Portable electrostatic spinning equipment and using method thereof

An electrospinning, portable technology, used in textiles and papermaking, filament/thread forming, feeding solution to spinnerets, etc. Efficiency, overcoming the effect of simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

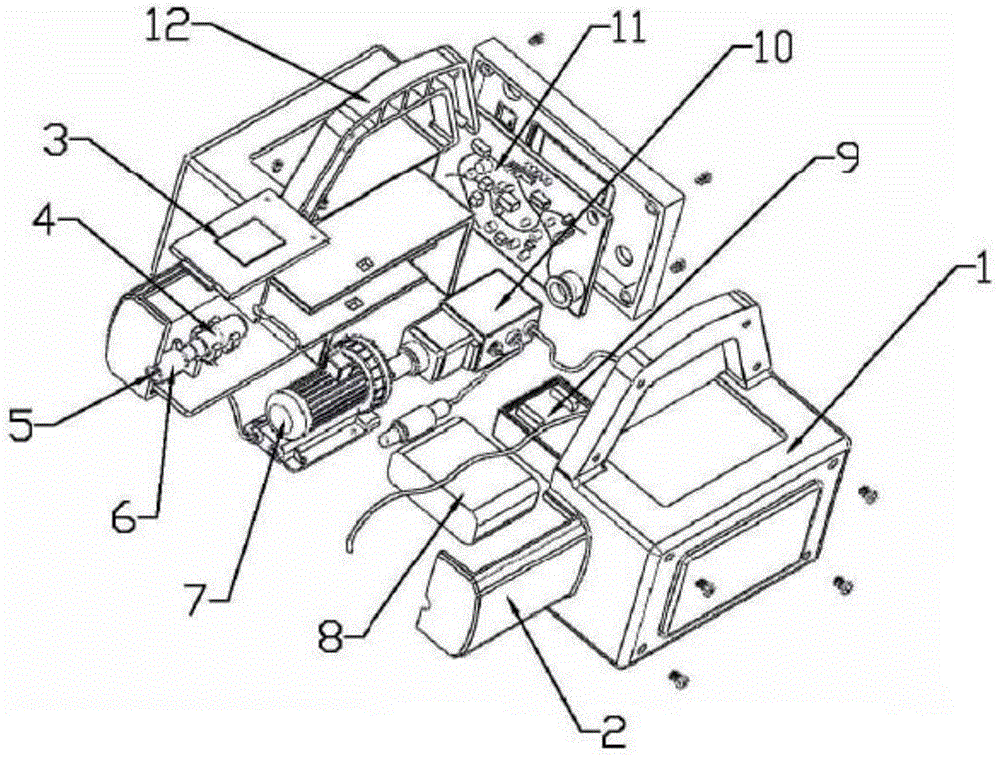

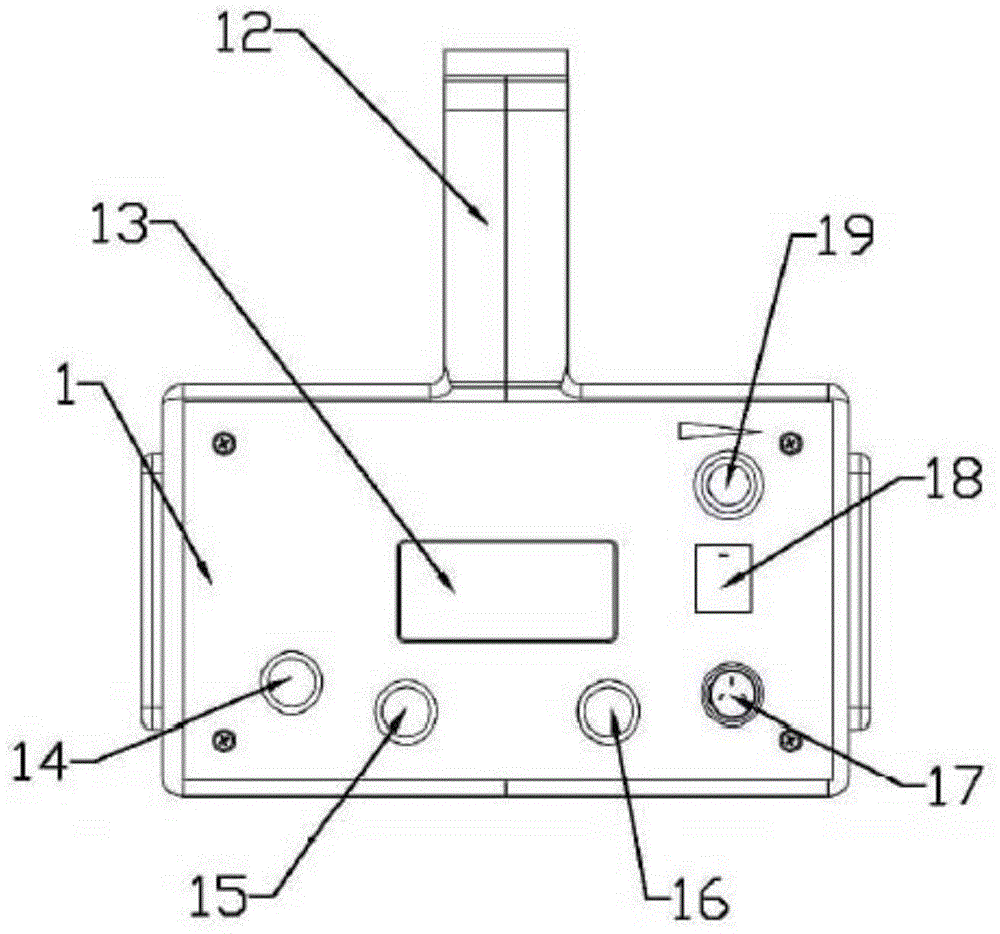

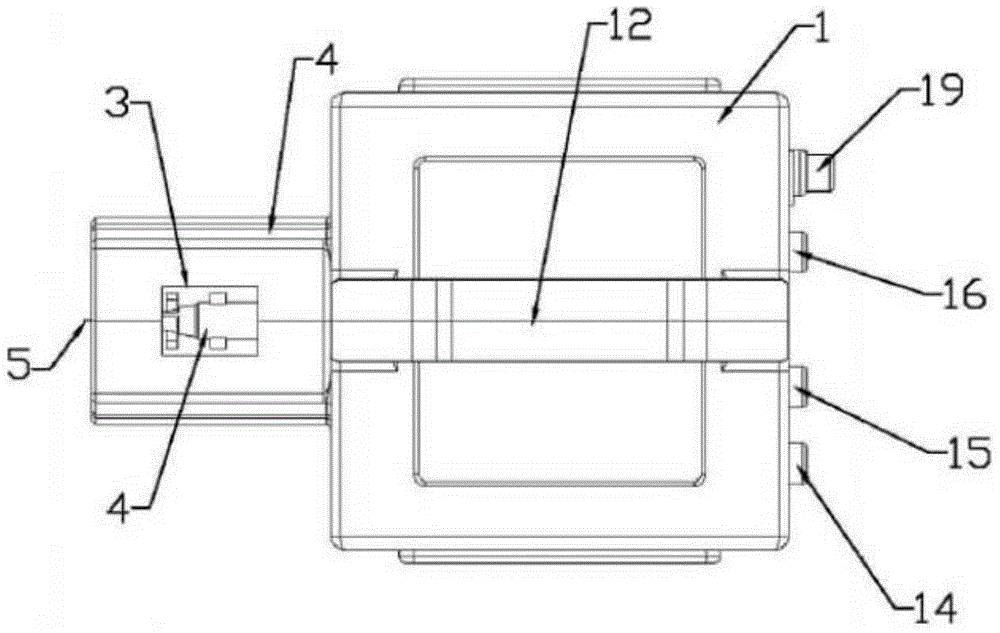

[0034] Such as Figures 1 to 3 As shown, a portable electrospinning device includes a battery compartment 8, a high-voltage electrostatic generating device, a feeding device, a gas generating device, a spinning injection device, and an insulating casing; Generating device, feeding device and gas generating device; the high-voltage electrostatic generating device includes a DC-high-voltage DC inverter 9 and a voltage regulation circuit, and the voltage input end of the DC-high-voltage DC inverter 9 is electrically connected to the battery compartment 8, and the DC - the voltage output end of the high-voltage DC inverter 9 is connected to a voltage regulating circuit that controls the output voltage of the high-voltage electrostatic generating device; the voltage output end of the voltage regulating circuit is the voltage output end of the high-voltage electrostatic generating device, and the voltage output of the high-voltage electrostatic generating device The negative electro...

Embodiment 2

[0040] Weigh 1.3 grams of polyvinylpyrrolidone powder (PVP, molecular weight 1.3 million), all dissolved in 8.7 grams of absolute ethanol, magnetically stirred at room temperature for 2 hours until completely dissolved, to obtain a uniform PVP electrospinning precursor with a solute mass fraction of 13%. liquid.

[0041] First, add the prepared PVP electrospinning precursor solution into the syringe barrel 4, open the transparent observation window 3, fix the syringe barrel 4 in the card slot in the outer compartment 2 of the insulating shell, and turn on the power switch of the micro linear motor 14. Rotate the propulsion rate adjustment knob 15 to set the propulsion rate of the spinning solution to 80 microliters / minute, and the injection volume is 5 milliliters, and the spinning precursor solution is slowly pushed into the metal capillary nozzle 5 of the spinning injection device; then turn on the micro air pump Power switch 17, the gas that miniature air pump 7 produces en...

Embodiment 3

[0043] Weigh 2 grams of polycaprolactone (PCL, molecular weight is 45000), all dissolved in 8 grams of acetone, magnetically stirred at room temperature for 2 hours until completely dissolved, to obtain a uniform PCL spinning precursor solution with a solute mass fraction of 20%.

[0044]First, add the prepared PCL electrospinning precursor solution into the syringe barrel 4, open the transparent observation window 3, fix the syringe barrel 4 in the card slot in the outer compartment 2 of the insulating shell, and turn on the power switch of the micro linear motor 14. Rotate the propulsion rate adjustment knob 15 to set the spinning liquid propulsion rate to 100 microliters per minute, and the injection volume is 5 milliliters, and the spinning precursor solution is slowly pushed into the metal capillary nozzle 5 of the spinning injection device; then turn on the micro air pump Power switch 17, the gas that miniature air pump 7 produces enters the airflow conduit 6 through the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com