Synthetic method for flame-retardant unsaturated polyester resin raw material applied to glass fiber-reinforced plastic septic tank

A polyester resin and glass tempering technology, applied in the field of polyester resin, can solve the problems of small specific gravity, high temperature, and a large amount of harmful smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

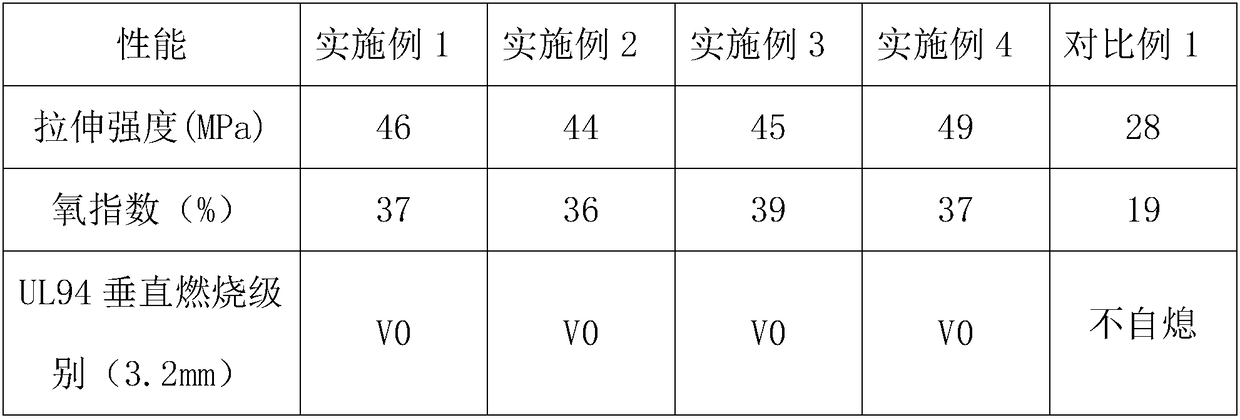

Embodiment 1

[0025] A kind of synthetic method of flame-retardant unsaturated polyester resin raw material for FRP septic tank comprises the following steps:

[0026] S1. In terms of molar parts, mix 2 parts of maleic acid, 8 parts of isophthalic acid and 10 parts of propylene glycol, and then heat up to melting at a rate of 10°C / min under nitrogen protection, and then continue to heat up to 160°C Stir the reaction until the acid value of the system is lower than 25mgKOH / g, and cool down to 140°C to obtain an unsaturated polyester prepolymer;

[0027] S2, in parts by weight, add 20 parts of phosphorus-containing vinyl monomers, 0.02 parts of hydroquinone, and 1 part of dicumyl peroxide to 30 parts of the unsaturated polyester prepolymer obtained in S1, and cool to Room temperature, obtain described unsaturated polyester resin raw material;

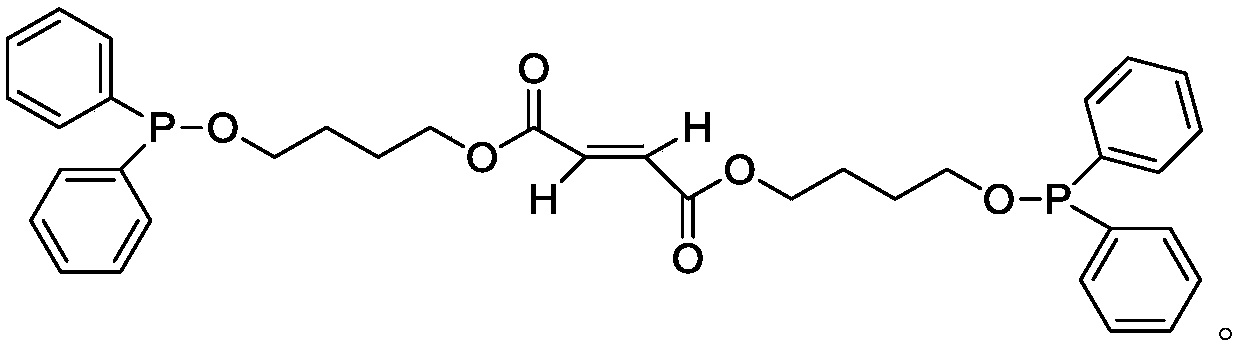

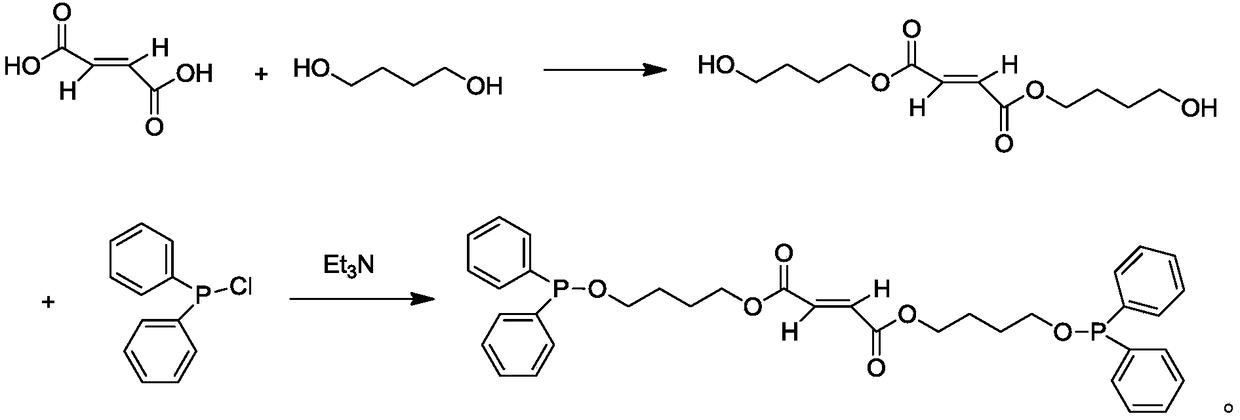

[0028] The method for synthesizing the phosphorus-containing vinyl monomer includes: in molar parts, under the protection of nitrogen, 1 part of dibu...

Embodiment 2

[0030] A kind of synthetic method of flame-retardant unsaturated polyester resin raw material for FRP septic tank comprises the following steps:

[0031] S1. In terms of molar parts, mix 5 parts of maleic anhydride, 5 parts of saturated phthalic acid and 15 parts of diethylene glycol, and then heat up to melting at a rate of 5°C / min under nitrogen protection. Continue to heat up to 200°C, stir and react until the acid value of the system is lower than 25mgKOH / g, then cool down to 130°C to obtain an unsaturated polyester prepolymer;

[0032] S2, in parts by weight, add 10 parts of phosphorus-containing vinyl monomers, 0.2 parts of tert-butylcatechol, and 0.1 parts of dibenzoyl peroxide successively to 40 parts of unsaturated polyester prepolymers obtained in S1, and cool to room temperature to obtain the unsaturated polyester resin raw material;

[0033] The method for synthesizing the phosphorus-containing vinyl monomer includes: adding 2 parts of dibutylene glycol fumarate t...

Embodiment 3

[0035] A kind of synthetic method of flame-retardant unsaturated polyester resin raw material for FRP septic tank comprises the following steps:

[0036]S1. In terms of molar parts, after mixing 3 parts of fumaric acid, 6 parts of adipic acid, 4 parts of dipropylene glycol, and 4 parts of ethylene glycol, the temperature is raised to 7°C / min under nitrogen protection. Melt, continue to heat up to 180°C, then stir and react until the acid value of the system is lower than 25mgKOH / g, then cool down to 135°C to obtain an unsaturated polyester prepolymer;

[0037] S2, in parts by weight, sequentially add 15 parts of phosphorus-containing vinyl monomers, 0.1 parts of p-benzoquinone, 0.5 parts of 1,1-bis(tert-butyl peroxide) to 35 parts of the unsaturated polyester prepolymer obtained in S1 Oxygen) cyclohexane, is cooled to room temperature, obtains described unsaturated polyester resin raw material;

[0038] The method for synthesizing the phosphorus-containing vinyl monomer compr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com