A kind of anti-heat radiation coating for glass and preparation method thereof

A thermal radiation and glass technology, applied in the field of coatings, can solve the problems of high cost and low light transmittance, and achieve the effects of stable physical and chemical properties, uniform quality, and reduction of solar radiation heat absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

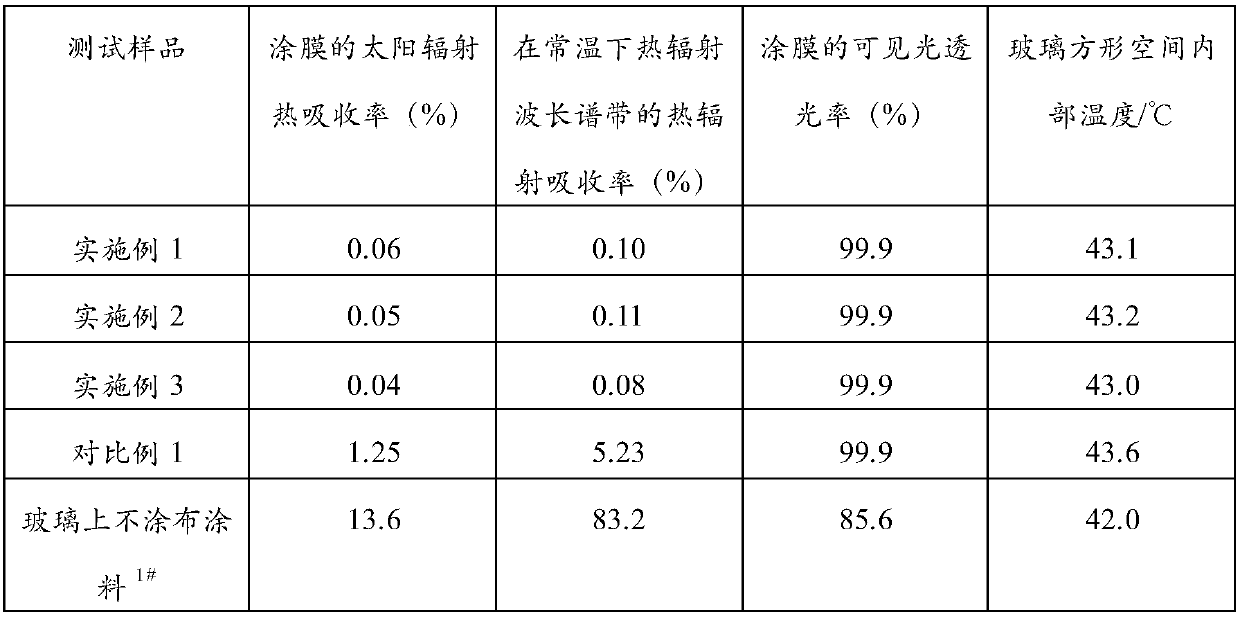

Examples

Embodiment 1

[0030] Prepare the anti-radiation coating for glass according to the following preparation method:

[0031] 1) Weigh 13 parts by weight of 2,4-diisocyanate-terminated poly(ethylene adipic acid), 4 parts by weight of trimethylolpropane triacrylate, and 5 parts by weight of vinyl polydimethylsiloxane and stir for 30- 40min to get the mixed solution A for use;

[0032] 2) disperse 11 parts by weight of 2-(1-piperidinyl) ethyl isothiocyanate and 3 parts by weight of aluminum monostearate in 45 parts by weight of organic solvent to obtain mixed solution B (organic solvent by volume ratio Calculate, butyl acetate: propylene glycol monomethyl ether: isopropanol=4:3:2);

[0033] 3) Control the stirring speed of the mixed solution B to be above 1200rpm, slowly drop the mixed solution A into the mixed solution B to obtain the mixed solution C;

[0034] 4) Control the stirring speed of the mixed solution C to 600-700rpm, then add 5 parts by weight of water-based fluorine-containing hyd...

Embodiment 2

[0037] Prepare the anti-radiation coating for glass according to the following preparation method:

[0038] 1) Weigh 15 parts by weight of 2,4-diisocyanate-terminated poly(ethylene adipic acid), 6 parts by weight of trimethylolpropane triacrylate, and 7 parts by weight of vinyl polydimethylsiloxane and stir for 30- 40min to get the mixed solution A for use;

[0039] 2) disperse 12 parts by weight of 2-(1-piperidinyl) ethyl isothiocyanate and 4 parts by weight of slurry calcium linoleate in 45-48 parts by weight of organic solvent to obtain mixed solution B (organic solvent Calculated by volume ratio, butyl acetate: propylene glycol monomethyl ether: isopropanol=4:3:2);

[0040] 3) Control the stirring speed of the mixed solution B to be above 1200rpm, slowly drop the mixed solution A into the mixed solution B to obtain the mixed solution C;

[0041] 4) Control the stirring speed of the mixed solution C to 600-700rpm, then add 7 parts by weight of water-based fluorine-contain...

Embodiment 3

[0044] Prepare the anti-radiation coating for glass according to the following preparation method:

[0045] 1) Weigh 14 parts by weight of 2,4-diisocyanate-terminated poly(ethylene adipic acid), 5 parts by weight of trimethylolpropane triacrylate, and 6 parts by weight of vinyl polydimethylsiloxane and stir for 30- 40min to get the mixed solution A for use;

[0046] 2) 11-12 parts by weight of 2-(1-piperidinyl) ethyl isothiocyanate and 4 parts by weight of slurry calcium linoleate are dispersed in 46 parts by weight of organic solvent to obtain mixed solution B (organic solvent Calculated by volume ratio, butyl acetate: propylene glycol monomethyl ether: isopropanol=4:3:2);

[0047] 3) Control the stirring speed of the mixed solution B to be above 1200rpm, slowly drop the mixed solution A into the mixed solution B to obtain the mixed solution C;

[0048]4) Control the stirring speed of the mixed solution C to 600-700rpm, then add 6 parts by weight of water-based fluorine-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com