Preparation method and application of coralline-shaped layered porous carbon in lithium sulfur battery

A coral-like and porous carbon technology is applied in the preparation of coral-like lamellar porous carbon and in the application field of lithium-sulfur batteries, which can solve the problems of easy cracking and powder removal of pole pieces, reducing sulfur content, and low tap density. The effect of improving electrochemical performance, improving electrical conductivity, excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also proposes a method for preparing a coral-like sheet-layer porous carbon material, comprising the following steps:

[0026] (1) Preparing the precursor solution: adding nickel nitrate, zinc acetate and urea into the mixed solution of water and ethylene glycol, stirring and dissolving, then adding resorcinol and formaldehyde solution in sequence, and stirring evenly to obtain the precursor solution.

[0027] Preferably, the mol ratio of nickel nitrate and zinc acetate is 1:(0.5~2); The mol ratio of described nickel nitrate and urea is 1:(0.5~4), and suitable ratio relation is beneficial to double metal hydroxide The formation of the template and the regulation and control of the template morphology; the volume ratio of the water to ethylene glycol is 1: (2-10), so that the nickel nitrate, zinc acetate and urea are fully dissolved and uniformly dispersed; the resorcinol The molar ratio to formaldehyde is 1:(1~2), which is conducive to the occurren...

Embodiment 1

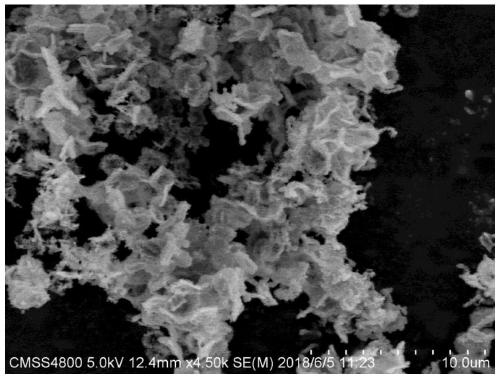

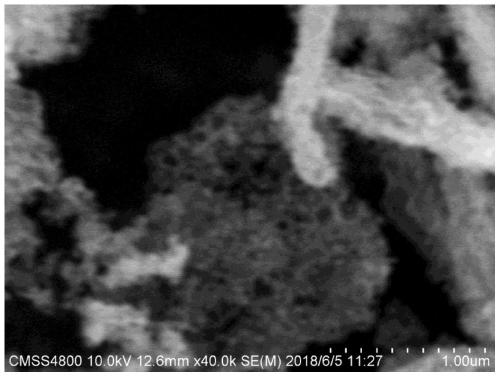

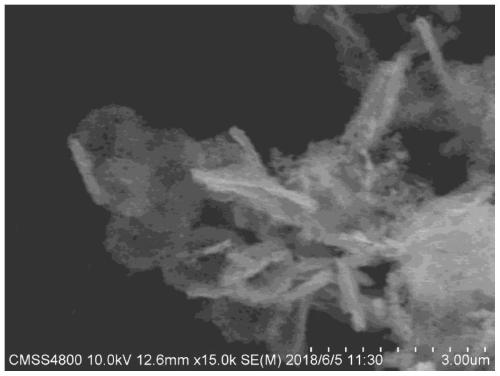

[0038] This embodiment provides a coral-like sheet-layer porous carbon, the coral-like sheet-layer porous carbon is a micro-nano hierarchical porous structure, which is formed by the aggregation of coral branch-like sheet-layer porous carbon; the thickness of the sheet-layer porous carbon is 50 ~200nm, the size is 1~5μm.

[0039] This embodiment also provides a preparation method of coral-like sheet porous carbon, comprising the following steps:

[0040] (1) Add 4.8g of nickel nitrate, 4.5g of zinc acetate and 2.4g of urea into a mixed solution of 80ml of water and 560ml of ethylene glycol to dissolve, then add 2.4g of resorcinol and 3.2g of formaldehyde solution in turn, and stir for 1.5h After obtaining the precursor solution;

[0041] (2) Seal the precursor solution in a hydrothermal kettle at 160°C for 12 hours, filter and wash after cooling, and dry at 100°C for 6 hours to obtain the precursor powder;

[0042] (3) Precursor powder in Ar / 20%H 2 Under the atmosphere, the...

Embodiment 2

[0052] This embodiment provides a coral-like sheet-layer porous carbon, which is a micro-nano hierarchical porous structure material; the thickness of the sheet-layer porous carbon is 50-200 nm, and the size is 1-2 μm.

[0053] This embodiment also provides a preparation method of coral-like sheet porous carbon, comprising the following steps:

[0054] (1) Add 4.8g of nickel nitrate, 2.4g of zinc acetate and 2.4g of urea into a mixed solution of 80ml of water and 560ml of ethylene glycol to dissolve, then add 2.4g of resorcinol and 3.2g of formaldehyde solution in turn, and stir for 0.5h After obtaining the precursor solution;

[0055] (2) Seal the precursor solution in a hydrothermal kettle at 200°C for 6 hours, filter and wash after cooling, and dry at 100°C for 5 hours to obtain the precursor powder;

[0056] (3) Precursor powder in Ar / 5%H 2 Raise the temperature to 1000°C for 10 hours under the atmosphere, and cool naturally to obtain black sintered powder;

[0057] (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com