Packaging structure for composition of radical polymerization

A technology of polymeric composition and packaging structure, applied in packaging, wrapping paper, packaged food, etc., can solve problems such as difficult to cope with, and achieve the effect of ensuring stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

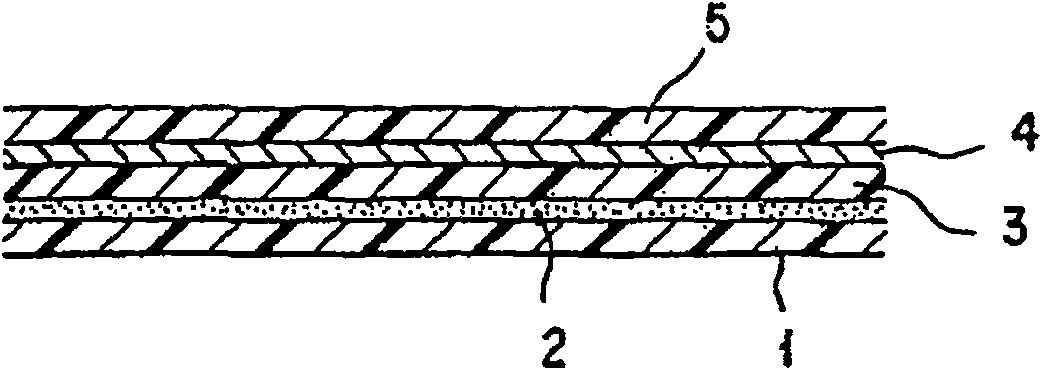

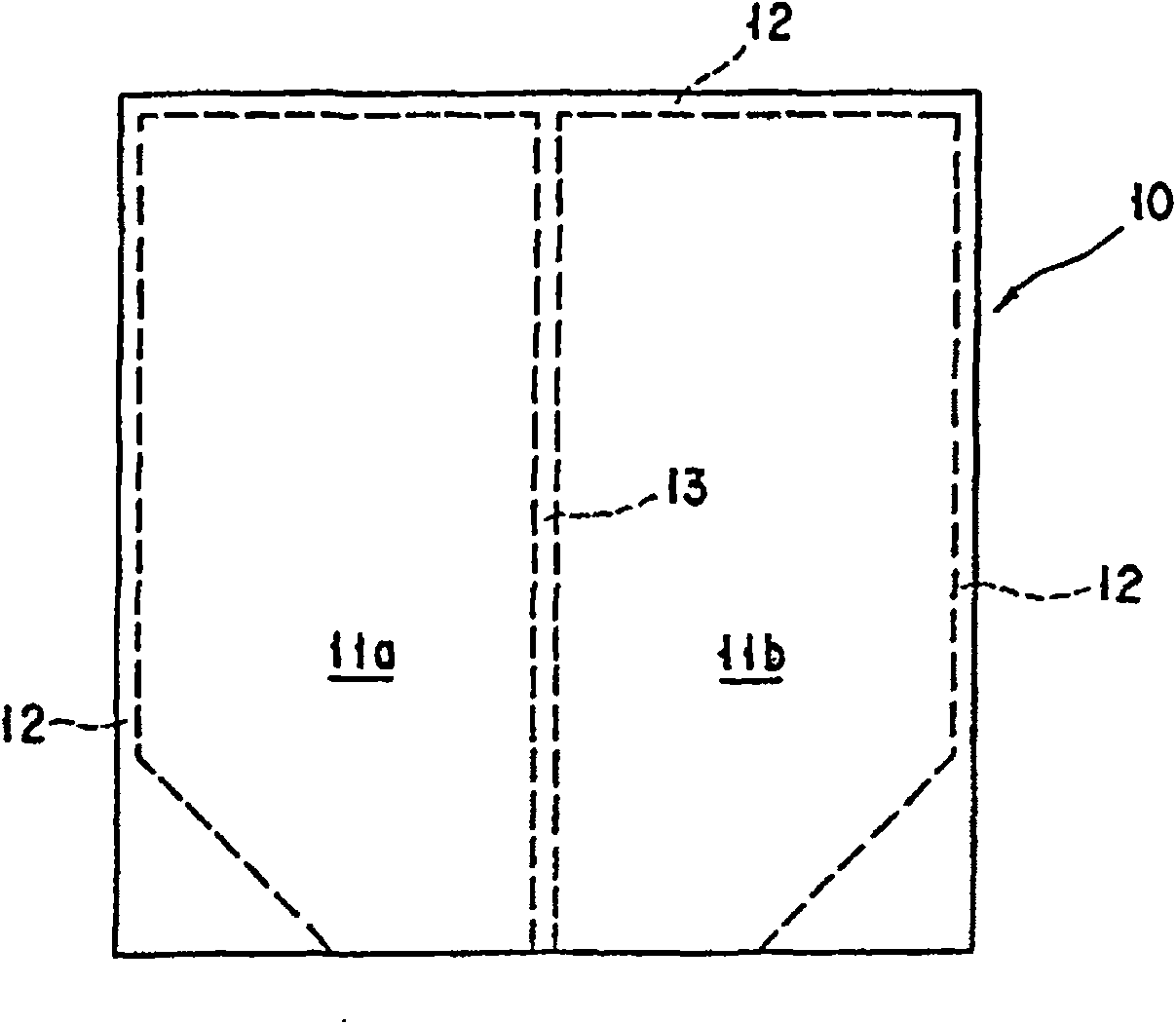

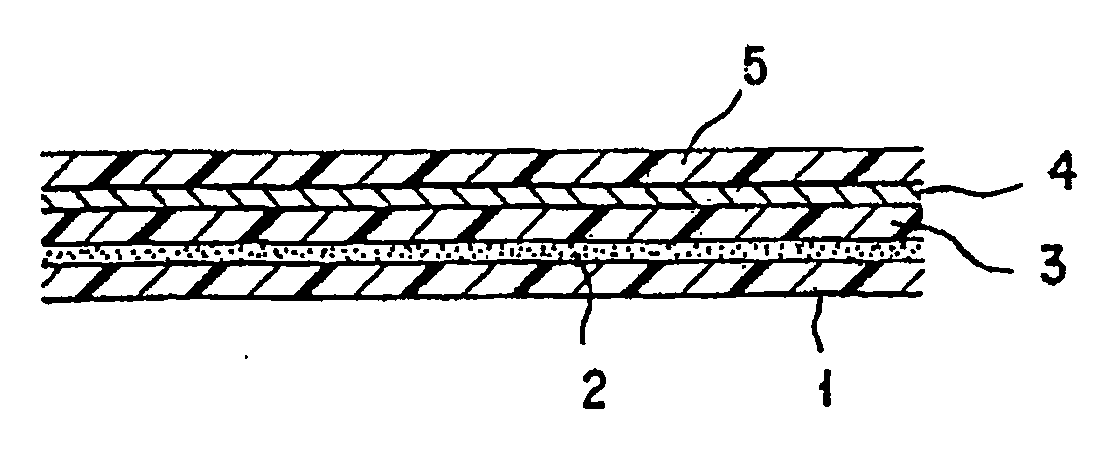

[0055] A flat-bottomed bag was made using a polyester / aluminum foil / polyester / adhesive / polyethylene layered film with a total thickness of 90 μm, and the radically polymerizable protective layer ink manufactured by Taiyo Ink Manufacturing Co., Ltd. The agent (PSR-4000Z26) and curing agent (CA-40Z26) are filled separately, and air remains when sealing. In addition, multiple flat bottom bags were made with various amounts of residual air.

Embodiment 2

[0062] In each of the following flat-bottomed bags, fill 1.6 kg of the main agent (PSR-4000Z26) and 0.6 kg of curing agent (CA-40Z26) of the radically polymerizable protective layer ink manufactured by Sun Ink Manufacturing Co., Ltd., and prepare 7 bags into 20 liter plastic packaging jars.

[0063] Use a flat bottom bag:

[0064] A film with a total thickness of 90 μm of polyester / aluminum foil (7 μm) / polyester / adhesive / polyethylene was used to form a flat-bottomed bag with polyester inside.

[0065] A flat-bottomed bag was made of a polyethylene / aluminum foil (7 μm) / polyethylene film having a total thickness of 43 μm.

[0066] A flat-bottomed bag was made of a film having a total thickness of 54 μm of polyethylene / aluminum foil (4 μm) / polyethylene.

[0067] A flat-bottomed bag was made of a polyethylene / aluminum foil (7 μm) / polyethylene film having a total thickness of 55 μm.

[0068] A polyester / nylon / aluminum foil (9 μm) / polyethylene film having a total thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com