Four-roller ultra-large drafting siro spinning AB yarns and production method thereof

A technology of super-large drafting and production method, applied in spinning machine, drafting equipment, yarn and other directions, can solve the problems of low spinning efficiency, limited drafting ratio, etc., to improve the added value of yarn, excellent comfort performance, The effect of improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

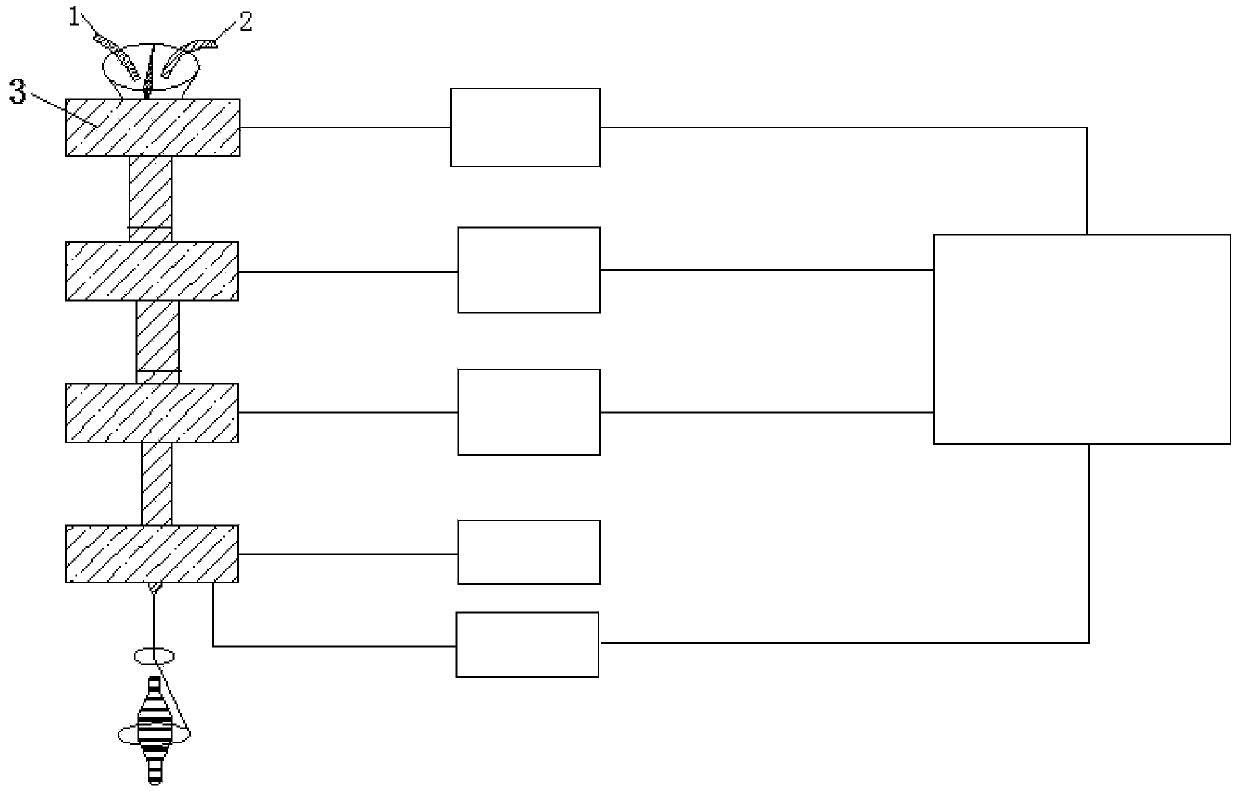

Method used

Image

Examples

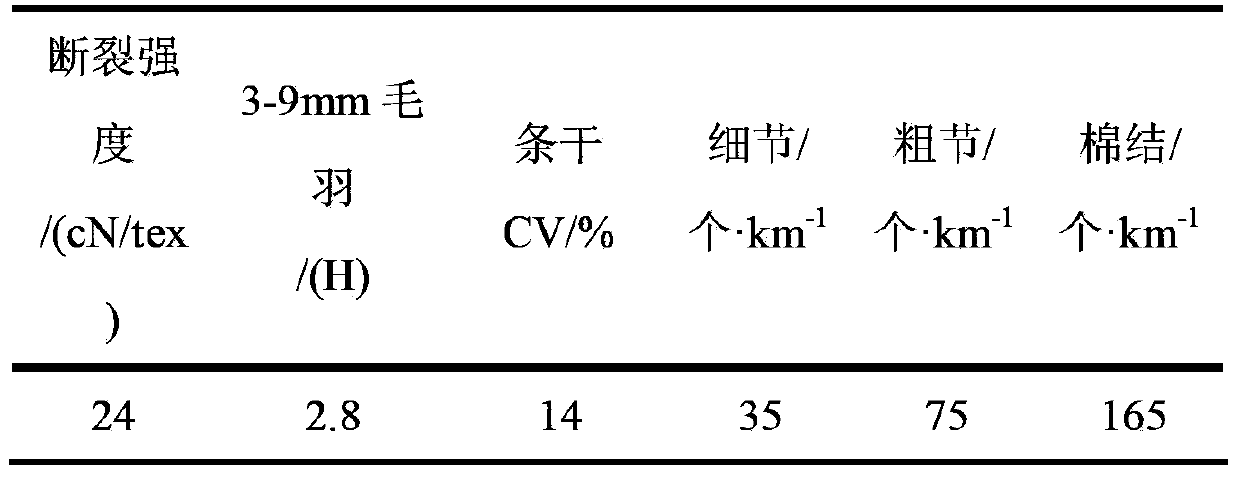

Embodiment 1

[0031] Embodiment 1: to produce 5.83tex (100 S ) AB yarn as an example. Raw cotton: For A roving, select long-staple cotton with a fineness of 1.42dtex, a main body length of 37.2mm, a short staple rate of less than 20mm of 4.3%, a breaking strength of 37.6cN / tex, a breaking elongation of 7.9%, a micronaire value of 3.9, and a uniformity of 78.7 %; Wool fiber is selected from cashmere with an average length of more than 36mm and a short cashmere rate of less than 25mm.

[0032] The specific process steps are as follows:

[0033] For a roving:

[0034] (1) Pretreatment

[0035] Dye the long-staple cotton fiber into yellow; dye the cashmere fiber into red, then weigh, inspect and shred, and then spray with antistatic agent and oil agent mixed with crude oil 999R / P, and put it in 28 Hour.

[0036] (2) Open and clean cotton

[0037] Adopt FA106 cotton opener, for long-staple cotton fiber, the beater speed is 475r / min, the distance between the cotton feeding roller and the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com