Organic EL coating device and method

A coating device, an organic technology, applied to the surface coating device, lighting device, coating, etc., can solve the problem of not being able to spit out organic EL materials stably, achieve improved maintenance performance, and easy filter replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] (first embodiment)

[0044] First, a first embodiment of the organic EL coating device of the present invention will be described. Since the filter is installed in the nozzle, clogging of the nozzle is effectively suppressed, and therefore, the first embodiment can stably discharge the coating liquid in which the organic EL material is mixed with a prescribed solvent (hereinafter simply referred to as "organic EL material"). Material").

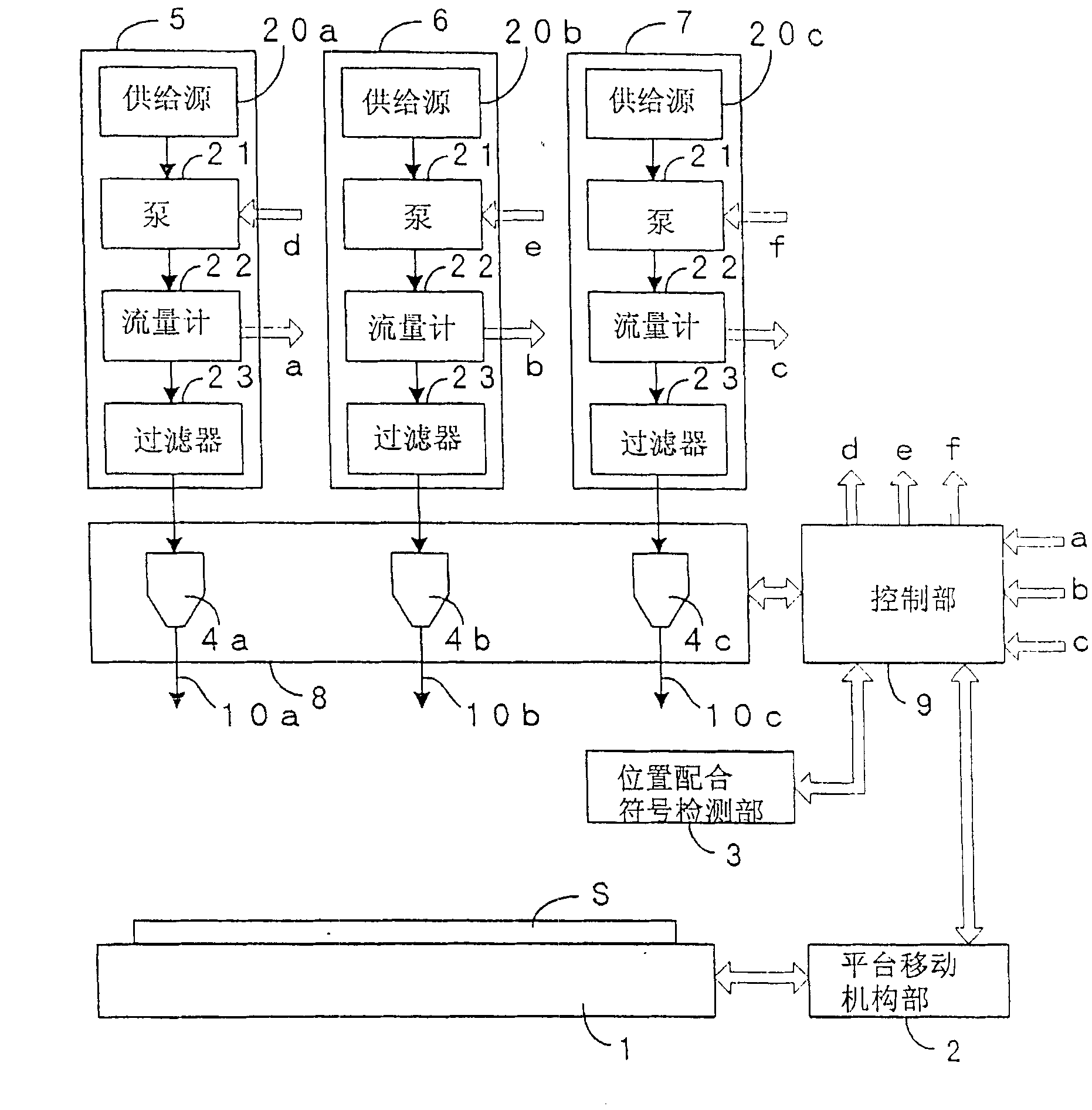

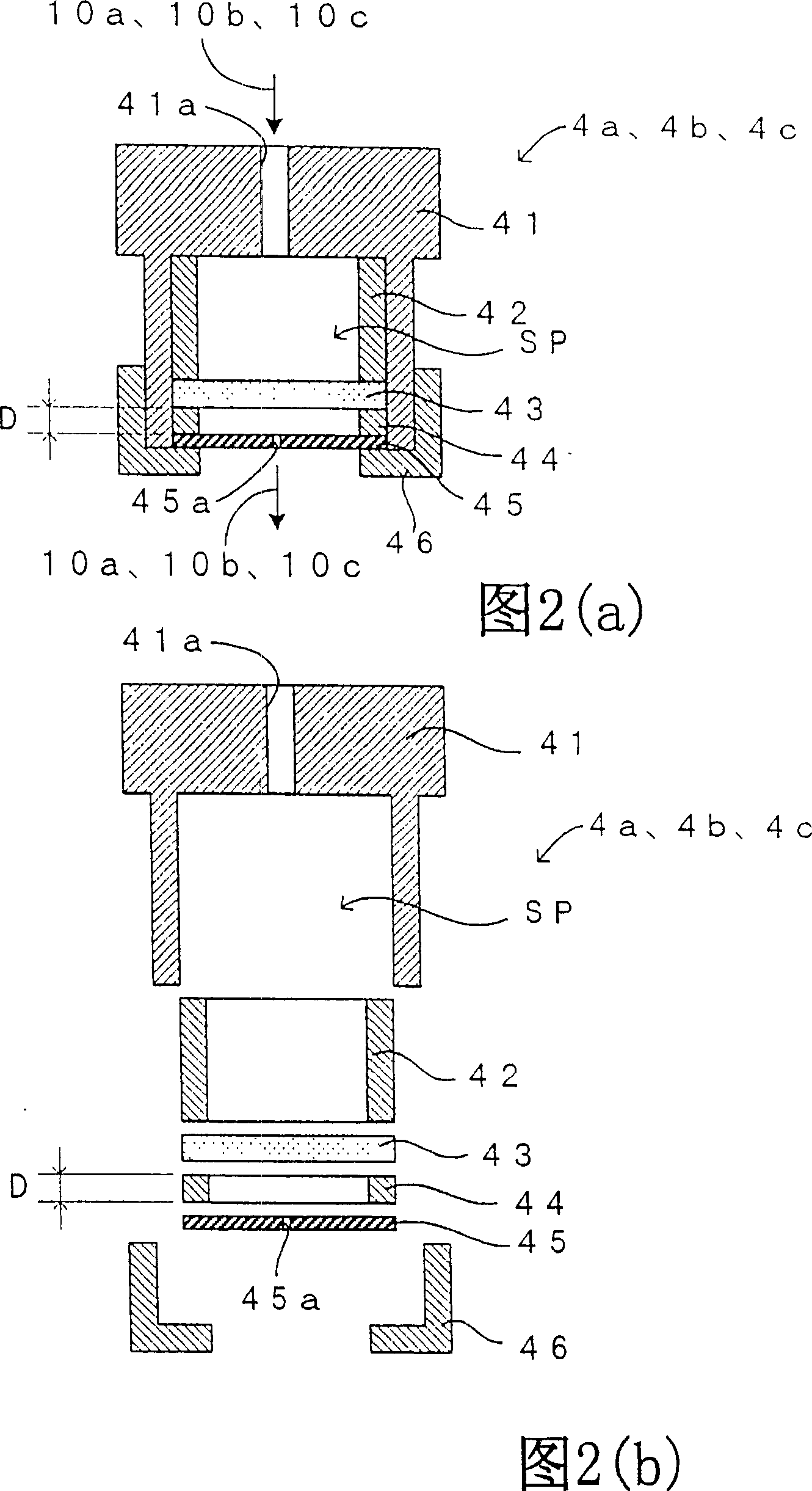

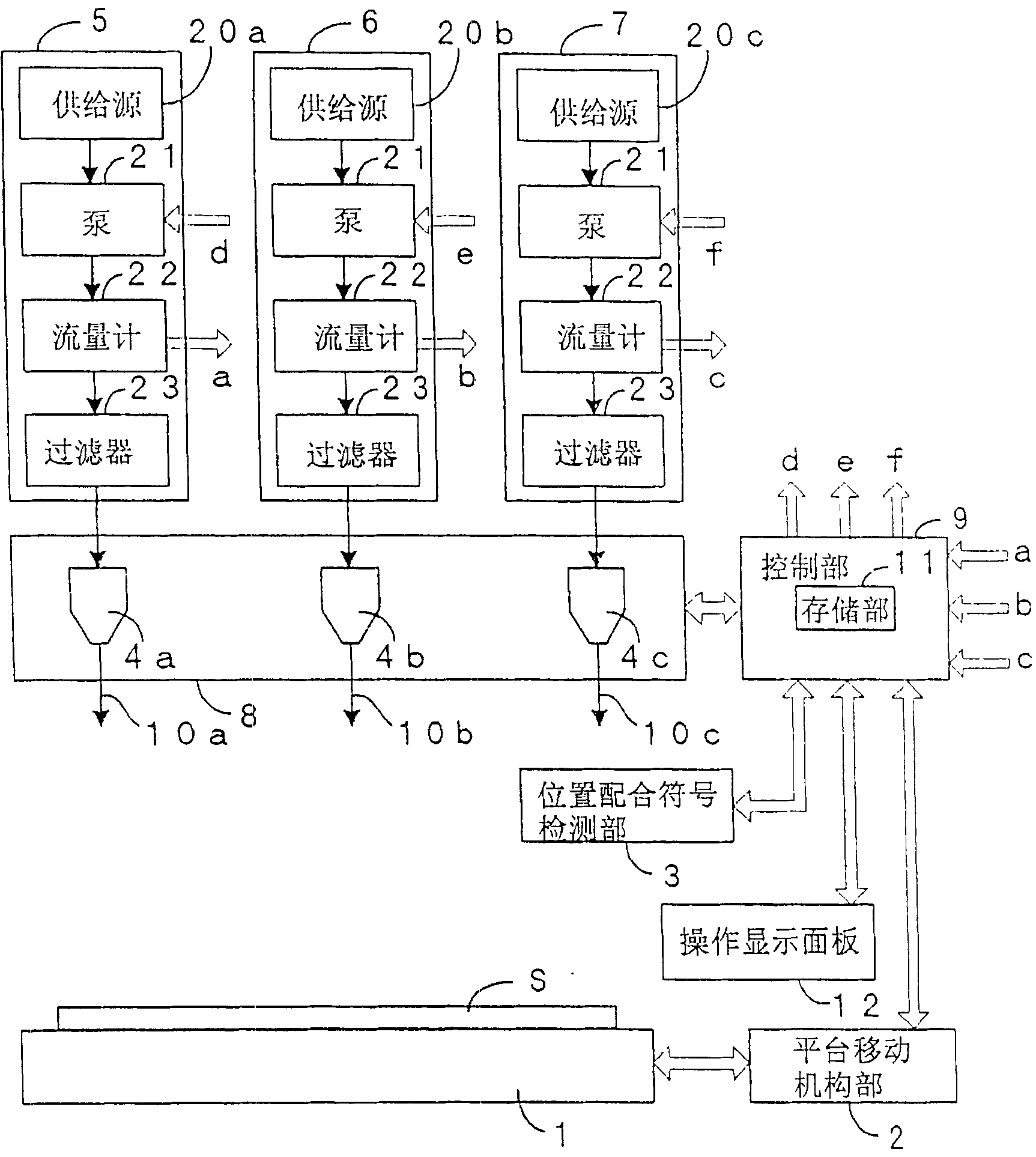

[0045] figure 1 It is a figure which shows 1st Embodiment of the organic EL coating apparatus of this invention. Such as figure 1 As shown, the organic EL coating device is composed of the following parts: a platform 1 loaded with glass substrates S coated with red, green and blue organic EL materials 10a-10c; a platform moving mechanism that moves the platform in a prescribed direction 2. A position matching symbol detection unit 3 that detects a position matching symbol formed on the glass substrate S; a first supply unit 5 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com