Atmosphere controllable static spinning device and industrial application thereof

An electrospinning and atmosphere technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, rayon recycling, etc., can solve the problems of large solvent consumption, interference with laying, difficult industrialized large-scale production, etc., to increase raw materials and Types of solvents, stable environmental factors, and the effect of reducing unit cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

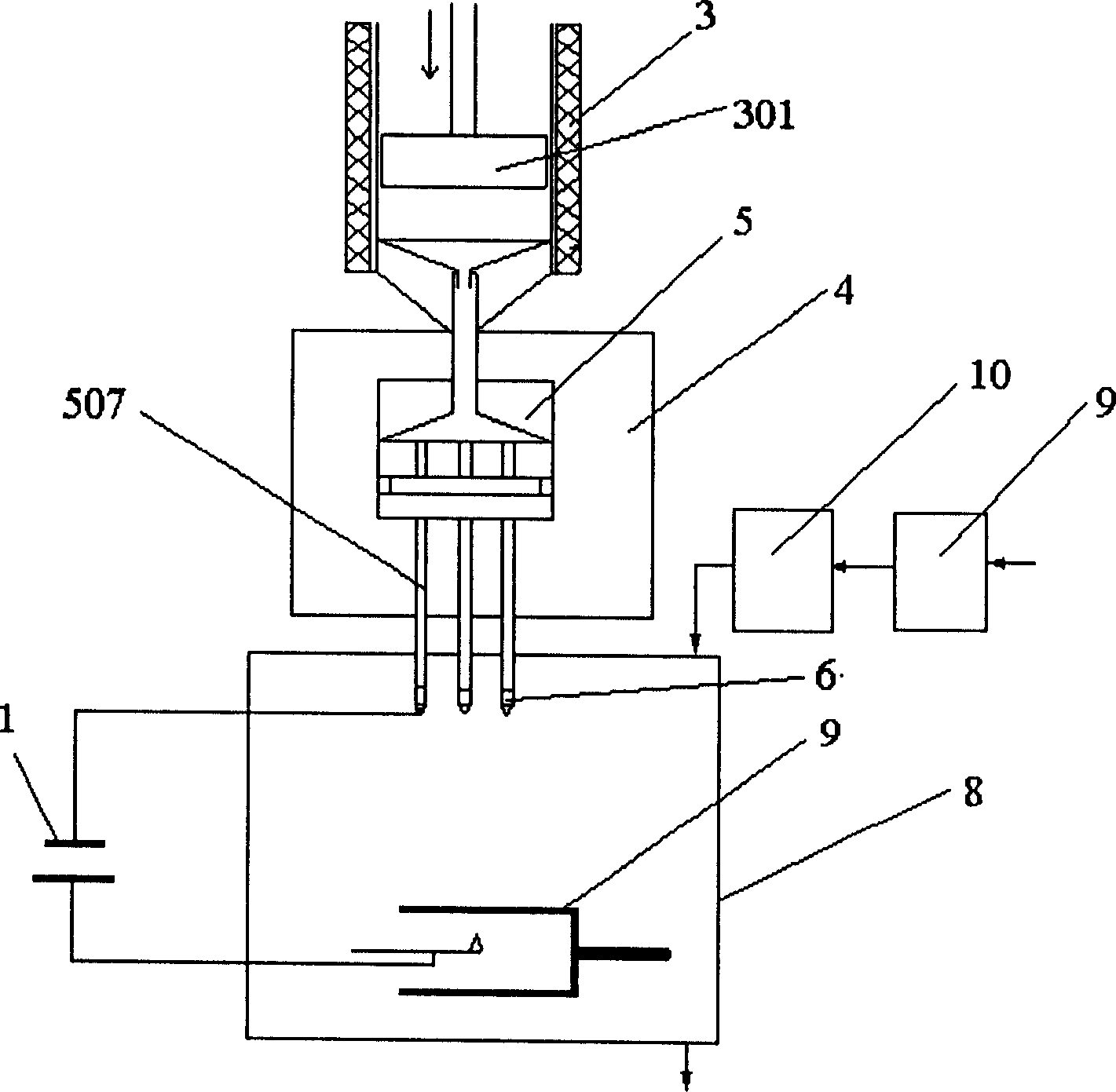

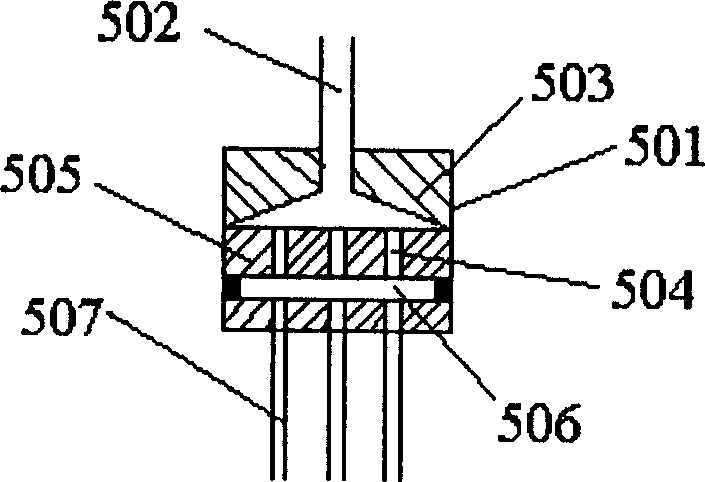

[0058] use as Figure 1 to Figure 5 The apparatus shown performs spinning. in:

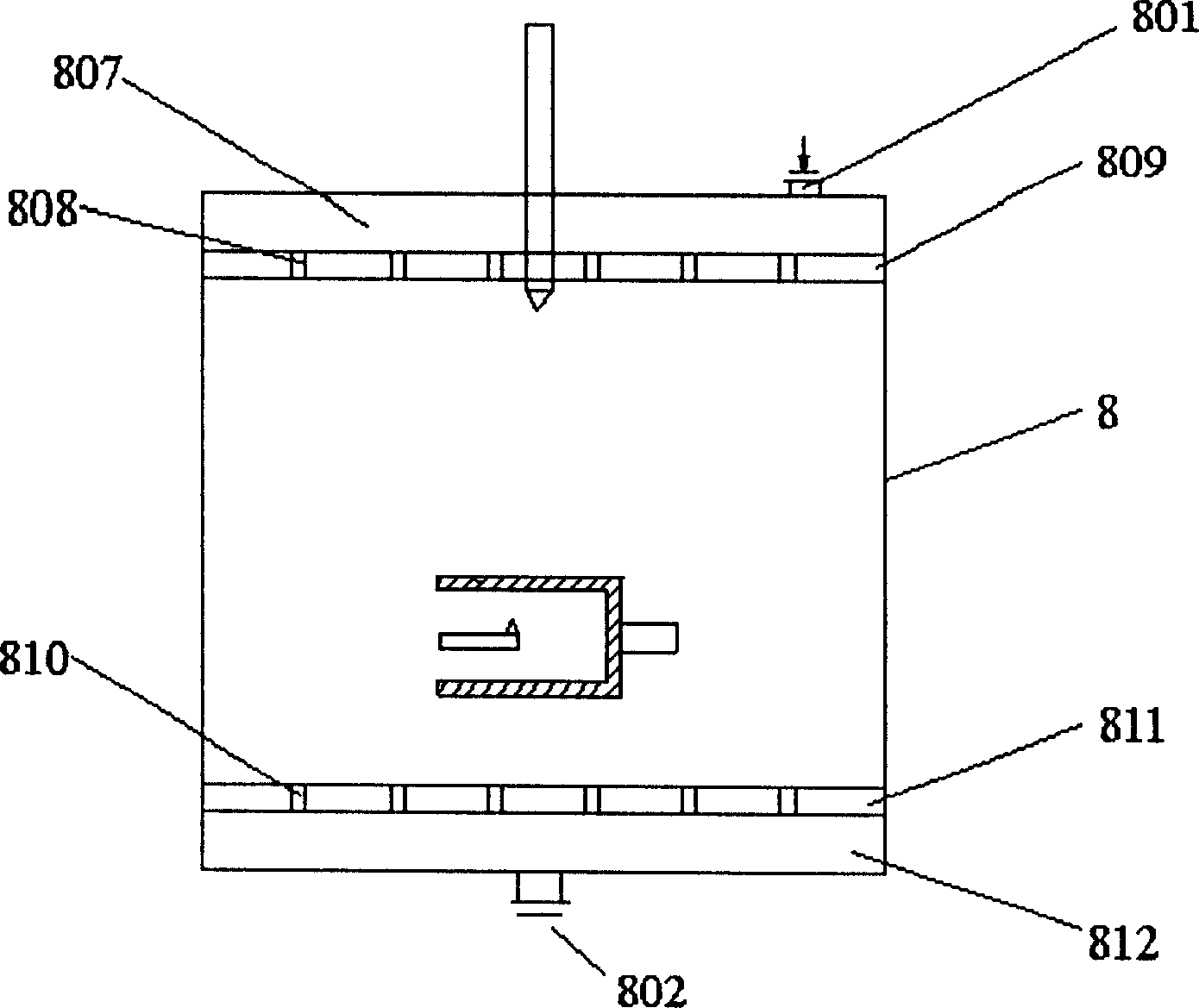

[0059] The height of said electrospinning air chamber (8) is 1m;

[0060] The number of nozzles 6 is 10,000, the diameter of the nozzles is 1 μm, and the arrangement of the nozzles is circular.

[0061] The diameter of the diversion hole 808 is 50 mm, the opening ratio of the guide plate 809 is 40%, the diameter of the collecting hole 810 is 50 mm, and the opening ratio of the collecting plate 811 is 40%.

[0062] Compressed air is used at a temperature of 60° C., a relative humidity of 30%, and a pressure of 0.5 MPa. The linear velocity of the air in the electrospinning chamber 8 is 0.3 m / s, and the voltage is 15 KV.

[0063] Spinning material: a polyhydroxybutyric acid-hydroxyvaleric acid copolyester / chloroform solution with a mass percentage concentration of 1.5%wt; the supply flow rate is 1ml / h;

[0064] The spinning result is as follows, the average fiber diameter is 100nm, and the solven...

Embodiment 2

[0066] use as Figure 1 to Figure 5 The apparatus shown performs spinning. in:

[0067] The height of said electrospinning air chamber (8) is 0.7m;

[0068] There are 100 nozzles 6, the diameter of nozzles is 10mm, and the arrangement of nozzles is rhombus;

[0069] The diameter of the diversion hole 808 is 100mm, the opening ratio of the guide plate 809 is 70%, the diameter of the collecting hole 810 is 100mm, and the opening ratio of the collecting plate 811 is 70%.

[0070] Nitrogen is used, the temperature is 60° C., the relative humidity is 0%, the pressure is 0.8 MPa, the linear velocity of the air in the electrospinning chamber 8 is 0.2 m / s, and the voltage is 25 KV.

[0071] Spinning material: polym-phenylene isophthalamide / N, N-dimethylformamide solution with a mass percentage concentration of 10%wt, containing 2%wtCaCl 2 As an additive; the supply flow rate is 1.2ml / h;

[0072] The spinning conditions are air chamber height, atmosphere temperature 70°C, relative...

Embodiment 3

[0075] use as figure 1 The apparatus shown performs spinning. in:

[0076] The height of said electrospinning air chamber 8 is 0.8m;

[0077] There is one nozzle 6, the diameter of the nozzle is 100mm, and the arrangement of the nozzle is circular;

[0078] The diameter of the diversion hole 808 is 10 mm, the opening ratio of the guide plate 809 is 40%, the diameter of the collecting hole 810 is 50 mm, and the opening ratio of the collecting plate 811 is 40%.

[0079] Compressed air is used at a temperature of 60° C., a relative humidity of 30%, and a pressure of 0.8 MPa. The linear velocity of the air in the electrospinning chamber 8 is 2 m / s, and the voltage is 25 KV.

[0080] Spinning material: mass percentage concentration is 8%wt silk protein / water solution, contains 40%wtZnCl 2 As an additive; the supply flow rate is 1.5ml / h;

[0081] The fibers are collected by a reciprocating drum collection device, and the spinning results are as follows: the average fiber diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

| Fiber average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com