Displacement device and magnetic levitation planar motor

A displacement device, the same technology, applied in the direction of electromechanical devices, magnetic attraction or thrust holding devices, electrical components, etc., can solve the problem of poor thrust accuracy of the workbench, low phase accuracy of the workbench, and different forces on the magnetic steel array and other issues to achieve the effect of increasing motion accuracy and reducing control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

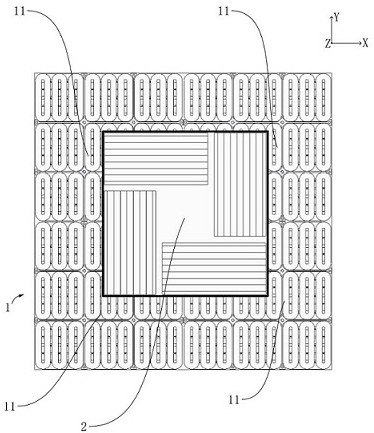

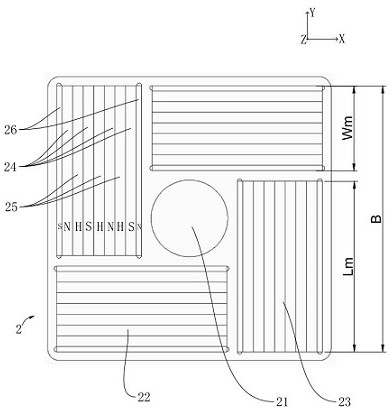

[0051] To solve the above problems, such as Figure 1-Figure 7 As shown, this embodiment provides a magnetic levitation planar motor, which includes a displacement device, and the displacement device includes a stator mechanism 1 and a working part 2 .

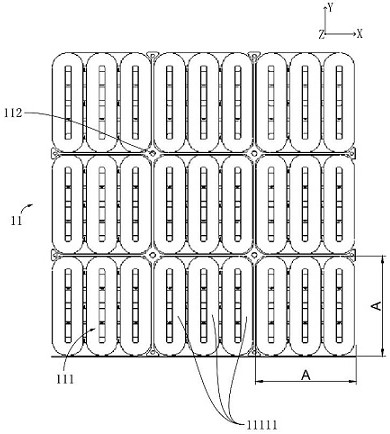

[0052] Specifically, in this embodiment, the stator mechanism 1 includes at least one module component 11, each module component 11 can generate a traveling wave magnetic field, the module components 11 have the same length in the X direction and the Y direction, and the X direction and the Y direction are orthogonal to each other. The number of rows and columns of the module assemblies 11 on the stator mechanism 1 are the same. The working part 2 is arranged above the stator mechanism 1, each module assembly 11 can generate a traveling wave magnetic field, and the traveling wave magnetic field interacts with the permanent magnetic field generated by the working part 2 to generate electromagnetic thrust, and the stator mechani...

Embodiment 2

[0066] In order to solve the problems in the prior art, this embodiment provides a magnetic levitation planar motor, including a displacement device, and the displacement device includes a stator mechanism 1 and a working part 2, and the structure of the magnetic levitation planar motor provided by this embodiment is basically the same as that of the first embodiment , only some differences exist in the structure of the module assembly 11, and this embodiment will not repeat the same structure as that of the first embodiment.

[0067] Such as Figure 8 As shown, the number of module assemblies 11 in this embodiment is four, and they are evenly arranged along the plane in a four-square grid pattern with two rows and two columns; each module assembly 11 includes at least nine coil array modules 111, arranged in three rows and three columns The Jiugongge pattern is evenly arranged along the plane. The difference between this embodiment and Embodiment 1 is that the coil array mod...

Embodiment 3

[0070] In order to solve the problems in the prior art, this embodiment provides a magnetic levitation planar motor, including a displacement device, and the displacement device includes a stator mechanism 1 and a working part 2, and the structure of the magnetic levitation planar motor provided by this embodiment is basically the same as that of the first embodiment In this embodiment, the same structure as that in Embodiment 1 will not be repeated.

[0071] In this example, if Figure 10 As shown, a plurality of module components 11 can be spliced together, and the stator mechanism 1 can be provided with a plurality of working parts 2 according to usage requirements, and each working part 2 can work independently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com