Positive-electrode composition for a nonaqueous-electrolyte secondary battery and method for manufacturing a positive-electrode slurry using said positive-electrode composition

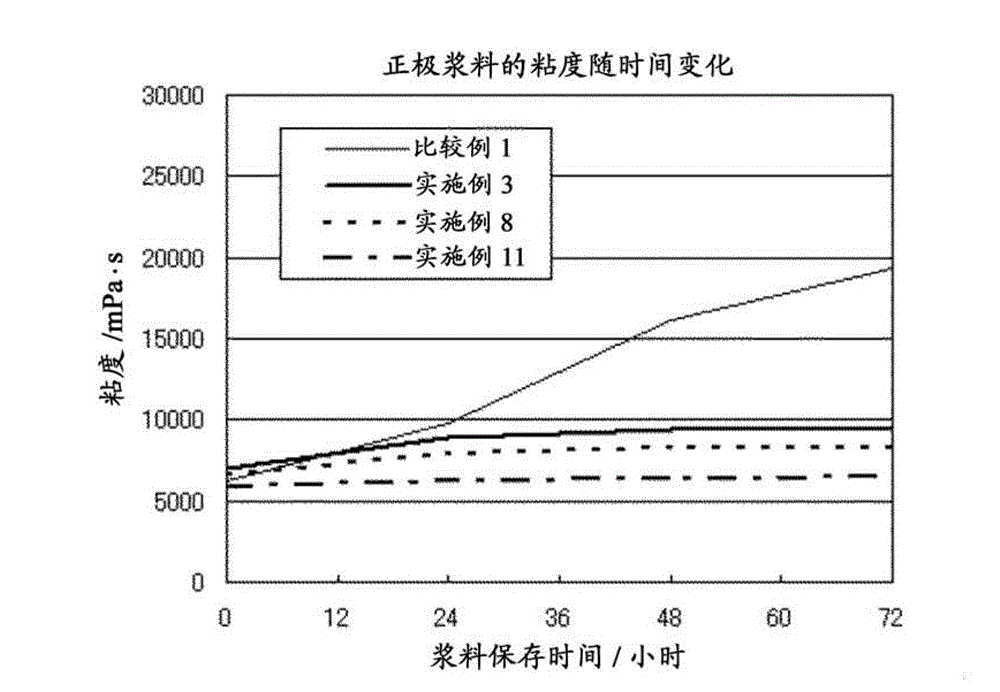

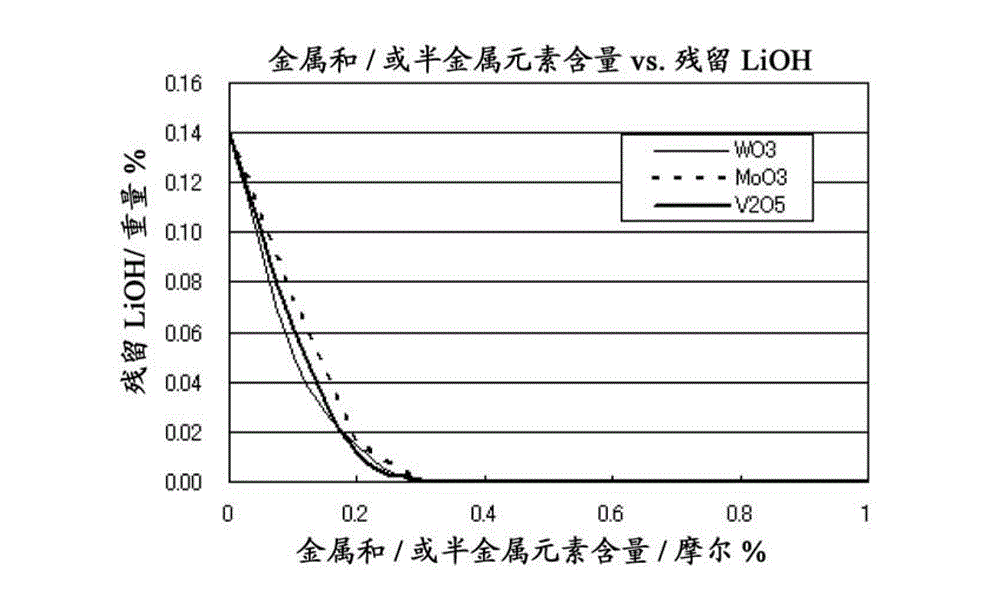

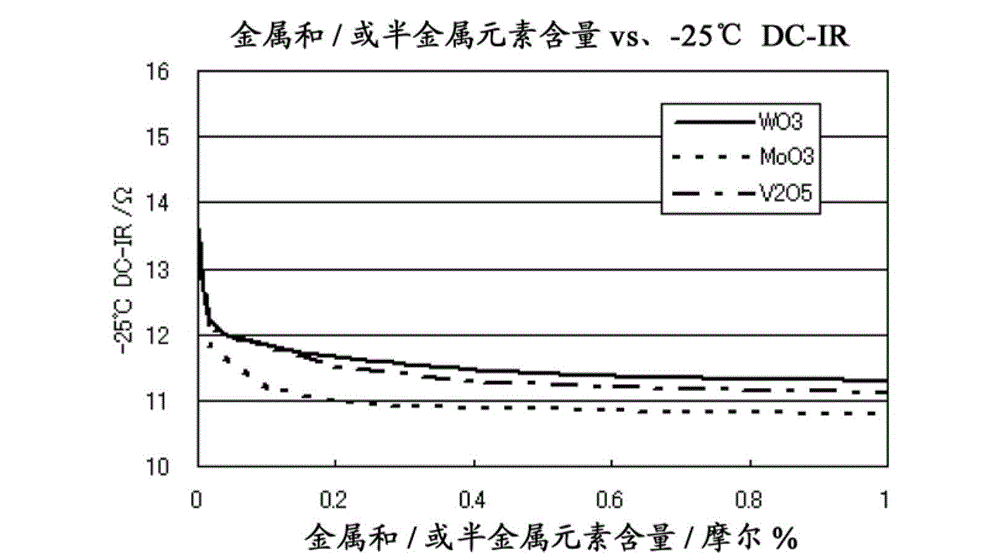

一种非水电解液、二次电池的技术,应用在二次电池、电池电极、电路等方向,能够解决输出特性降低、成本降低等问题,达到输出特性提高、生产效率改善、改善制造效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Pure water in a stirred state was prepared in the reaction tank, and nickel sulfate aqueous solution, cobalt sulfate aqueous solution, and manganese sulfate aqueous solution were added dropwise at a flow ratio of Ni:Co:Mn=5:2:3 in molar ratio. After the dropwise addition, set the liquid temperature to 65° C., and add a certain amount of aqueous sodium hydroxide solution dropwise to obtain nickel / cobalt / manganese co-precipitated hydroxide. Wash the obtained co-precipitated hydroxide with water, filter and separate, and mix lithium carbonate and zirconia (IV) so that Li:(Ni+Co+Mn):Zr=1.10:1:0.005 to obtain a mixed raw material. The obtained mixed raw material was fired at 850° C. for 2.5 hours in an air atmosphere, and then fired at 900° C. for 4.5 hours to obtain a sintered body. The obtained sintered body is pulverized and applied on a dry sieve to obtain the composition formula Li 1.10 Ni 0.5 co 0.2 mn 0.3 Zr 0.005 o 2 Indicates the positive active material. The...

Embodiment 2

[0048] A positive electrode composition was obtained in the same manner as in Example 1, except that tungsten (VI) oxide as additive particles was mixed in a ratio of (Ni+Co+Mn+Zr):W=1:0.002.

Embodiment 3

[0050] A positive electrode composition was obtained in the same manner as in Example 1, except that tungsten (VI) oxide as additive particles was mixed in a ratio of (Ni+Co+Mn+Zr):W=1:0.003.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com