Equipment for assembling atomizing nozzle and pressing nozzle of aerosol valve

A technology for installing equipment and aerosol valves, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of slow assembly speed, low efficiency, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

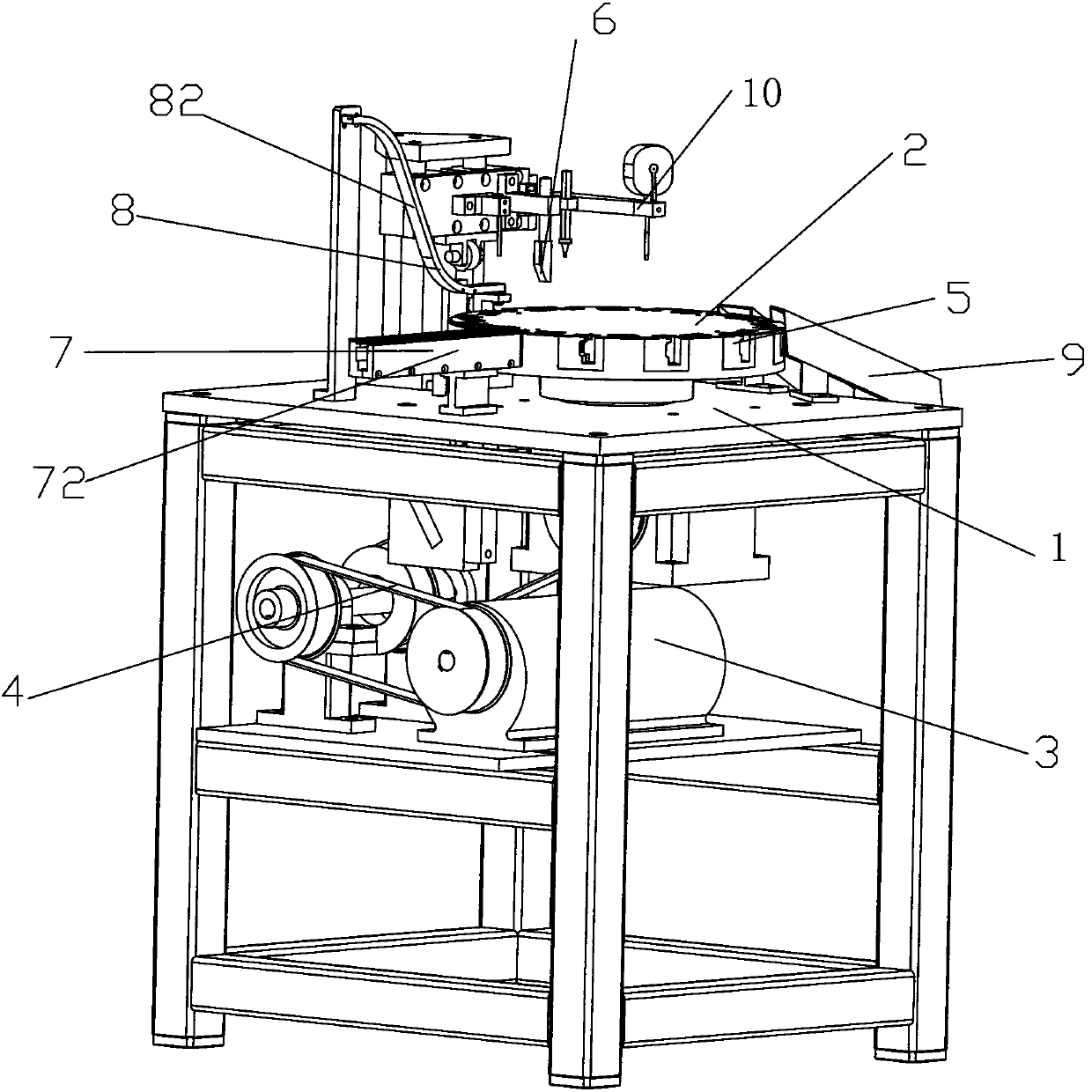

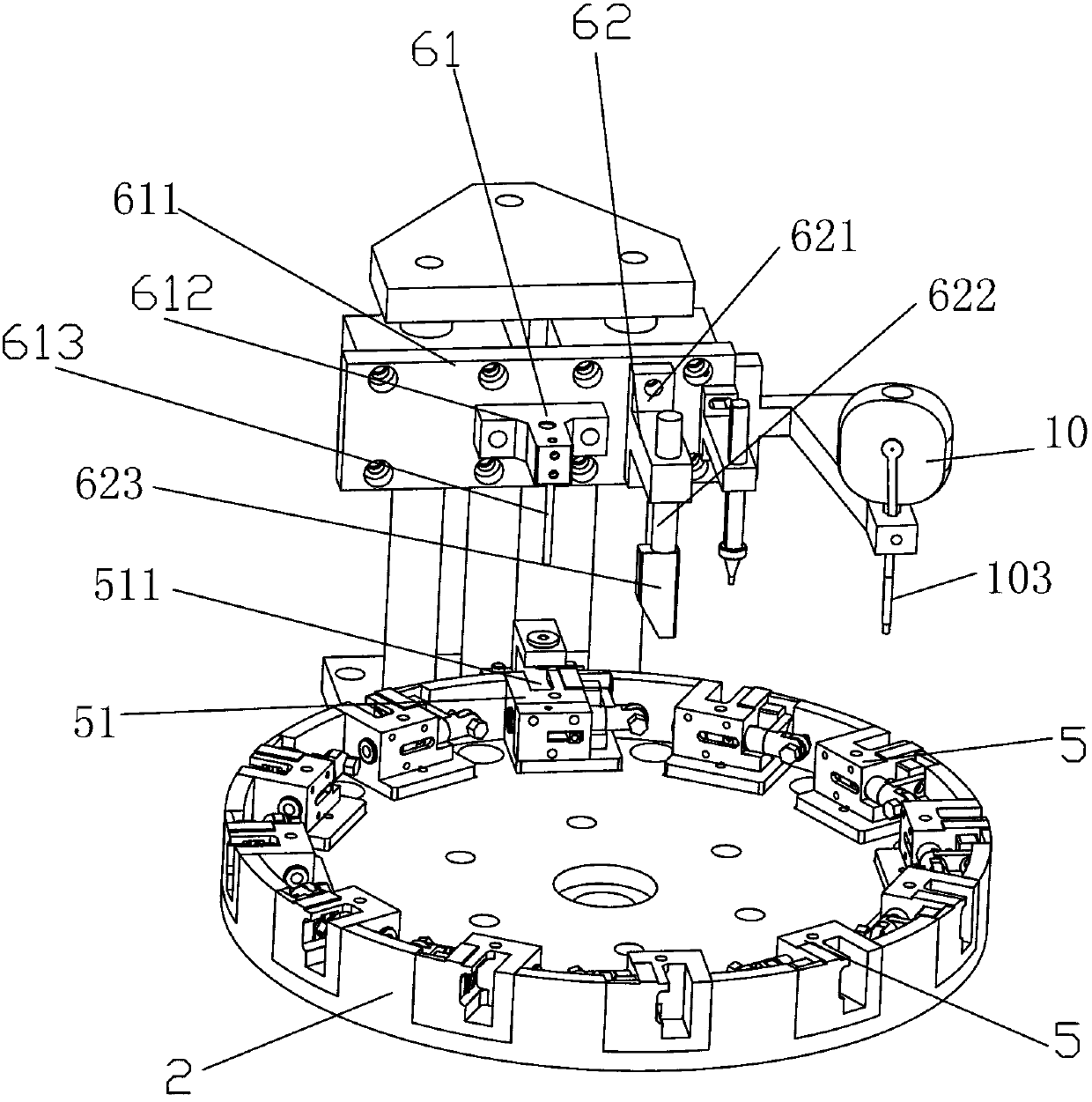

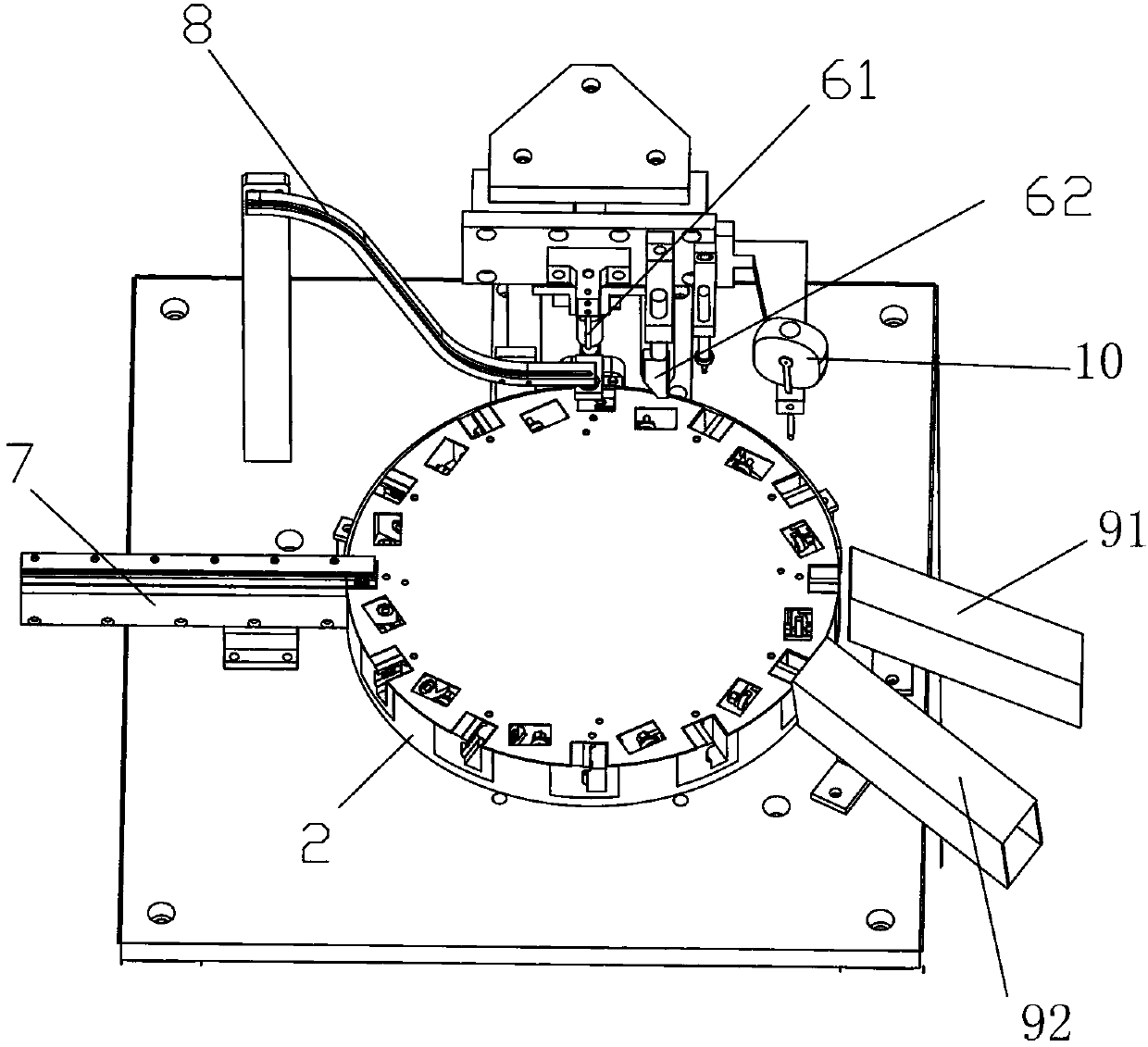

[0021] The installation equipment for the mist nozzle and press nozzle of the aerosol valve, which includes a frame 1, on which there is a rotating disk 2 that can rotate on the frame 1, and a driving device 3 and a transmission device that drive the rotating disk 2 to rotate 4. A plurality of nozzle fixing devices 5 are provided on the rotating disk 2, and a nozzle pushing installation mechanism 6 that integrates the pushing of the nozzle 100 and the installation of the nozzle 101 is arranged beside the rotating disk 2. The frame 1 described above is also provided with a nozzle feeding device 7 for feeding the nozzle 101 into the nozzle fixing device 5 and a nozzle feeding device 8 for feeding the nozzle 100 into the nozzle pushing and installing mechanism 6, and the outlet Material device 9. The mouth feeding device 7 includes a mouth feeding tray (not shown in the figure), and an outlet of the mouth feeding tray is connected with a mouth feeding track 72 . The nozzle feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com