Manufacturing method and manufacturing apparatus of organic device and organic device

A technology for organic devices and manufacturing methods, which can be used in semiconductor/solid-state device manufacturing, lighting devices, electric solid-state devices, etc., and can solve problems such as higher manufacturing costs and lower productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Deformed example 1

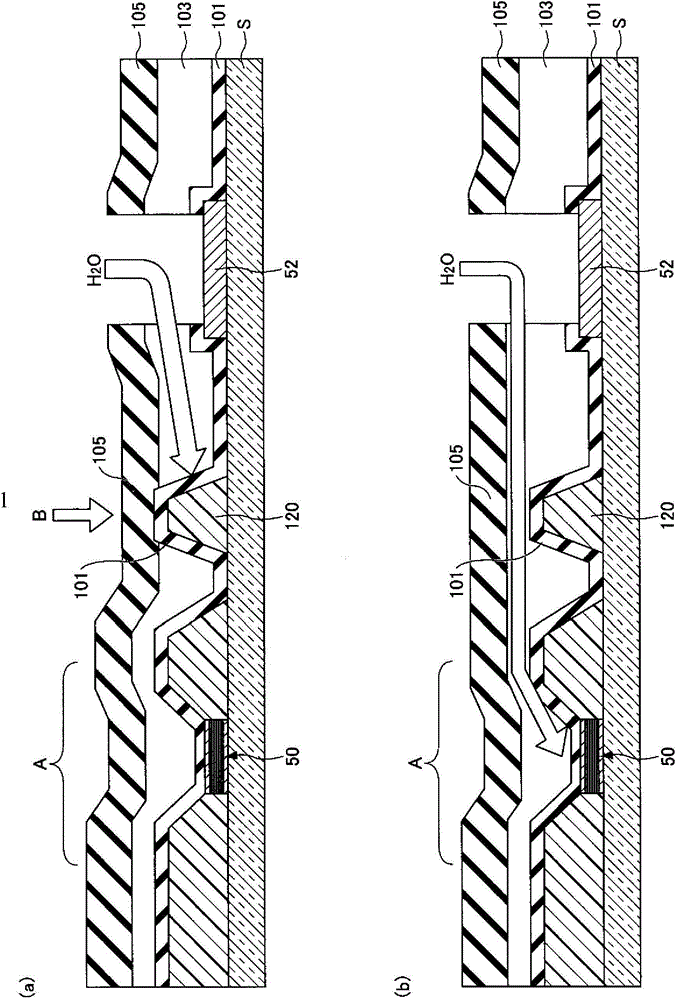

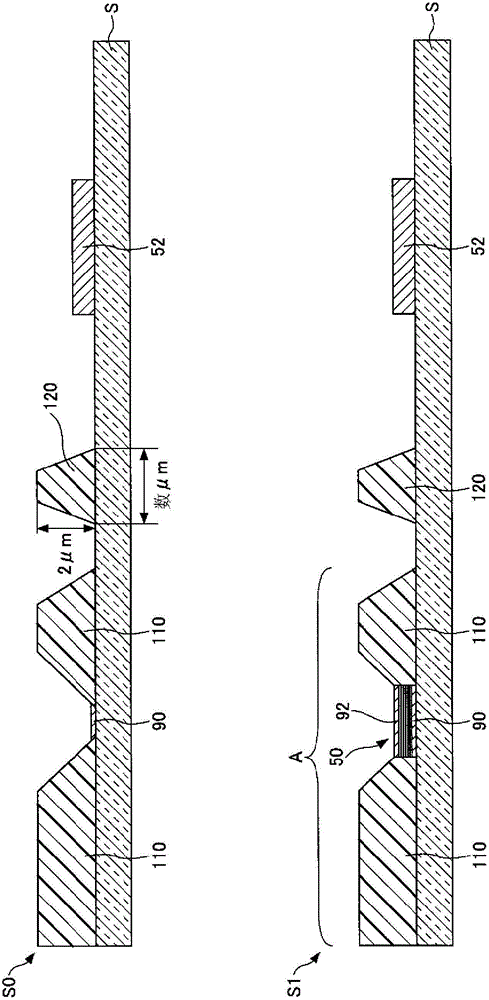

[0088] in Figure 3C In the case of "S5", at position B on the partition wall 120, the sealing layer 101 and the sealing layer 105 are brought into close contact with each other to form a wall, thereby blocking the penetration of moisture from the electrode pad 52 side. In contrast, in Modification 1, as Image 6 As shown in "S4", not only at position B on the partition wall 120, but also at positions C and D on the partition wall 110, the wall formed by the sealing layer 101 and the sealing layer 105 blocks moisture from Immersion on the electrode pad portion 52 side. At this time, such as Image 6 As shown in "S4", etch back is performed until the sealing layer 101 is exposed from the intermediate layer 103 at positions B, C, and D. Thus, as Image 6 As shown in "S5", the sealing layer 105 is in contact with the sealing layer 101 exposed from the intermediate layer 103 at positions B, C, and D.

[0089] With the above structure, the wall portions formed at the positions B, C, ...

Deformed example 2

[0091] In addition, in Modification 2, as Figure 7 As shown in "S4", not only at positions B, C, D on the partition wall portions 110 and 120, but also at positions E and F where the partition wall portion 110 is not formed, the sealing layer 101 and the sealing layer 105 also contact each other. In the manufacturing process, such as Figure 7 As shown in "S4", the etch back is performed until the sealing layer 101 is exposed from the intermediate layer 103 at positions B, C, D, E, and F. In this case, the intermediate layer 103 is formed only on the side surface of the partition wall. Thus, as Figure 7 As shown in "S5", the sealing layer 105 formed on the intermediate layer 103 is in contact with the sealing layer 101 exposed from the intermediate layer 103 at positions B, C, D, E, and F.

[0092] With the above structure, the wall portions formed at the positions B, C, D, E, and F can more reliably block moisture, and thus can more reliably suppress the intrusion of moisture ...

Deformed example 3

[0094] In Modification 3, the formation of the intermediate layer and the etch back are repeatedly performed. For example, a substrate having an intermediate layer 103 formed after the sealing layer 101 having a thickness of 100 nm to 500 nm is formed Figure 7 "S4" shows the etch back of the intermediate layer 103. After that, like Figure 8A As shown in "S4-1", the intermediate layer 103 is formed again. Next, like Figure 8A As shown in "S4-2", the formed intermediate layer 103 is etched back again. Next, like Figure 8B The sealing layer 105 is formed as shown in "S5-1". Here, the formation and etch-back of the intermediate layer 103 are repeatedly performed twice, but the number of repetitions of the formation and etch-back of the intermediate layer 103 is not limited to this.

[0095] Next, like Figure 8C As shown in "S6-1", the cover sheet 107 is attached with an adhesive (adhesive layer) so that the cover sheet 107 covers the organic EL element 50. Thereby, the mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com