Spinning method of multi-component multi-segment color yarns

A multi-color, multi-component technology, applied in the direction of yarn, textiles and papermaking, can solve the problems of low spinning efficiency, draft ratio limitation, etc., to increase the added value of yarn, improve spinning efficiency, and improve spinning fit Effects of sex and yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

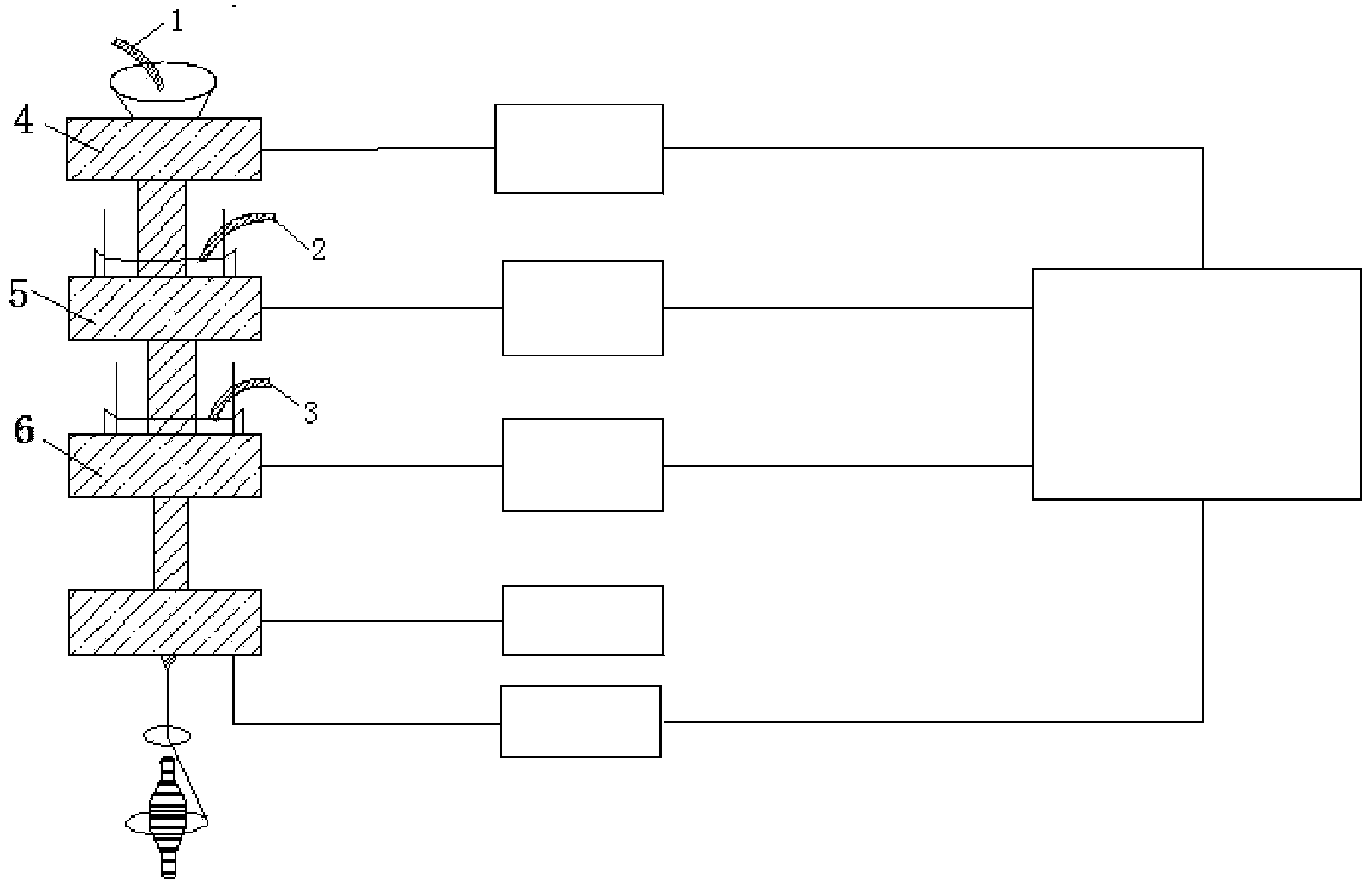

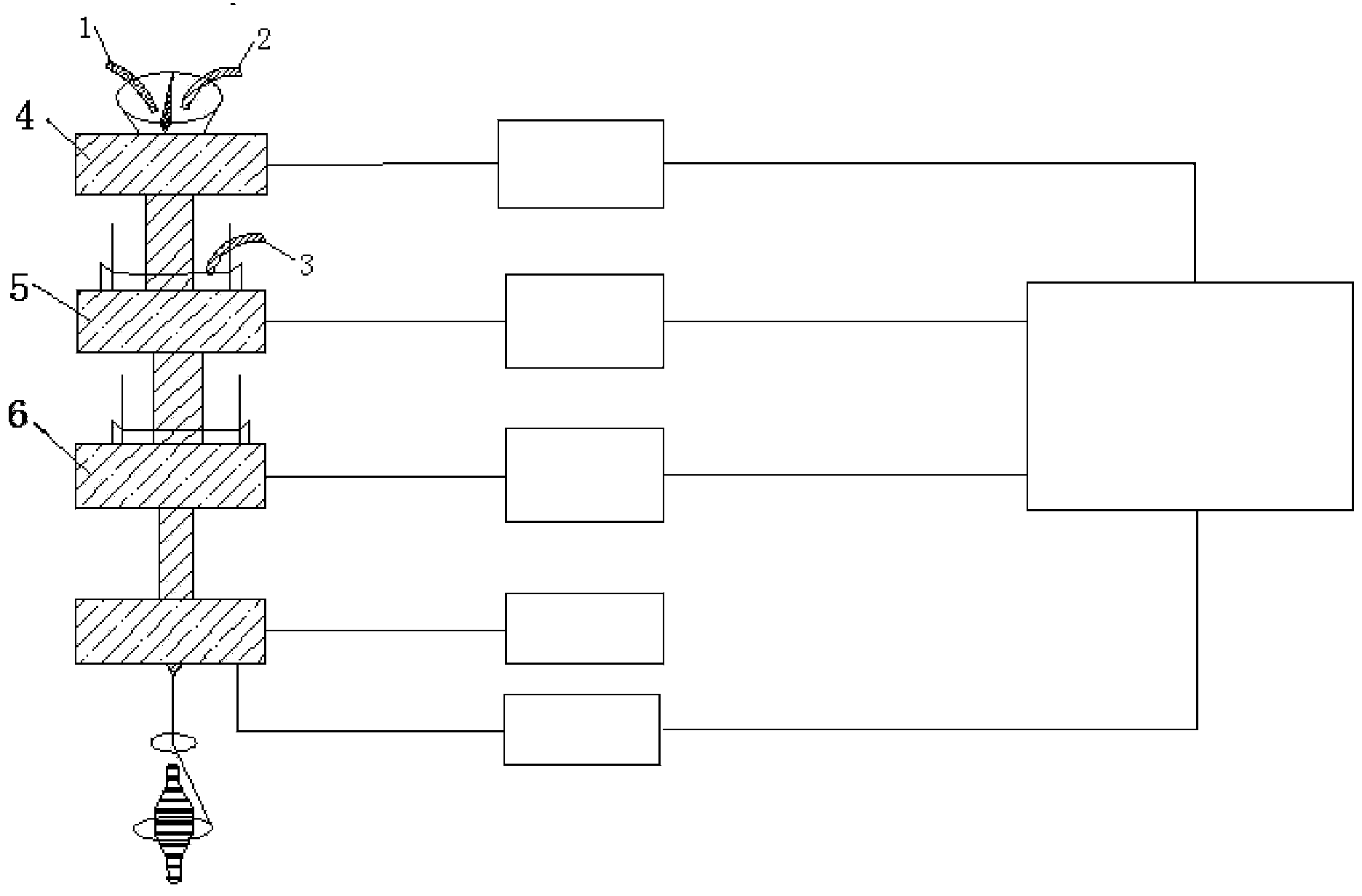

[0023] Example 1: Taking brown roving, green roving, and white roving fed simultaneously on TH558 four-roller, four-apron ultra-large draft ring spinning frame to produce 9.7tex yarn as an example, the green roving is fed from the rear roller through a single bell mouth , the brown roving is fed by the middle and rear rollers through the yarn guide groove, and the white roving is fed by the middle and front rollers through the yarn guide groove. When three rovings are fed at the same time, the proportion of green yarn, brown yarn and white yarn in the spun yarn 3:3:4; when two rovings are fed, the ratio of brown yarn and white yarn in the spun yarn is 1:1; raw cotton: white cotton is 100% Xinjiang long-staple cotton, the main body length is 35.6mm, micronaire Value 3.6, short-staple rate 10.5%, moisture regain 7.07%; natural brown cotton fiber main body length 27.6, micronaire value 4.2, short-staple rate 21%, impurity content 3.2%, sugar content 5.0%; natural green cotton fibe...

Embodiment 2

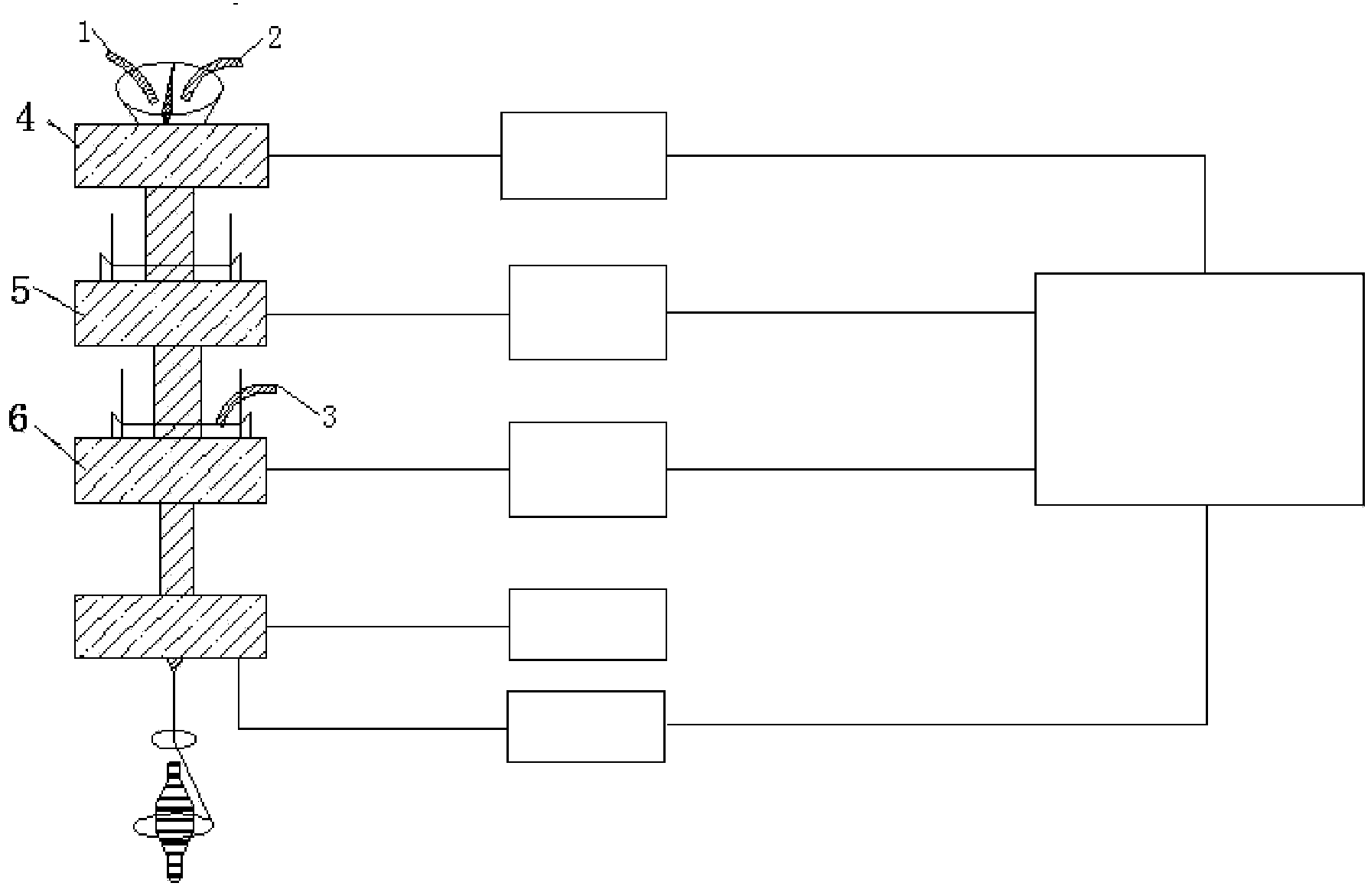

[0039] Example 2: Take brown roving, green roving, and white roving fed simultaneously on TH558 four-roller, four-apron ultra-large draft ring spinning machine to produce 11.7tex yarn as an example, the green roving and brown roving are passed through double horns by the back rollers Mouth feeding, the white roving is fed by the middle front roller through the yarn guide groove, when three rovings are fed at the same time, the ratio of the two colored yarns including green yarn and brown yarn to white yarn in the spun yarn is 1:1; Raw cotton: white cotton is made of 100% Xinjiang long-staple cotton, the main body length is 35.8mm, the micronaire value is 3.1, the short-staple rate is 10.8%, and the moisture regain is 7.15%; the main length of natural brown cotton fiber is 27.6, the micronaire value is 4.2, and the short-staple rate is 22 %, impurity content 3.3%, sugar content 5.1%; natural green cotton fiber main body length 26.7, micronaire value 2.7, short-lint rate 21%, imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com