Rubber composition for tire, method for producing same, and pneumatic tire using the rubber composition for tire

A technology for rubber compositions and tires, applied in special tires, tire parts, educts, etc., can solve the problem of reducing the unreacted rate of silane coupling agents, not realizing heat supply, and not realizing fully improving tire fuel consumption performance and other problems to achieve the effect of improved grip performance and improved rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

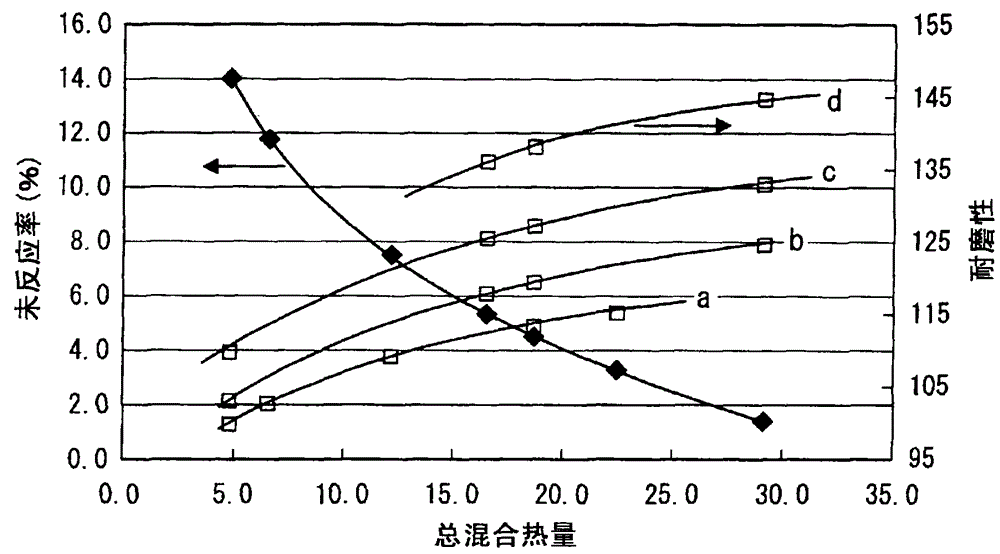

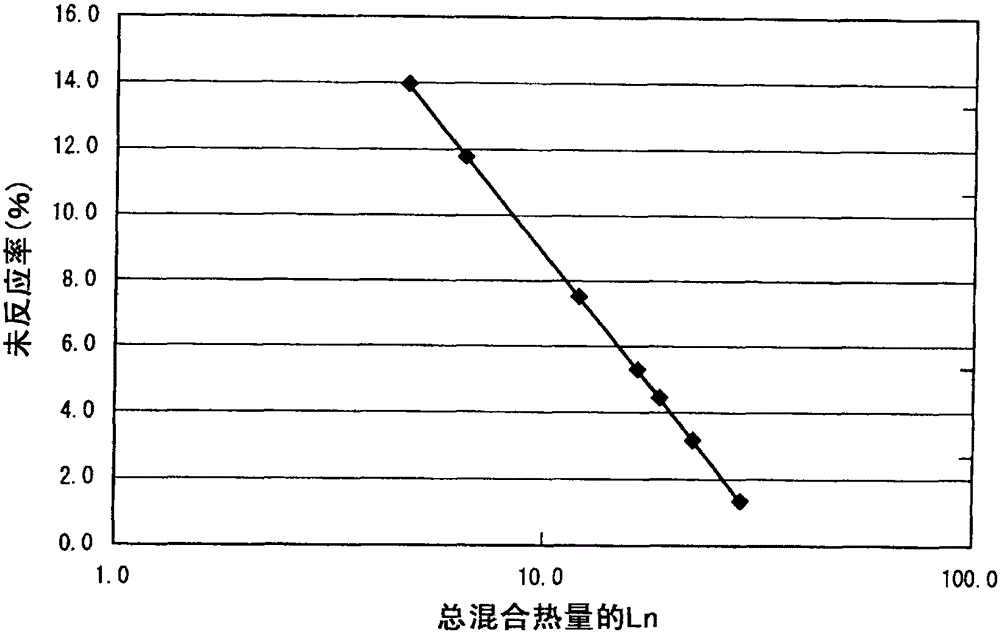

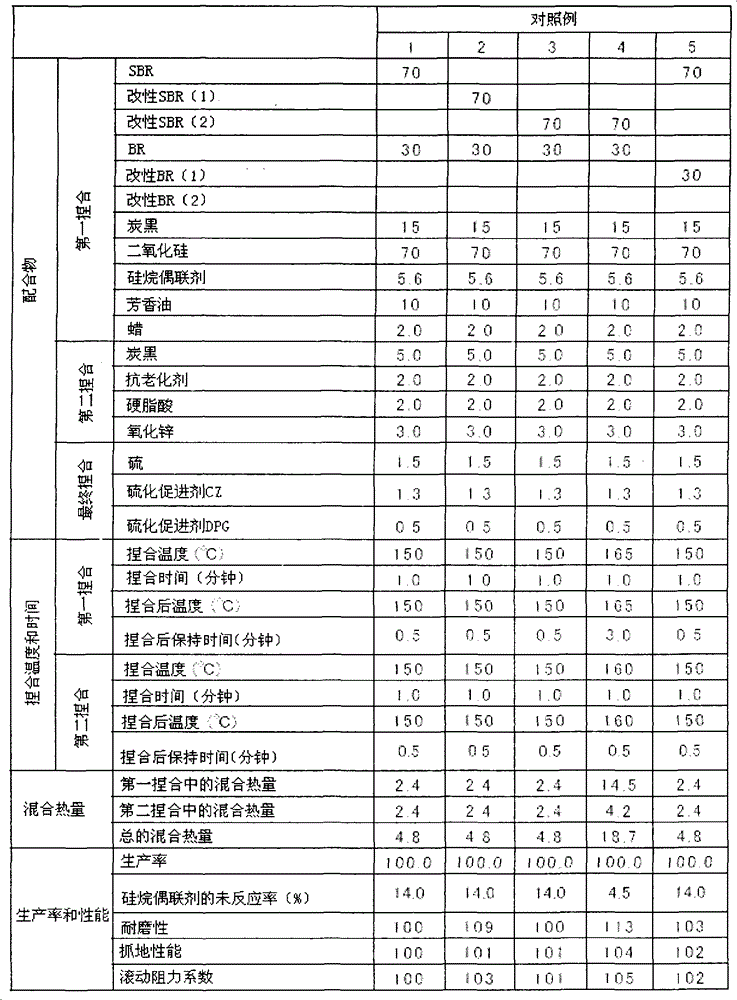

[0124] Next, the present invention will be described in further detail based on examples.

[0125] 1. Rubber material

[0126] In the following examples, the rubber materials shown in Tables 1-4 were used. The rubber materials shown in Tables 1-4 will be described below.

[0127] In Table 3, Examples 1 to 3 are examples in which end-modified SBR and temperature-controlled kneading conditions were used in combination. Examples 4-6 are examples in which modified BR and temperature-maintained kneading conditions were used in combination. Examples 7 to 9 are examples in which end-modified SBR and modified BR were used in combination with temperature-maintained kneading conditions.

[0128] (1) Raw rubber

[0129] SBR: SBR1502 (unmodified, styrene content: 23.5% by mass), manufactured by JSR Corporation.

[0130] End-modified SBR (1): E10 (solution-polymerized, end group: amino group, modification rate: 51% by mass, styrene content: 39% by mass, ethylene bonded amount: 31% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com