A construction method of non-excavation pipe jacking prestressed beam

A technology of prestressed beams and construction methods, which is applied in the directions of earthwork drilling, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. It can solve problems such as inability to meet the requirements of site protection, affect the construction progress of the project, and difficulties in earthwork transportation. , to achieve the effect of improving construction measurement accuracy, ensuring smooth operation, reducing construction efficiency and environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

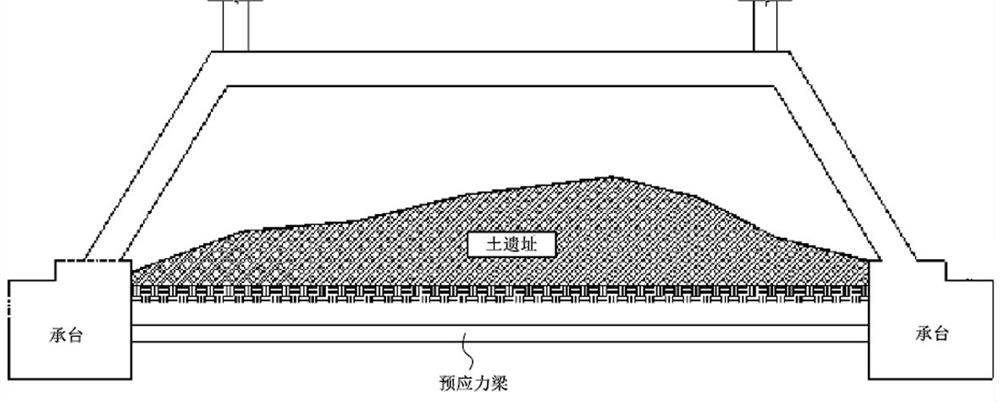

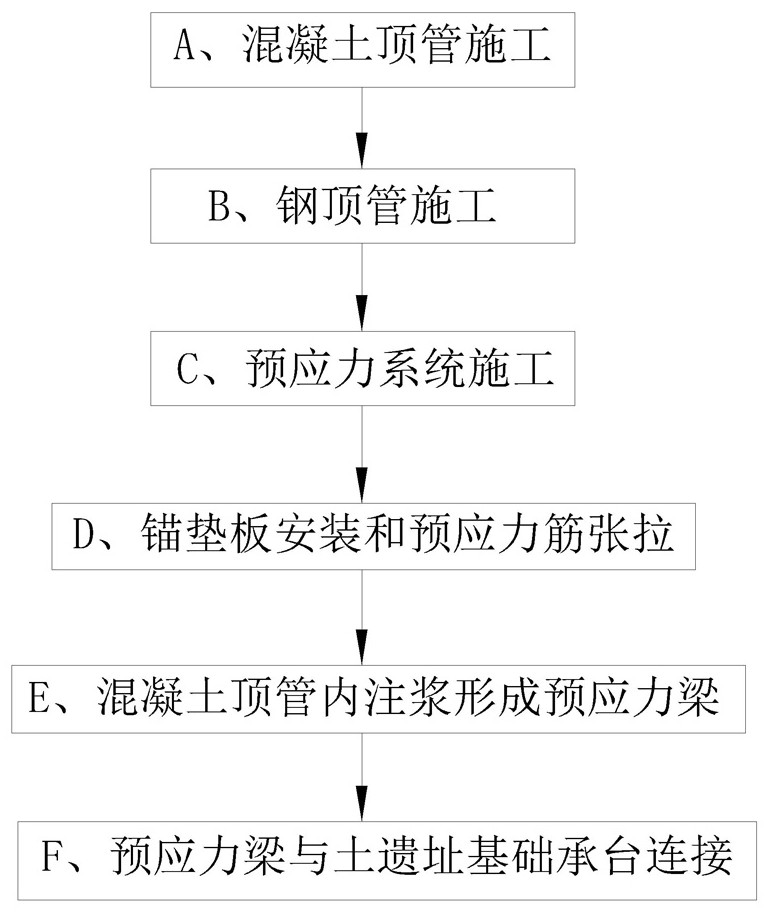

[0049] The present invention comprises the following steps:

[0050] A. Concrete pipe jacking construction;

[0051] B. Steel pipe jacking construction;

[0052] C. Construction of prestressed system;

[0053] D. Installation of anchor pads and tensioning of prestressed tendons;

[0054] E. Grouting in the concrete jacking pipe to form a prestressed beam;

[0055] F. The prestressed beam is connected to the foundation cap of the earthen site.

[0056] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0057] The invention discloses a construction method of a non-excavation type pipe jacking prestressed beam. Before the construction of the prestressed beam, due to its complicated structural layout, the construction parameters are determined by BIM modeling, scheme simulation and other simulation means, and then the construction parameters are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com