Environment-friendly high temperature-resistant inorganic insulated paint and preparation method thereof

An inorganic insulation and high temperature resistant technology, applied in the direction of coating, etc., can solve the problems of short stable time, high curing temperature and environmental protection of insulating varnish, and achieve the effect of prolonging the coating time, high silicon content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

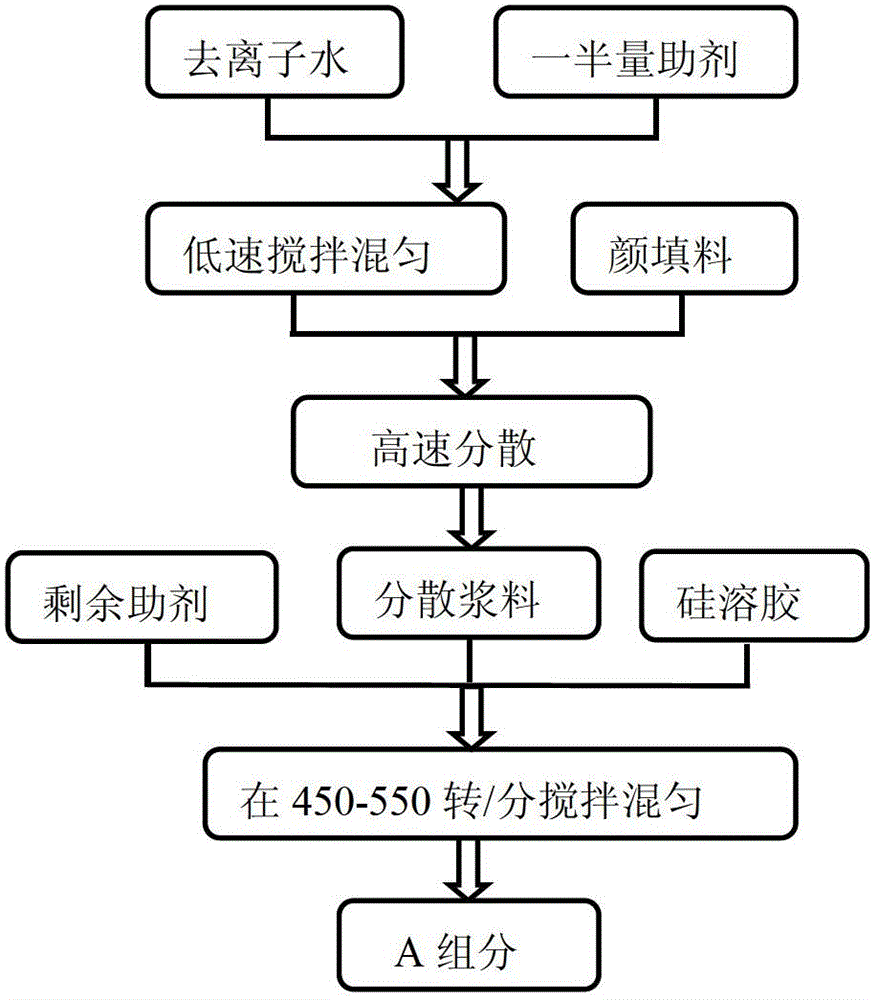

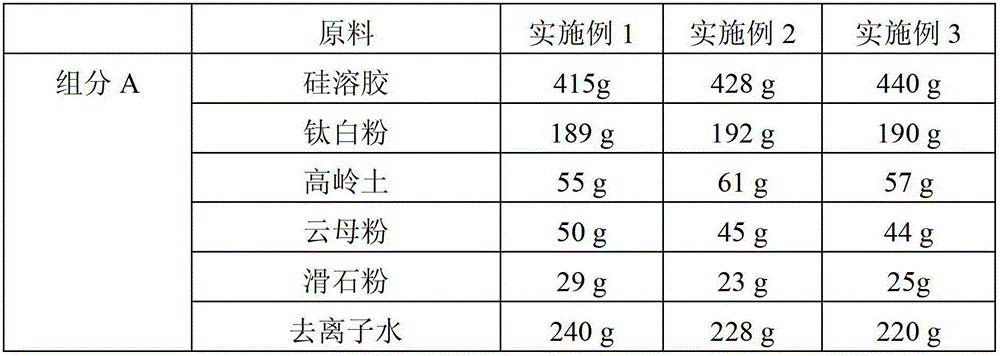

[0040] The optimized process used in the example is as follows: First, stir deionized water and half the amount of additives under the condition of 200r / min for 10min, then add inorganic pigments, kaolin, mica powder and talcum powder, and proceed under the condition of 1200r / min Disperse at high speed, after stirring for 30 minutes, reduce the stirring speed to 500r / min, add silica sol and the remaining additives, continue stirring for 60 minutes, and finally obtain component A with a pH of 9.3-9.5;

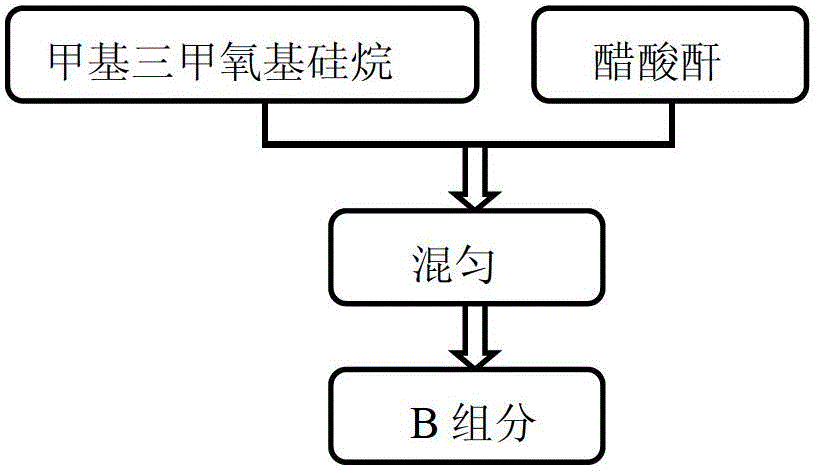

[0041] Mix acetic anhydride and methyltrimethoxysilane and stir evenly to obtain component B.

[0042] Stir the prepared above component A and component B according to the mass ratio of 100:37 (Example 1), 100:39 (Example 2), 100:40 (Example 3) under the condition of 300r / min , stirred for 60 minutes, and then aged at room temperature for 20 hours to finally obtain the finished insulating varnish. After the finished inorganic insulating varnish is prepared, it needs to be used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com