Reaction type flame-retardant unsaturated polyester resin for glass fibre reinforced plastic matrix

A reactive flame retardant and polyester resin technology, applied in the field of polyester resin, can solve the problems of serious hidden dangers in the safety of life and property, small specific gravity, and failure to meet requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

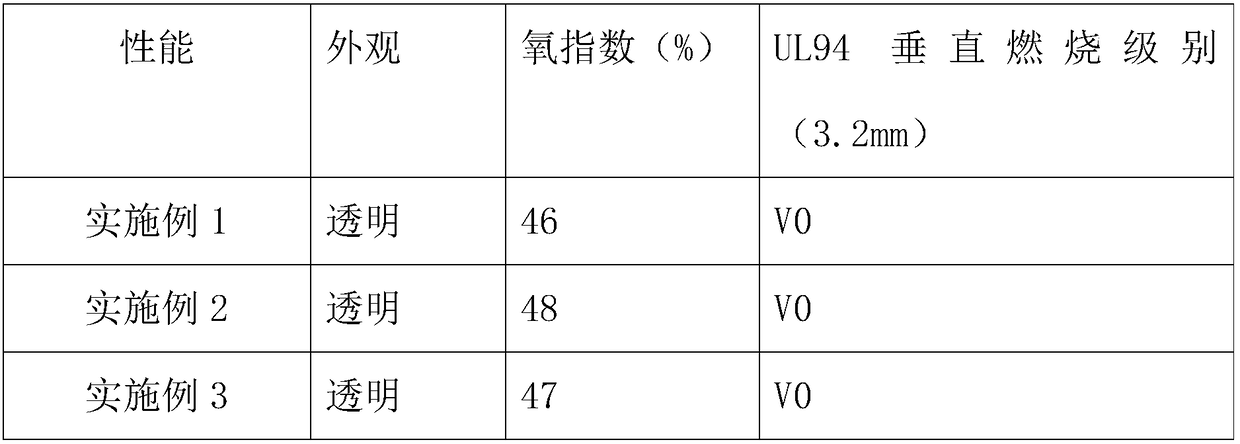

Embodiment 1

[0020] A reactive flame-retardant unsaturated polyester resin for a glass fiber reinforced plastic matrix. The raw materials include: 20 parts of maleic anhydride, 20 parts of phthalic anhydride, 10 parts of DOPO-MA, and 15 parts of ethylene glycol in parts by weight. 10 parts, 10 parts of propylene glycol, 35 parts of diethylene glycol, 15 parts of phosphorus-containing vinyl monomer, 0.2 part of hydroquinone, 0.1 part of dicumyl peroxide;

[0021] Wherein, the DOPO-MA is prepared by the following method: under the condition of nitrogen protection, 50 parts by weight of DOPO are dissolved in toluene, and after the temperature is raised to 100°C, 20 parts of maleic anhydride is added into the THF solution , keep stirring and react for 24h, remove the solvent, wash with xylene, and dry to obtain the DOPO-MA;

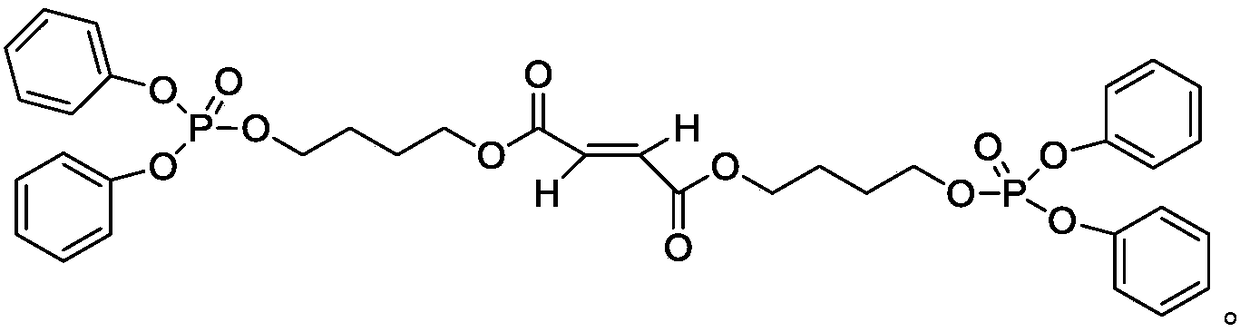

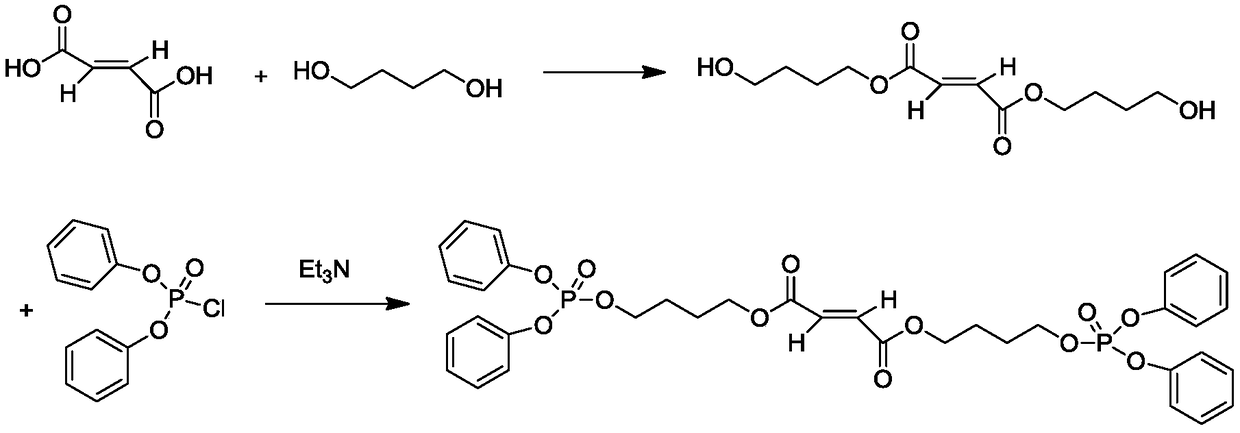

[0022] The phosphorus-containing vinyl monomer is prepared by the following method: under the protection of nitrogen, fumaric acid and 1,4-butanediol with a molar ratio o...

Embodiment 2

[0025] A reactive flame-retardant unsaturated polyester resin for a glass fiber reinforced plastic matrix. The raw materials include: 30 parts of maleic anhydride, 10 parts of phthalic anhydride, 20 parts of DOPO-MA, 5 parts of ethylene glycol in parts by weight 20 parts, 20 parts of propylene glycol, 25 parts of diethylene glycol, 25 parts of phosphorus-containing vinyl monomers, 0.02 parts of tert-butylcatechol, 1 part of dibenzoyl peroxide;

[0026] Wherein, the DOPO-MA is prepared by the following method: under the condition of nitrogen protection, 55 parts by weight of DOPO are dissolved in toluene, and after the temperature is raised to 90°C, a THF solution in which 25 parts of maleic anhydride is dissolved is added. , keep stirring and react for 20h, remove the solvent, wash with xylene, and dry to obtain the DOPO-MA;

[0027] The phosphorus-containing vinyl monomer is prepared by the following method: under the protection of nitrogen, fumaric acid and 1,4-butanediol wi...

Embodiment 3

[0030]A reactive flame-retardant unsaturated polyester resin for a glass fiber reinforced plastic matrix. The raw materials include: 25 parts of maleic anhydride, 15 parts of phthalic anhydride, 15 parts of DOPO-MA, and 10 parts of ethylene glycol in parts by weight. part, 15 parts of propylene glycol, 30 parts of diethylene glycol, 20 parts of phosphorus-containing vinyl monomer, 0.1 part of p-hydroxyanisole, 0.5 part of 1,1-di(tert-butylperoxy)cyclohexane;

[0031] Wherein, the DOPO-MA is prepared by the following method: under the condition of nitrogen protection, 52 parts of DOPO are dissolved in toluene in parts by weight, and after the temperature is raised to 95°C, a THF solution in which 22 parts of maleic anhydride is dissolved is added. , keep stirring and react for 22h, remove the solvent, wash with xylene, and dry to obtain the DOPO-MA;

[0032] The phosphorus-containing vinyl monomer is prepared by the following method: under the protection of nitrogen, fumaric ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com