Ageing resisting master batche for spinning polypropylene material and products and preparation method for ageing resisting master batche

A technology of polypropylene material and anti-aging masterbatch, which is applied in the direction of single-component polyolefin artificial filament, etc., can solve the problems of extruder pressure and extrusion temperature increase, increase current loss, and decrease spinning efficiency. Achieve the effects of improving resin processing performance, inhibiting thermal degradation, and improving spinning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

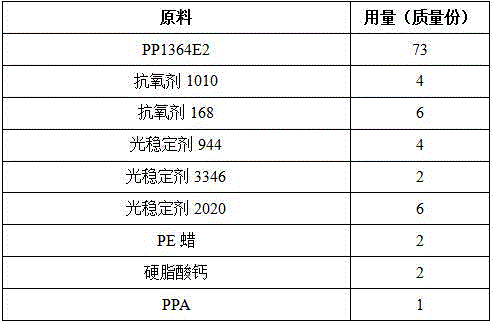

[0026] An anti-aging masterbatch for spinning polypropylene materials and products, the formulation of which is as follows in Table 1:

[0027] Table 1:

[0028]

Embodiment 2

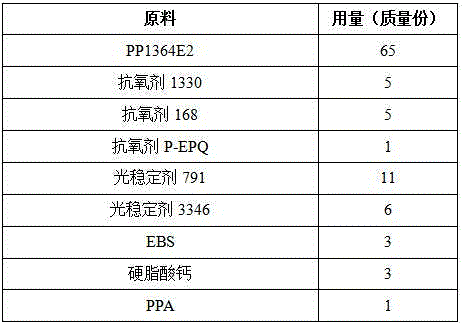

[0030] An anti-aging masterbatch for spinning polypropylene materials and products, the formula composition of which is shown in Table 2:

[0031] Table 2:

[0032]

Embodiment 3

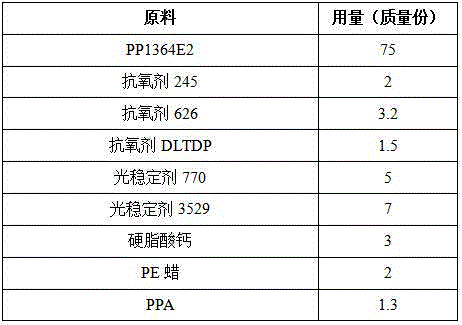

[0034] An anti-aging masterbatch for spinning polypropylene materials and products, the formulation of which is as follows in Table 3:

[0035] table 3:

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com