A kind of composite 3D current collector and its preparation and application

A current collector and 3D technology, which is applied in the field of composite 3D current collectors and current collectors for lithium secondary batteries, can solve problems such as inability to achieve directional deposition of lithium metal, low cycle efficiency, and safety issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

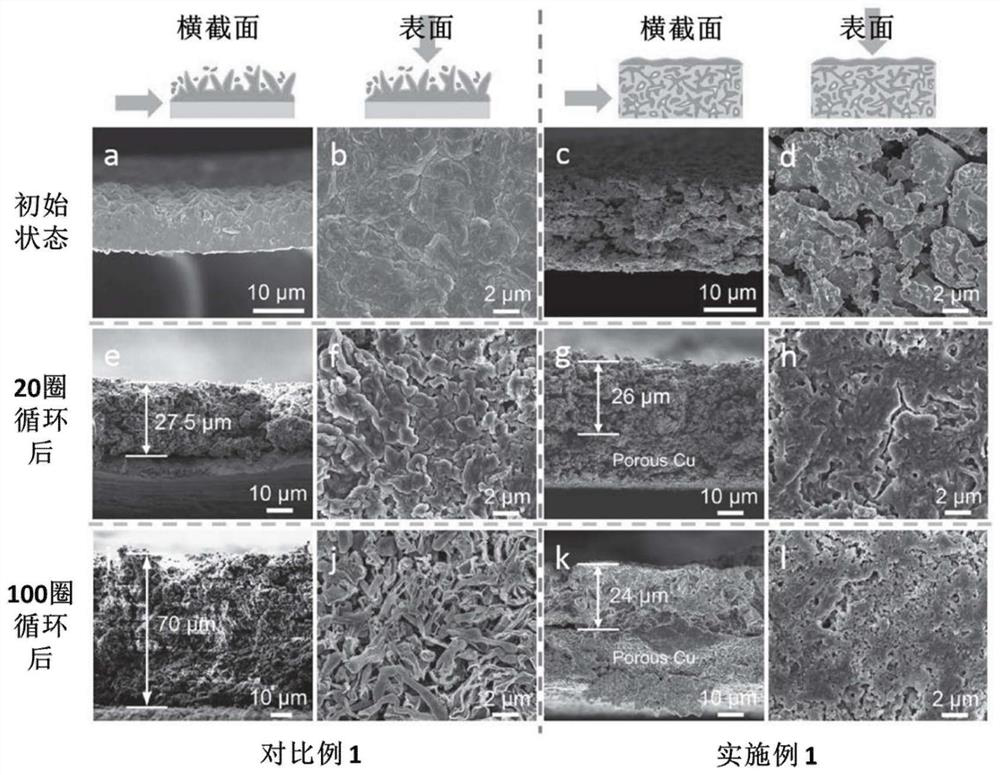

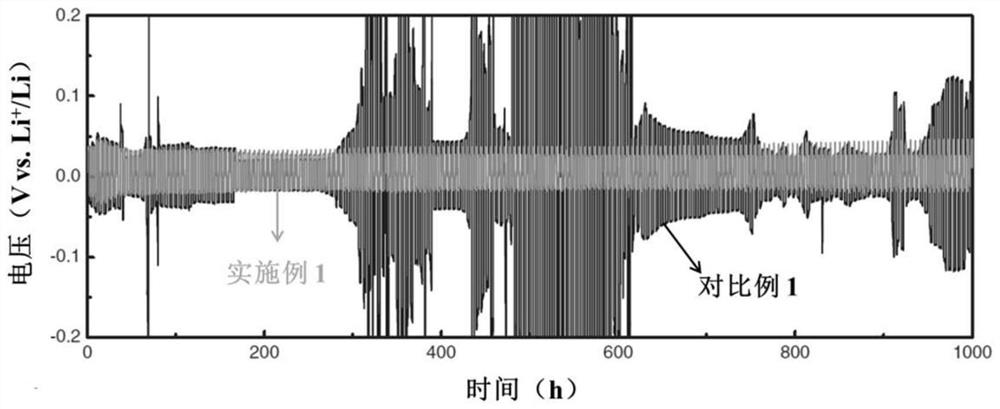

Embodiment 1

[0036] 0.4g CNTs were uniformly dispersed in the aqueous solution with a mass fraction of 5%. Add 16.5g of 2% sodium carboxymethyl cellulose aqueous solution, stir for 4 hours to mix evenly, then add 1.65g of 40% styrene-butadiene rubber aqueous solution, and stir for 0.5h to cause crosslinking reaction of the binder. The prepared slurry was evenly spread on the nickel foam, frozen with liquid nitrogen, and dried with a freeze dryer at -45°C for 10 h. The prepared precursor was then placed in a tube furnace and calcined at 900°C for 4 hours under argon gas to carbonize the polymer binder in the precursor to obtain a composite 3D current collector. The mass content of the carbon material in the composite 3D current collector is 1.2%, and the specific surface area of the composite 3D current collector is 173cm 3 / g, the pore volume is 5cm 3 / g, the density is 7.3g / cm 3 .

[0037] The obtained composite 3D current collector was cut into discs with a diameter of 1.9 mm, and ...

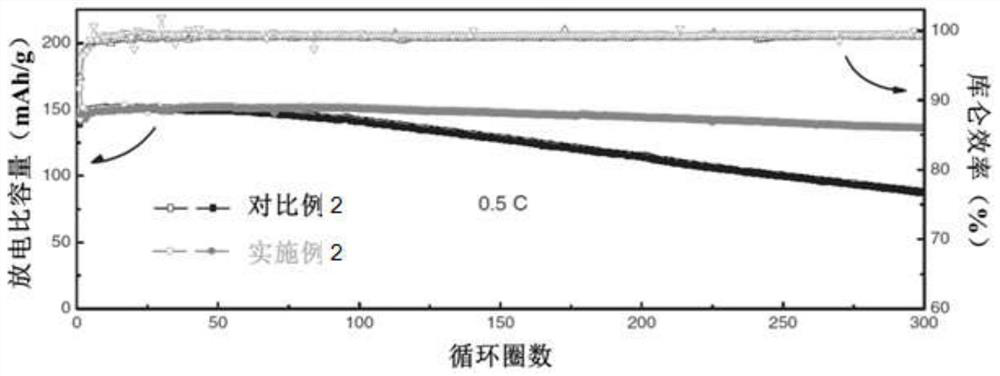

Embodiment 2

[0039] Adopt the method of comparative example 2 to prepare LiFePO 4 Positive electrode, the composite 3D current collector of pre-deposited lithium in Example 1 is the negative electrode, celgard 2325 is the diaphragm, with 1mol / L LiPF 6 The solution of EC+DMC (volume ratio 1:1) is used as the electrolyte, and the CR2016 button battery is assembled, and the cycle performance charge and discharge test is carried out at a rate of 0.5C.

Embodiment 3

[0041]0.4g CNTs were uniformly dispersed in the aqueous solution with a mass fraction of 5%. Add 16.5g of 2% sodium carboxymethyl cellulose aqueous solution, stir for 4 hours to mix evenly, then add 1.65g of 40% styrene-butadiene rubber aqueous solution, and stir for 0.5h to cause crosslinking reaction of the binder. The prepared slurry was evenly spread on the nickel foam, frozen with liquid nitrogen, and dried with a freeze dryer at -45°C for 10 h. The prepared precursor was then placed in a tube furnace and calcined at 900°C for 4 hours under argon gas to carbonize the polymer binder in the precursor to obtain a composite 3D current collector. The mass content of the carbon material in the composite 3D current collector is 0.5%, and the specific surface area of the composite 3D current collector is 82cm 3 / g, the pore volume is 1.2cm 3 / g, the density is 6.7g / cm 3 .

[0042] The obtained composite 3D current collector was cut into discs with a diameter of 1.9 mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com