Free-surface coaxial centrifugal electrostatic spinning spinneret

An electrospinning and spinneret technology, which is applied in textile and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of complex process influencing factors, blockage of nozzle holes, and difficulty in cleaning equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

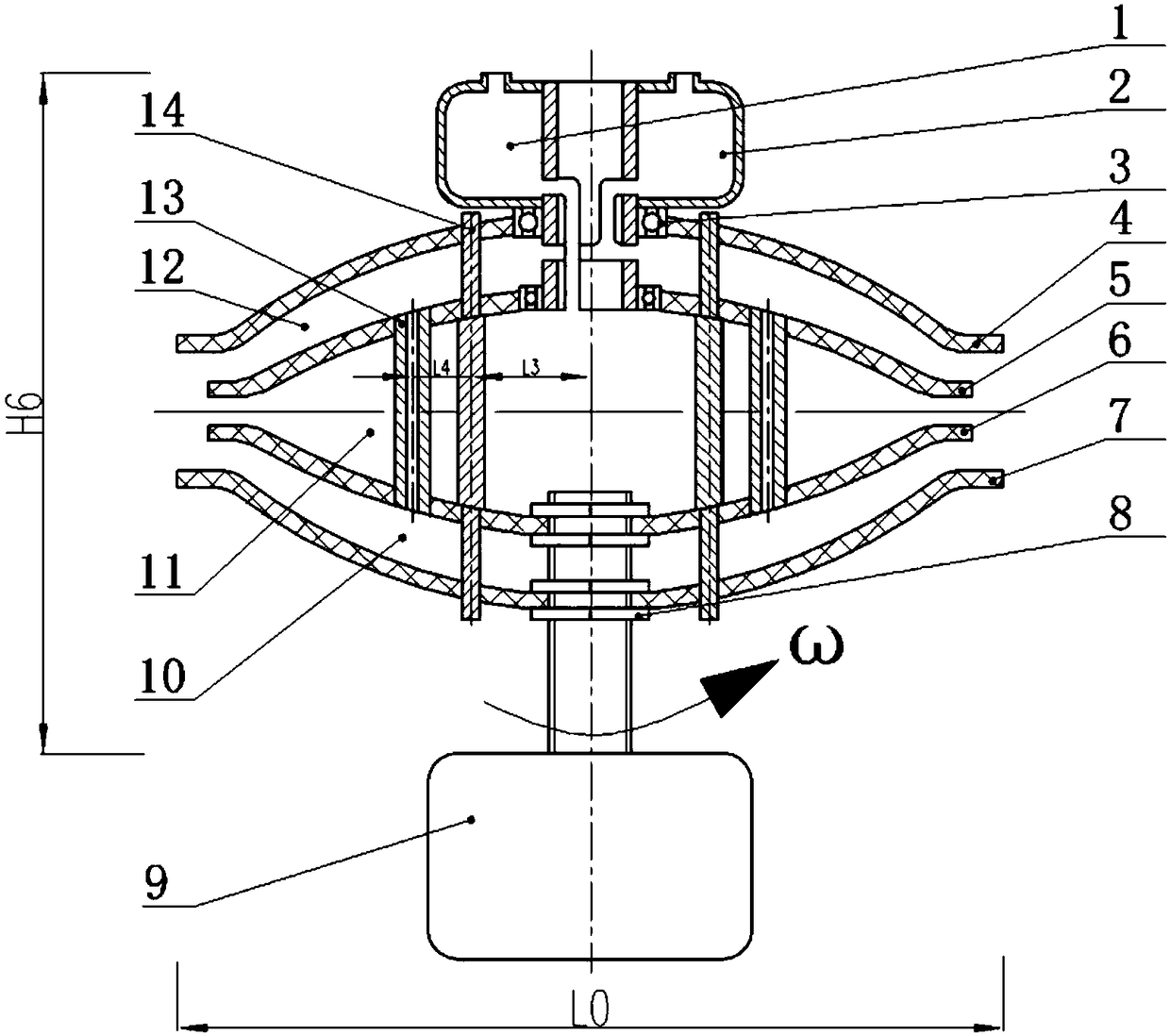

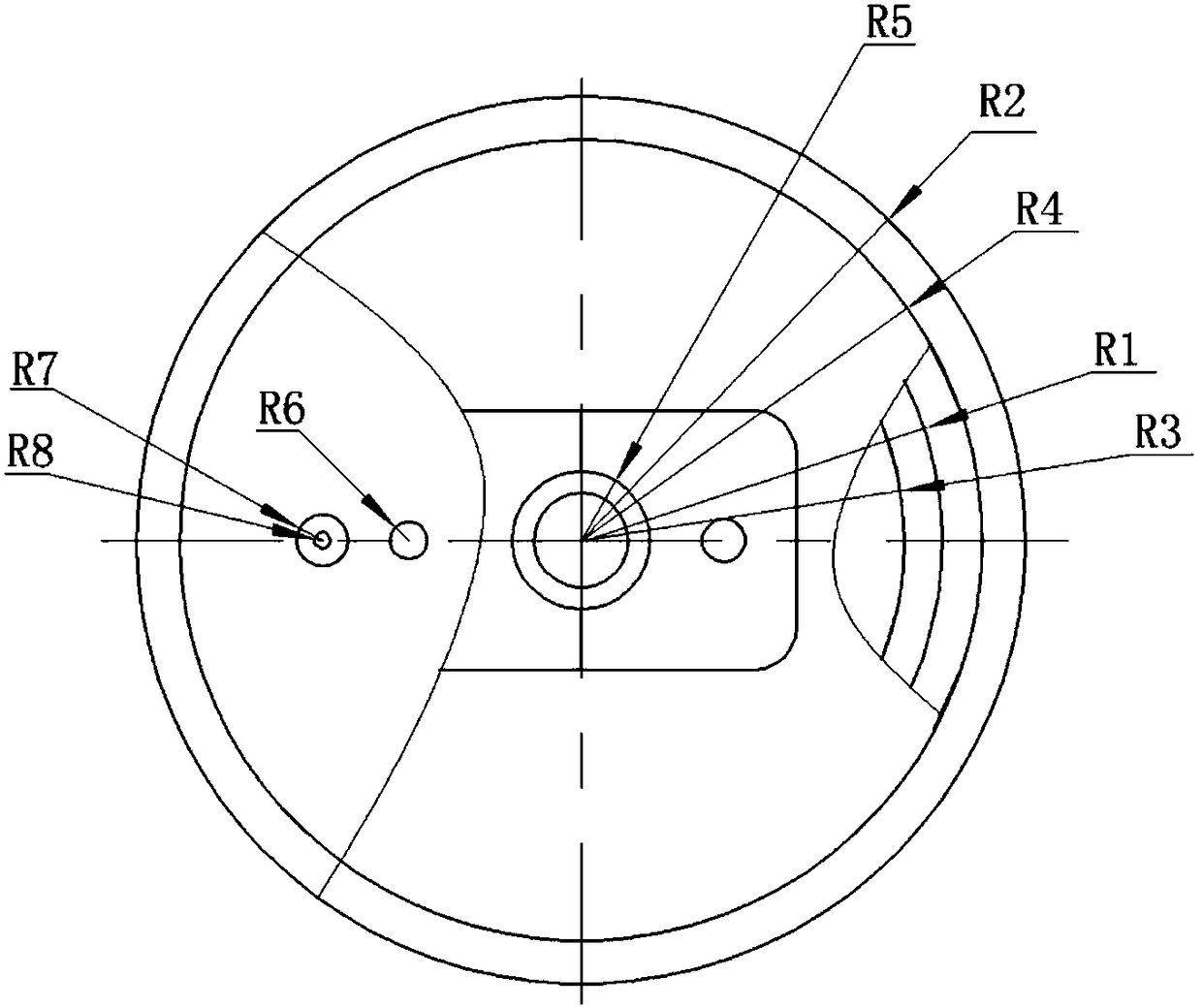

[0045] Such as Figure 1-Figure 3 As shown, a free surface coaxial centrifugal electrospinning spinneret includes 3 spinning cavities composed of 4 laminations, respectively the first spinning cavity 12, the second spinning cavity 11, the third spinning cavity The wire cavity 10 and the laminations are connected by connecting posts 14 . The stainless steel spinning disk can rotate at high speed along the output shaft of the motor, and the rotation speed is 3000r / min.

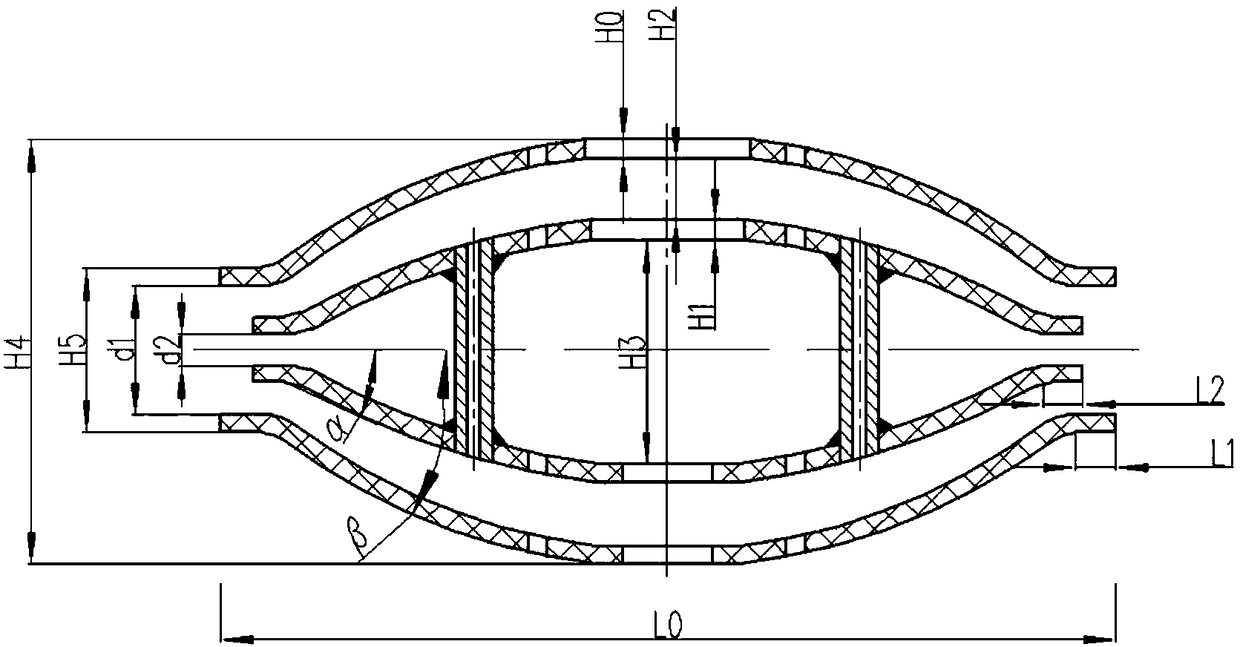

[0046] The thickness H0 of the first lamination 1 and the fourth lamination 4 is 0.2mm; the thickness H1 of the second lamination 2 and the third lamination 3 is 0.2mm; the height H2 of the first spinning cavity 12 is 1mm, the third The height of the spinning chamber 10 is 1mm; the height H3 of the second spinning chamber 11 is 2mm; the overall thickness H4 of the spinning disk represented from the top of the first lamination 1 to the bottom of the fourth lamination 4 is 4.8mm. The height between the outer edg...

Embodiment 2

[0054] Such as Figure 1-Figure 3 As shown, a free surface coaxial centrifugal electrospinning spinneret includes 3 spinning cavities composed of 4 laminations, respectively the first spinning cavity 12, the second spinning cavity 11, the third spinning cavity The wire cavity 10 and the laminations are connected by connecting posts 14 . The stainless steel spinning disk can rotate at high speed along the output shaft of the motor, and the rotation speed is 4000r / min.

[0055] The thickness H0 of the first laminate 1 and the fourth laminate 4 is 0.1mm; the thickness H1 of the second laminate 2 and the third laminate 3 is 0.3mm; the height H2 of the first spinning cavity 12 is 2mm, and the third The height of the spinning chamber 10 is 2mm; the height H3 of the second spinning chamber 11 is 2mm; the overall thickness H4 of the spinning disc represented from the top of the first lamination 1 to the bottom of the fourth lamination 4 is 6.8mm. The height between the outer edge of...

Embodiment 3

[0063] Such as Figure 1-Figure 3 As shown, a free surface coaxial centrifugal electrospinning spinneret includes 3 spinning cavities composed of 4 laminations, respectively the first spinning cavity 12, the second spinning cavity 11, the third spinning cavity The wire cavity 10 and the laminations are connected by connecting posts 14 . The stainless steel spinning disk can rotate at high speed along the output shaft of the motor, and the rotation speed is 5000r / min.

[0064] The thickness H0 of the first lamination 1 and the fourth lamination 4 is 1.0mm; the thickness H1 of the second lamination 2 and the third lamination 3 is 0.3mm; the height H2 of the first spinning chamber 12 is 1.5mm, the second The height of the three spinning chambers 10 is 1.5 mm; the height H3 of the second spinning chamber 11 is 3.0 mm; the overall thickness H4 of the spinning disc represented from the top of the first lamination 1 to the bottom of the fourth lamination 4 is 8.6 mm. mm, the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com