carrier).

[0016] The assembly relationship is described as follows:

[0017] Gear shifting execution part: rear auxiliary box cylinder shaft and cylinder piston are connected by bolts, cylinder shaft and shift fork are connected by 2 fastening screws, shift fork is set in shifting groove of sliding gear sleeve through shifting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com