Light beam direction controlling element and display device

A technology of direction control and light beam, which is applied in the direction of optical components, identification devices, installation, etc., to achieve the effect of reducing productivity and suppressing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

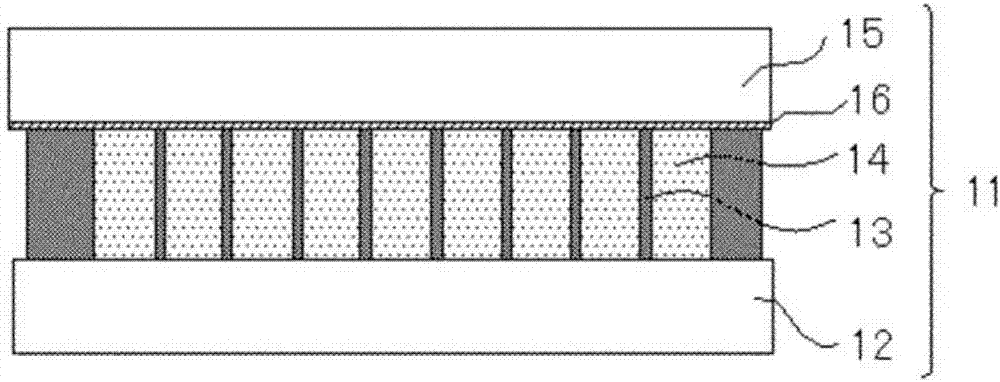

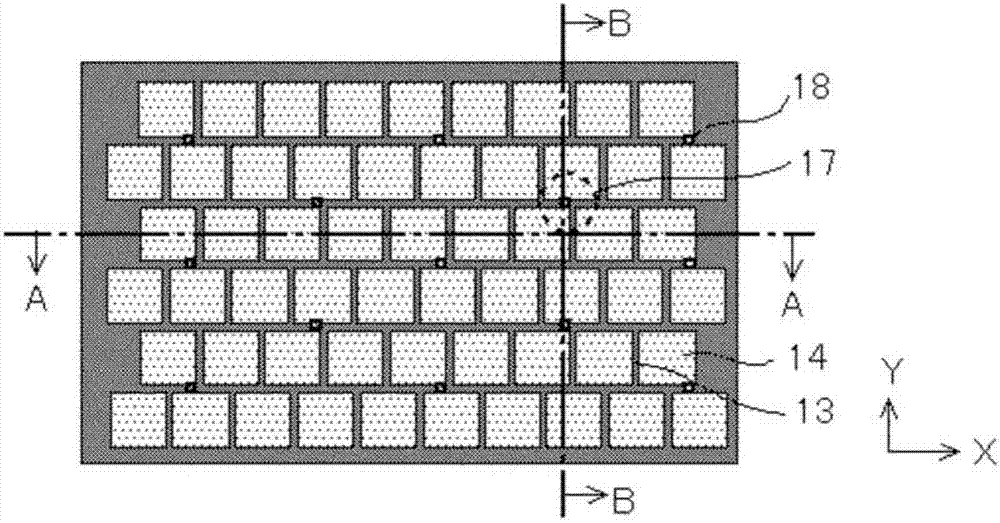

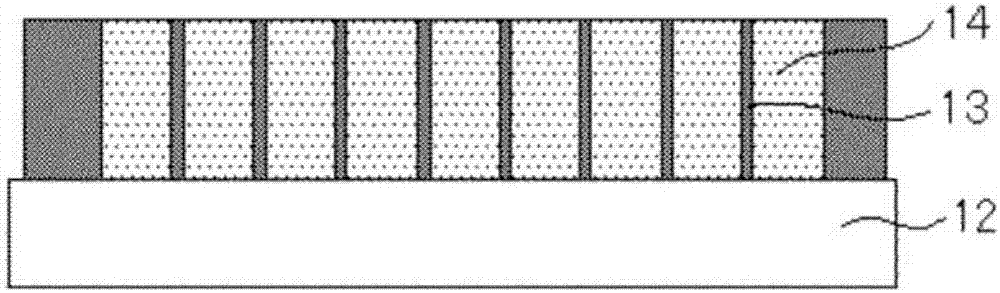

[0057] figure 1 It is a sectional view showing the structure of the light beam direction control element (ultrafine louver) according to the first embodiment of the present invention. Figure 2A is the top view of the beam direction control element, Figure 2B is a sectional view taken along the line A-A, Figure 2C It is a cross-sectional view taken along line BB. According to the beam direction control element 11 of the present embodiment, the light-absorbing regions 13 made of a light-absorbing material and the light-transmitting regions 14 made of a light-transmitting material are alternately arranged on a transparent substrate 12 (with The light-transmitting region 14 on the top and the light-absorbing region 13 filling the gap between the light-transmitting regions 14), another transparent substrate 15 is laminated on the transparent substrate 12 via an adhesive 16 and bonded to the transparent substrate 12.

[0058] In the light beam direction control element 11, am...

Embodiment approach 2

[0071] Now, will refer to Figure 5A and Figure 5B A second embodiment of the present invention will be described. The beam direction control element according to the second embodiment and Figure 1 to Figure 3 Similar to the illustrated beam direction control element according to the first embodiment, in order to bend the light-absorbing region 13, the shape and arrangement pattern of the light-transmitting region 14 are changed.

[0072] Figure 5A is a top view of a beam direction control element according to a second embodiment, Figure 5B It is a sectional view taken along line C-C. The present embodiment is characterized in that patterns of different shapes are used as the light-transmitting regions 14 , and the bent portion 17 of the light-absorbing region 13 is formed by proper arrangement of the light-transmitting regions 14 . Therefore, there is no need for a pattern including the specific structure 18 like the first embodiment. As a method of manufacturing th...

Embodiment approach 3

[0075] now refer to Figure 6 A third embodiment of the present invention will be described. Figure 6 is a plan view of the beam direction control element according to the third embodiment. According to the beam direction control element of the third embodiment, by using the first embodiment and the second embodiment (specifically, Figure 1 to Figure 3 The pattern of the structures 18 in the shown first embodiment) as a base for bending the light-absorbing regions 13 has a closed configuration of the light-absorbing regions 13 with respect to the X-direction and the Y-direction (i.e., a closed configuration in which the light-absorbing regions are separated by the structures 18). pattern). In this case, stress distribution due to thermal contraction of the light absorbing material 23 is also attempted, whereby concentration and accumulation of stress in a specific linear direction (X direction or Y direction) can be prevented, and warpage on the transparent substrate 12 ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com