Automatic bullet sorting and assembling device

A technology for automatic sorting and assembling devices, applied in ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of low degree of automation and achieve the effects of reducing labor intensity, fast assembly speed, and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

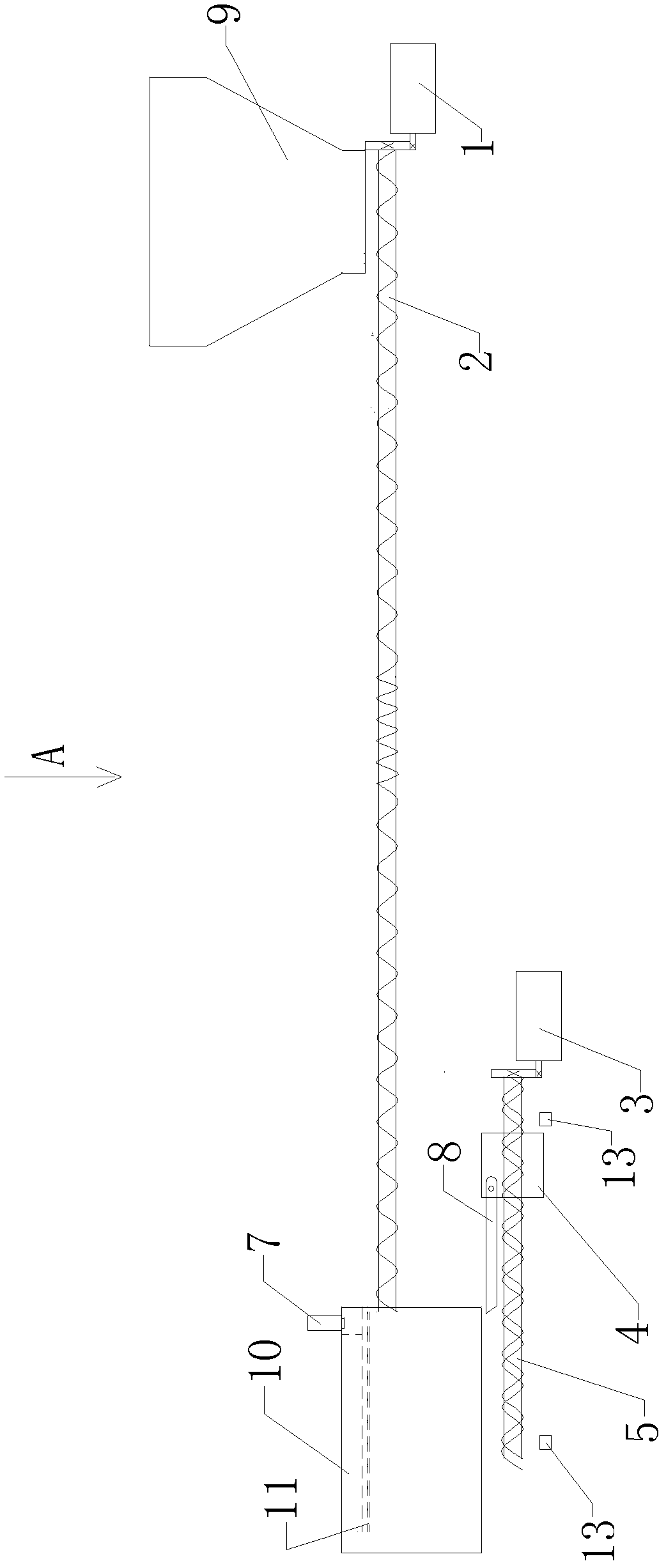

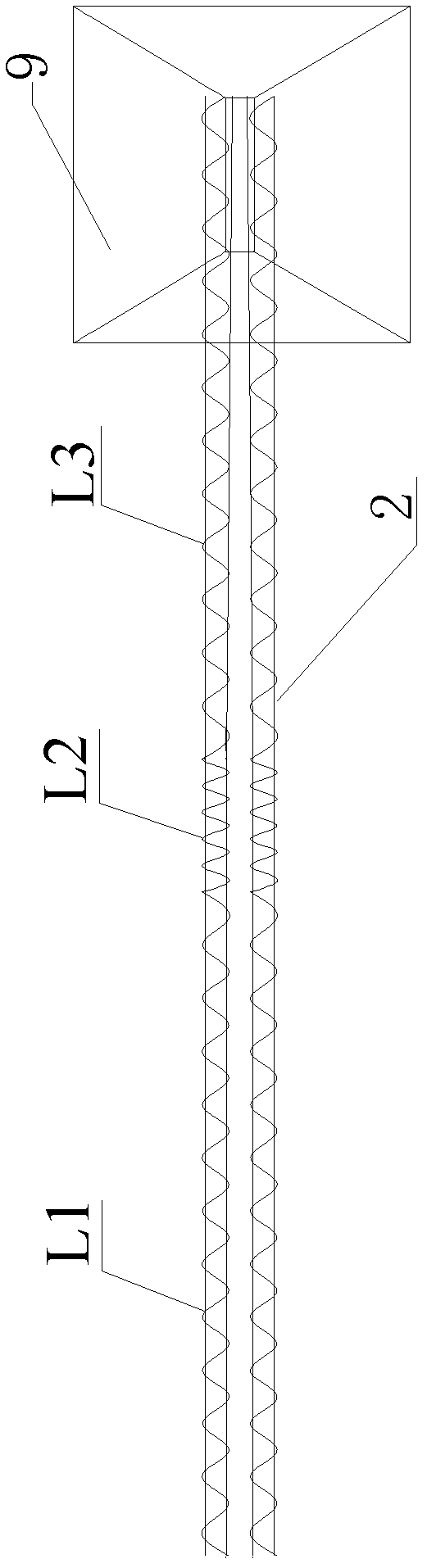

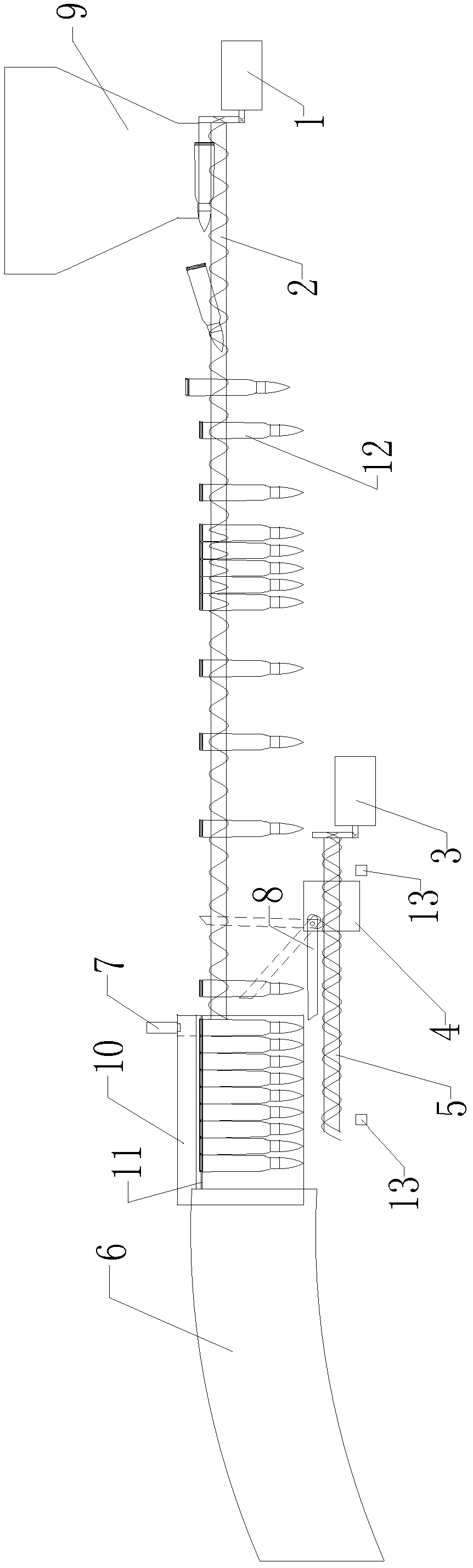

[0021] like figure 1 , figure 2 and image 3 As shown, a bullet automatic sorting assembly device includes a feed bin 9 with a vibration source, a feeding screw 2, a magazine docking device 10 and a clamping device for pushing bullets 12, and the outlet of the feed bin 9 with a vibration source The feed port of the feed port and the magazine docking device 10 is connected by two feed screw rods 2, and the two feed screw rods 2 are provided with threads and are driven by the feed motor 1, and the two feed screw rods 2 are provided with the same thread, wherein , is divided into three sections, L1, L2 and L3, the thread density of the middle section L2 should be denser than the thread density of the two side sections L1 and L3, and the bullet delivery matching the size of the bullet 12 is formed between the two feeding screw rods 2 Passage, one end of the bullet conveying passage communicates with the outlet of the feed bin 9 with the vibration source, and the other end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com