Phosphorus-containing unsaturated polyester resin special for production of fiber reinforced plastics and preparation method thereof

A polyester resin, unsaturated technology, applied in the field of polyester resin, can solve the problems of poor flame retardant durability, poor thermal stability, harmful effects on human body and environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

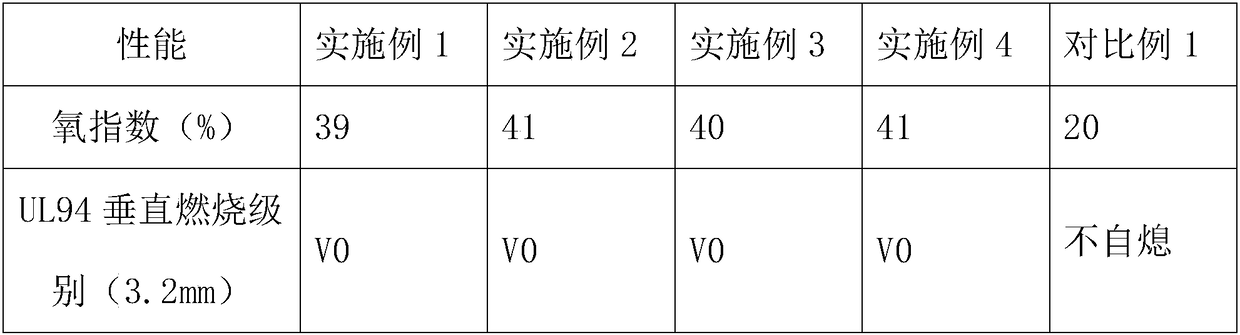

Embodiment 1

[0025] A special phosphorus-containing unsaturated polyester resin for the production of glass fiber reinforced plastics. In parts by weight, its raw materials include: 20 parts of maleic acid, 20 parts of isophthalic acid, 40 parts of 1,2-propylene glycol, and 25 parts of phosphorus-containing vinyl monomer 0.02 part of hydroquinone, 1 part of dicumyl peroxide;

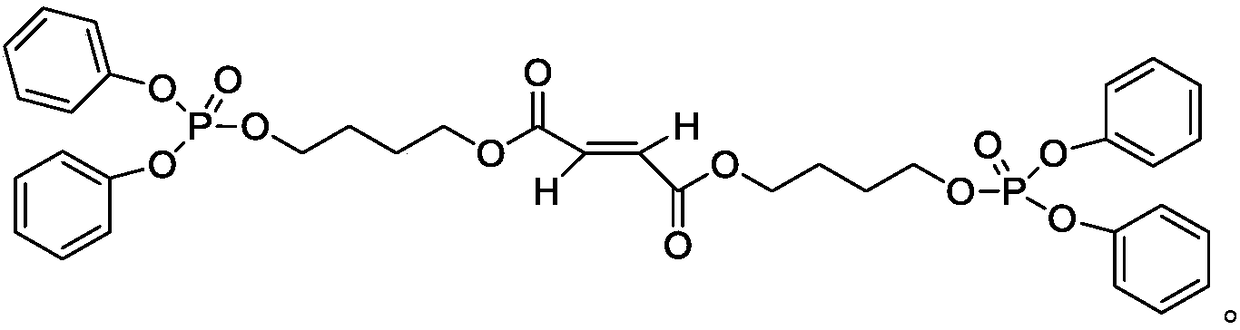

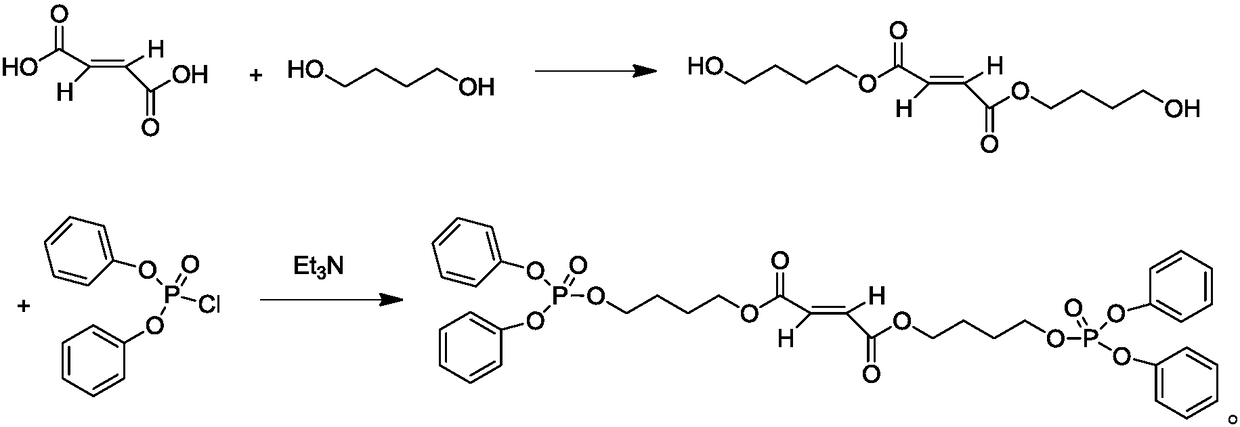

[0026] Wherein, the phosphorus-containing vinyl monomer is prepared by the following method: under nitrogen protection, fumaric acid and 1,4-butanediol with a molar ratio of 1:3 are added to toluene, heated to 100°C and then stirred Reaction 5h, carry out recrystallization with the mixed solution of dichloromethane and methanol after removing solvent, obtain described dibutylene fumarate; In molar parts, dibutylene fumarate 1 2.2 parts of triethylamine were added after cooling in an ice-water bath for 1 hour, and 2.6 parts of diphenyl chlorophosphate was added dropwise with dichloromethane solution under stirring con...

Embodiment 2

[0031] A phosphorus-containing unsaturated polyester resin specially used for the production of glass fiber reinforced plastics. The raw materials include: 30 parts of maleic anhydride, 10 parts of phthalic anhydride, 50 parts of diethylene glycol, phosphorus-containing vinyl mono Body 15 parts, tert-butylcatechol 0.2 parts, dibenzoyl peroxide 0.1 parts;

[0032] Wherein, the phosphorus-containing vinyl monomer is prepared by the following method: under nitrogen protection, fumaric acid and 1,4-butanediol with a molar ratio of 1:5 are added to toluene, heated to 90°C and then stirred Reaction 7h, carry out recrystallization with the mixed solution of dichloromethane and methanol after removing solvent, obtain described dibutylene fumarate; In molar parts, dibutylene fumarate 2 2.5 parts of triethylamine was added after cooling in an ice-water bath for 0.5 h, and 2.2 parts of diphenyl chlorophosphate was added dropwise with dichloromethane solution under stirring conditions, an...

Embodiment 3

[0037] A special phosphorus-containing unsaturated polyester resin for the production of glass fiber reinforced plastics. The raw materials include: 25 parts of fumaric acid, 3 parts of phthalic acid, 6 parts of tetrahydrophthalic acid, and hexahydrophthalic acid in parts by weight. 6 parts, 15 parts of ethylene glycol, 30 parts of dipropylene glycol, 20 parts of phosphorus-containing vinyl monomers, 0.05 parts of p-benzoquinone, 0.05 parts of p-hydroxyanisole, 1,1-di(tert-butyl peroxy ) 0.5 part of cyclohexane;

[0038]Wherein, the phosphorus-containing vinyl monomer is prepared by the following method: under nitrogen protection, fumaric acid and 1,4-butanediol with a molar ratio of 1:4 are added to toluene, heated to 95°C and then stirred Reaction 6h, carry out recrystallization with the mixed solution of dichloromethane and methanol after removing solvent, obtain described dibutylene fumarate; In molar parts, dibutylene fumarate 1.5 2.3 parts of triethylamine was added aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com