Ultra-high-count pure cotton combing yarn and spinning technology of ultra-high-count pure cotton combing yarn

An ultra-high-count, pure cotton technology, applied in the direction of combing machine, yarn, spinning machine, etc., can solve the problems of high yarn quality requirements, high difficulty of high-count yarn, easy end breakage, etc. Guarantee the effect of yarn quality and fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

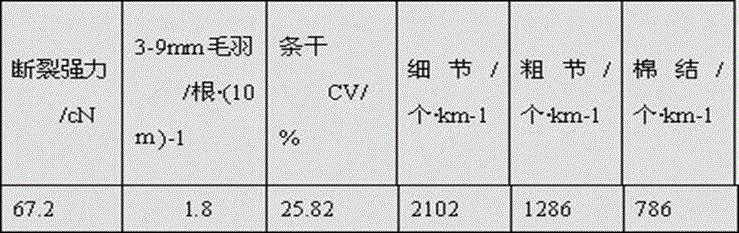

Embodiment 1

[0029] Example 1: Taking the addition of a fully polyspun device on the TH558 four-roller ultra-large draft ring spinning frame as an example, the pure cotton combed 2.7tex yarn is used as an example, and the weight percentage of raw cotton is 22% Egyptian cotton, 33% American cotton, and 45% Xinjiang cotton. The long-staple cotton is mixed, and the specific process steps are as follows:

[0030] (1) Blowing and carding unit:

[0031] The technological process includes: bale grabbing, first cotton opening, cotton blending, second cotton opening, impurity removal, and carding.

[0032] Using Trützschler blowing carding unit, the specific equipment and process are as follows:

[0033] BDT, BOBA, AFC double-axis flow opener, LvSA heavy object separator, MM6 multi-compartment mixing box, CVT opener, DX multi-tube cyclone dust collector, FBK fine impurity remover, TC03 type carding machine.

[0034] The AFC type double-axial flow opener adopts the comb beater with a speed of 950r / ...

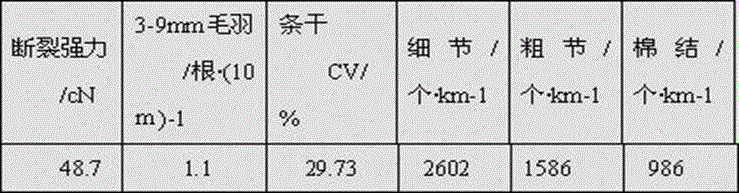

Embodiment 2

[0053] Example 2: Take the addition of pure cotton combed 1.9tex yarn with full-poly spinning device on the TH558 four-roller ultra-large draft ring spinning frame as an example, the raw cotton is 20% Egyptian cotton, 30% American cotton, and 50% Xinjiang by weight The long-staple cotton is mixed, and the specific process steps are as follows:

[0054] (1) Blowing and carding unit:

[0055] The technological process includes: bale grabbing, first cotton opening, cotton blending, second cotton opening, impurity removal, and carding.

[0056] Using Trützschler blowing carding unit, the specific equipment and process are as follows:

[0057] BDT, BOBA, AFC double-axis flow opener, LvSA heavy object separator, MM6 multi-compartment mixing box, CVT opener, DX multi-tube cyclone dust collector, FBK fine impurity remover, TC03 type carding machine.

[0058] The AFC type double-axial flow opener adopts the comb beater with a speed of 950r / min, the speed of the licker-in roller of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com